TiAl-based alloy stator blade isothermal forming manufacturing method and device thereof

A technology of a stator blade and a manufacturing method, which is applied in the field of warm forming manufacturing, can solve the problems that the structure and performance of the stator blade cannot meet the design requirements, and cannot control the difficulty of forming, so as to save the consumption of raw materials, reduce the cost of materials, and improve the structure and efficiency. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

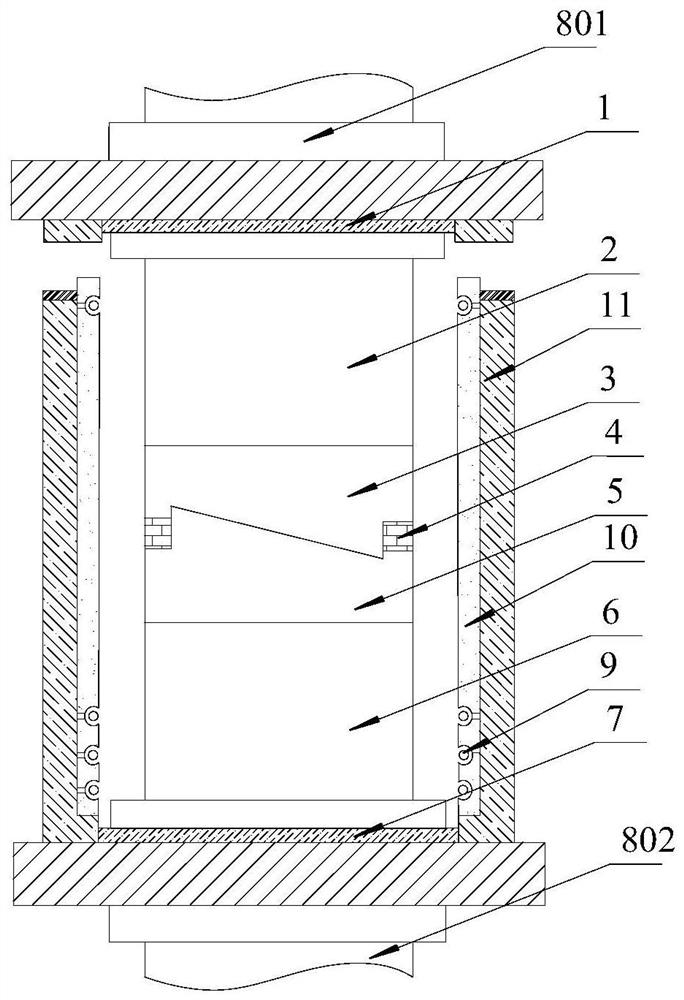

[0052] A TiAl-based alloy stator vane isothermal forming device, the schematic diagram of which is shown in image 3 , including the isothermal forging heater and the isothermal forging die, the structural diagram of the isothermal forging die is shown in Figure 4 , wherein, the isothermal pre-forging and isothermal final forging in the isothermal forming manufacturing method of the TiAl-based alloy stator blade are both implemented by the TiAl-based alloy stator blade isothermal forming device.

[0053] The isothermal forging die includes an upper die 3, a lower die 5, a limit keyway 12 and an adjustment backing plate 4; Adjusting backing plate 4 is provided, upper die 3 is also provided with upper die limit keyway 1201, and lower die is provided with lower die limit keyway 1202; both upper die limit keyway and lower die limit keyway are used to prevent mold misalignment occurs.

[0054] In the above-mentioned isothermal forging die, the upper die 3 and the lower die 5 are...

Embodiment 2

[0073] A TiAl-based alloy stator vane isothermal forming device, the same as in Example 1.

[0074] A TiAl-based alloy stator blade isothermal forming manufacturing method, comprising the following steps:

[0075] Step 1: Machining

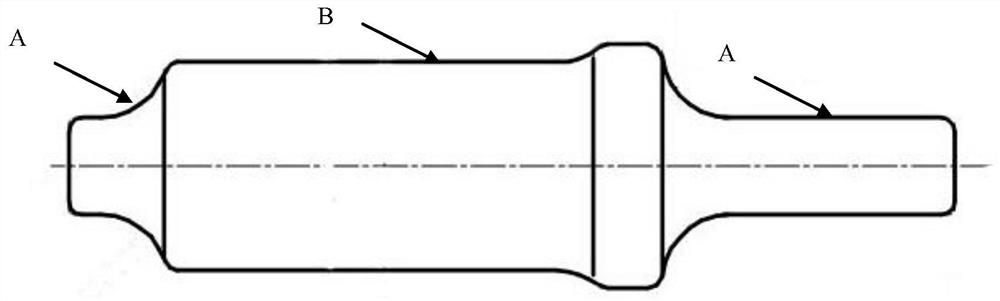

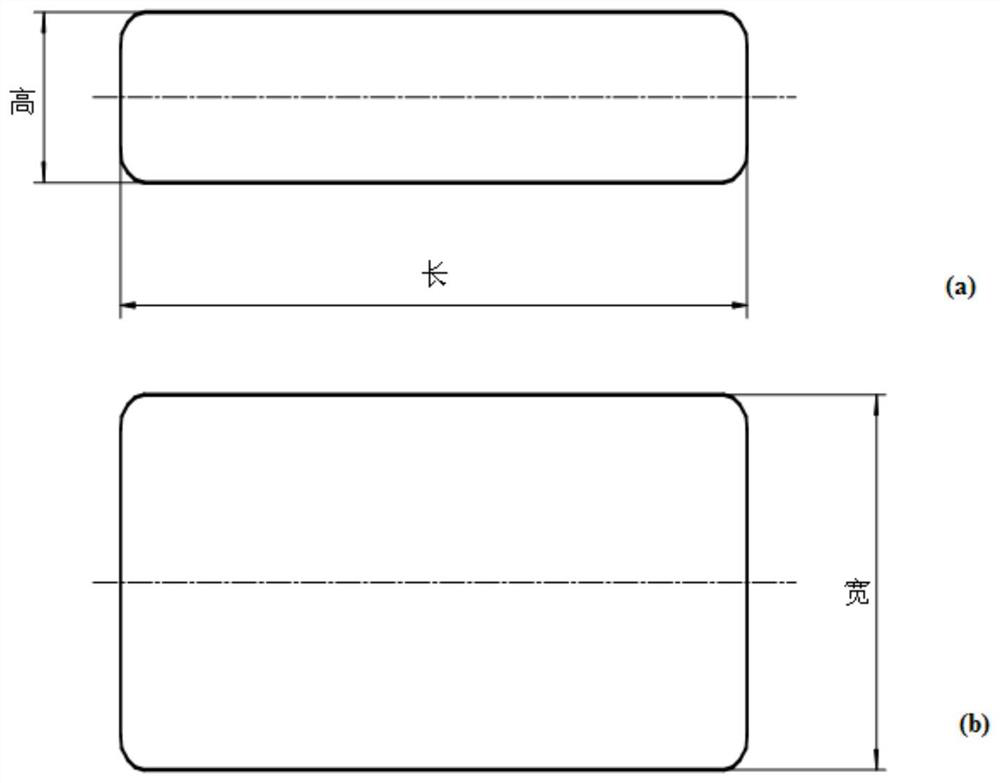

[0076] According to the structural size of the TiAl-based alloy stator blade, the TiAl-based alloy is machined into a billet to obtain a machined blank; the machined blank is a blank of the TiAl-based alloy stator blade, and its structural diagram is shown in figure 1 , which is an irregular cylindrical structure; the machined blank includes an airfoil portion and a shaft portion;

[0077] Step 2: Isothermal Pre-Forging

[0078] Coat the surface of the machined blank with glass lubricant and wrap it with 5mm-10mm thick asbestos felt. First raise the temperature of the heating furnace to 900°C, then put the machined blank wrapped with asbestos felt into the furnace, heat it up to 1220°C at a heating rate of 600°C / h, keep it warm for 2.5 hours, ...

Embodiment 3

[0094] A TiAl-based alloy stator vane isothermal forming device, the same as in Example 1.

[0095] A TiAl-based alloy stator blade isothermal forming manufacturing method, comprising the following steps:

[0096] Step 1: Machining

[0097] According to the structural size of the TiAl-based alloy stator blade, the TiAl-based alloy is machined into a billet to obtain a machined blank; the machined blank is a blank of the TiAl-based alloy stator blade, which is an irregular cylindrical structure; The machined blanks include airfoil parts and shaft parts;

[0098] Step 2: Isothermal Pre-Forging

[0099] Coat the surface of the machined blank with glass lubricant and wrap it with 5mm-10mm thick asbestos felt. First raise the temperature of the heating furnace to 850°C, then put the machined blank wrapped with asbestos felt into the furnace, heat it up to 1200°C at a heating rate of 550°C / h, keep it warm for 3.5 hours, and then place it in an isothermal forging mold at a tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com