Integral forging forming method for reactor pressure vessel cylinder flange connection section

A technology for cylinder flanges and pressure vessels, which is applied in the field of integral forging and forming process of the flange connection section of the cylinder body, which can solve the problems of reducing the safety of the flange connection section of the cylinder body, poor quality stability in complex stress areas, and increasing in-service inspections The workload and other issues can be shortened to shorten the equipment manufacturing cycle, solve the anisotropy of forgings, and avoid the structural defects of forgings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

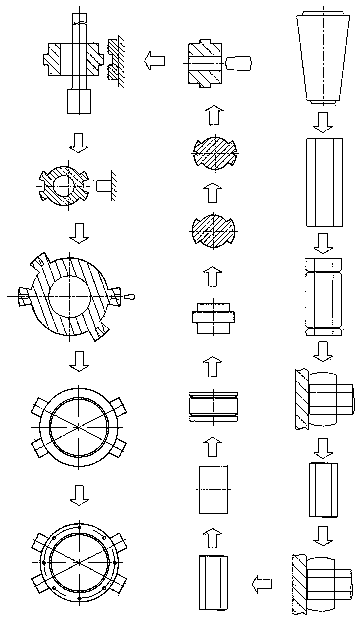

[0044] figure 1 It is a flow chart of the process steps of the overall forging forming method of the flange connection section of the present invention. In each step of the process method, the initial forging temperature of the steel ingot forging is 850°C, and the final forging temperature of the steel ingot forging is 1270°C. When the temperature is lower than 850°C, the forging should be re-sent into the heating furnace for heating to 1270°C, so that the forging temperature of the forging should be kept within the range of 850°C-1270°C. Its steps of the forging forming method of the present embodiment are as follows:

[0045] Steel ingot heating: the material of the steel ingot in this embodiment is 508-3 steel, and the amount of steel ingot is 100 tons. First, the steel ingot is heated in sections, and the steel ingot is put into the heating furnace for heating to improve the plasticity of the metal, make it easy to flow and form and obtain a good forged structure, and ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com