Method for monitoring production state and operation and maintenance state of wind power blade

A technology for wind power blades and state monitoring, applied in electrical program control, comprehensive factory control, comprehensive factory control, etc., can solve the problems of lack of blade-related data information, inability to share and analyze wind power blade information, and achieve the effect of rapid positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

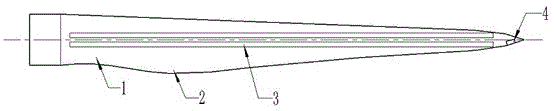

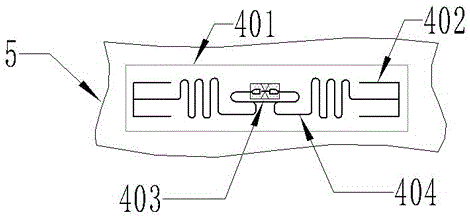

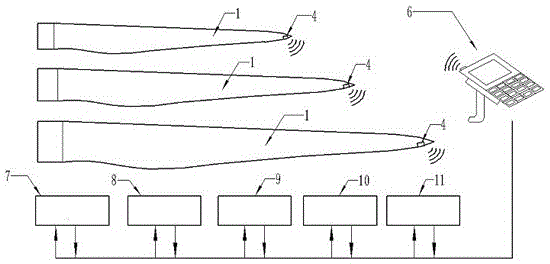

[0021] The present invention is described below in conjunction with accompanying drawing and specific embodiment:

[0022] RFID radio frequency identification is a wireless communication technology that identifies radio frequency tags and reads and writes relevant data through radio signals: After the radio frequency tag enters the magnetic field, it receives the radio frequency signal sent by the reader (reader), and sends out the energy obtained by the induced current to the The product information in the chip, or a signal of a certain frequency actively sent by the tag, the reader reads and decodes the information, and then sends it to the central information system for data processing. A radio frequency tag is a physical carrier of a product's electronic code and is attached to a trackable item. RFID technology can work in various harsh environments, identify multiple tags at the same time, and is easy to operate. At present, RFID technology has been widely used in identif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com