Combined machining method for blade air film holes and device thereof

A technology of composite processing and processing equipment, applied in metal processing and other directions, can solve the problems of low efficiency, thermal damage, and inability to process thermal barrier coatings of single crystal alloys, and achieves simple and easy methods, strong environmental adaptability, and improved performance. The effect of hole efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

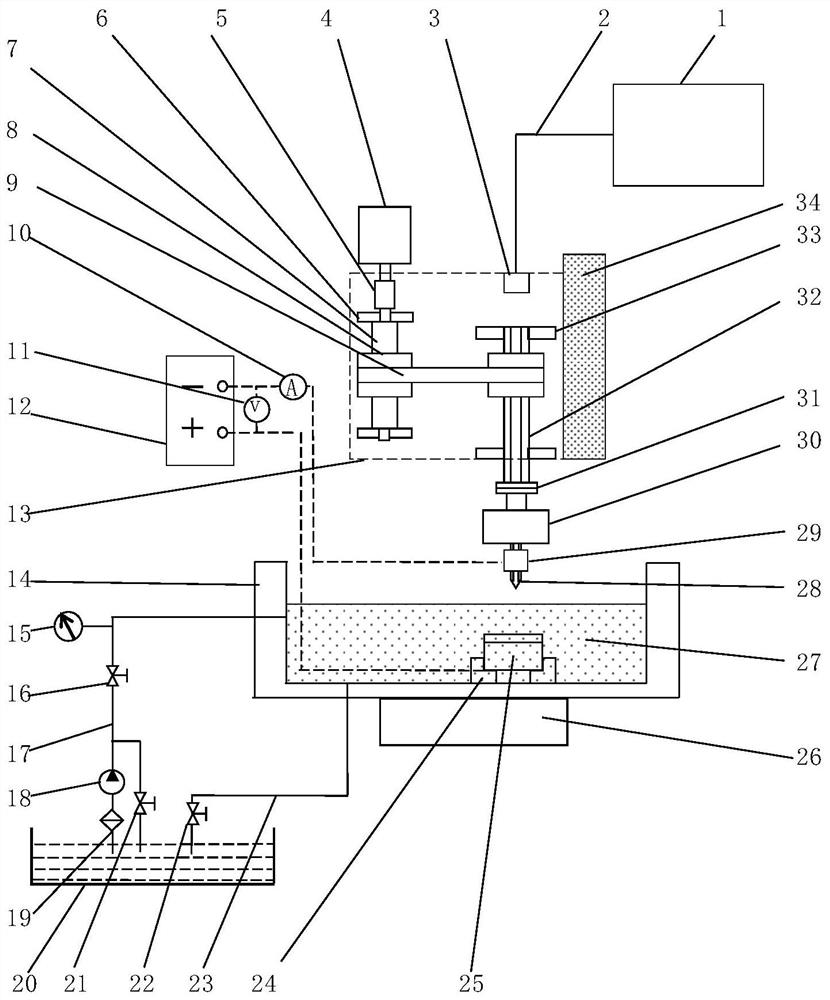

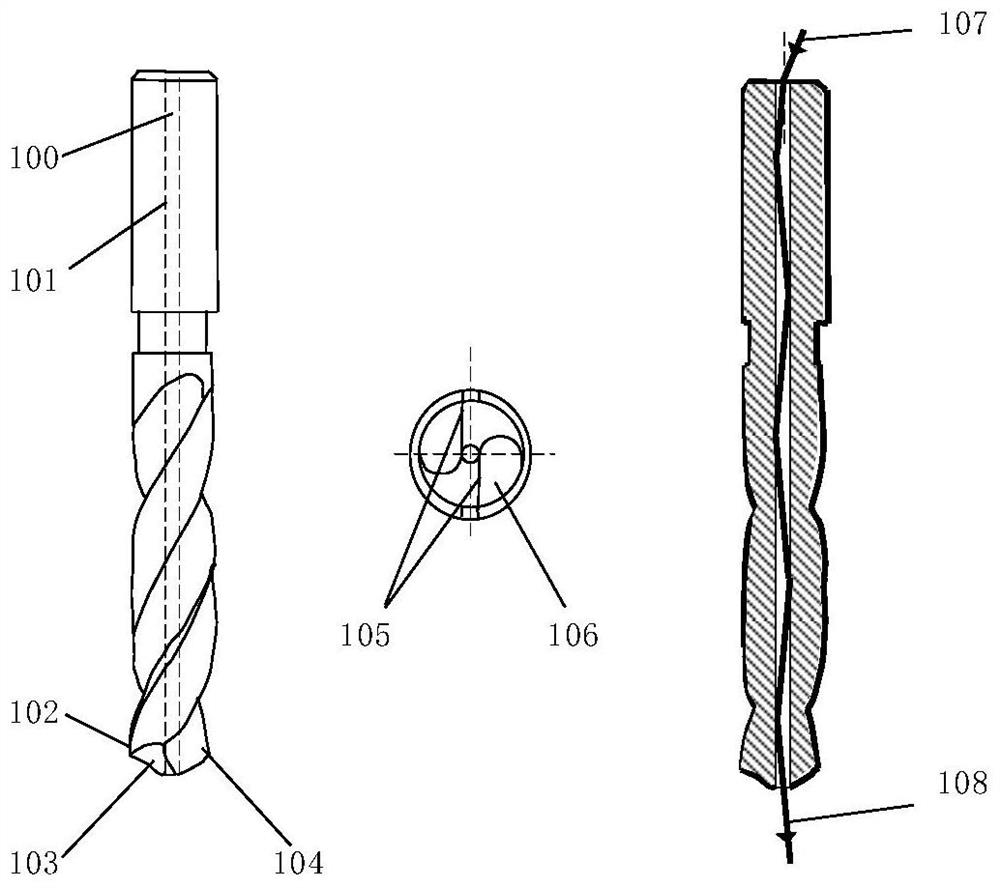

[0030]Example 1: This example is a composite processing method of laser-assisted drilling, electrolysis, and post-polishing post-treatment for superalloy blades with thermal barrier coatings. The outer surface of the quartz rod is coated and embedded in the drill bit , so that the laser beam produces total reflection inside the quartz rod, and then irradiates on the surface of the material to be processed, resulting in a local high temperature area, softening the material near the drill bit contact position, greatly reducing the drilling difficulty, increasing the drilling efficiency, and improving the drilling quality. After drilling through, with the drill bit as the cathode and the blade material as the anode, the drill bit rotates at a high speed and moves up and down, and performs electrolytic post-treatment on the metal part of the gas film hole to eliminate the residual stress, microcracks, and thermal damage areas of the hole wall; at the same time, the electrolyte in th...

Embodiment 2

[0034] Example 2: Coaxially embed the coated quartz rod in the drill bit, utilize the low absorption and total reflection of the laser in the quartz rod, irradiate the laser energy evenly on the surface to be processed, soften the material, and improve the drilling efficiency And quality, and rely on electrolysis and particle impact scratching to further improve the quality of air film holes. The processing method is divided into two steps. First, through laser heating to assist drilling, the required size of the air film hole is quickly drilled on the thermal barrier coating and the superalloy substrate; second, the high-speed rotating drill bit is used as the cathode, and the blade is used as the anode. , the drill bit moves up and down, and performs on-line electrolytic post-treatment on the gas film holes of the metal substrate to eliminate the residual stress and heat-affected zone defects during the drilling process; at the same time, there are tiny abrasive particles sus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com