A coal-thermal co-mining method based on high ground temperature mine

A high ground temperature, mine technology, applied in geothermal energy, surface mining, underground mining, etc., can solve the problems of heat damage in mines, neglect, slow transformation and utilization of abandoned mines, etc., to reduce mining costs and reduce drilling difficulty , Improve the effect of heat extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034]The present invention will be further described in detail below in conjunction with the drawings.

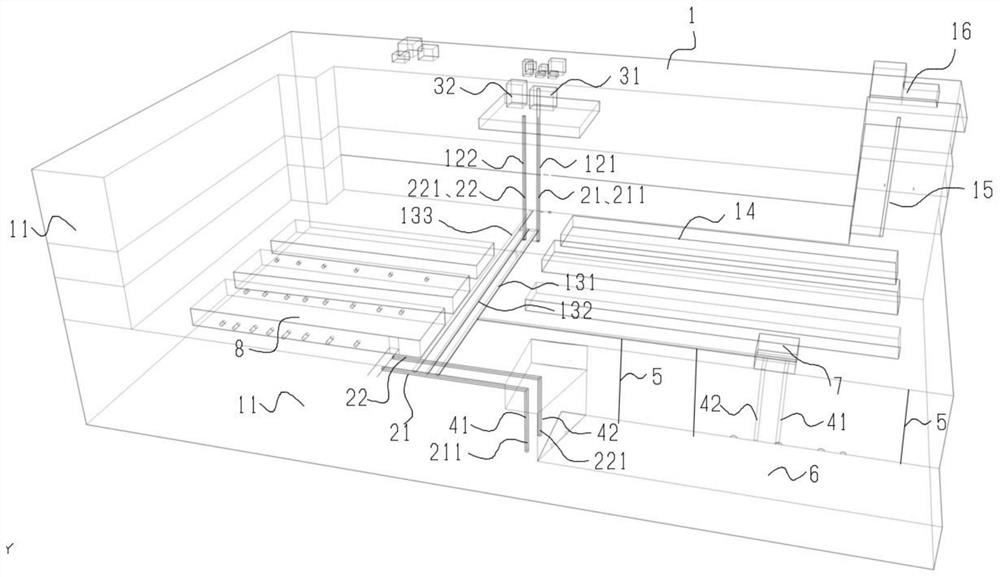

[0035]Such asfigure 1As shown, a coal-thermal co-mining method based on high ground temperature mines is mainly aimed at high ground temperature mines or mines with geothermal resources under the coal seams. The method includes the following steps:

[0036](1) Coal mining: According to the coal seam storage conditions, arrange the main shaft 121, auxiliary shaft 122, and ventilation shaft 15 to determine the mining level. Excavate roadways, chambers, and mining faces within the mining level to carry out coal mining work. During the mining process of the adjacent mining face, roadways are reserved along the goaf and coal pillars are reserved; the current domestic coal mining technology is relatively mature, andfigure 1As an example, the main shaft 121, the auxiliary shaft 122, and the ventilation shaft 15 are excavated from the ground 1 in the rock layer 11, the transport roadway 131 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com