Single-sided annular kerf energy gathering grain, indoor test and application

A technology of slitting and graining, which is applied in the preparation of test samples, fuel testing, measuring devices, etc., can solve problems such as large performance differences, difficulty in measuring explosion stress waves, errors, etc., to reduce the bulk rate, improve Crushing effect, effect of increasing the number of cut holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

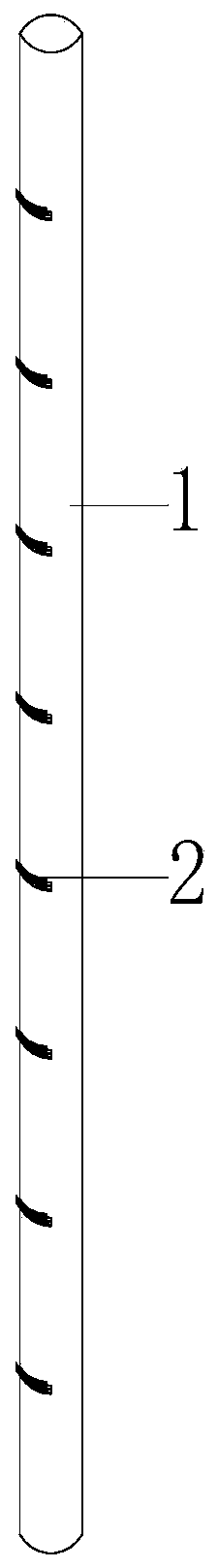

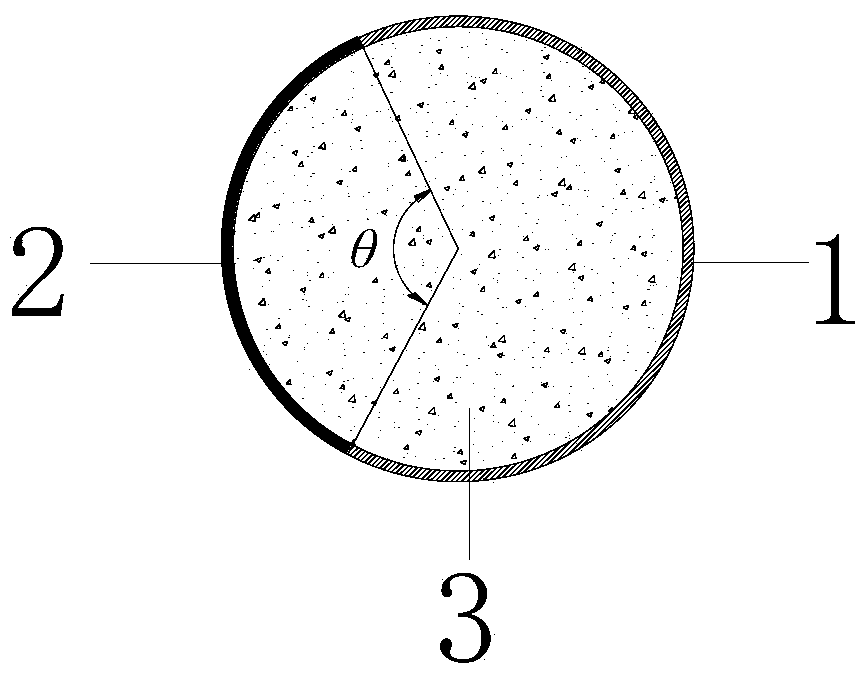

[0053] The blast crack and blast stress wave test of the single-sided circumferentially slit shaped charge includes the following steps:

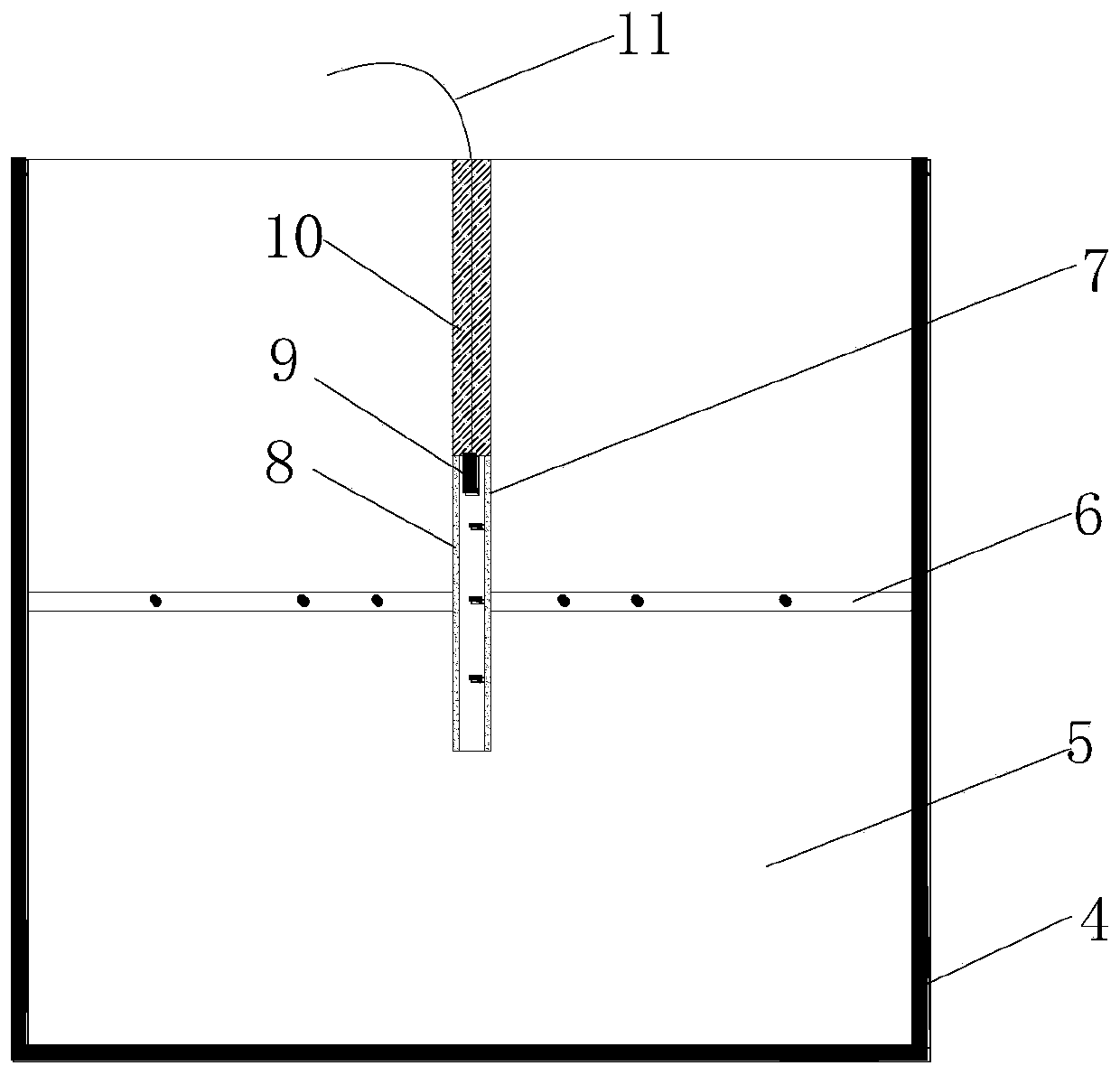

[0054] 1) Mix cement, fine sand and water in a ratio of 1:4:1 to prepare cement mortar, and then add cement mortar into the steel sleeve 4 with a diameter of 600 mm and a height of 600 mm. When the cement mortar is poured to a height of 250 mm, the A PVC pipe with a diameter of 25mm is fixed in the middle of the steel sleeve 4 to reserve a blasthole 7, and two sets of strain bricks 6 are placed close to the blasthole in advance, and the two sets of strain bricks 6 are respectively facing the designed slit position and back-to-cut. Seam position, the material used for the strain gauge carrier in the strain brick 6 is also made of cement, fine sand and water in a ratio of 1:4:1, mainly to ensure that the measured explosion stress wave energy can most truly reflect the stress wave test piece 5 The medium transmission has consistency, the strai...

Embodiment 2

[0060] An underground 800m sandstone roadway adopts a cutting blasting method with a single-sided circumferential slit and energy-concentrating charge, including the following steps:

[0061] 1) Hydraulic drilling rig, 2.6m long drill rod, and Φ42mm drill bit are used to carry out drilling operations according to the blasting design plan, using wedge-shaped cutouts, and the outside of the cutout hole is one circle of caving holes and two circles of caving holes in sequence , three circles of caving holes and peripheral holes, the designed cutting hole depth (the depth of the vertical working face) is 2.4m, the depth of other blasting holes is 2.2m, the left and right symmetrical hole spacing of the cutting holes is 1500mm, and the upper and lower hole spacing is 450mm, close to the digging The distance between a circle of caving holes and the opening of the cutting hole should be strictly controlled at about 250mm, the distance between the caving holes and the row distance betw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com