Distribution-drilling method for floating screen frame of banana-shaped flip-flow screen

A technology of relaxation screen and screen frame, which is applied in the direction of drilling mold, boring/drilling, drilling/drilling equipment for workpieces, etc. It can solve the problem that the position of the hole is difficult to determine, cannot be assembled, and affects the smooth production To reduce the difficulty of drilling and improve the drilling accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

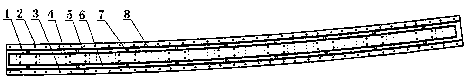

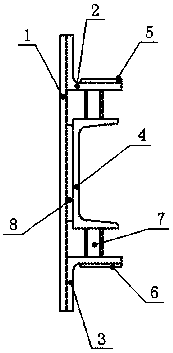

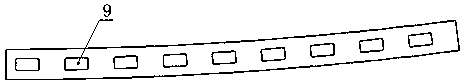

[0032] The invention provides a drill matching method for the floating screen frame of the banana-shaped relaxation screen, so as to ensure the smooth progress of later assembly of the banana-shaped relaxation screen.

[0033] see figure 1 , figure 2 and image 3 , the present invention first makes side square drill template 1, upper drill template 5 and lower drill template 6 according to the assembly diagram of banana-shaped relaxation screen, and then they are combined with the upper support angle steel 2 made, the lower support angle steel 3 and the floating screen frame 4 are assembled together to form a drill assembly, and finally the drill assembly is placed on a CNC drilling machine to drill holes for the upper support angle steel 2, the lower support angle steel 3 and the floating screen frame 4.

[0034] In the assembly of drill components, the side square drill template 1 replaces the actual side plate of the relaxed screen, and the material is automatically cut ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com