Welding device for preventing welding hot cracking and deformation

A welding device and hot crack technology, applied in welding equipment, welding accessories, arc welding equipment, etc., can solve the problems of limiting aluminum alloy welding structure, human injury, and difficulty in quantifying the magnitude of impact force, and reduce welding residual stress. and deformation, preventing welding thermal cracking, and compact structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

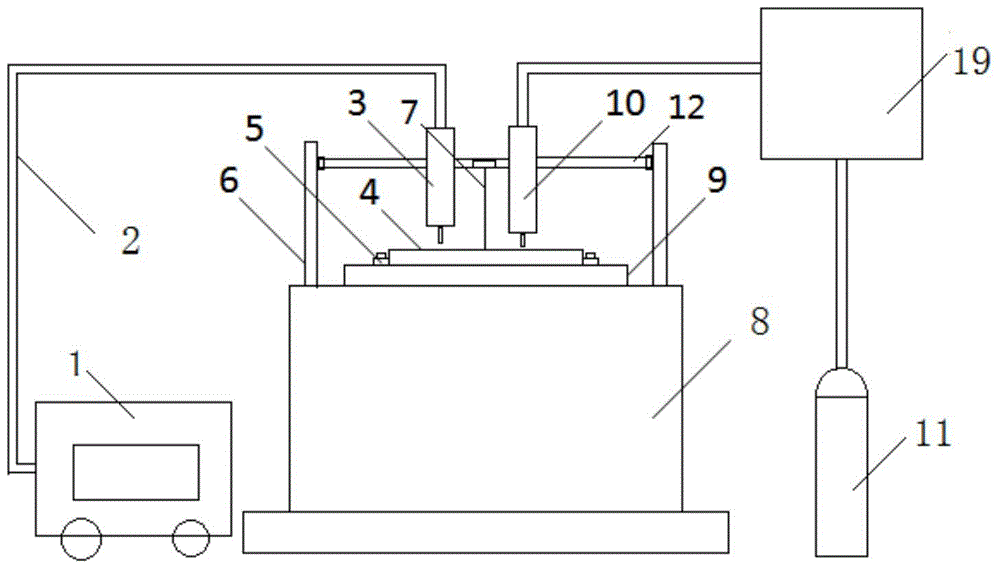

[0018] Referring to the accompanying drawings, a welding device for preventing welding heat cracks and deformation includes a workbench 8 on which a fixing device for positioning an aluminum alloy plate 4 is provided, and a welding device is provided around the workbench 4 and cooling units,

[0019] Described welding device comprises the gas tungsten arc welding machine 19, welding torch 10 and argon cylinder 11 connected by pipeline, and described cooling device comprises the spray gun 3 and dry ice injector 1 connected by pipeline 2;

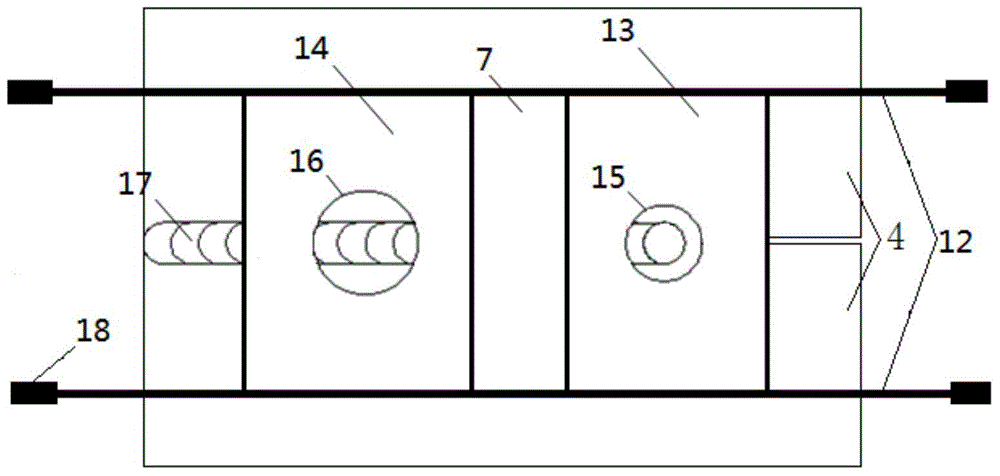

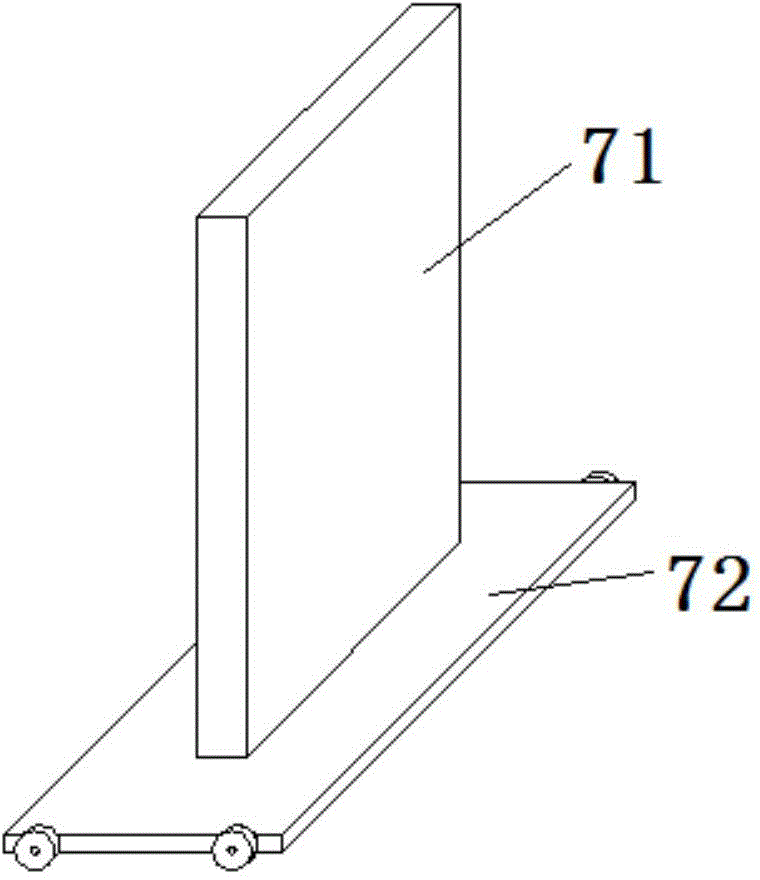

[0020] The fixing device includes a supporting plate 9 for placing the aluminum alloy plate, a fixing block 5 for positioning the aluminum alloy plate is arranged around the supporting plate 9, a slide rail 12 is erected above the supporting plate 9, and the sliding rail 12 is erected above the supporting plate 9. The rail 12 is parallel to the welding seam 17 of the aluminum alloy plate 4, the welding gun slider 13 and the spray gun slider 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com