Steel tube joint

A technology of steel pipes and joints, which is applied in the direction of construction and building structures, can solve the problems of large stress and deformation at the intersecting parts of the main pipes, reduce the bearing capacity of the main pipes of the joints, and the residual stress of the weld, so as to reduce the probability of lap joints, Simple and reasonable structural layout, the effect of improving bearing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The specific embodiments of the present invention will be further described in detail below with reference to the accompanying drawings.

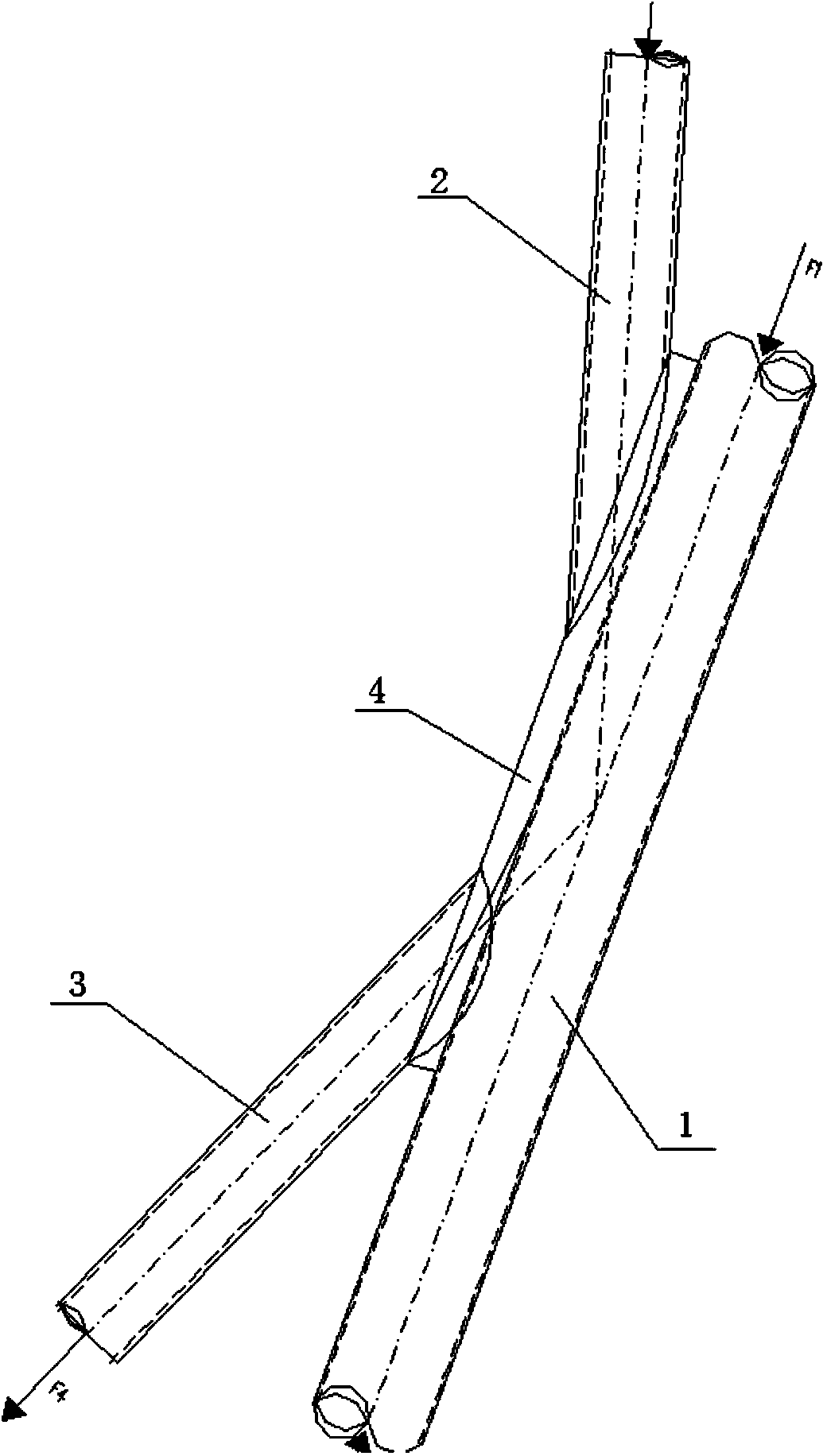

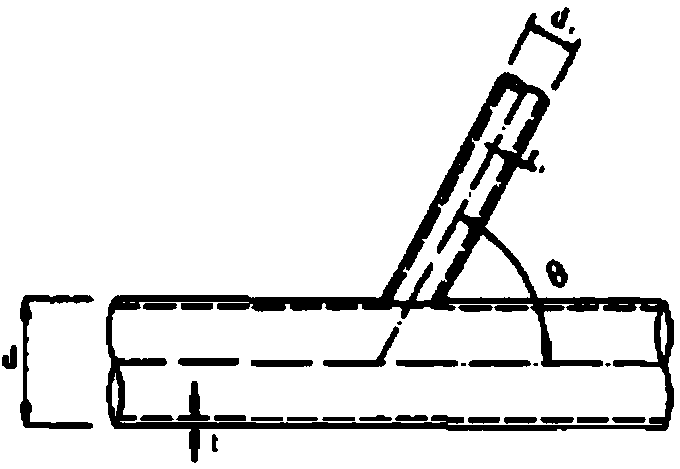

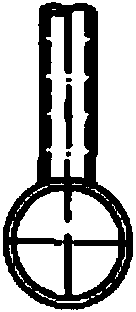

[0052] This embodiment takes the installation of two branch pipes in one main pipe of a flat steel pipe node as an example, such as figure 1 As shown, the steel pipe node provided by the embodiment of the present invention includes: a main pipe 1 , an upper branch pipe 2 , a lower branch pipe 3 , and a backing plate 4 . The backing plate 4 is an arc-shaped plate that fits with the main pipe 1 in an arc. The backing plate 4 covers the main pipe 1 with an arc between 90° and 360°, and can provide welding space for the ends of the upper branch pipe 2 and the lower branch pipe 3. Are 90°, 120°, 150°, 180°, 210°, 240°, 270°, 300°, 330° or 360° curved plates. The upper branch pipe 2 is welded or bolted to the upper edge of the backing plate 4, the lower branch pipe 3 is welded or bolted to the lower edge of the backing plate 4, the backin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com