Electron beam welding method of thin-walled casing gas-collecting hood structure

A technology of electron beam welding and gas collecting hood, which is applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve the problems of poor welding protection effect, affecting the quality of parts, and long weld length, etc., so as to reduce the development cycle and cost input, improve the quality of parts, and the effect of small deformation of weldments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described in detail below with reference to the drawings and embodiments.

[0044] An electron beam welding method for a thin-walled casing gas hood structure includes the following steps:

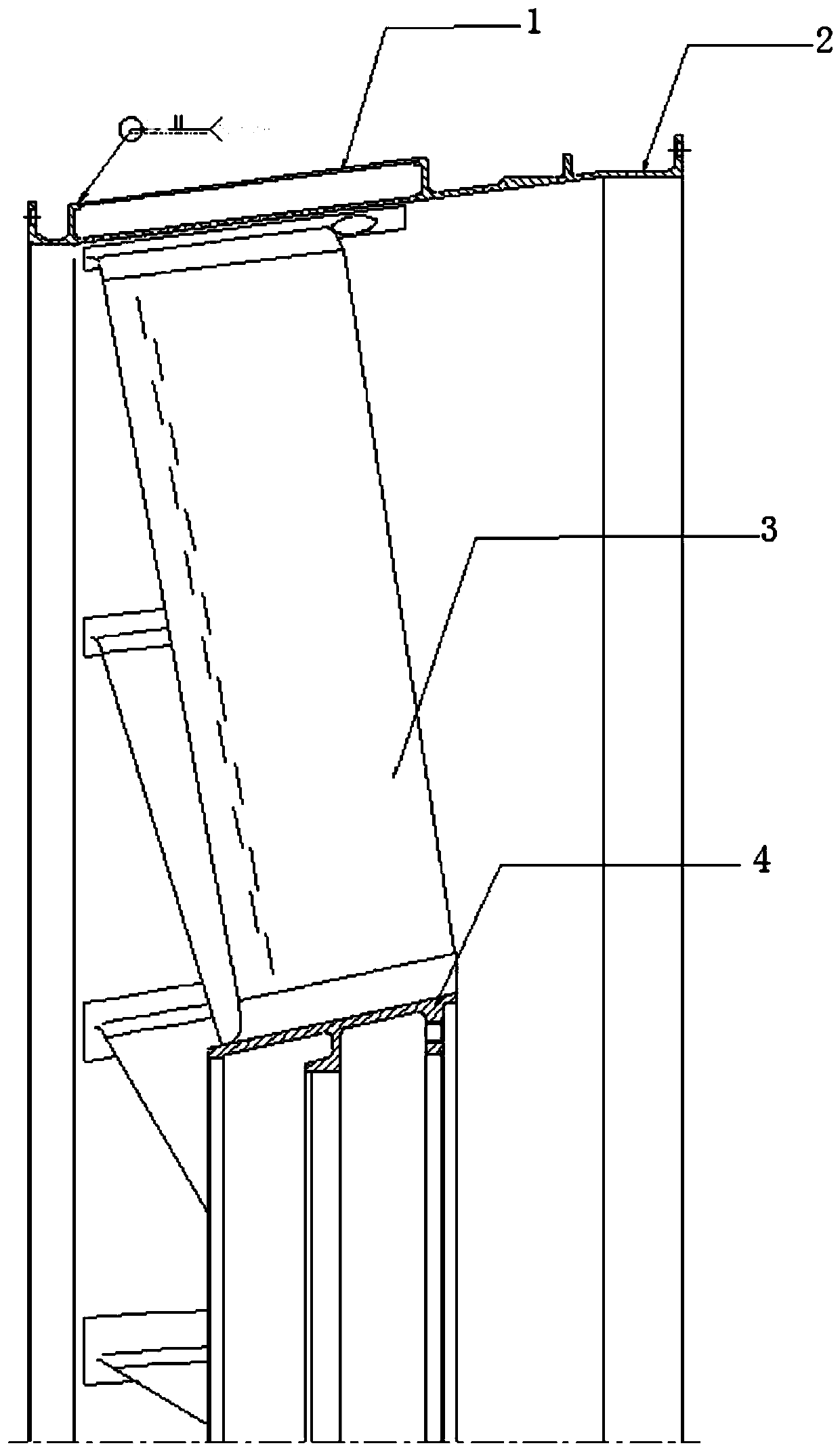

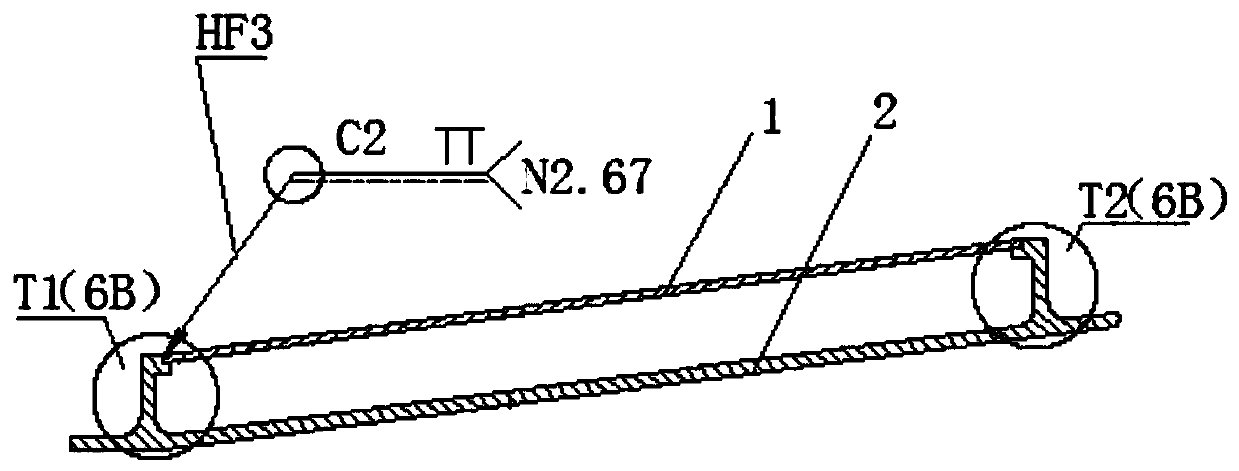

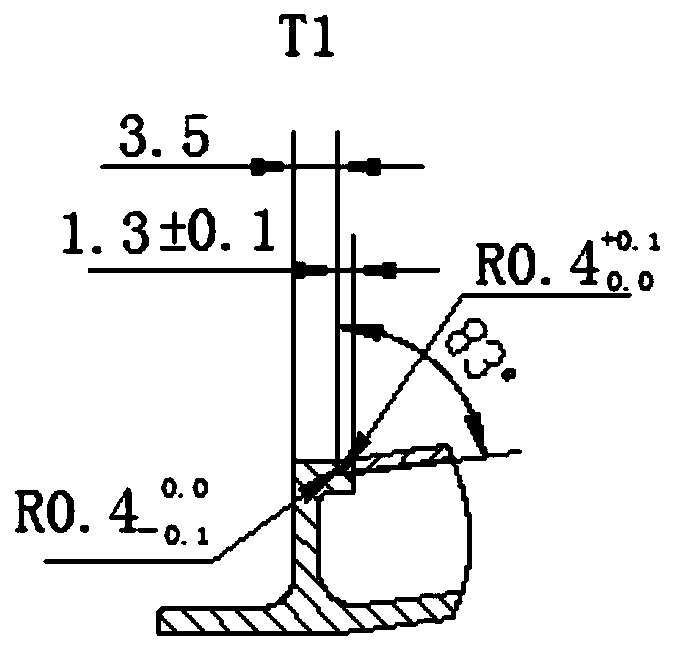

[0045] Step 1. Welding structure design: The electron beam welding gap is 0.1mm, the pre-welding misalignment is 0.1mm, and the deformation of the outer ring 2 and the support plate needs to be considered at the same time, and the original argon arc welding with a broken joint The form is changed to the butt joint form, and a certain amount of welding deformation is reserved; the original argon arc welding structure has a 60°V groove, and the assembly gap is 0.5mm. Now it is changed to no groove, and the original radial increase is 1mm margin. , After the support plate and outer ring 2 and inner ring 4 are welded, the assembly processing is performed; the thin-walled casing is welded by electron beam welding on the outer ring 2 and the fixed support ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com