Patents

Literature

38results about How to "Reduce turning times" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Welding method for vertically spliced super-thick steel plate

ActiveCN102861972AControl welding deformationReduce turning timesWelding/cutting auxillary devicesArc welding apparatusSheet steelTurnover time

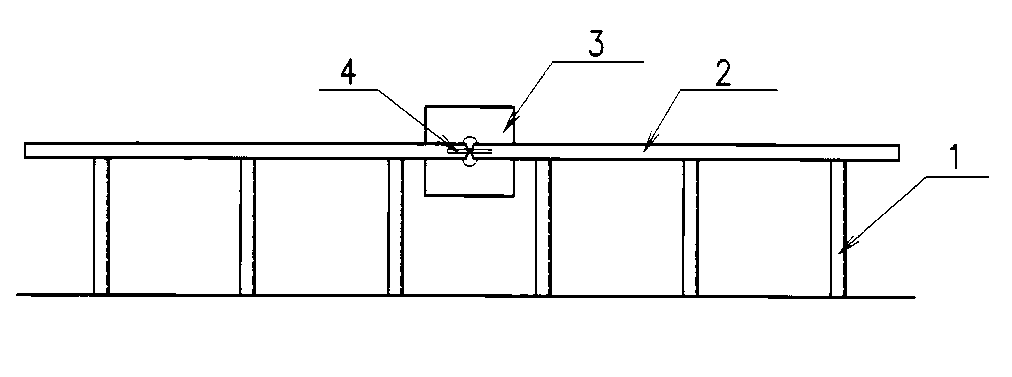

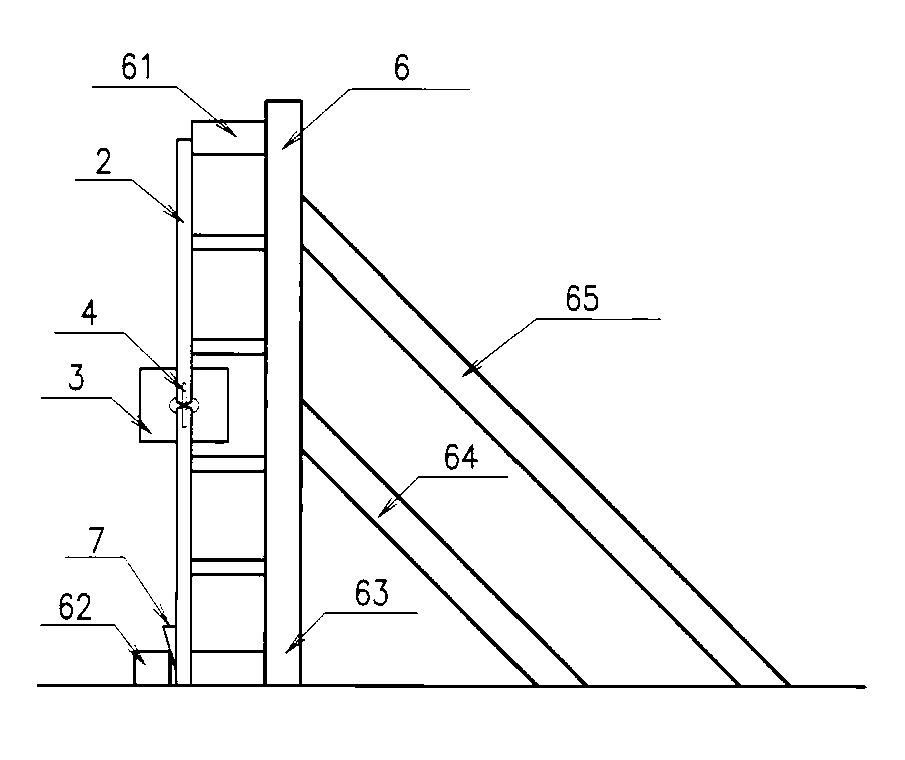

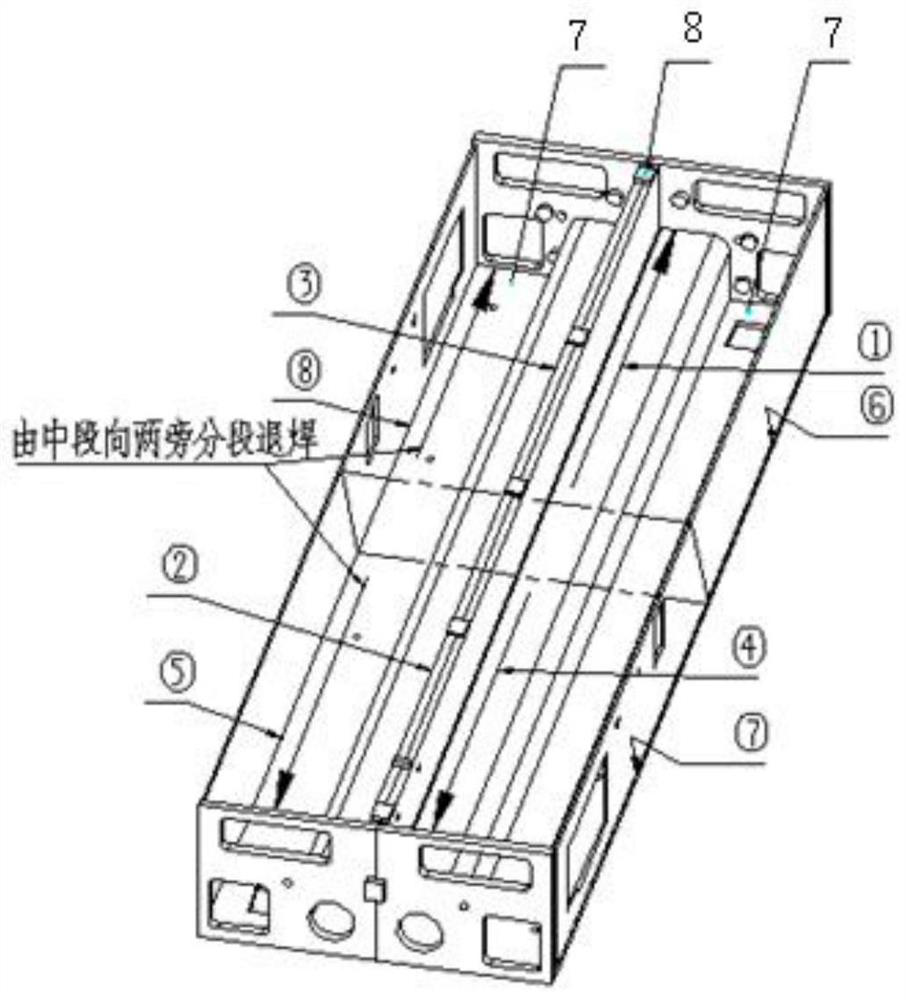

A welding method for a vertically spliced super-thick steel plate is a welding method for a super-thick steel plate with the thickness ranging from 60mm to 120mm. The method is characterized by including: hoisting a primarily spliced super-thick steel plate onto a special jig frame for horizontal welding, fixing the super-thick steel plate with a waler of the jig frame by welding prior to fastening the super-thick steel plate with a ground abutting floor stand by the aid of a wedge, then using carbon dioxide arc welding for sequential symmetry horizontal welding on the front side and the back side of the super-thick steel plate respectively by even welders until spliced plate welding is finished, and finally performing postheat treatment to prevent cracks. The method has the advantages that welding deformation of the spliced super-thick steel plate can be well controlled, welding deformation correction is avoided, welding cracks are prevented, welding quality is improved, and construction requirements are met. The carbon arc air gouging process for back gouging is omitted, welding procedure is simplified, turnover times of the super-thick steel plate are decreased, workload is reduced, labor intensity is relieved, and production efficiency is improved.

Owner:QINGDAO BEIHAI SHIPBUILDING HEAVY IND CO LTD

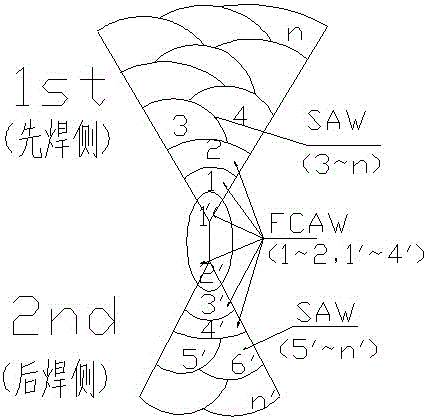

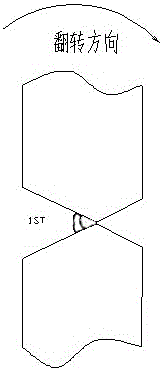

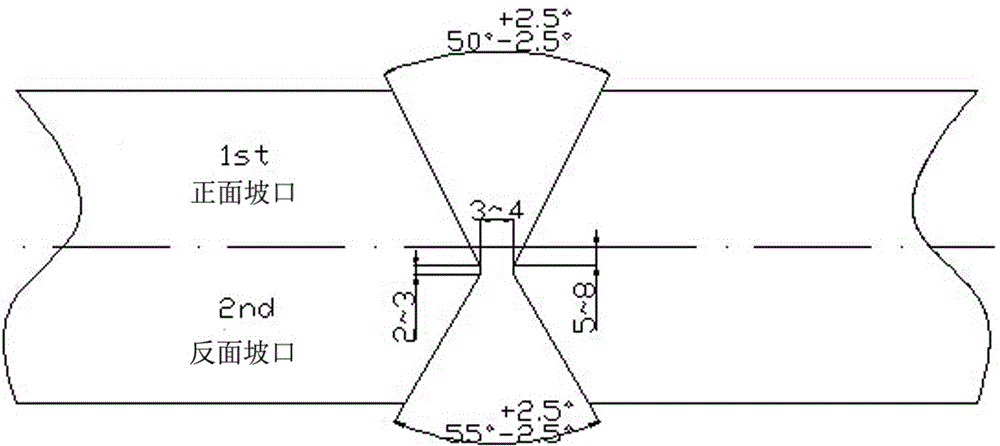

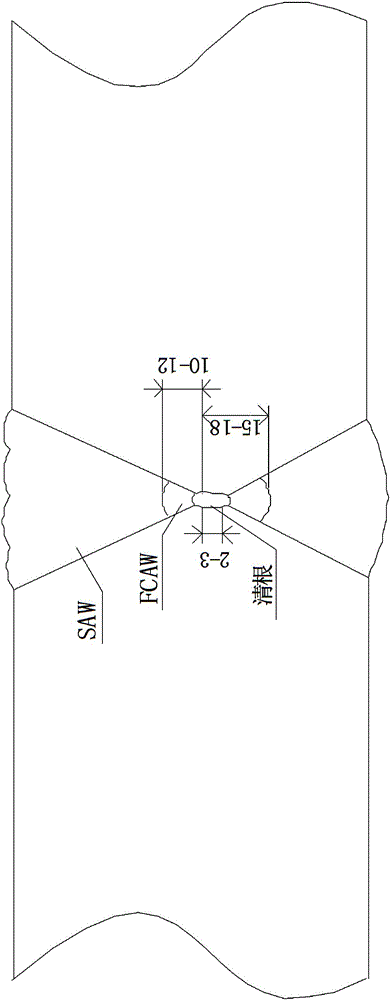

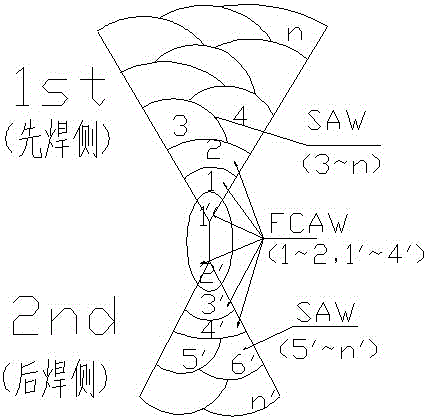

Extra-thick sheet submerged-arc welding technique

ActiveCN105057856ASmall amount of welding deformationReduce turning timesArc welding apparatusWelding/soldering/cutting articlesThick plateWelding residual stress

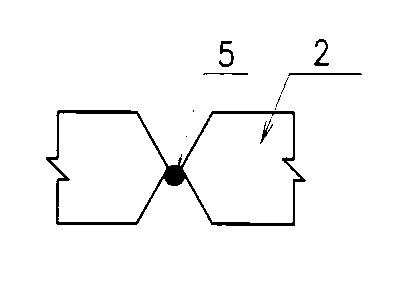

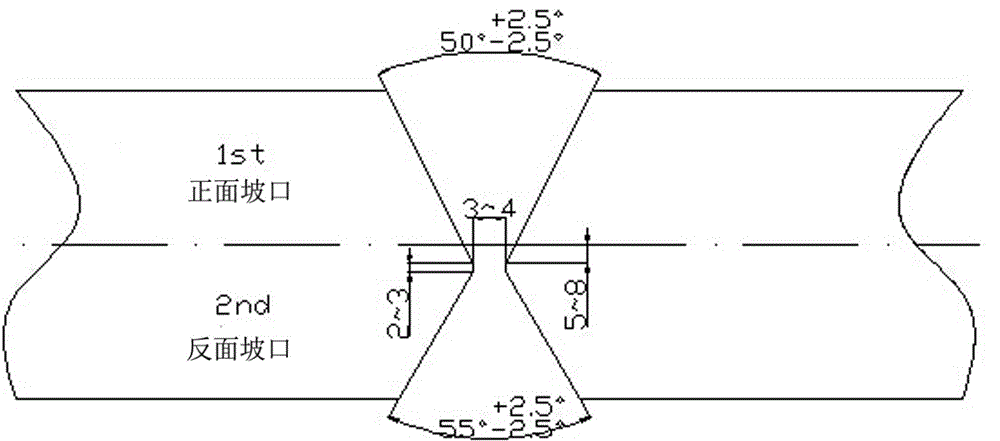

The present invention discloses an extra-thick sheet submerged-arc welding technique. The technique comprises the following technological parameters and steps: 1) connector preparation: X-type beveled edges are adopted by extra-thick sheets; 2) preheating: first heating a back side of an extra-thick sheet and then a front side of the extra-thick sheet, a preheating temperature being 150 DEG C to 160 DEG C, and a heating rate being not higher than 105 DEG / h; 3) backing welding: after preheating, using flux-cored wire gas shield welding for backing welding for two paths to form two layers, and using submerged-arc welding to fill at least two paths to form one layer, maintaining interlayer temperature to be not higher than 230 DEG C; 4) turning over after an inter-welding deformation is not larger than 6-8 mm; 5) backside welding: after carbon gouging and back chipping, backing welding according to the step 3) after the extra-thick sheet reaches a preheating requirement according to the preheating method described in the step 2); 6) stress relief treatment; and 7) carrying out post heating treatment at 200 DEG C / 2h after the welding, then slowly cooling the extra-thick sheet to be at the room temperature. With adoption of the technique provided by the present invention, rooting welding deformation is reduced, welding residual stress for subsequently filling a cover face is also reduced, and thus turn-over times in welding of the extra-thick sheet are reduced.

Owner:CHINA MERCHANTS HEAVY IND JIANGSU +1

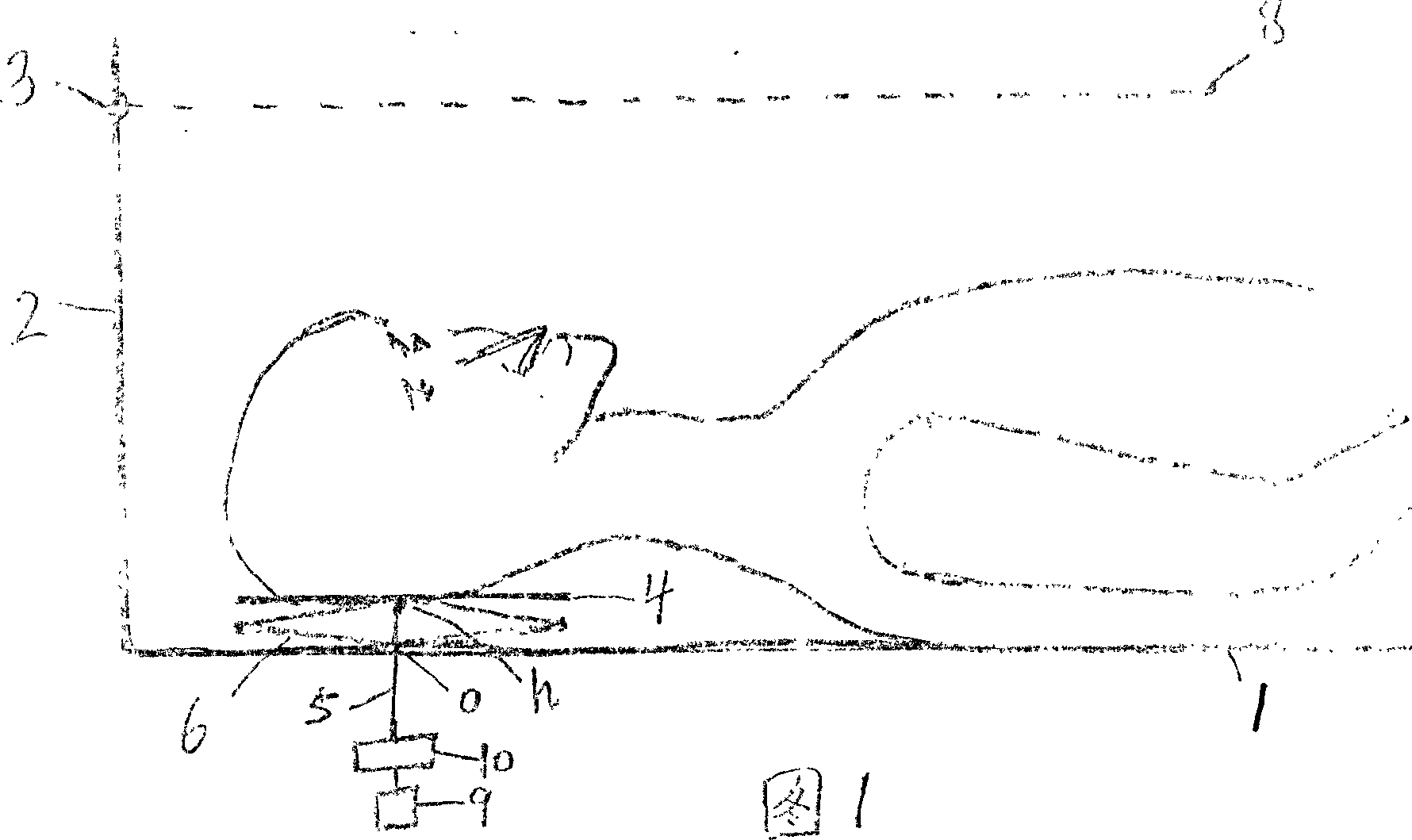

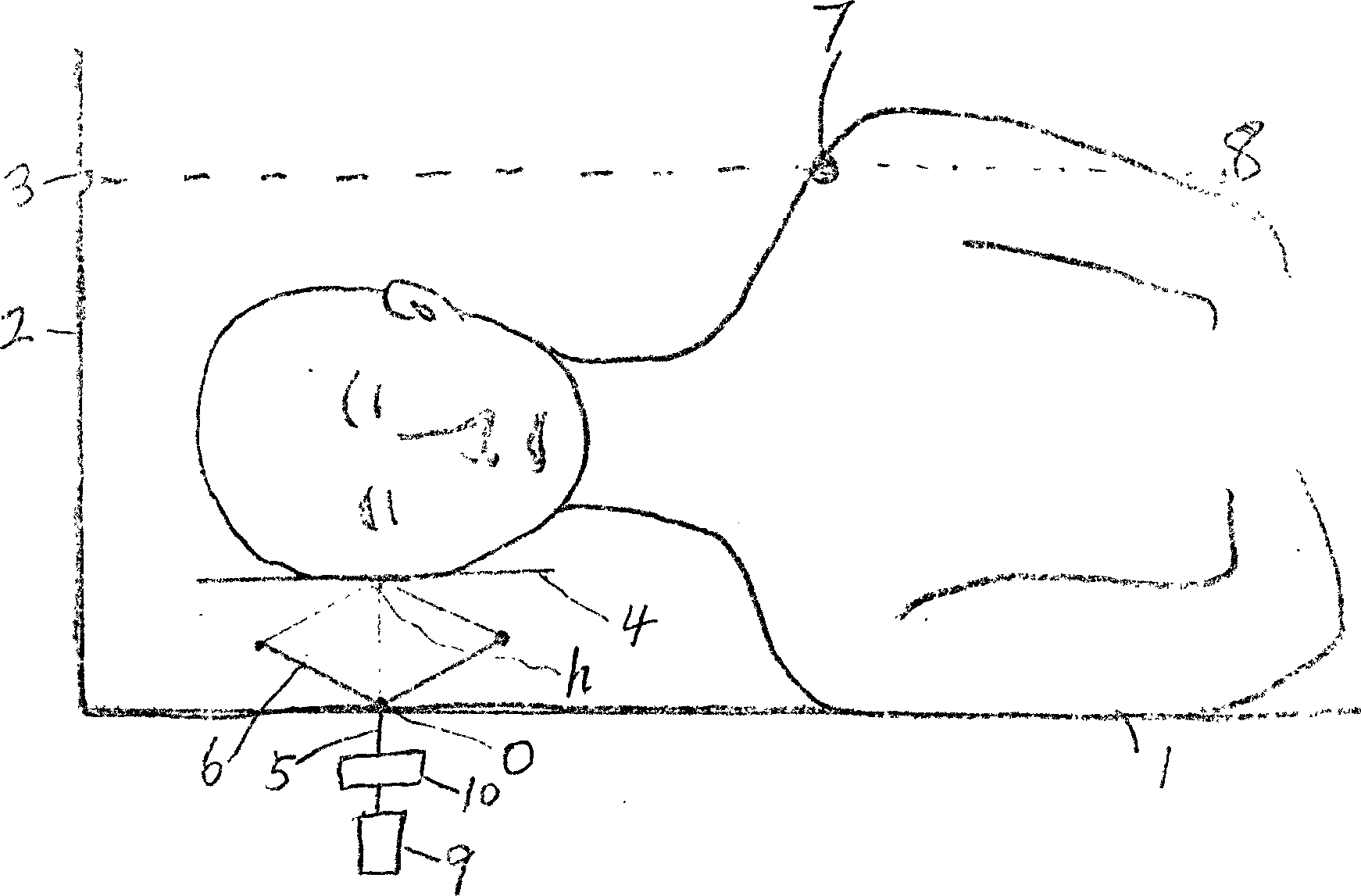

Pillow with automatic height adjustment

InactiveCN1679434AEasy to relaxConducive to unimpededPillowsSnoring preventionResistive sensorsMicrowave range

Pillow with automatic height adjustment comprises: sensor, pillow, lifting mechanism. The wire is installed on one side of the pillow. The sensor is installed on one side of bed or the bed head. The sensor is human body infrared spectrum sensor or active infrared launching and accepting sensor or ultrasonic ranging sensor or microwave ranging sensor. The wire is the sensitive element of the resistive sensor or capacitive sensor. The input terminal of the relay connects to the output terminal of the sensor. The output terminal of the relay is series or parallel with the control switch of the lift mechanism of the pillow. The pillow automatically changes the height of the pillow following the change of the sleep gesture so as to accord with the physiological curve of the human cervical vertebra.

Owner:彭小毛

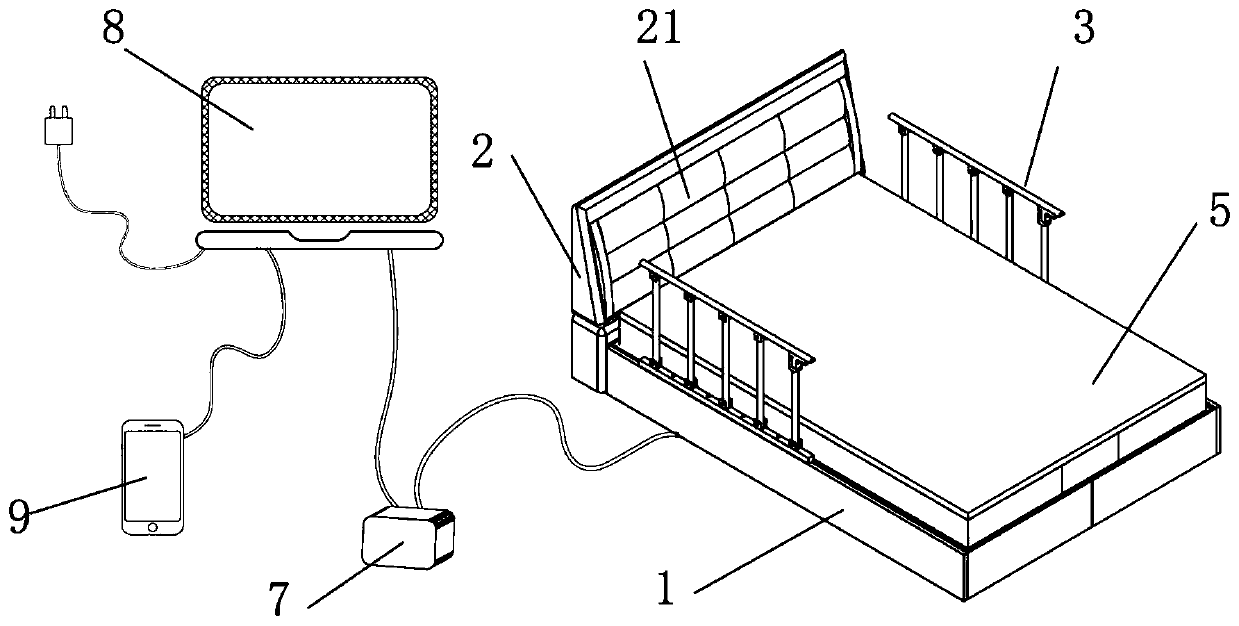

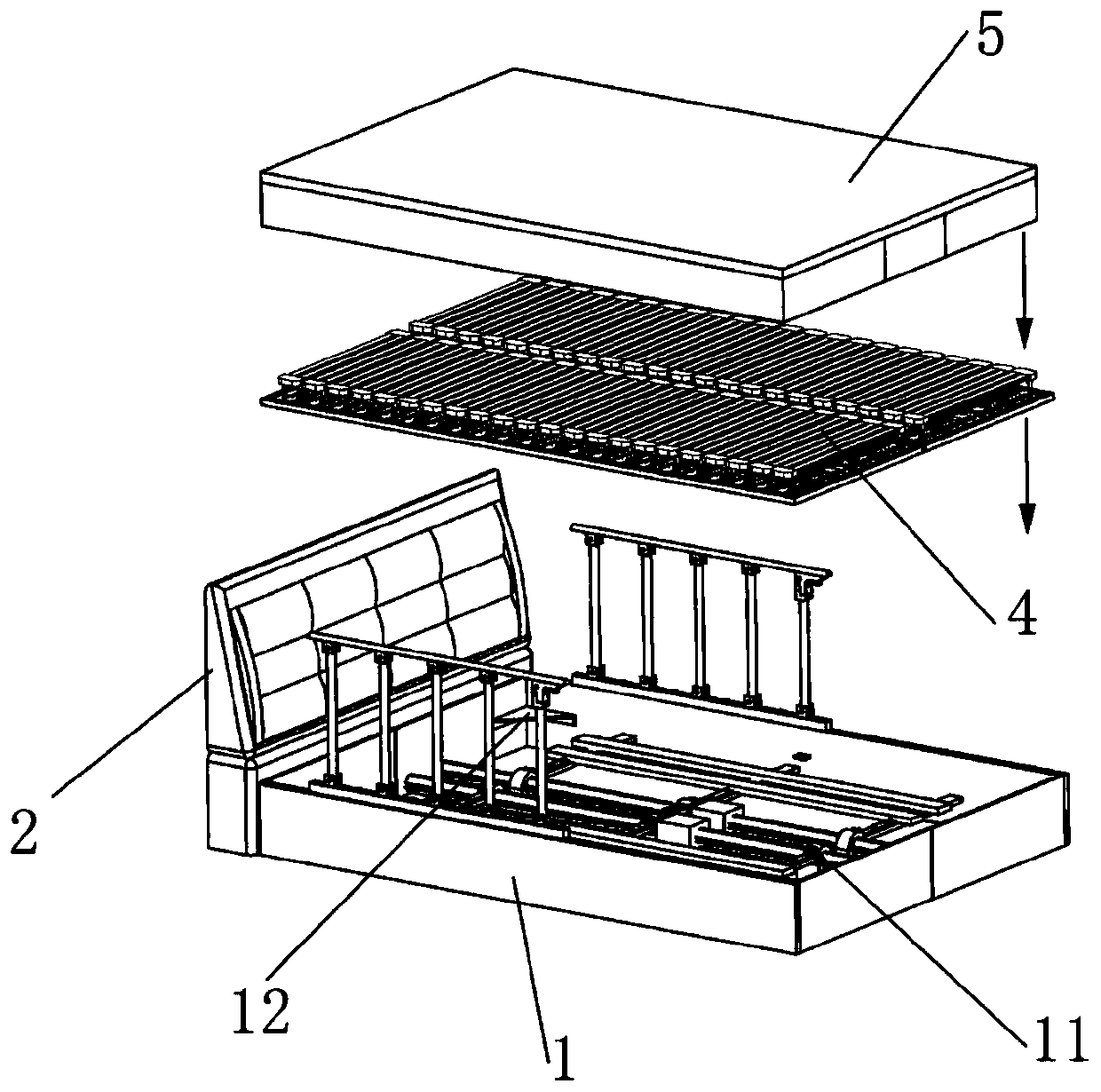

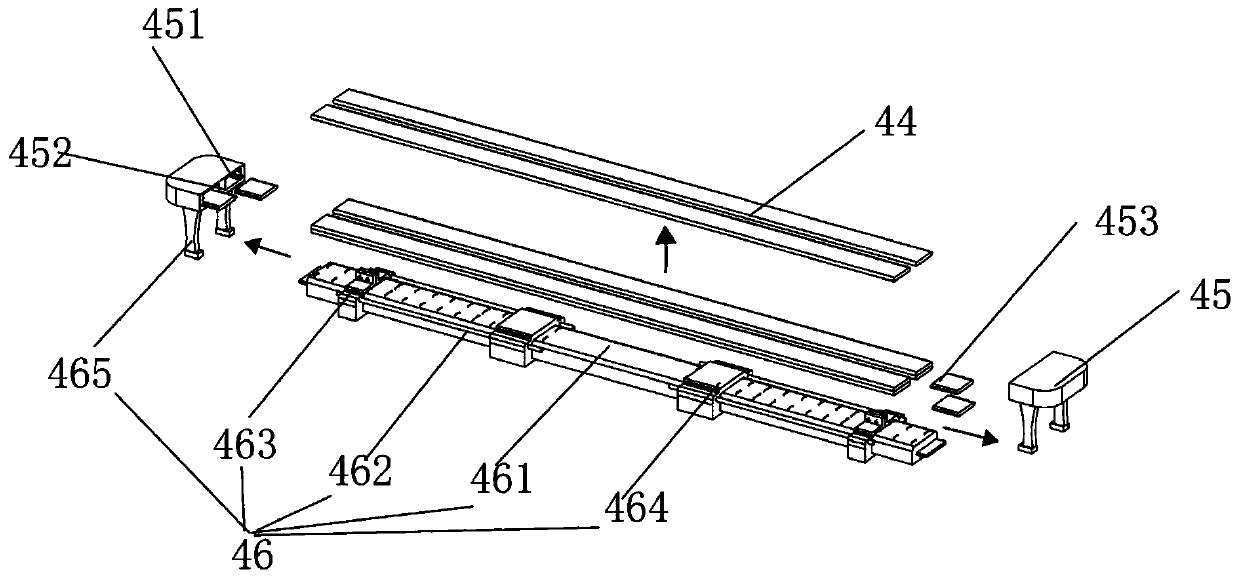

Nursing bed having functions of monitoring risks, relieving pressure and assisting in overturning

PendingCN110652402AStable supportRealize automatic adjustmentPneumatic massageNursing bedsNursing careEngineering

The invention provides a nursing bed having functions of monitoring risks, relieving pressure and assisting in overturning. The nursing bed comprises a bed bottom frame, a bed frame and a mattress, wherein the bed frame comprises a left region and a right region, and is erected on the bed bottom frame; an overturning assisting mechanism is arranged at the bottom in the bed bottom frame; a pressuresensor is arranged in the mattress, and is connected with an information acquirer; the information acquirer is connected with a host machine processor; the host machine processor is used for performing real-time monitoring and analyzing on pressure; when local pressure of the mattress is greater than bed sore risk alarm pressure, and the duration time is greater than bed sore risk alarm time, thehost machine processor sends an alarm to control the overturning assisting mechanism to overturn; an air sac core layer is also arranged in the mattress; and when the local pressure on the mattress is greater than pressure relieving starting pressure, and the duration time is greater than pressure relieving starting time, the pressure is relieved by the air sac core layer. The nursing bed disclosed by the invention can perform real-time monitoring on man-bed interface pressure; and based on the monitoring result, the pressure relieving design and the overturning assisting design are combined,so that different supporting requirements of people of different shapes are met, and intelligent pressure relieving and nursing are realized.

Owner:ANHUI AGRICULTURAL UNIVERSITY

Negative ion polyurethane memory foam composition, and preparation method and application thereof

The invention provides a negative ion polyurethane memory foam composition. The memory foam composition comprises 47-57wt% of polyether polyol, 25-28wt% of methyl diphenylene diisocyanate (MDI), 0.1-0.5wt% of stannous octoate, 1-2wt% of water-soluble silicone oil, 0.5-1.0wt% of triethylenediamine, 0.5-3.0wt% of polypropylene glycol (PPG350), and the balance of water. The composition can also comprise 2-8wt% of diatom powder. The invention also provides a preparation method and an application of the composition. Memory foam made by using the composition has a slow rebound performance, and has breathing, ventilating and blood circulation improving effects, and the memory foam containing the diatom powder can release negative ions.

Owner:LUOLAI LIFESTYLE TECH CO LTD

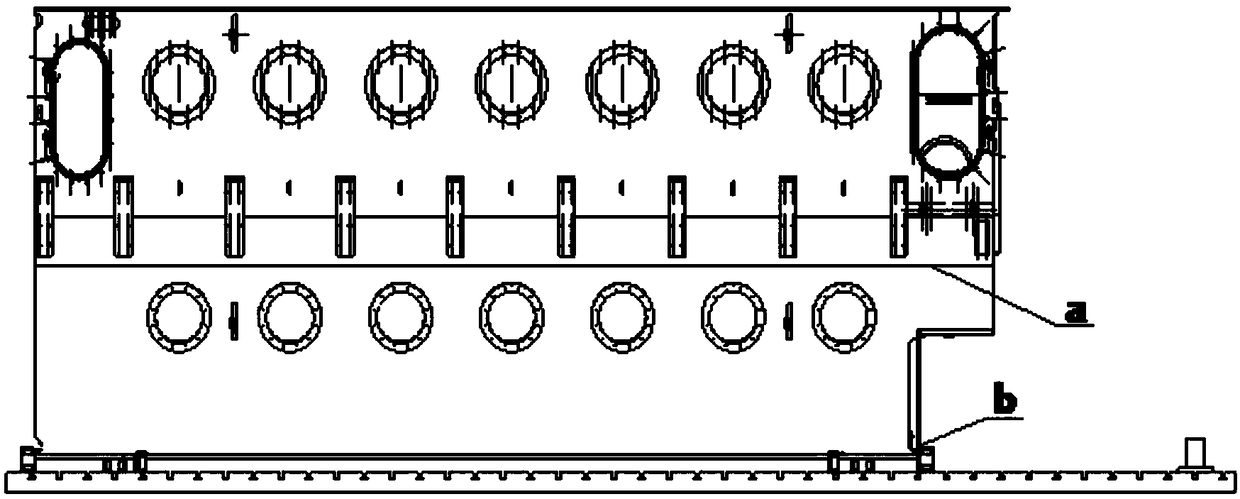

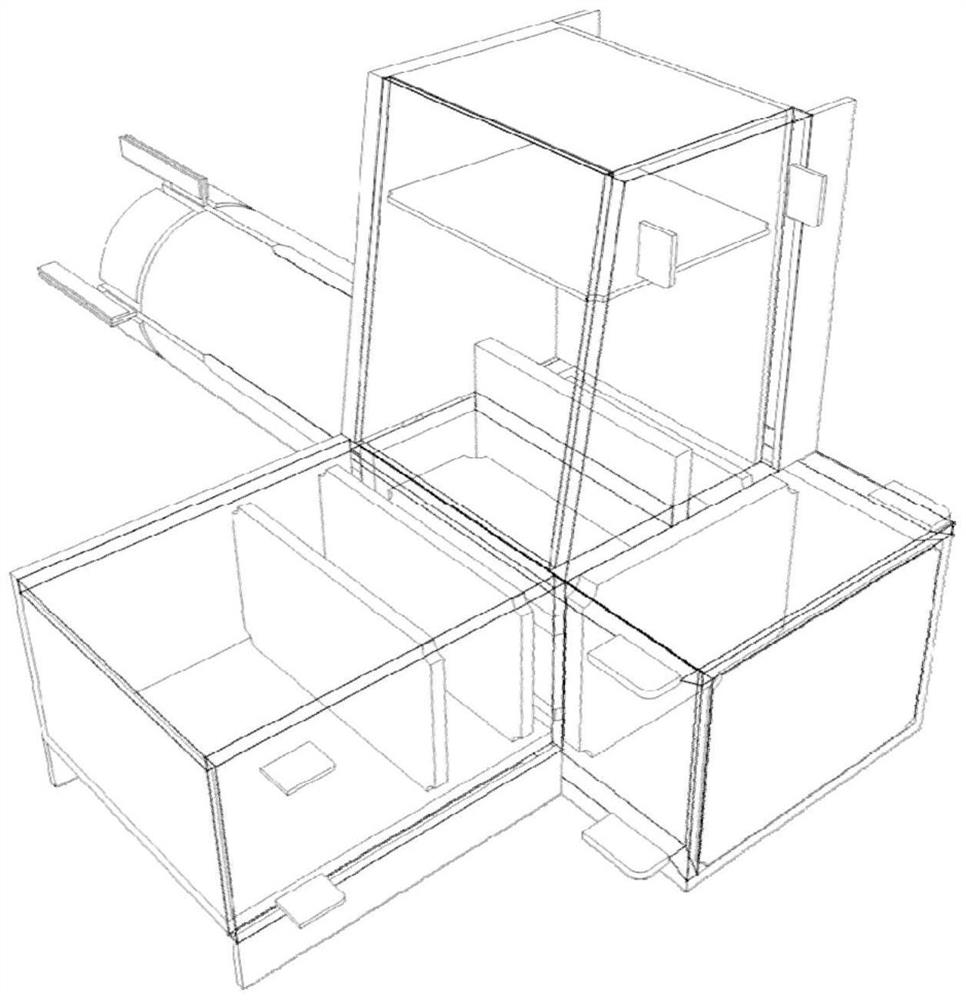

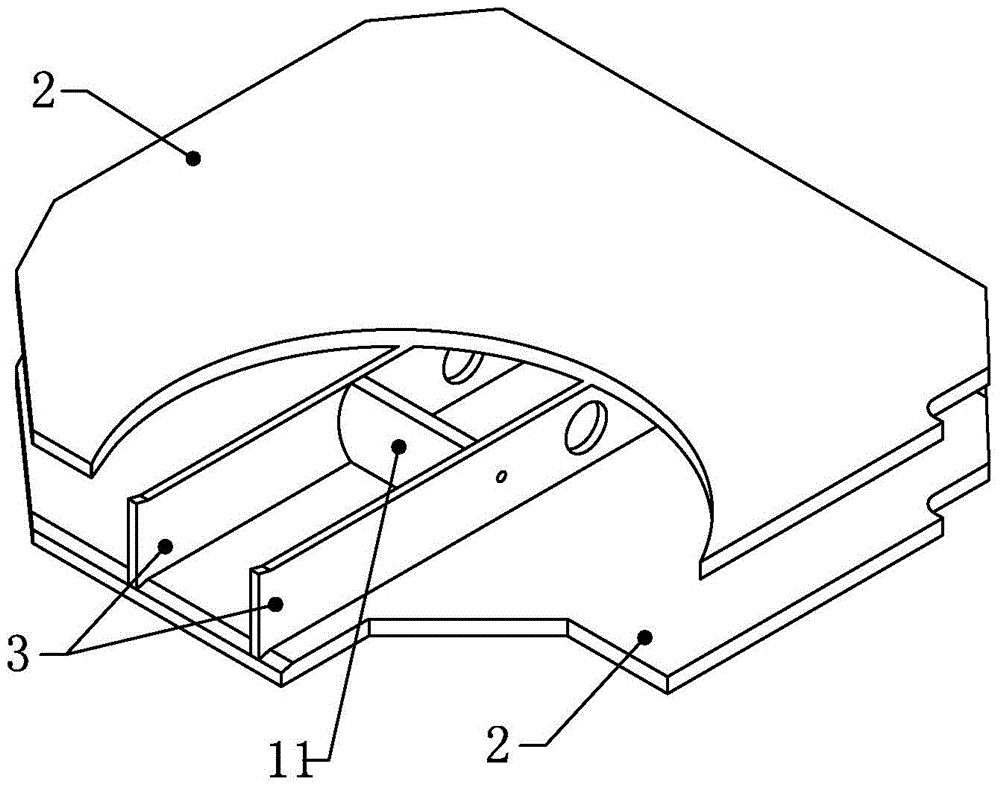

Large container ship wing bridge block integrated construction method

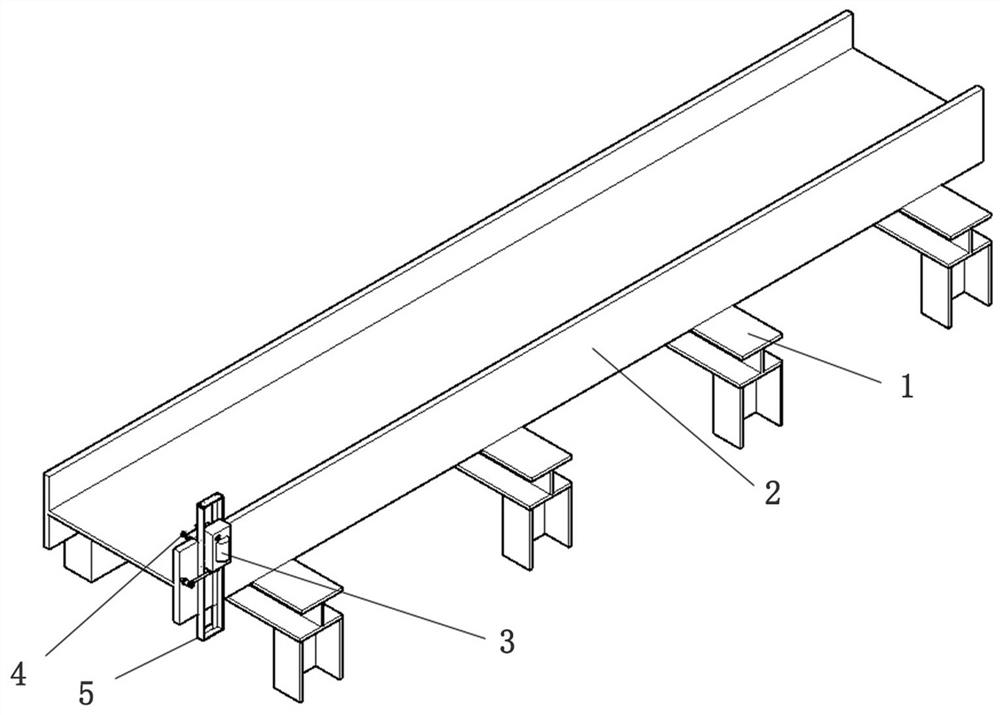

ActiveCN109625157AReduce turning timesImprove product qualityVessel designingSteel platesGantry crane

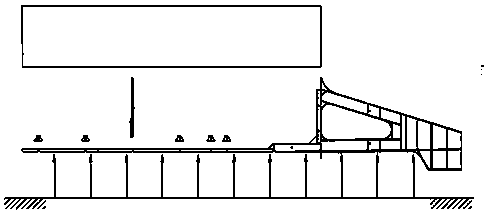

The invention discloses a large container ship wing bridge block integrated construction method. The method comprises the following steps that 1, a straight universal moulding bed is arranged, whereinthe straight universal moulding bed used for reverse integrated construction of superstructure wing bridge blocks and bridge deck blocks of a large container ship is arranged on a total configurationplatform; 2, steel plates are reversely laid, wherein with the deck surfaces as the reference surfaces, the steel plates used for construction of the left and right deck surfaces of the wing bridge blocks and the bridge deck blocks are laid on the straight universal moulding bed respectively, and a union melt welding way is adopted for welding. By means of the method, the situation of separate construction of the wing bridge blocks and total assembly of hoisting can be avoided, the turnover times of the blocks and the using number of gantry cranes can be reduced, the overall precision of theblocks is better controlled, the product quality is improved, the production cost is saved, and the production efficiency is improved. Aerial work can be avoided, the trouble that scaffolds are set upat a high altitude is omitted, and the operation safety is increased.

Owner:SHANGHAI JIANGNAN CHANGXING SHIPBUILDING

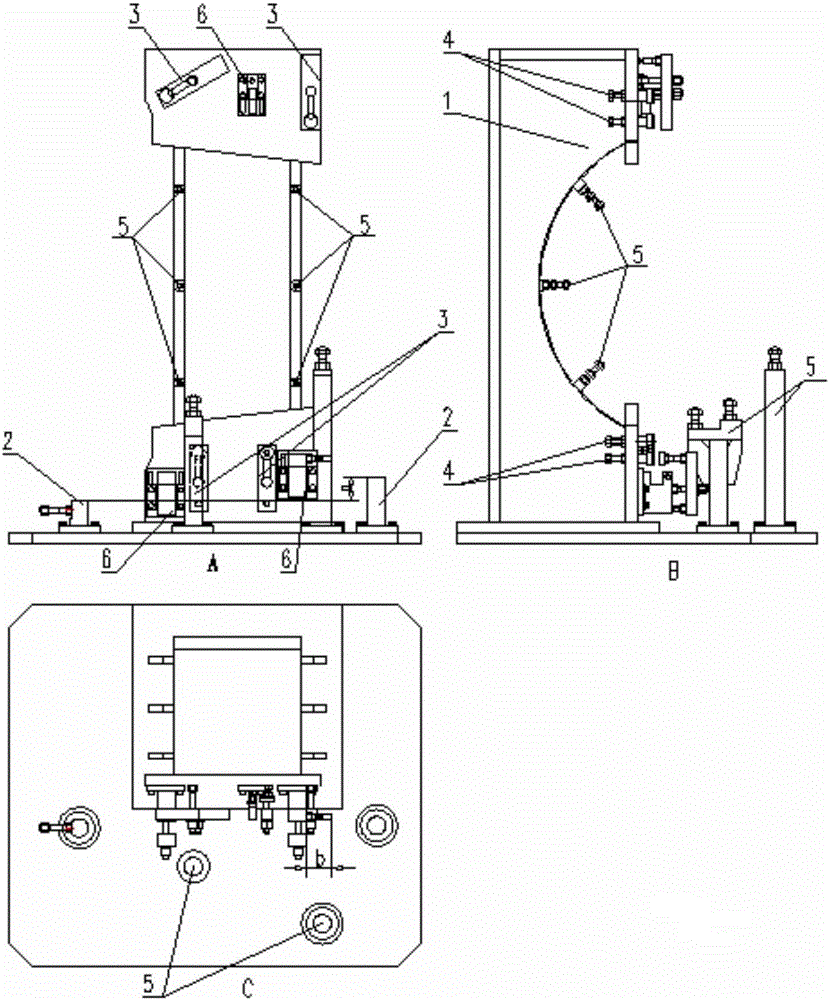

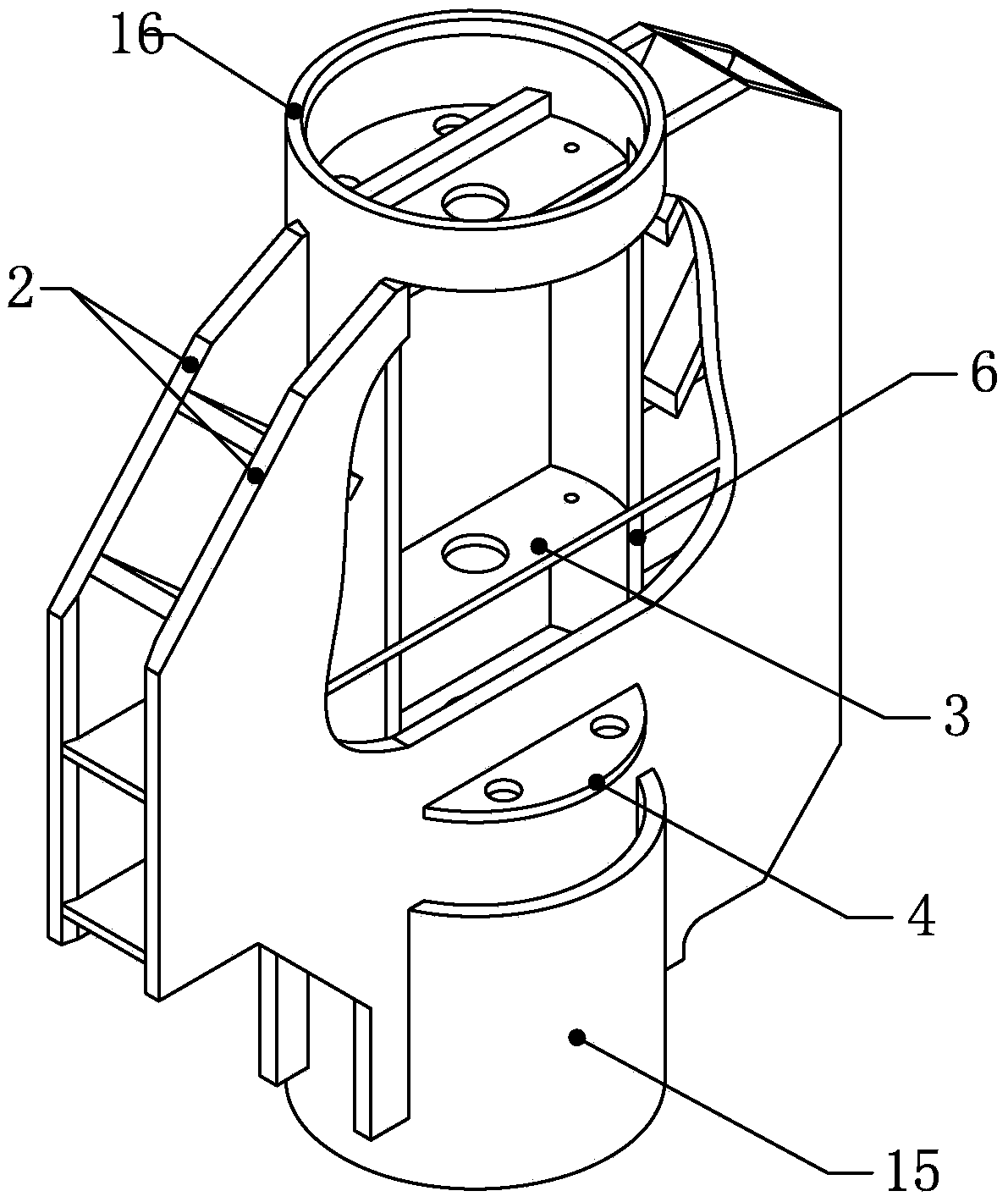

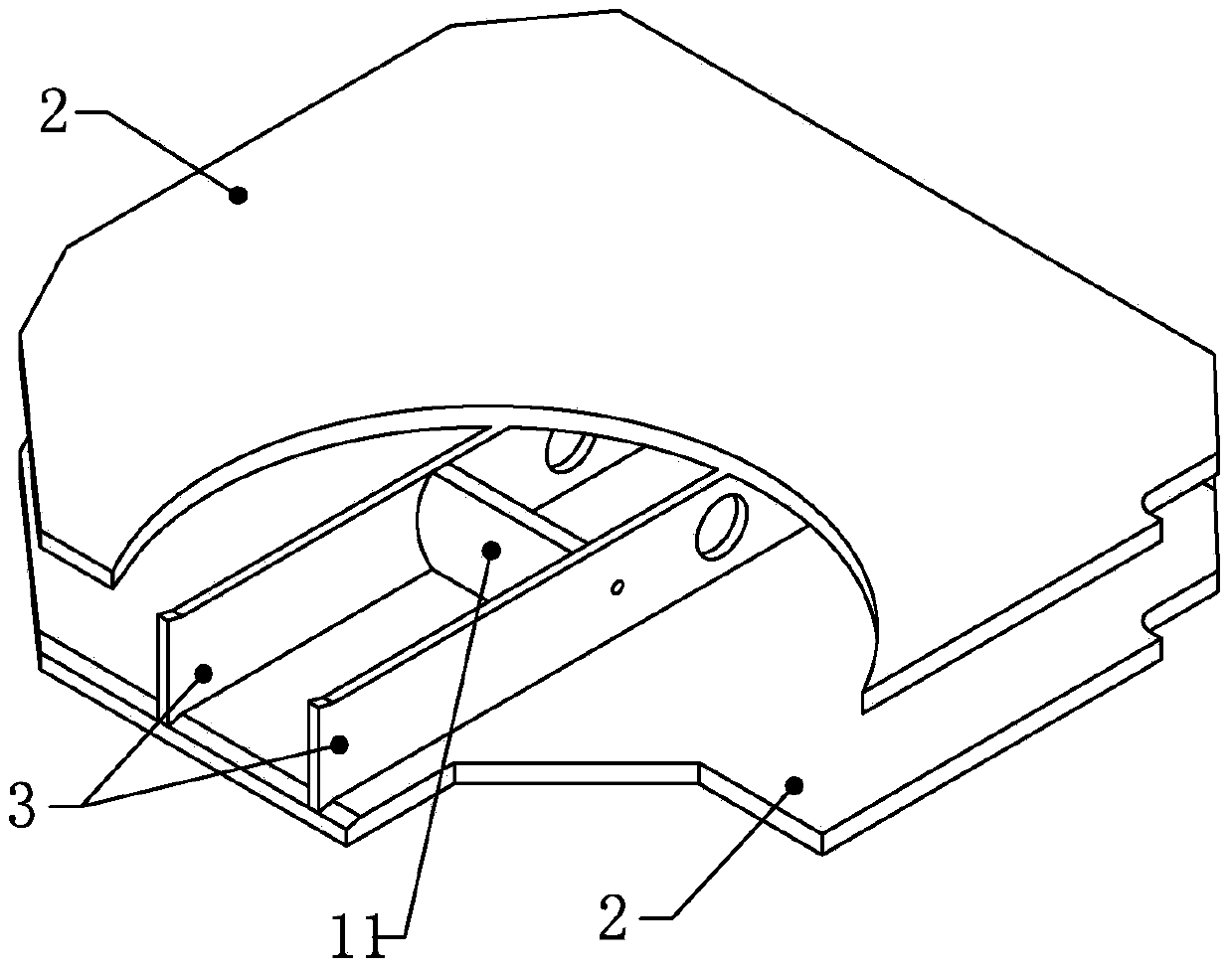

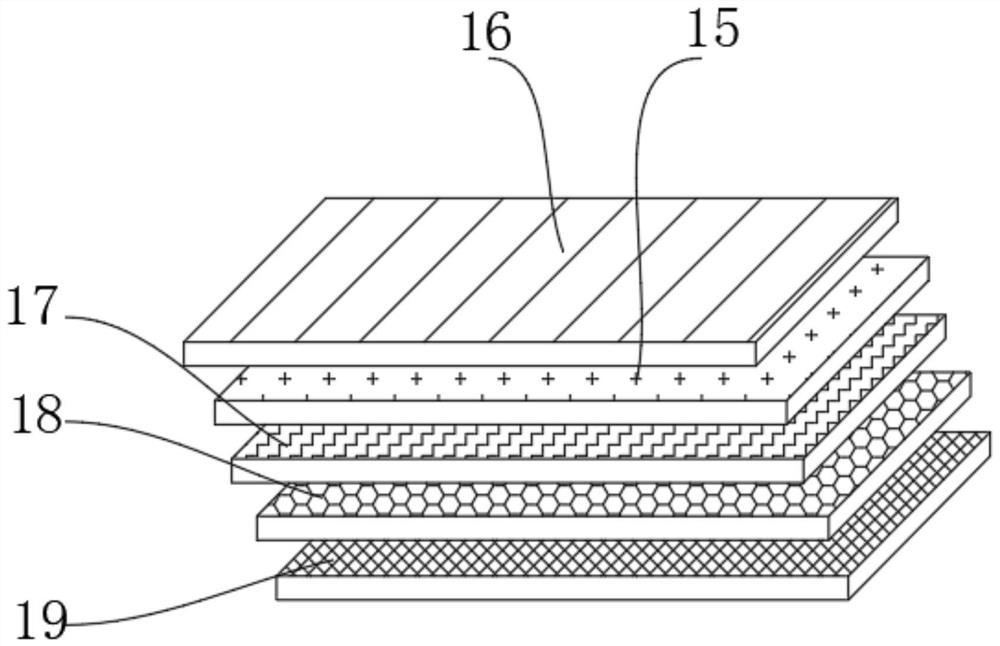

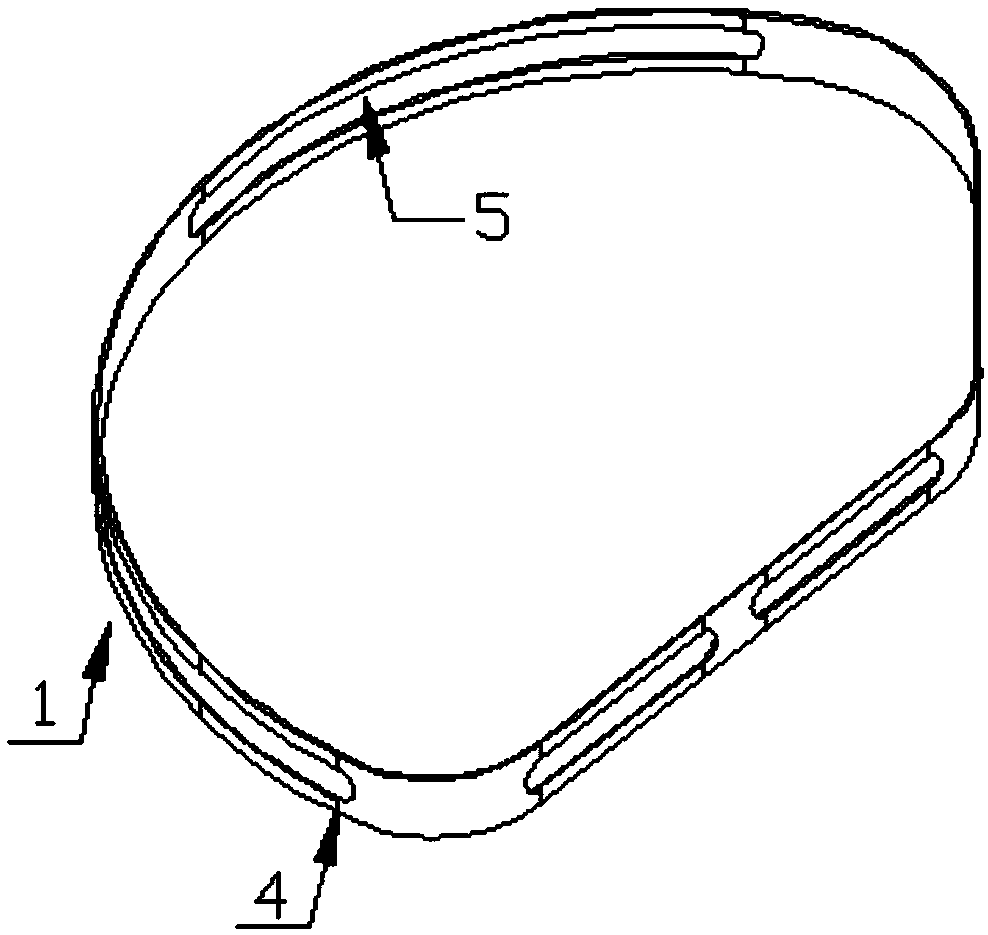

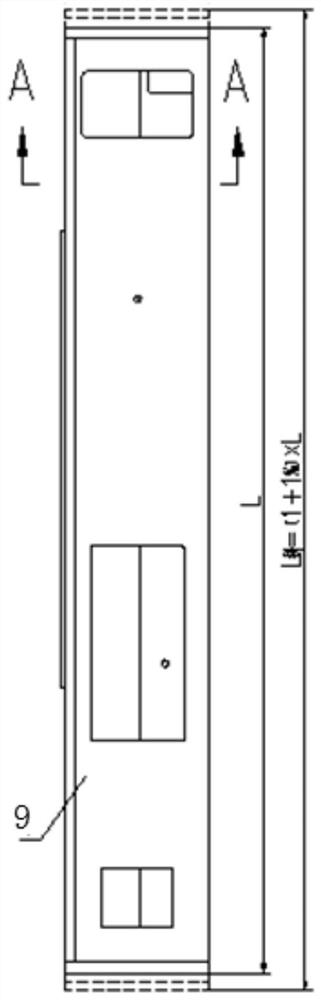

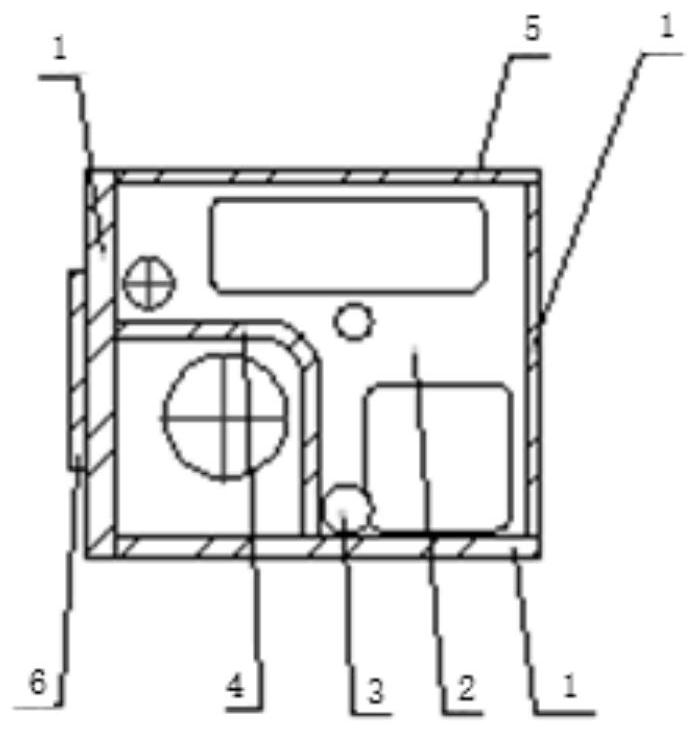

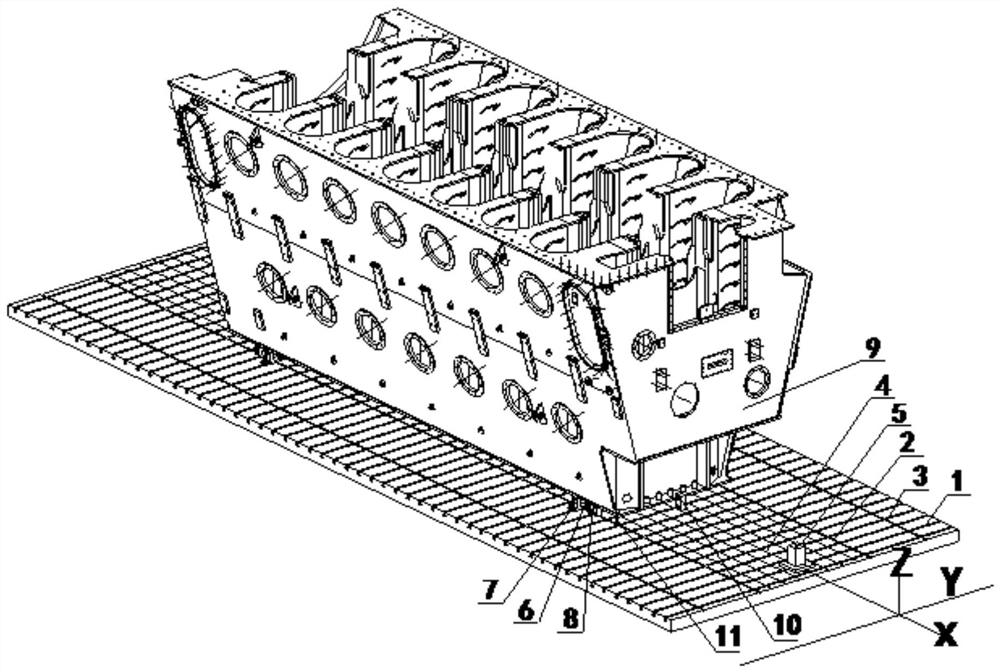

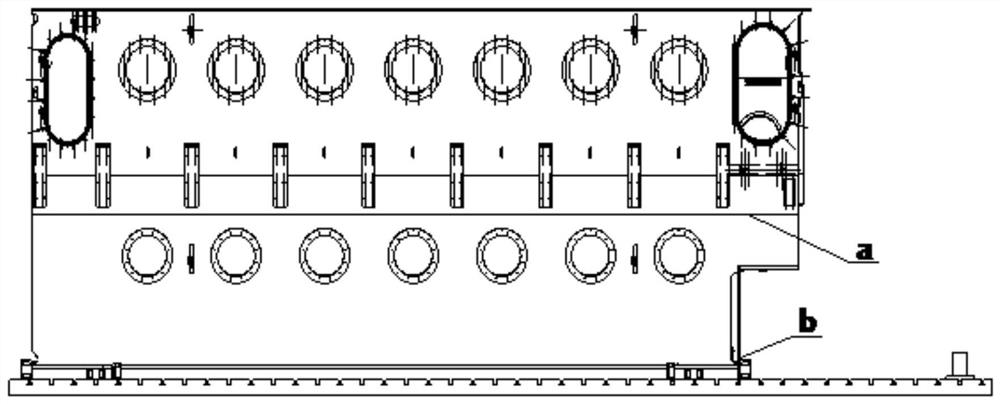

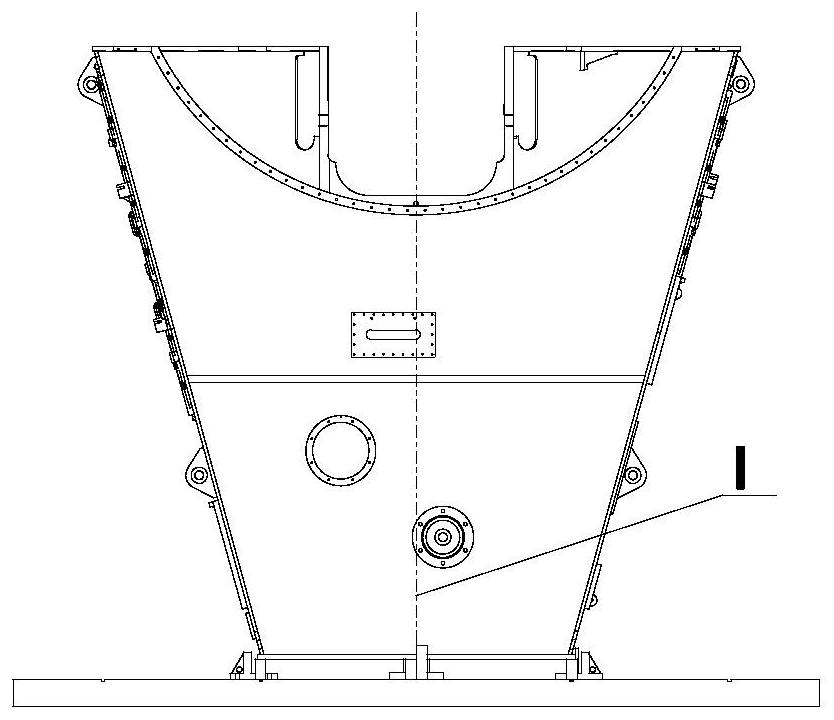

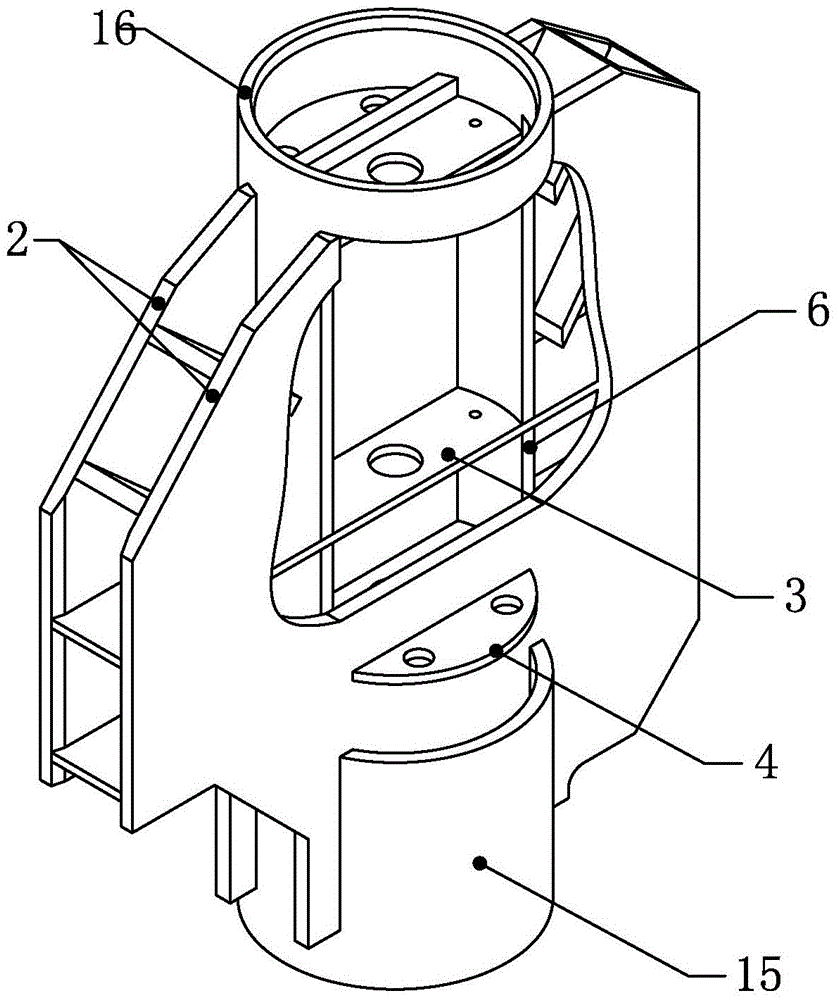

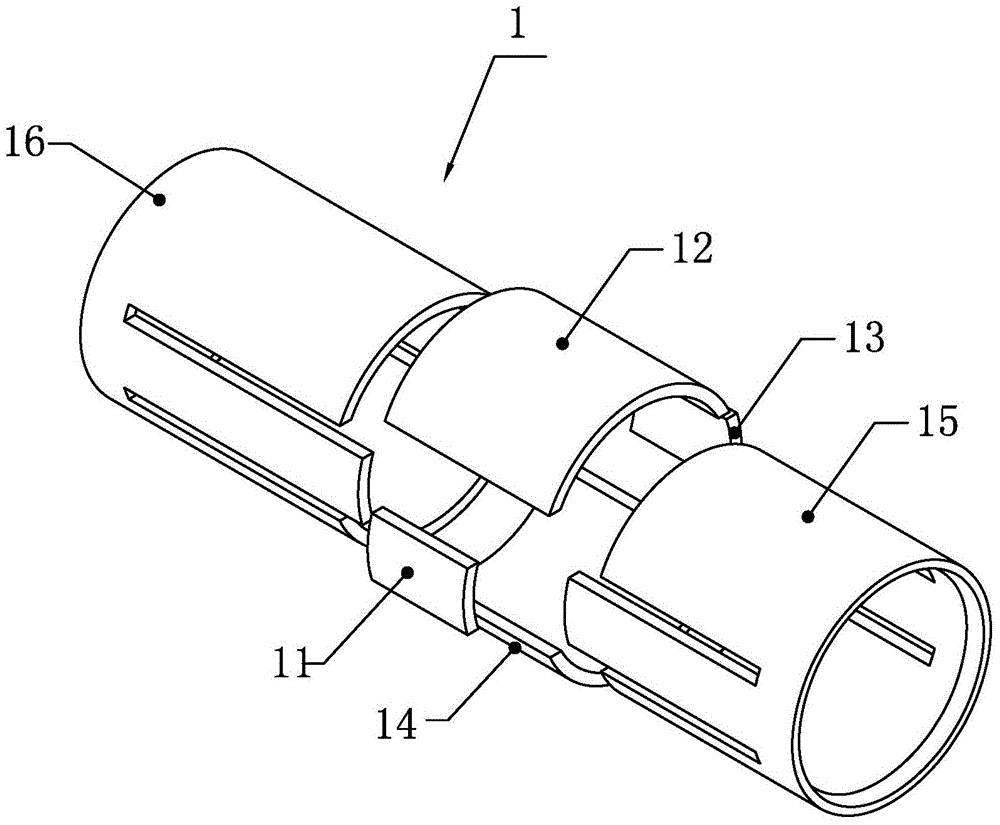

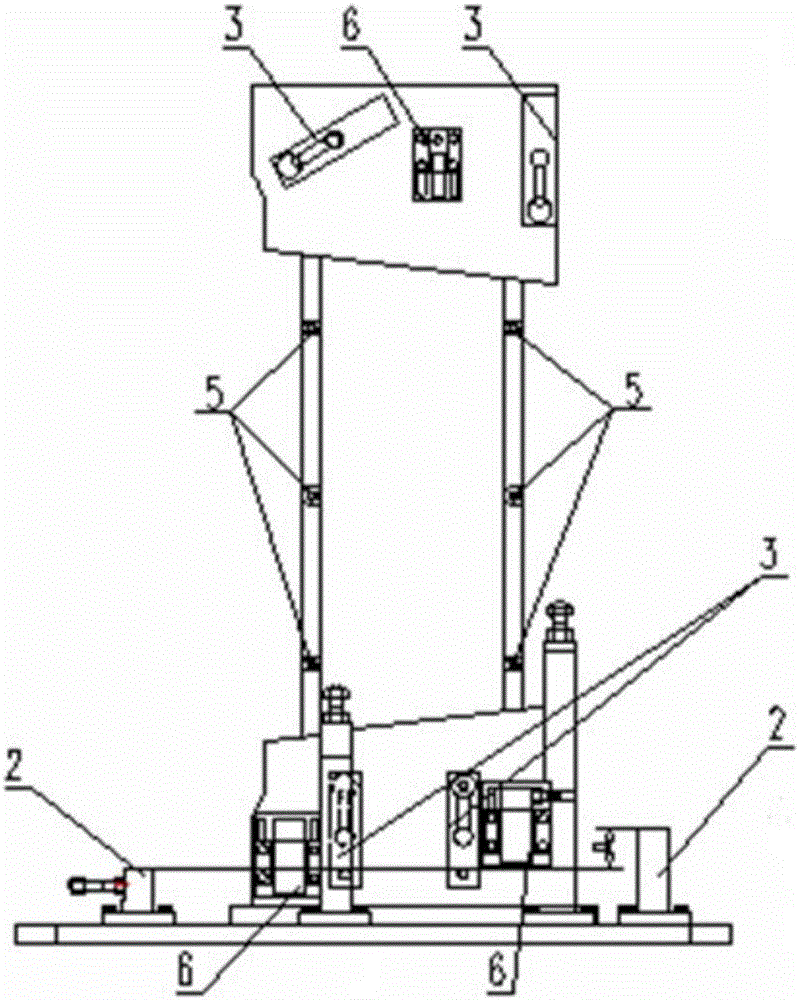

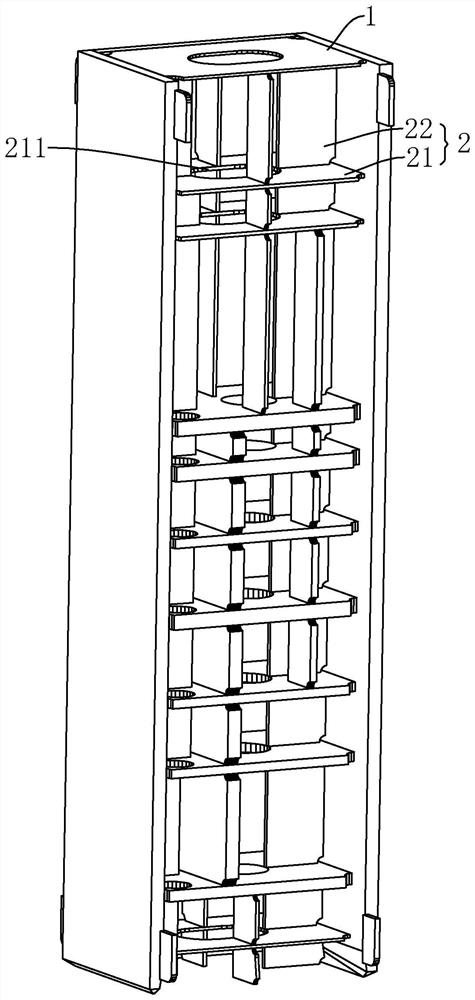

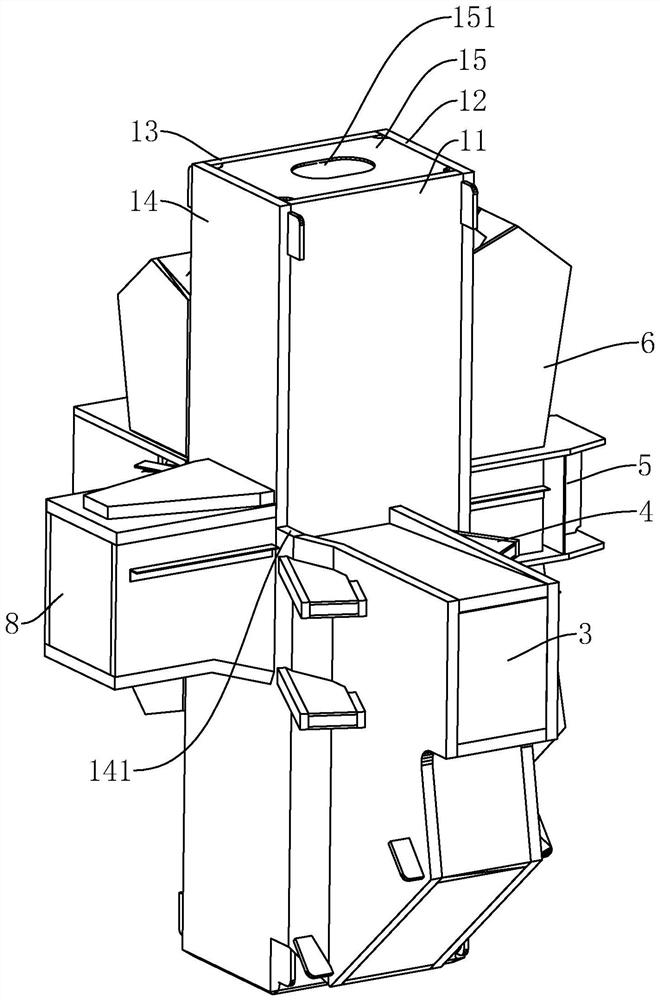

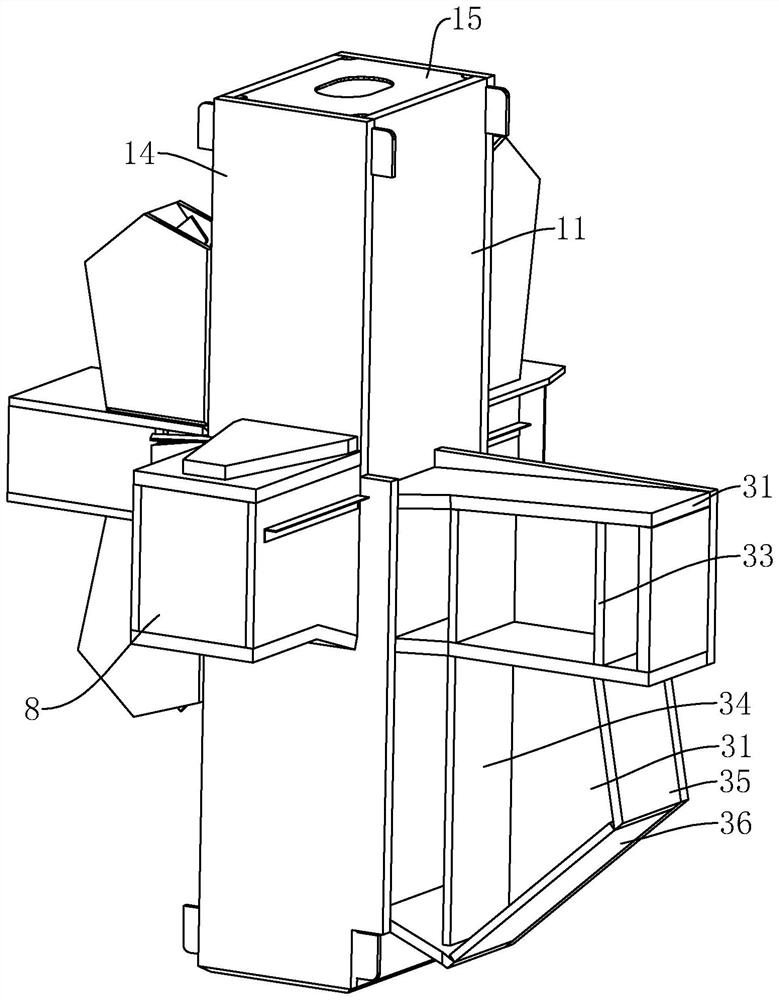

Special tool clamp for wind driven generator one-piece bearing pedestal casting and machining technology

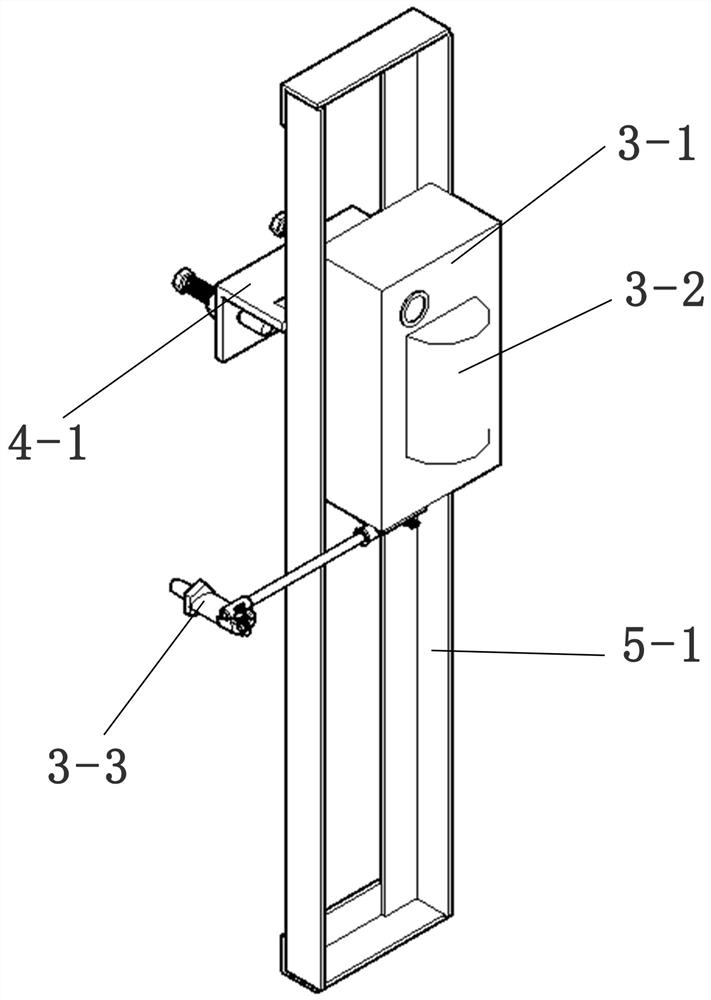

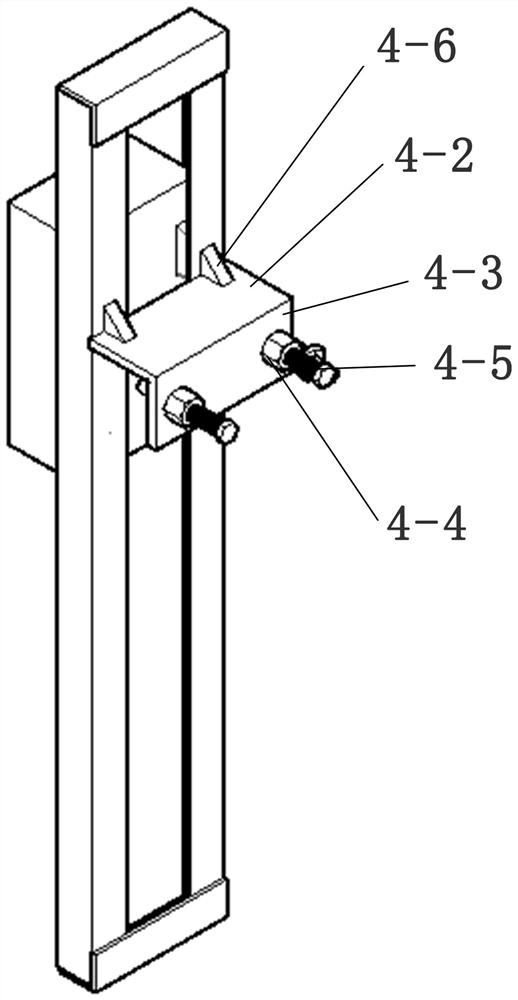

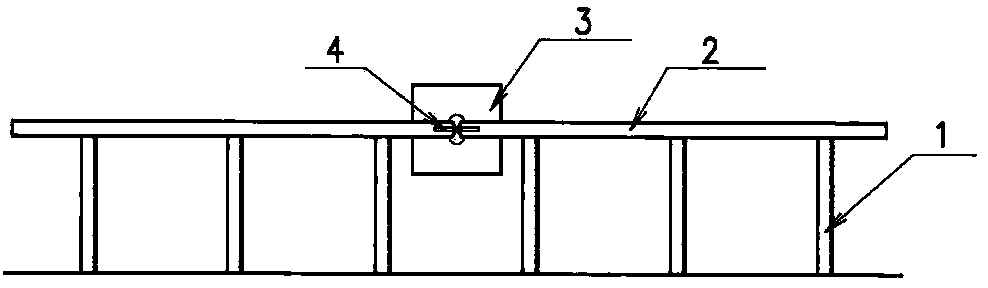

ActiveCN105234701AReduce turning timesGuaranteed cylindricityPositioning apparatusMetal-working holdersUltimate tensile strengthMechanical engineering

The invention relates to a special tool clamp for a wind driven generator one-piece bearing pedestal casting and a machining technology and belongs to the technical field of mechanical part machining. The special tool clamp comprises a box, a positioning device, a pressing device, an adjusting device and a supporting device. According to the special tool clamp for the wind driven generator one-piece bearing pedestal casting, a one-piece bearing pedestal lies one side to be clamped on the special tool clamp, a rotating workbench, bearing pedestal holes, a blast hole, an end face and peripheral faces complete finish machining through one time of clamping, the cylindricity and the coaxiality of the bearing pedestal holes in the two ends are guaranteed, the overturning frequency of the casting is reduced, the machining precision required in graph paper is achieved, production efficiency is improved, and production cost and labor intensity of workers are reduced.

Owner:JIANGSU JIXIN WIND ENERGY TECH

Medicine for preventing bedsore

InactiveCN101024030AFormulation ScienceSignificant preventionDermatological disorderPlant ingredientsVegetable oilRemove blood

The present invention provides a Chinese medicine with the functions of promoting blood circulation, removing blood stasis, astringing sore and subduing swelling for preventing bed sore with obvious effect. Said Chinese medicine is made up by using 9 Chinese medicinal materials of anomalous Artemisia, biota leaf, rose-of Sharon root bark, coptis root, aloe and others and vegetable oil through a certain preparation process.

Owner:巩翠贤

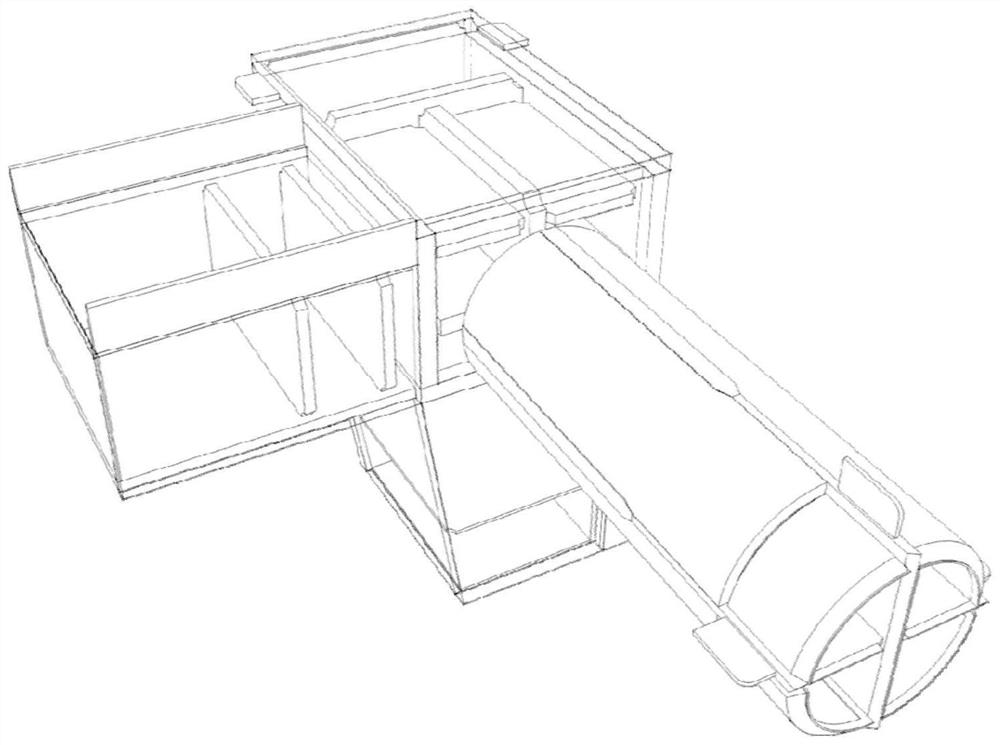

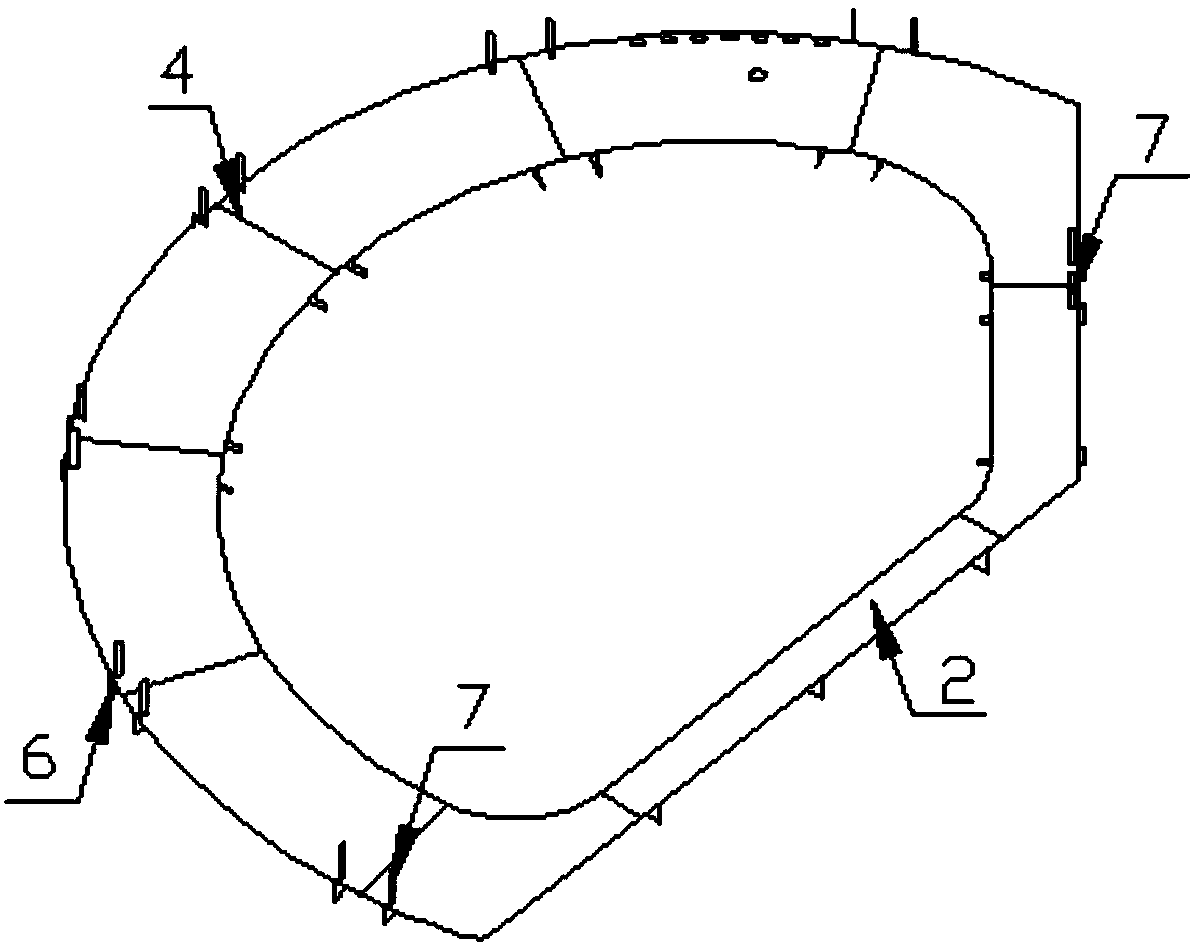

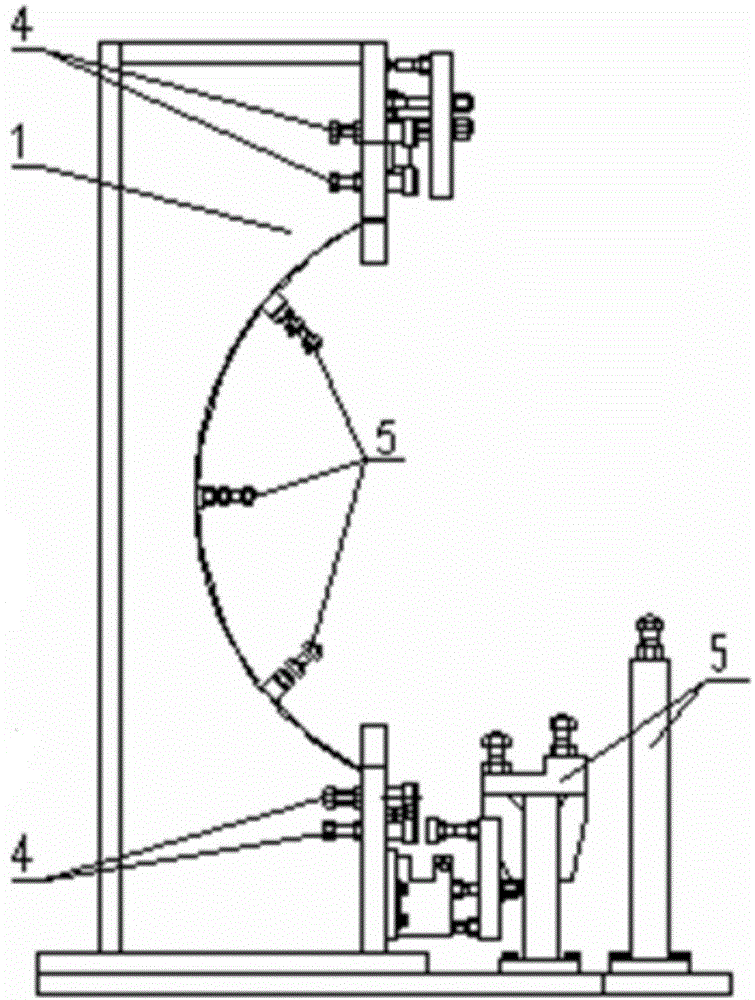

Round tube joint conversion structure and manufacturing method thereof

ActiveCN103437424AGood operabilityGuarantee welding qualityArc welding apparatusBuilding constructionsCarbon dioxideEngineering

The invention mainly discloses a round tube joint conversion structure and a manufacturing method thereof. According to a joint structure, a round tube is cut and divided into a plurality of arc tiles and irregular round tube sections, and the divided arc tiles, the irregular round tube sections and a penetrating plate are welded in a cross mode to obtain the round tube joint conversion structure. A horizontally-arranged rectangular inner partition plate is welded in the round tube joint conversion structure, an annular inner partition plate is arranged between the penetrating plate and the round tube, the annular inner partition plate, the penetrating plate and the round tube are welded in a cross mode through carbon dioxide shield welding or manual arc welding, and accordingly a rib plate, the penetrating plate and the round tube are integrally welded. On the premise without reducing structural safety, the round tube joint conversion structure solves the problems that an internal structure of a similar round tube conversion joint is difficult to achieve and the quality is difficult to guarantee. Meanwhile, the round tube joint conversion structure saves production cost.

Owner:ZHEJIANG JINGGONG STEEL BUILDING GRP

A super thick plate submerged arc welding process

ActiveCN105057856BSmall amount of welding deformationReduce turning timesArc welding apparatusWelding/soldering/cutting articlesThick plateWelding residual stress

The present invention discloses an extra-thick sheet submerged-arc welding technique. The technique comprises the following technological parameters and steps: 1) connector preparation: X-type beveled edges are adopted by extra-thick sheets; 2) preheating: first heating a back side of an extra-thick sheet and then a front side of the extra-thick sheet, a preheating temperature being 150 DEG C to 160 DEG C, and a heating rate being not higher than 105 DEG / h; 3) backing welding: after preheating, using flux-cored wire gas shield welding for backing welding for two paths to form two layers, and using submerged-arc welding to fill at least two paths to form one layer, maintaining interlayer temperature to be not higher than 230 DEG C; 4) turning over after an inter-welding deformation is not larger than 6-8 mm; 5) backside welding: after carbon gouging and back chipping, backing welding according to the step 3) after the extra-thick sheet reaches a preheating requirement according to the preheating method described in the step 2); 6) stress relief treatment; and 7) carrying out post heating treatment at 200 DEG C / 2h after the welding, then slowly cooling the extra-thick sheet to be at the room temperature. With adoption of the technique provided by the present invention, rooting welding deformation is reduced, welding residual stress for subsequently filling a cover face is also reduced, and thus turn-over times in welding of the extra-thick sheet are reduced.

Owner:CHINA MERCHANTS HEAVY IND JIANGSU +1

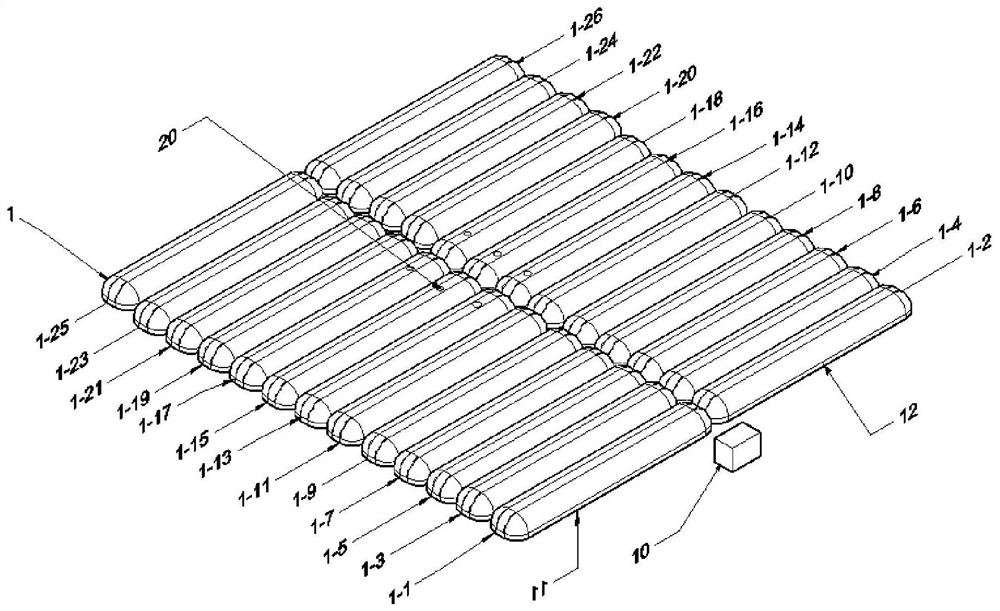

Air cushion bed based on pressure change rate

InactiveCN112603678AShorten the timeReduce energyNursing bedsPhysical medicine and rehabilitationDevice Monitor

The invention discloses an air cushion bed based on a pressure change rate. The air cushion bed comprises a detection module, a data processing module and an execution module. The detection module is provided with a pressure sensor, an excrement and urine sensing device and an air pressure sensor, the pressure sensor is used for detecting the pressure and controlling the inflation and deflation rates of the air cushion bed according to the pressure change rate, the excrement and urine sensing device monitors whether a patient suffers from incontinence or not, the air pressure sensor detects the inflation and deflation state of the air cushion, and safety is guaranteed. The data processing module carries out remote data transmission by using Zig Bee, carries out data processing on received detection data by using an RANSAC algorithm, and carries out PWM (Pulse-Width Modulation) automatic adjustment on the inflating and deflating speed according to the processed data. The execution module comprises an upper-layer air cushion and a lower-layer air cushion, and body position changes such as left-side turning over, right-side turning over and sitting up are achieved through the combined action of inflation and deflation of the upper-layer air cushion and the lower-layer air cushion. Compared with a traditional air cushion bed, the air cushion bed has the advantages that the inflation and deflation rate of the air cushion can be automatically adjusted, the comfort of a patient is greatly improved, and greater convenience is brought to medical staff.

Owner:NANCHANG UNIV

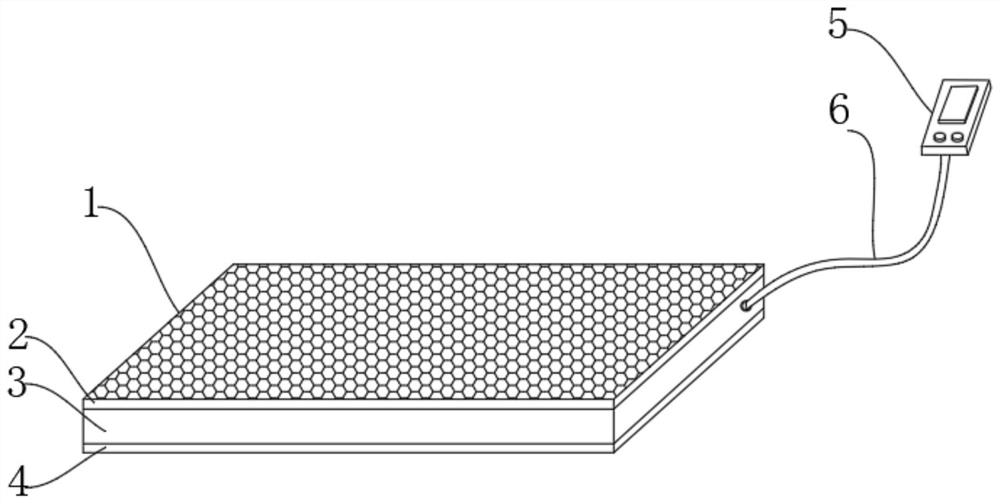

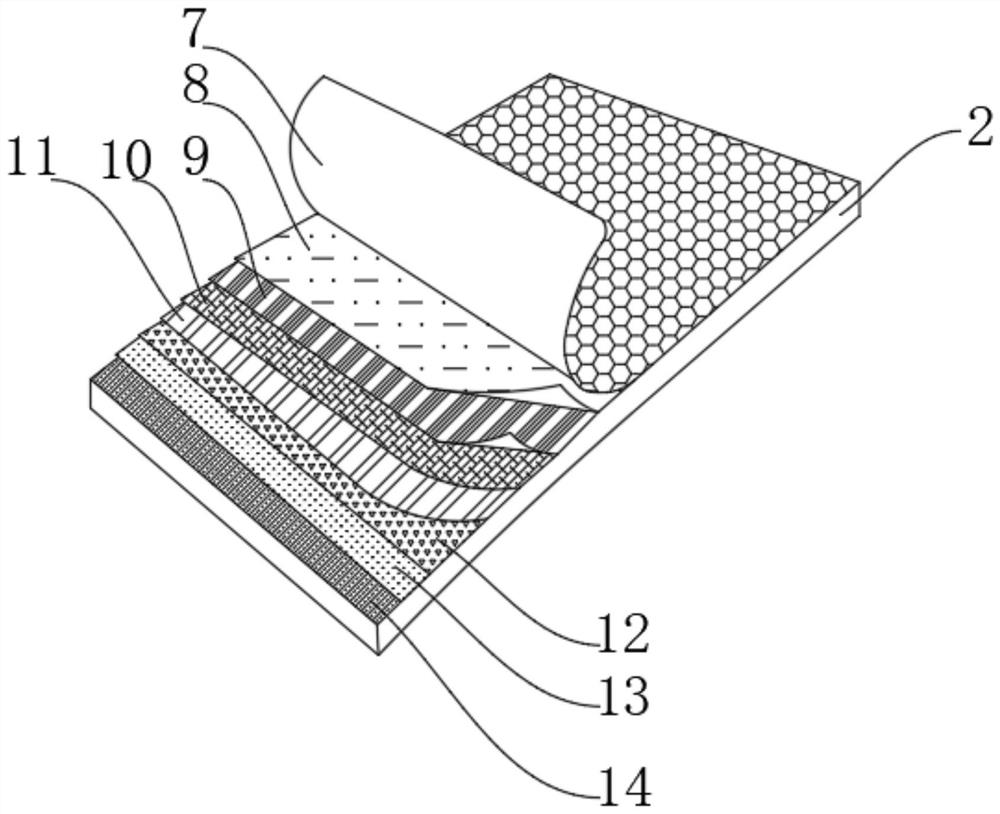

Efficient graphene physiotherapy cushion and production method

InactiveCN112841996AGood antibacterial and antibacterial propertiesAvoid breedingElectrotherapyStuffed mattressesWhole bodyCotton cloth

The invention discloses an efficient graphene physiotherapy cushion which comprises a physiotherapy cushion body, and the interior of the physiotherapy cushion body is jointly composed of a composite protection surface layer, a graphene combination layer and a bottom plate cushion layer. The interior of the composite protection surface layer is jointly composed of an artificial cotton surface layer, a latex layer, a coconut fiber wrapping layer, an elastic fiber surface layer, an environment-friendly PVC surface layer, a traditional Chinese medicine carbon cotton layer, an ecological cotton layer and an ecological non-woven fabric layer, a heat conduction layer, a hollow interlayer and an electric heating layer are arranged in the graphene combination layer, and the electric heating layer is located on the lower surface of the hollow interlayer. A graphene plate is arranged in the hollow interlayer, and a heat preservation cotton layer, an antibacterial anti-mite layer, a non-woven fabric protection layer, a wool heat preservation layer and a wear-resistant woven cotton cloth layer are arranged in the bottom plate cushion layer. When a person sleeps or lies on the magnetic mattress, the person can make contact with the whole body of the person comfortably and evenly, after magnetism in the mattress and iron elements contained in blood of the human body act, the massage effect is achieved, and the magnetic mattress is beneficial to human health and improvement of sleep quality.

Owner:浙江时奥医疗科技有限公司

Novel beam base machining and fixing structure

InactiveCN104551745AIncrease productivityShort processing timeWork holdersPositioning apparatusEngineering

The invention relates to a novel beam base machining and fixing structure comprising a beam base tooling. The beam base tooling comprises a base plate and a side plate; the side plate is provided with a fixing press plate, and the base plate is provided with an adjustable baffling plate. The structure is simple, accurate in positioning, time saving and force saving, the rate of finished products is high, and the operating efficiency is improved greatly.

Owner:无锡蕾菲赛尔机械科技有限公司

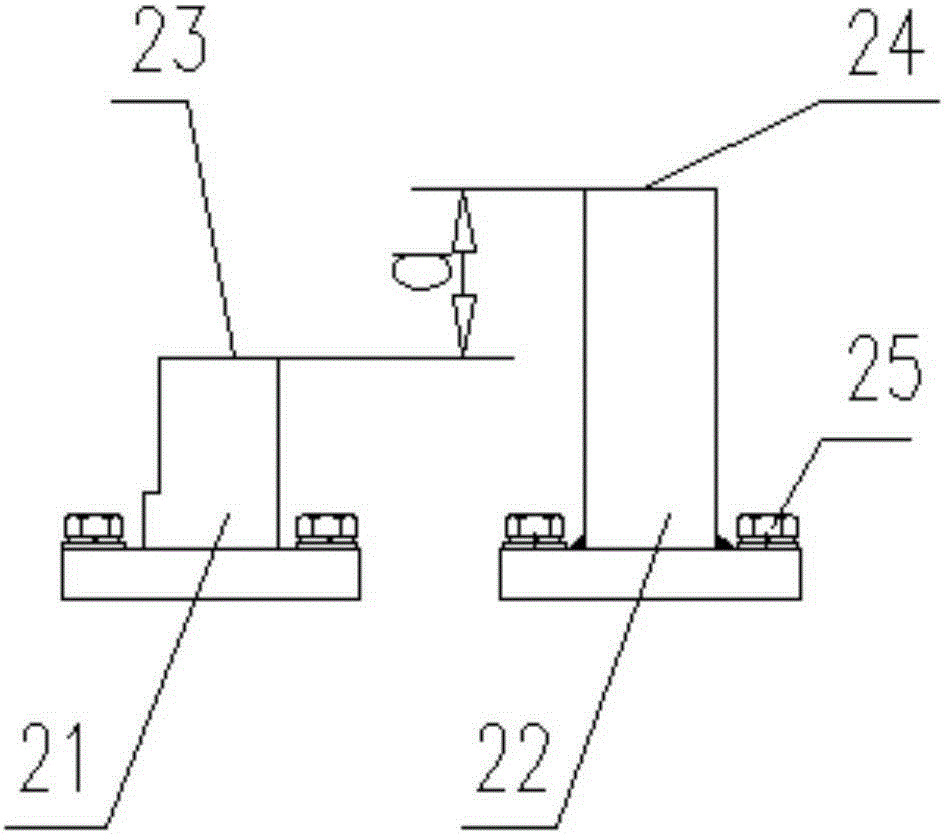

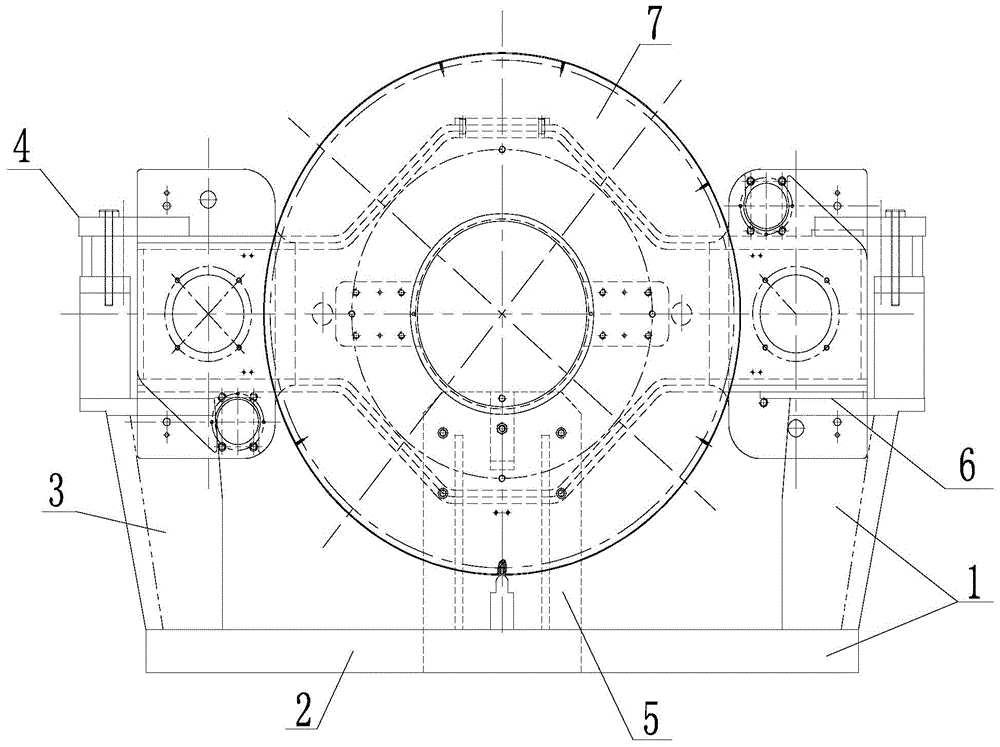

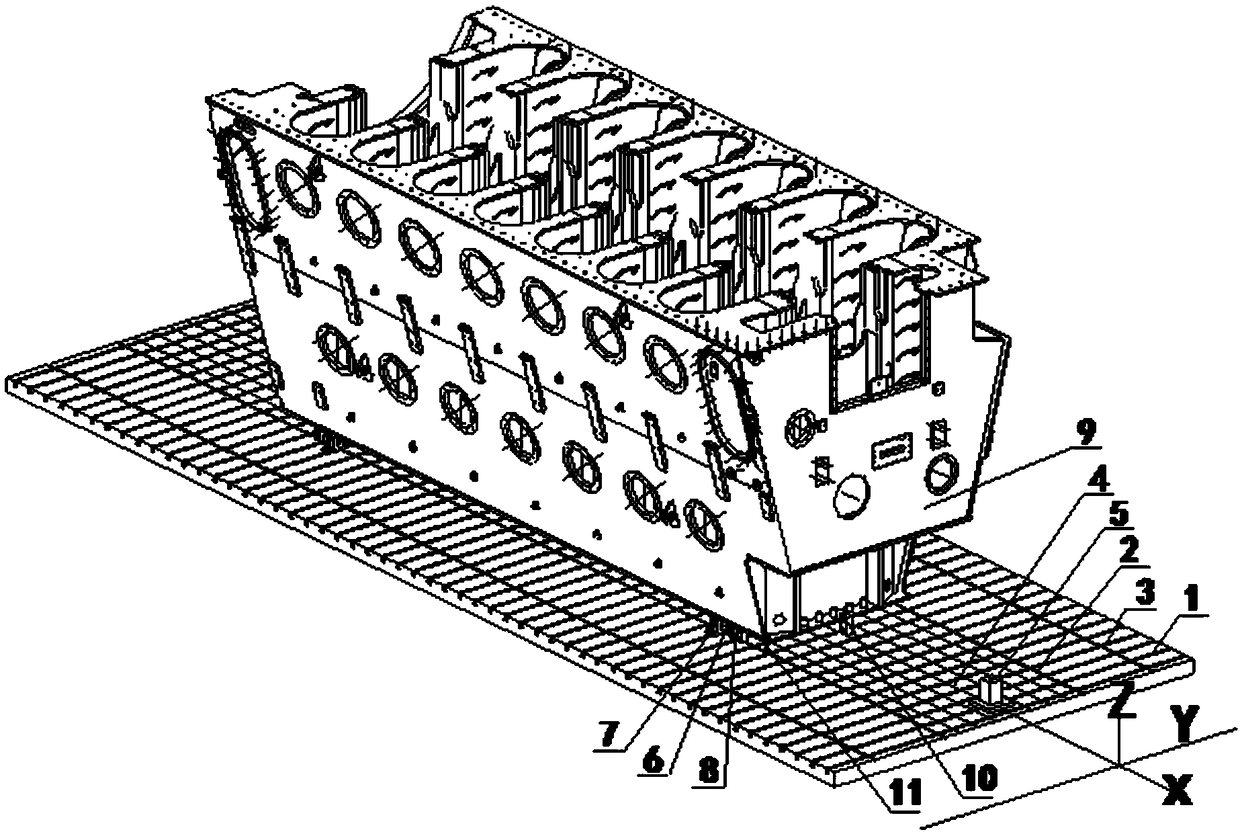

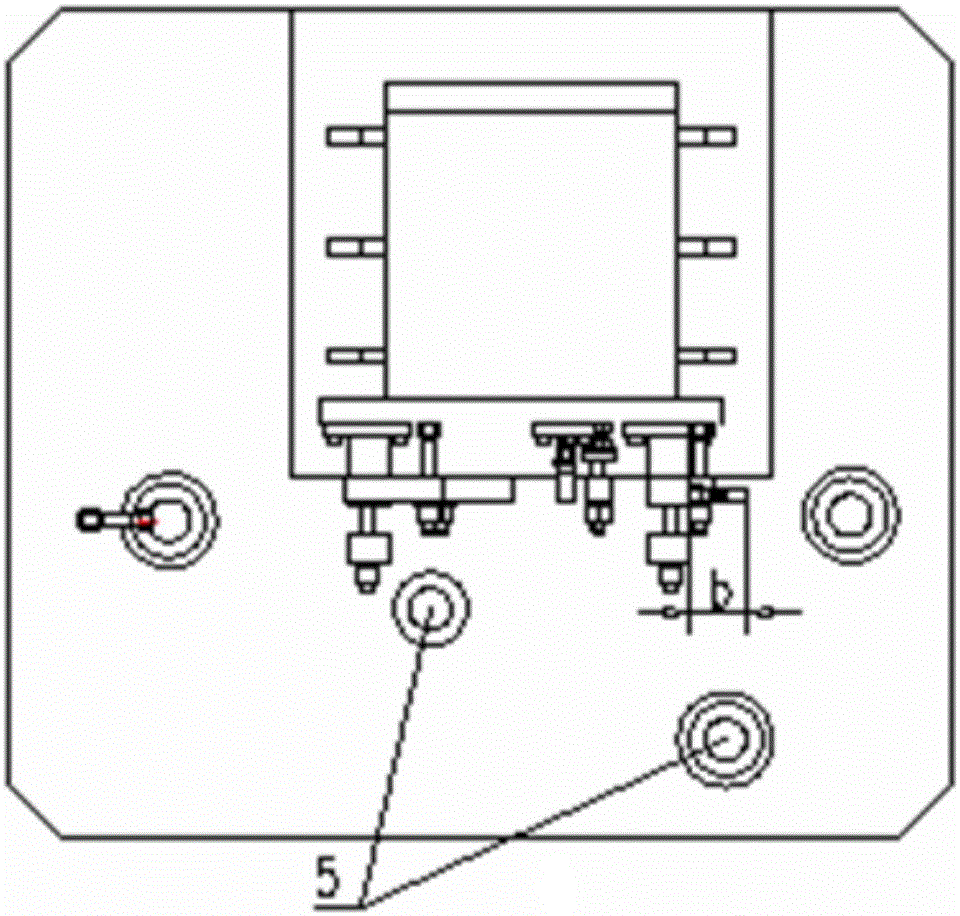

Rapid getting-on correcting method of large-scale diesel engine rack on gantry milling machine

ActiveCN108748064AReduce turning timesReduce labor intensityAutomatic control devicesFeeding apparatusNumerical controlKeel

The invention provides a rapid getting-on correcting method of a large-scale diesel engine rack on a gantry milling machine. The rapid getting-on correcting method comprises that wherein X, Y and Z coordinate processing lines, a waist line, a workpiece center line and a workpiece zero position reference line are marked by adopting a laser reference scribing method, and further, a keel milling table top mark, a positioning and positioning groove, a positioning and supporting stop block, a positioning key, a reference alignment tool block, an adjusting cushion block, a correcting block, a reference measuring block and a machine frame laser scribing technical measure are further adopted on numerical control keel milling, so that the machine frame is guaranteed to be rapidly corrected, and coordinate setting is completed. The method has the advantages of being easy to operate, safe, efficient and convenient to adjust, and has the beneficial effects of reducing the machine frame getting-oncorrecting time and reducing the labor intensity of workers, and the rapid getting-on correcting method is particularly suitable for on-line correction, positioning and coordinate setting of large-scale diesel engine racks and similar large-scale parts on the numerical control keel milling.

Owner:CSSC MES DIESEL

Embedded cross-shaped circular tube davit node component and manufacturing method thereof

ActiveCN114150770ASection size controlSimple preparation processExtraordinary structuresWelding apparatusStructural engineeringUltimate tensile strength

The invention discloses an embedded cross-shaped circular tube davit node member and a manufacturing method thereof, an L-shaped wing web plate structure is formed by assembling a web plate on one side of a slotted wing plate, then an I-shaped member is welded on the L-shaped wing web plate structure, and a vertical stiffening plate of the I-shaped member penetrates through a slot; a web plate on the other side and two stiffening plates parallel to the wing plate with the groove are assembled; the method comprises the following steps: welding a variable cross-section bracket on one side, subsequently welding a wing plate on the other side, completing the welding of a box-shaped column body, then sequentially welding the variable cross-section bracket, the box-shaped bracket and an embedded cross-shaped circular tube on the box-shaped column body, finally welding a floor bearing plate, a lifting lug plate, a connecting lug plate and the like, and carrying out component integrity acceptance after all parts are welded. The structure is simple, assembling is convenient, and welding is convenient; and through integral rigid connection of the embedded cross-shaped round pipe and the box type, the problem that the connection strength and rigidity are not high enough due to node conversion is solved, and the node connection strength and rigidity of the conversion layer are improved.

Owner:CHINA CONSTR STEEL STRUCTURE ENG CO LTD +1

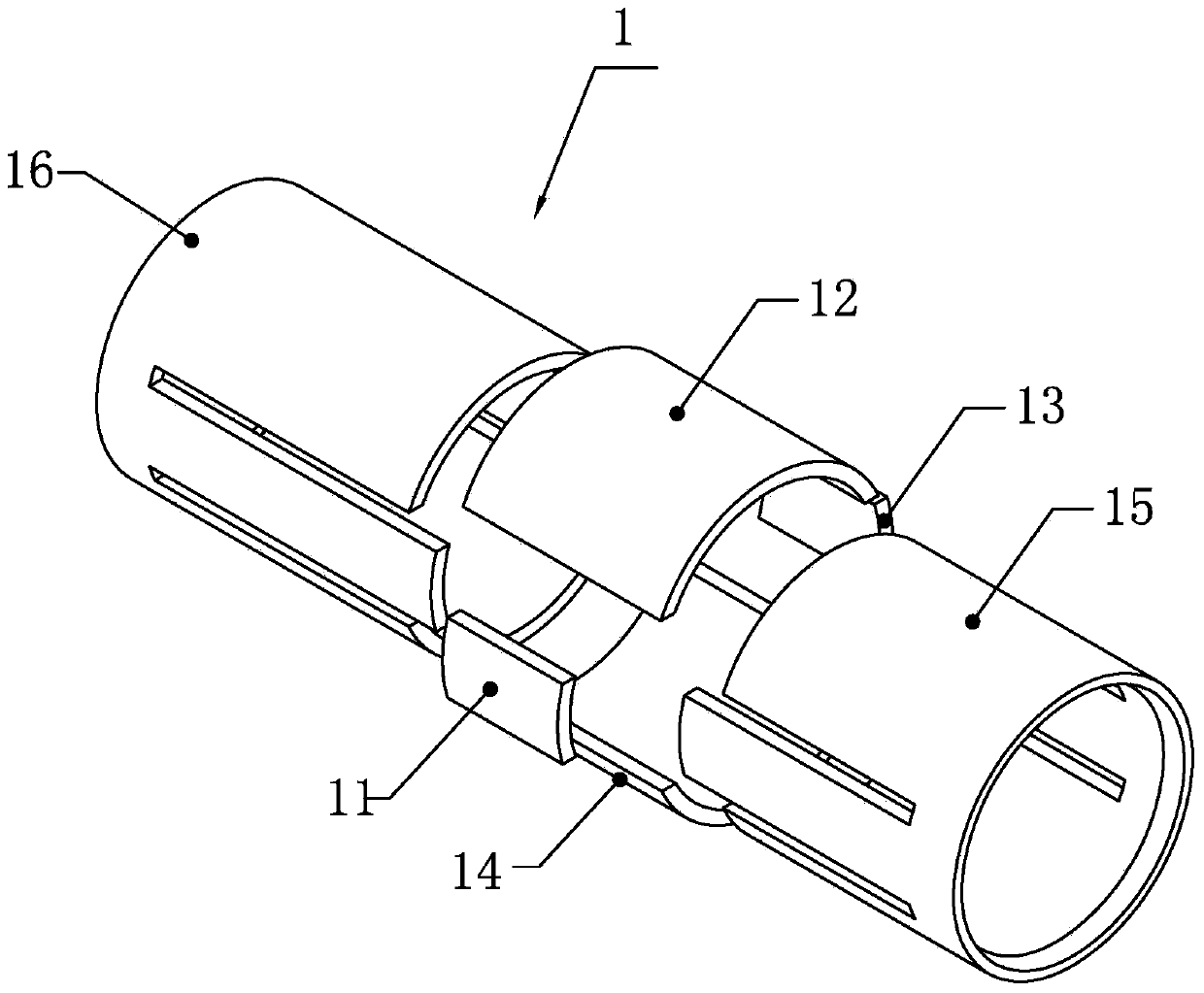

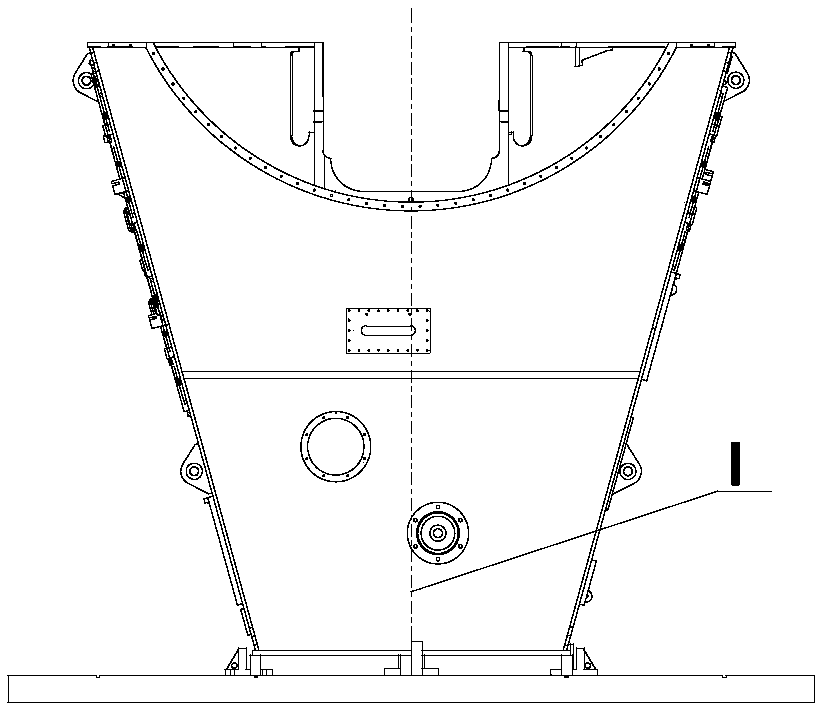

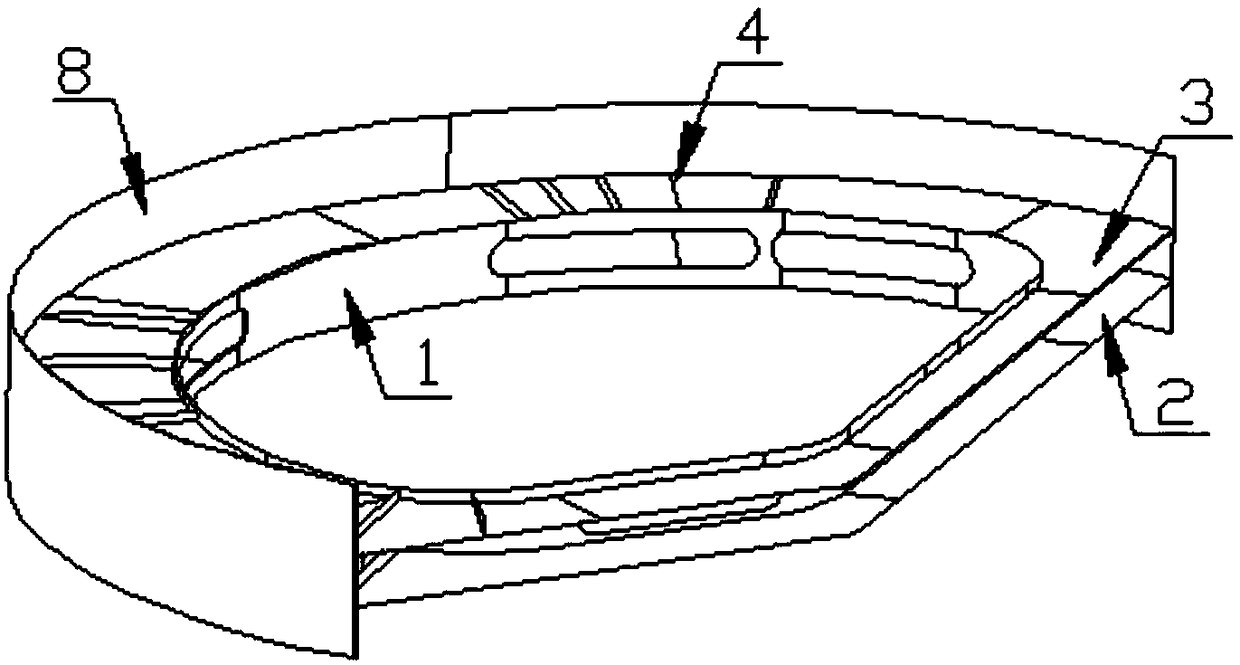

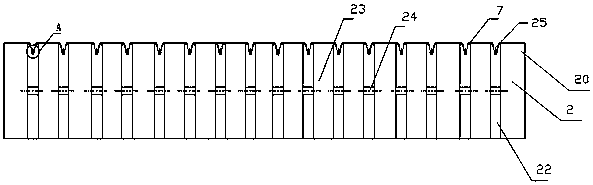

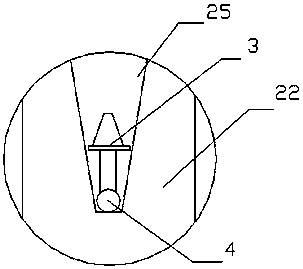

Dual reinforcing ring of marine large liquefied gas storage tank and construction scheme of dual reinforcing ring

PendingCN109506123AHigh yield strengthIncreased dynamic loadVessel manufacturingContainer filling methodsMarine engineeringUltimate tensile strength

The invention discloses a dual reinforcing ring of a marine large liquefied gas storage tank. The dual reinforcing ring comprises a panel, web plates and reinforcing ribs. The two layers of web platesare arranged, the web plates comprise the bow web plate and the stern web plate, and a reinforcing ring structure is formed by the bow web plate, the stern web plate and the panel. Mounting holes corresponding to the outline of the panel are formed in the bow web plate and the stern web plate. The reinforcing ribs are arranged on the bow web plate, the stern web plate and the panel. Multiple kidney-shaped holes are formed in the part, between the bow web plate and the stern web plate, of the panel. Mounting bed jigs are arranged at the bottom of the outer edge of the bow web plate, and clampsare arranged at the top of the outer edge of the bow web plate. The dual reinforcing ring is reasonable and simple in structure and convenient to use; the yield strength and dynamic loads of the reinforcing ring are greatly improved, the emergence of the ultra-large liquefied gas storage tank becomes real from the paper; and by means of the structural characteristics of the storage tank, the production process is optimized, the number of times of turnover of the structure is effectively reduced, the segmented manufacturing efficiency is greatly improved, and meanwhile consumption of manpowerand resources is reduced from the cost.

Owner:江苏华滋能源工程有限公司

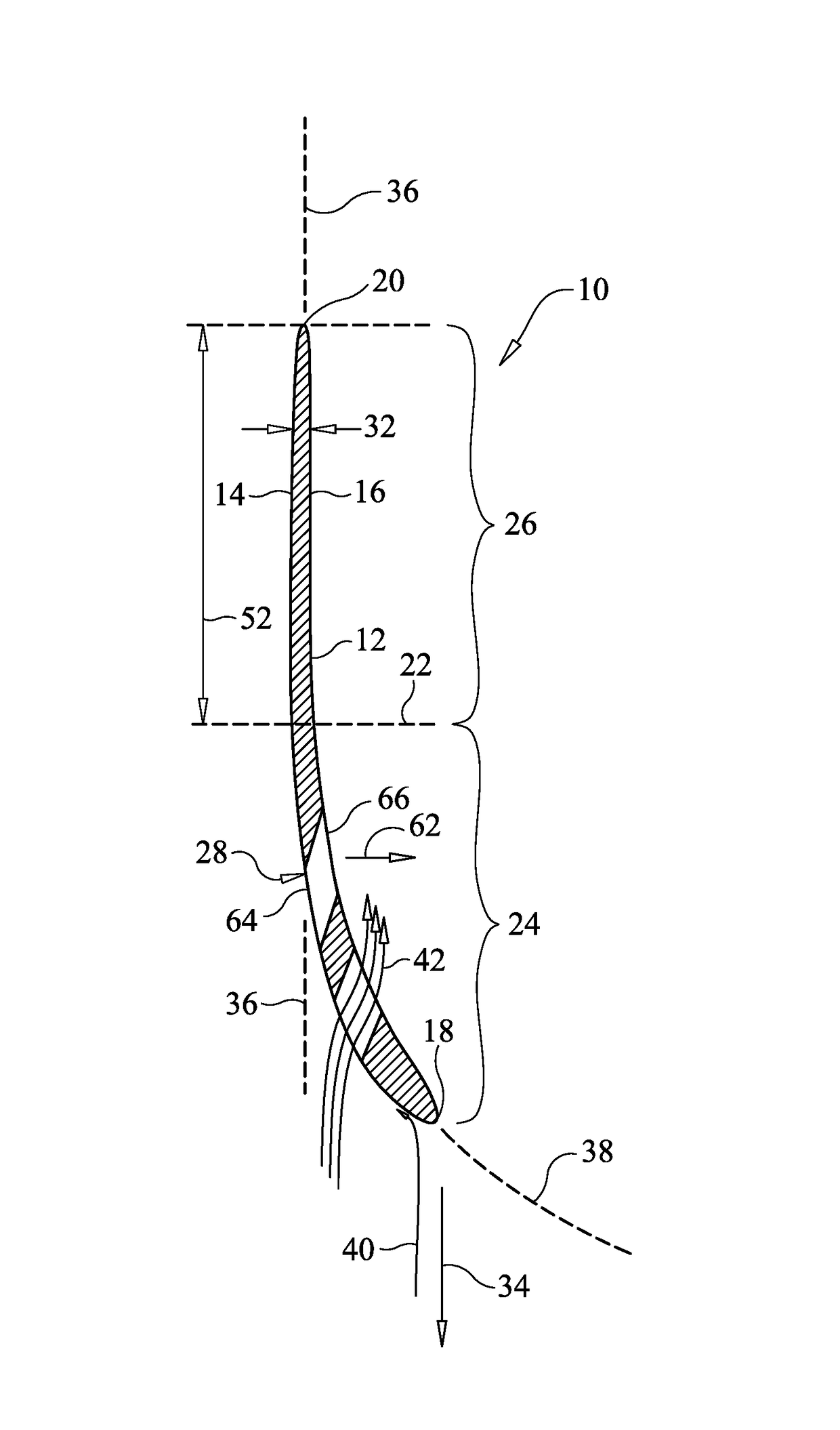

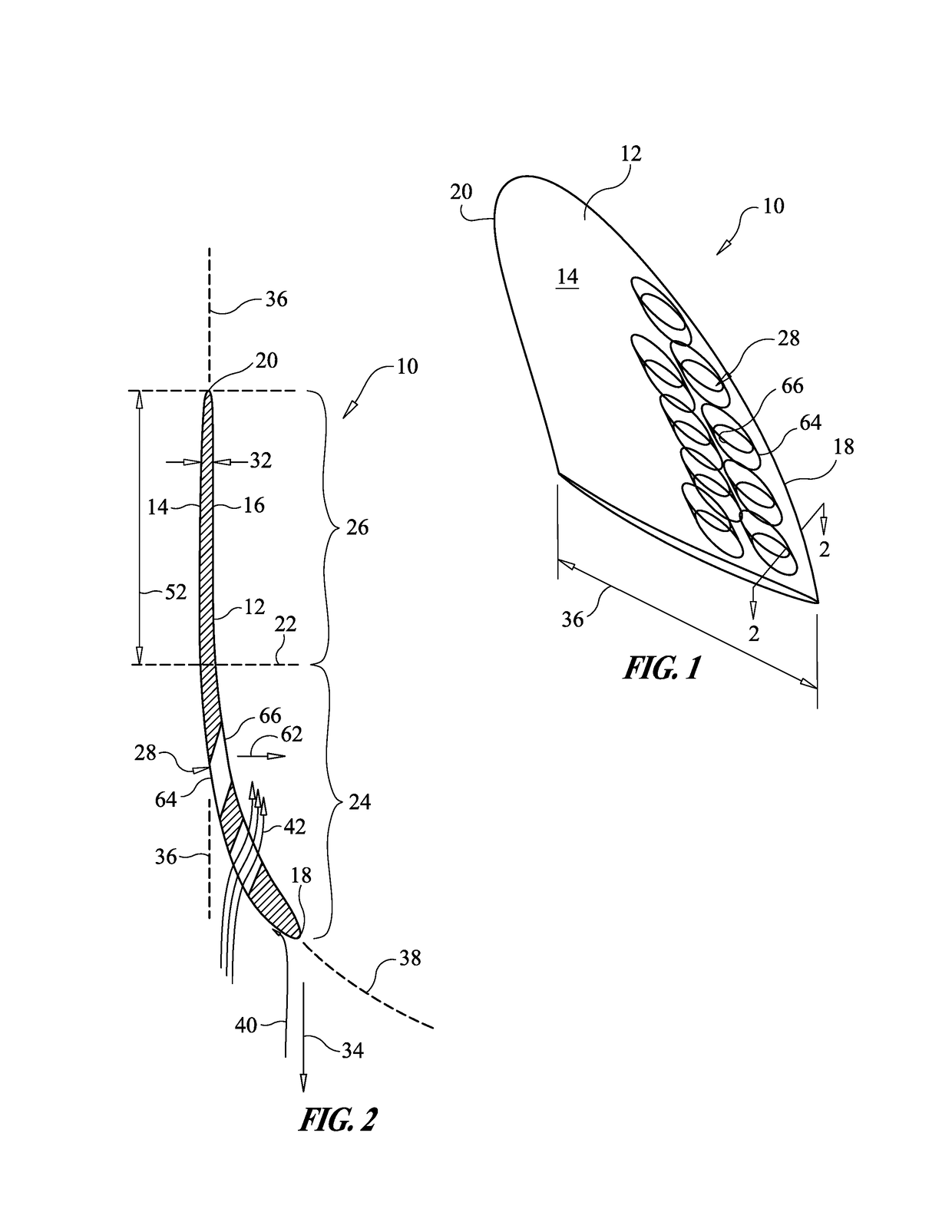

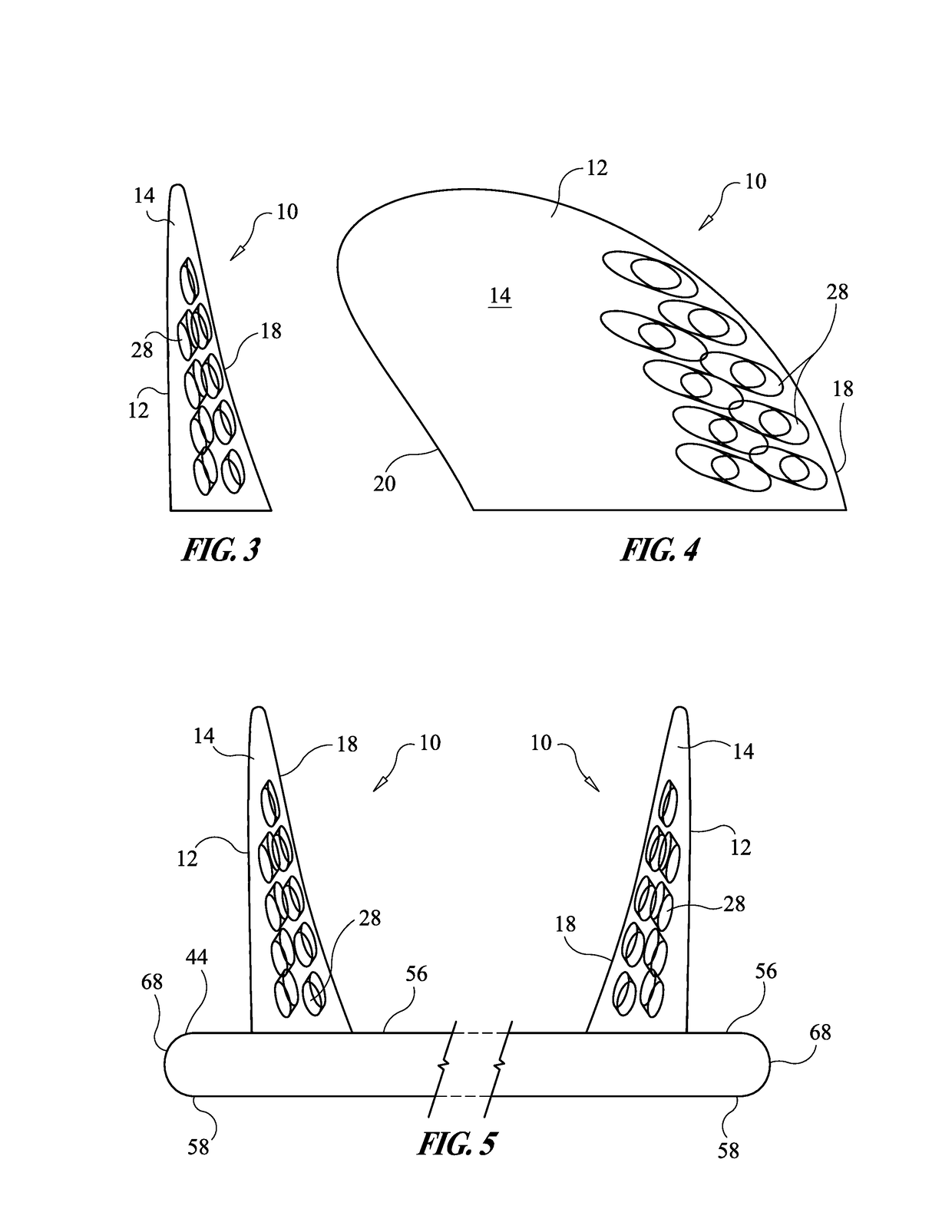

Curved surfboard fin

ActiveUS9637205B1Improve mobilityReducing speed lossWaterborne vesselsWater sport boardsSurfboard finEngineering

A surfboard fin has a curved forward fin portion and a straight rearward fin portion. When attached to a surfboard, the curved forward portion is positioned on the surfboard so the curvature of the forward portion is directed toward the centerline of the surfboard. The concave curve of the forward portion allows for faster and easier maneuverability of a surfboard while in use. In order to reduce drag caused by the curvature of the forward fin portion, one or more through holes may be formed through the forward fin portion to allow water to pass through the fin and reduce drag.

Owner:SAUNOOKE JACOB

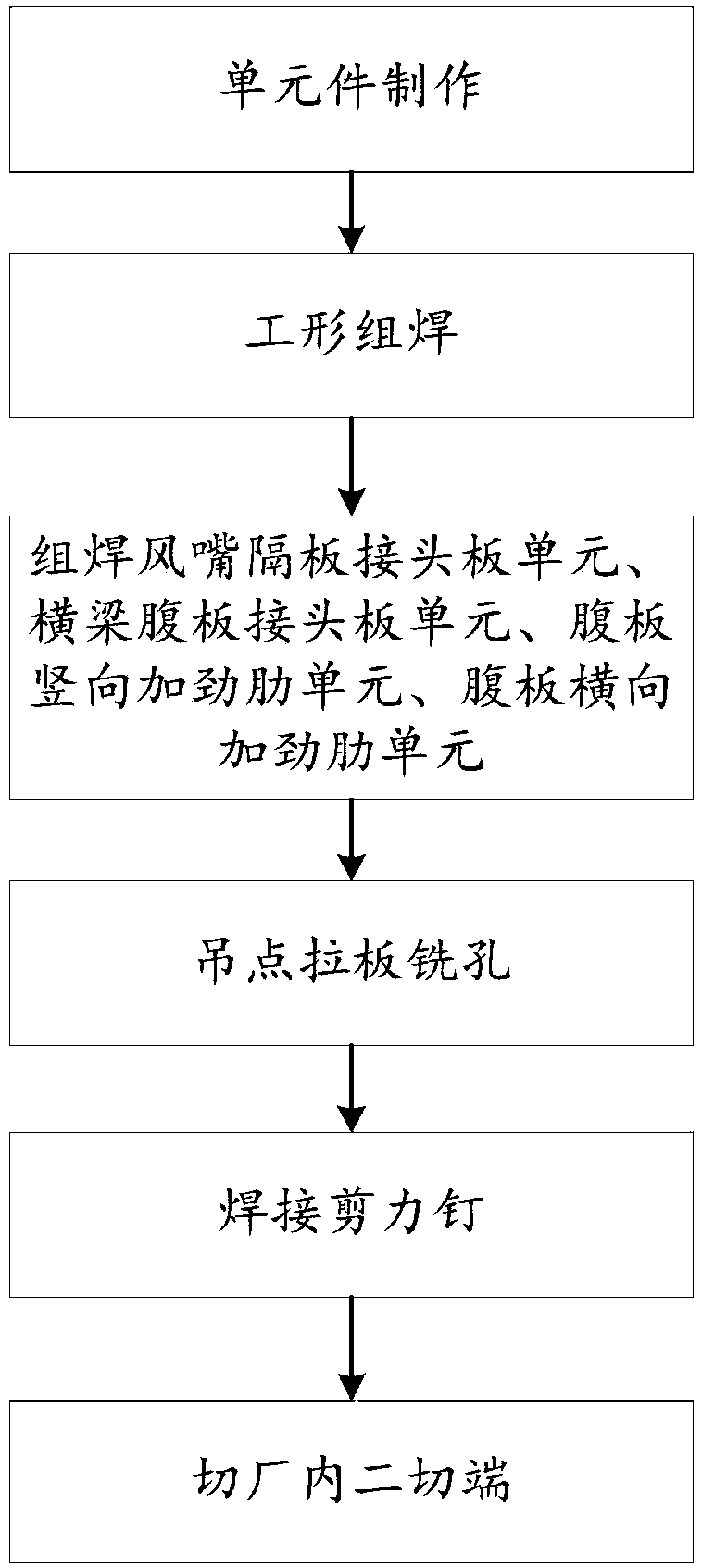

Method for manufacturing side main beam with suspension centre penetrating through I shape weathering resistance steel

ActiveCN108381128AReasonable welding sequenceAdvanced welding technologyBridgesWeather resistanceCalculation methods

The invention discloses a method for manufacturing a side main beam with a suspension centre penetrating through I shape weathering resistance steel. The method comprise the steps that element piecesare manufactured; I shape assembling and welding is carried out; an air nozzle separation plate joint plate element, cross beam web plate joint plate element, web plate vertical stiffening rib elementand web plate transverse stiffening rib element are assembled and welded; a lifting point pulling plate is subjected to hole milling; shear nails are welded; the center of the hanging point pulling plate is used as the base to mark the line after the shear nails are welded; the in-plant second tangency end is cut, and the in-plant base ends of an upper horizontal plate element, a web plate element and a lower horizontal plate element are cut. According to the method, each assembly element is resolved in a modularized mode, the assembling and welding sequence is reasonable, the welding processis advanced, the degree of automation is high, the deformation caused by welding is small, and the assembling precision is high; and rod pieces are assembled by the forward-calculation method, so that the number of turning over is reduced, the efficiency and precision of assembling and welding are improved, and good economic results are obtained.

Owner:CHINA RAILWAY SHANQIAO GRP CO LTD

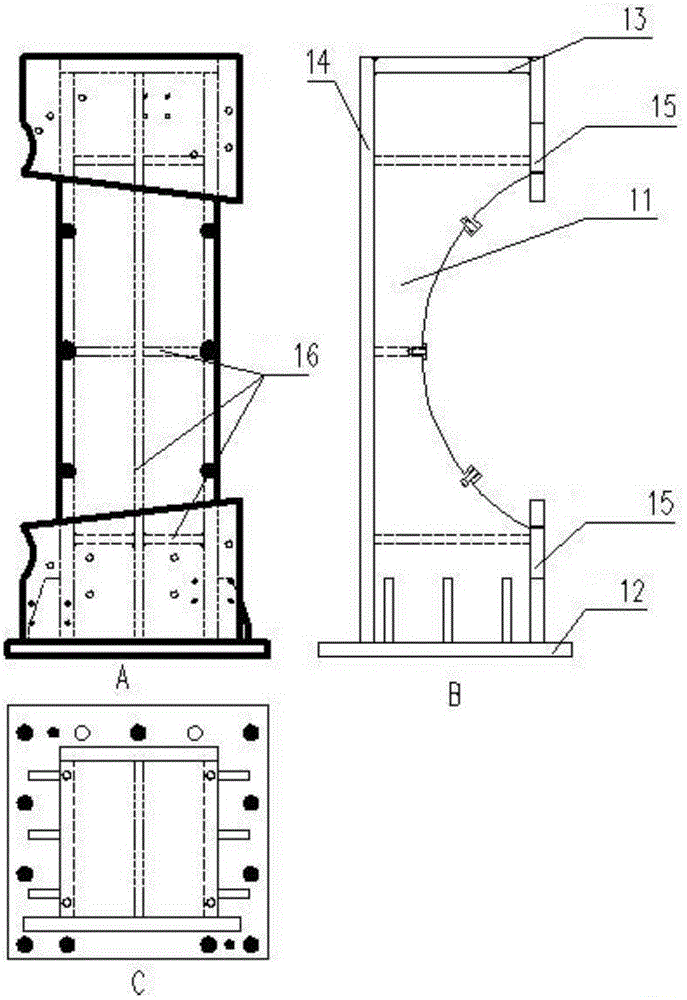

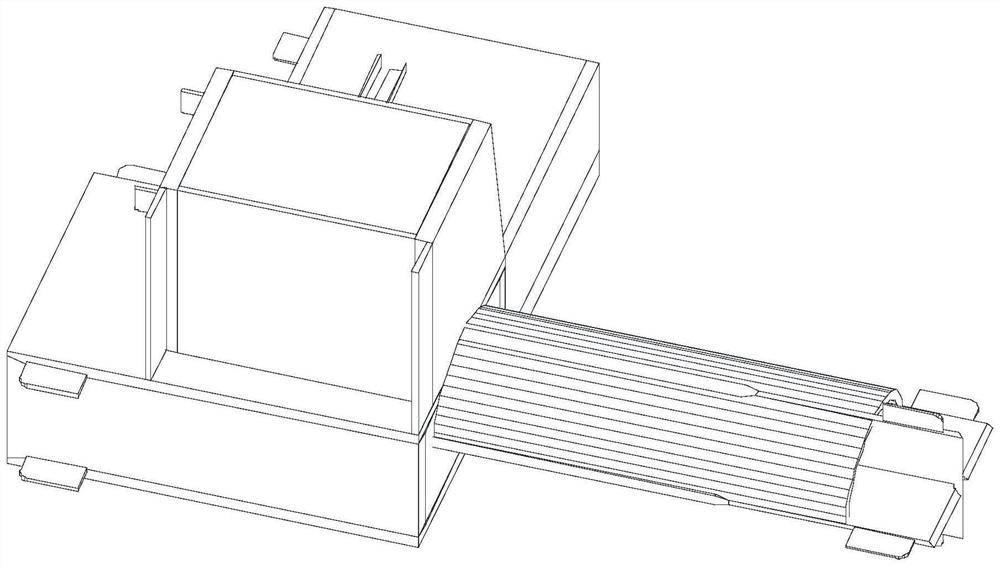

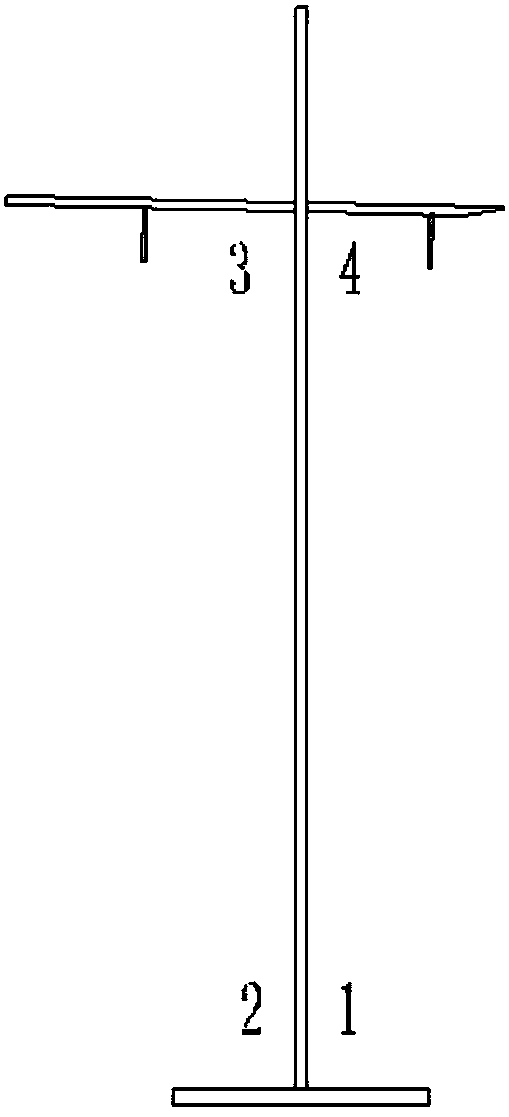

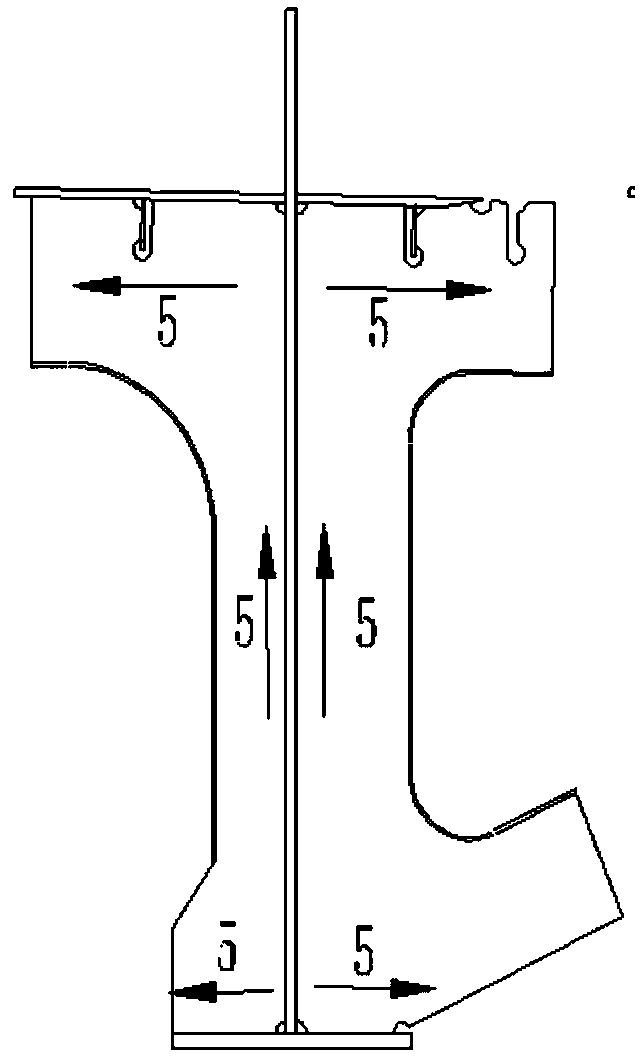

Tailor-welding method for stand columns of pressure machine tool

InactiveCN112122739APrevent side bend deformationPut an end to the phenomenon of insufficient machining allowanceWelding accessoriesStructural engineeringStress relief

The invention relates to the technical field of forging equipment, and particularly relates to a tailor-welding method for stand columns of a pressure machine tool. The tailor-welding method comprisesthe following steps that 1, U-shaped boxes are spliced, the splicing size of the stand columns is reserved, and reserved side plates and guide rail plates at the openings of the U-shaped boxes are not installed; 2, the U-shaped boxes are paired in pairs, and every two U-shaped boxes are welded together in a back-to-back mode through a plurality of connecting iron plates; 3, the interior of each U-shaped box is welded; 4, the connecting iron plates are removed, the paired U-shaped boxes are separated, and the reserved side plates and the guide rail plates are welded to each U-shaped box to form the stand columns; and 5, stress relief annealing is conducted on the stand columns. By the adoption of the tailor-welding method, the problems that in the prior art, after each stand column is welded, the corresponding reserved side plate is laterally bent and deformed, manual flame leveling is needed, a large amount of time is wasted, the stand columns are laterally bent and twisted to be deformed, the stand columns are shrunk in the length direction, and consequently the machining allowance is insufficient can be solved.

Owner:WORLD PRECISE MACHINERY CO LTD CHINA

Portable flame cutting device for H-shaped steel

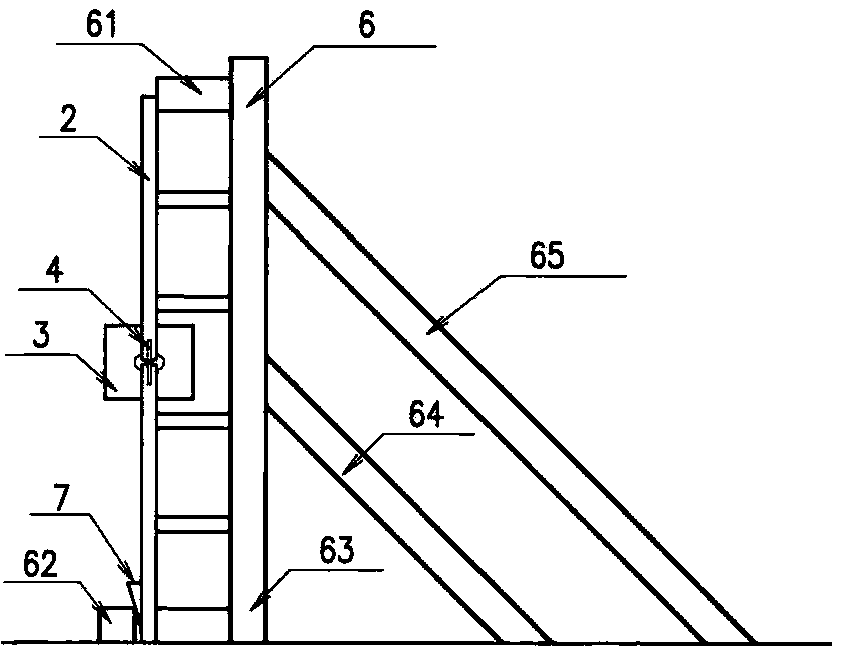

PendingCN113681108ALightweight and easy to storeEasy to storeGas flame welding apparatusTorchFlame cutting

The invention relates to a portable flame cutting device for H-shaped steel. The portable flame cutting device comprises stirrups, the H-shaped steel and a tube climbing machine, wherein the stirrups are located below the H-shaped steel, and the tube climbing machine is located on the H-shaped steel; a web plate of the H-shaped steel is horizontally arranged, and the lower end part of a flange plate of the H-shaped steel is propped against the stirrups; the H-shaped steel is further provided with a clamp and a rail which are connected, and the clamp and the rail are connected to the flange plate of the H-shaped steel in a sleeved mode; the rail is located on the outer side of the flange plate, and the clamp is located on the inner side of the flange plate; and the tube climbing machine is located in the rail, and the rail is vertically arranged in the width direction of the flange plate. Compared with the prior art, the portable flame cutting device has the advantages that the turning-over frequency is reduced, and the unhooking danger probability and the safety accident coefficient are reduced. The device can be hung on the outer side of the flange plate during blanking of the flange plate, and the device and the inner side of the flange plate are fixed through an adjusting bolt. The tube climbing machine is fixed to a rail frame, and the tube climbing machine is adsorbed to the rail after being powered on. The tube climbing machine runs to drive a flame cutting torch to perform blanking and beveling on the flange plate, and the turning-over condition of a component is reduced.

Owner:ZHEJIANG DADONGWU CONSTR TECH CO LTD

Method of fast loading and correction of large diesel engine frame on gantry milling machine

ActiveCN108748064BQuick correctionReduce turning timesAutomatic control devicesFeeding apparatusDieselingLaser scribing

A method for quickly loading and correcting a large diesel engine frame on a gantry milling machine, comprising: marking the X, Y, and Z coordinate processing lines, waistlines, and workpiece centerlines of the frame by using a laser reference marking method before loading the frame and the zero reference line of the workpiece, and further adopt the milling table surface engraving and milling positioning groove on the CNC dragon milling, install the positioning support stopper, positioning key and reference tool setting block, place the adjustment pad, calibration block and reference measuring block The technical measures of laser scribing of blocks and racks ensure fast correction of racks on the vehicle and complete coordinate setting. The invention has the advantages of simple operation, safety, high efficiency, and convenient adjustment, and has the beneficial effects of reducing the correction time on the frame and reducing the labor intensity of workers, and is especially suitable for large-scale diesel engine frames and similar large-scale parts on CNC dragon milling. On-board calibration, positioning and coordinate setting.

Owner:CSSC MES DIESEL

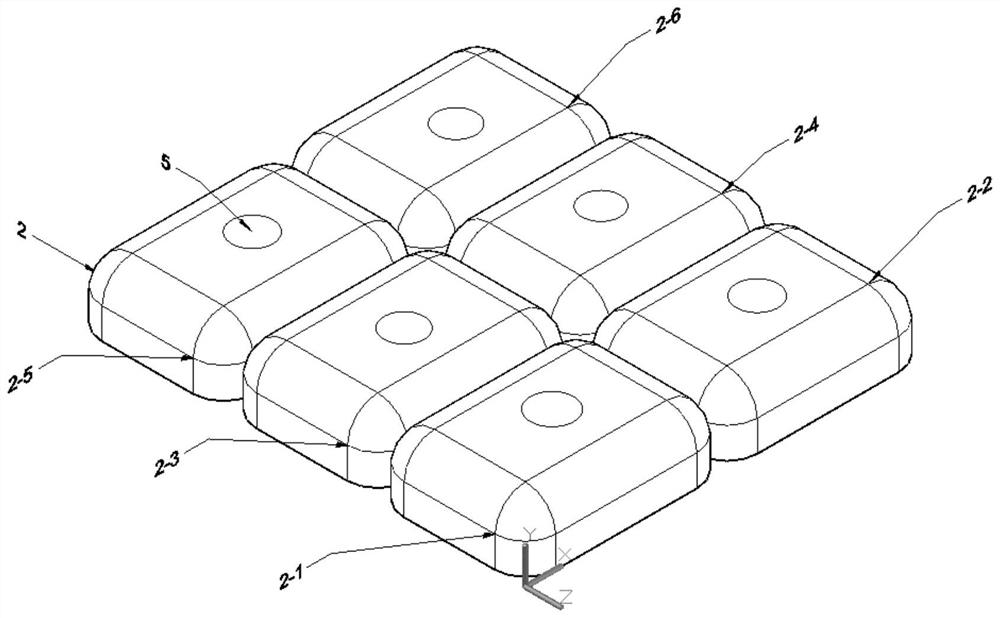

Health care mattress

InactiveCN108185719APromotes the elimination of fatigueSelf-weight pressure reductionElectrotherapyFluid mattressesEngineeringHealth hazard

The invention discloses a health care mattress. The health care mattress comprises a bed cover and a bag, wherein the bag is sleeved by the bed cover. The health care mattress is characterized in thatthe bag comprises a frame and partition plates, the partition plates comprise horizontal partition plates and vertical partition plates, the horizontal partition plates are mounted in the frame in parallel, the vertical partition plates are mounted in the frame in parallel, the horizontal partition plates are vertical to the vertical partition plates, the horizontal partition plates and the vertical partition plates form a plurality of filling areas, through holes are formed in the horizontal partition plates and the vertical partition plates in each filling area, each filling area is sealedby liquid, V-shaped grooves are formed in the central positions of the tops of the horizontal partition plates and the vertical partition plates, and the openings of the V-shaped grooves face upwards.For the health care mattress, through the arranged air exhaust grooves, the purpose of ventilation is achieved, and the potential health hazards caused by failure of air ventilation due to complete contact between the human body and the bag can be effectively eliminated.

Owner:陆嘉禾

A circular tube node conversion structure and its manufacturing method

ActiveCN103437424BGuarantee the welding quality of the weld seamIntegrity guaranteedArc welding apparatusBuilding constructionsShielded metal arc weldingEngineering

The invention mainly discloses a round tube joint conversion structure and a manufacturing method thereof. According to a joint structure, a round tube is cut and divided into a plurality of arc tiles and irregular round tube sections, and the divided arc tiles, the irregular round tube sections and a penetrating plate are welded in a cross mode to obtain the round tube joint conversion structure. A horizontally-arranged rectangular inner partition plate is welded in the round tube joint conversion structure, an annular inner partition plate is arranged between the penetrating plate and the round tube, the annular inner partition plate, the penetrating plate and the round tube are welded in a cross mode through carbon dioxide shield welding or manual arc welding, and accordingly a rib plate, the penetrating plate and the round tube are integrally welded. On the premise without reducing structural safety, the round tube joint conversion structure solves the problems that an internal structure of a similar round tube conversion joint is difficult to achieve and the quality is difficult to guarantee. Meanwhile, the round tube joint conversion structure saves production cost.

Owner:ZHEJIANG JINGGONG STEEL BUILDING GRP

Special tooling and fixture for castings of one-piece bearing seat of wind power generator

ActiveCN105234701BReduce turning timesGuaranteed cylindricityPositioning apparatusMetal-working holdersWind drivenEngineering

The invention relates to a special tool clamp for a wind driven generator one-piece bearing pedestal casting and a machining technology and belongs to the technical field of mechanical part machining. The special tool clamp comprises a box, a positioning device, a pressing device, an adjusting device and a supporting device. According to the special tool clamp for the wind driven generator one-piece bearing pedestal casting, a one-piece bearing pedestal lies one side to be clamped on the special tool clamp, a rotating workbench, bearing pedestal holes, a blast hole, an end face and peripheral faces complete finish machining through one time of clamping, the cylindricity and the coaxiality of the bearing pedestal holes in the two ends are guaranteed, the overturning frequency of the casting is reduced, the machining precision required in graph paper is achieved, production efficiency is improved, and production cost and labor intensity of workers are reduced.

Owner:JIANGSU JIXIN WIND ENERGY TECH

Slowly-rebounded mattress made from recovered grease polyether polyol

InactiveCN101543363AReal loopDoes not block circulationStuffed mattressesSpring mattressesHuman bodyPolyol

The invention discloses a slowly-rebounded mattress made from recovered grease polyether polyol, which comprises a surface fabric layer and a core layer, wherein the core layer adopts a rebound polyurethane soft foam body made by taking recovered grease polyether polyol as the main raw material, and ventilation holes are arranged on the surface fabric layer. The invention has the advantages that the slowly-rebounded polyurethane soft foam of the core layer can effectively convert human body pressure into zero pressure, offsets reaction force, provides most even and real support for human body, enables the part contacted by human body to be at the status of no pressure, does not inhibit the blood circulation and does not cause fatigue and ache of people, thereby reducing the unnecessary turning over time of people in sleep and having very good health care and sleep assistant functions.

Owner:林玲

Welding method of super thick steel plate vertical jigsaw

ActiveCN102861972BControl welding deformationReduce turning timesWelding/cutting auxillary devicesArc welding apparatusSheet steelTurnover time

A welding method for a vertically spliced super-thick steel plate is a welding method for a super-thick steel plate with the thickness ranging from 60mm to 120mm. The method is characterized by including: hoisting a primarily spliced super-thick steel plate onto a special jig frame for horizontal welding, fixing the super-thick steel plate with a waler of the jig frame by welding prior to fastening the super-thick steel plate with a ground abutting floor stand by the aid of a wedge, then using carbon dioxide arc welding for sequential symmetry horizontal welding on the front side and the back side of the super-thick steel plate respectively by even welders until spliced plate welding is finished, and finally performing postheat treatment to prevent cracks. The method has the advantages that welding deformation of the spliced super-thick steel plate can be well controlled, welding deformation correction is avoided, welding cracks are prevented, welding quality is improved, and construction requirements are met. The carbon arc air gouging process for back gouging is omitted, welding procedure is simplified, turnover times of the super-thick steel plate are decreased, workload is reduced, labor intensity is relieved, and production efficiency is improved.

Owner:QINGDAO BEIHAI SHIPBUILDING HEAVY IND CO LTD

Mattress and sickbed

PendingCN112022539AReduce workloadAvoid pressure soresNursing bedsSuction-kneading massageEngineeringPressure Sores/Ulcers

The invention provides a mattress and a sickbed. The mattress comprises a supporting bed body, a bed surface buffer cushion and a plurality of telescopic rods, wherein the telescopic rods are fixedlymounted on the supporting bed body and can stretch and retract relative to the upper surface of the supporting bed body; the bed surface buffer cushion is laid on the upper surface of the supporting bed body, and the edge of the bed surface buffer cushion is fixedly connected with the supporting bed body; and the telescopic rods can stretch and retract alternately, so that different parts on the bed surface buffer cushion are recessed or bulged alternately. The mattress can effectively prevent pressure sores.

Owner:许庆林

A kind of medicine for treating decubitus and its preparation method

InactiveCN103356771BPromote blood circulationPromote rapid growthHeavy metal active ingredientsDermatological disorderShellacTherapeutic effect

The invention relates to a medicine for treating bedsores, and preparation method thereof, and belongs to the traditional Chinese medicinal field. The medicine is composed of leaf of Rhus verniciflua Stokes, Leaf of Common Jujube, Root of Cherokee Rose, pericarp of Maximorwica Waterchesnut, ferrosic oxide, Gomphrena globosa, verdigris, coriaceous knotweed rhizome, iron filings, Praescutata viperina, Orostachys fimbriatus, shellac, sophora japonica, Patrinia heterophylla, P.freynianaBornm.var.sinica Migo and bigleaf fig leaf. The medicine has the efficacies of blood circulation promoting, blood stasis removing, slough removing, tissue regeneration growth promoting, heat clearing, detoxifying, sore astringing and swelling mitigating, and can improve the blood circulation of compressed tissues of a long-term bedridden patient and promote the rapid growth of epithelial cell tissues in order to treat the bedsores; and the medicine has the advantages of substantial treatment effect, fast effectiveness, mitigation of the patient's pains, reduction of the turn-over frequency of the patient, reduction of the labor intensity of a nursing personnel, low price, and convenient use.

Owner:李孝芹

Supporting structure and connecting method

PendingCN114164935ASolve the problem of excessive welding volumeSmall heat affected zoneBuilding constructionsEngineeringStructural engineering

The invention discloses a supporting structure and a connecting method, taking one of the supporting structure as an example, the supporting structure comprises a box-shaped body, the box-shaped body is vertically arranged, a grouting channel is formed in the box-shaped body, grouting holes are formed in the two ends of the box-shaped body respectively, the grouting holes communicate with the grouting channel, a reinforcing assembly is arranged in the grouting channel, and the reinforcing assembly is arranged in the box-shaped body. The reinforcing assembly comprises a plurality of first reinforcing plates, the first reinforcing plates are sequentially arranged in the grouting direction of the grouting channel, and through holes are formed in the first reinforcing plates and communicate with the grouting channel; and the bracket assembly is connected to the outer side wall of the box type body. The reinforcing assembly is arranged in the box type body and comprises a plurality of first reinforcing plates connected to the grouting channel, and the structural strength of the box type body can be enhanced through the first reinforcing plates.

Owner:CHINA CONSTR STEEL STRUCTURE ENG CO LTD +1

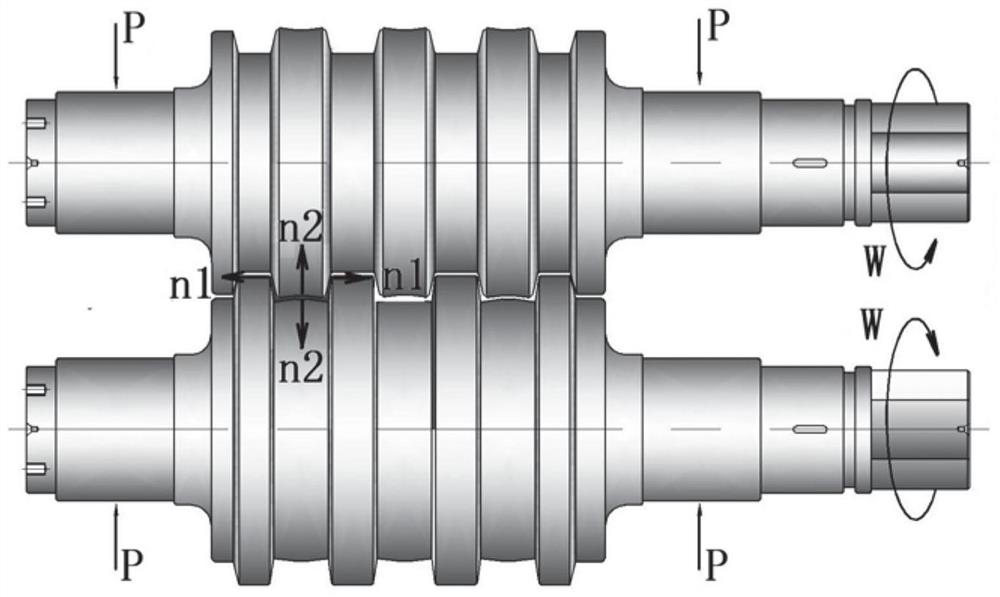

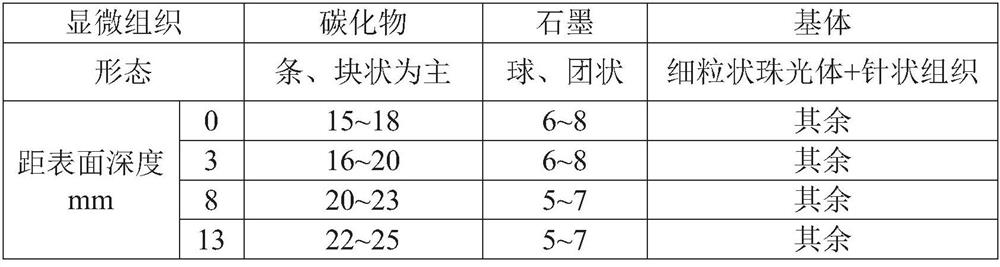

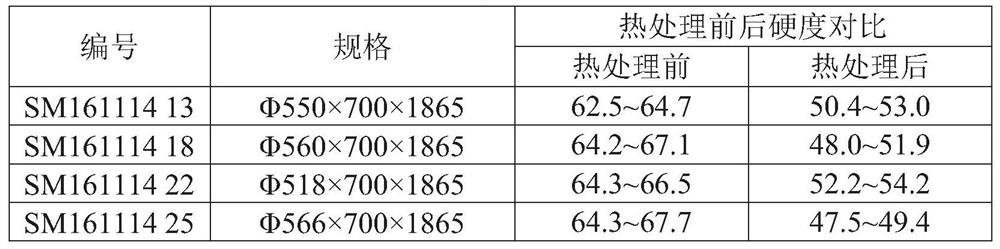

Hot-rolled section steel roll and its production method

ActiveCN110508785BImprove wear resistanceImprove thermal cracking resistanceFurnace typesHeat treatment furnacesCrack resistanceCarbide

A hot-rolled section steel roll, with the material of brand SGA1 as the outer layer and the material of brand QT500‑5 as the core material. After heat treatment, the metallographic composition of the outer layer changes, such as: at a depth of 0mm from the surface, by 30% ~35% carbide, 5%~7% graphite, and matrix with lamellar structure pearlite, transformed into 15%~18% carbide, 6%~8% graphite, and fine granular pearlite and acicular structure the matrix. The hot-rolled profiled steel roll provided by the invention is produced by a centrifugal composite bimetallic casting method, which not only greatly increases the alloy content of the outer layer of the roll, but also further improves the wear resistance and thermal crack resistance of the product. After actual rolling, the amount of passing steel has increased by more than 30%, and there is no phenomenon of ring collapse or roll breakage. Reduce the direct cost of roll consumption by more than 30% for iron and steel enterprises.

Owner:思诺冶金设备(上海)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com