Round tube joint conversion structure and manufacturing method thereof

A technology for converting structures and manufacturing methods, which is applied in the direction of manufacturing tools, building structures, arc welding equipment, etc., can solve problems such as difficult welding and difficult quality assurance, and achieve the effect of ensuring welding quality and good operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The preferred embodiments of the present invention will be described in further detail in conjunction with the accompanying drawings.

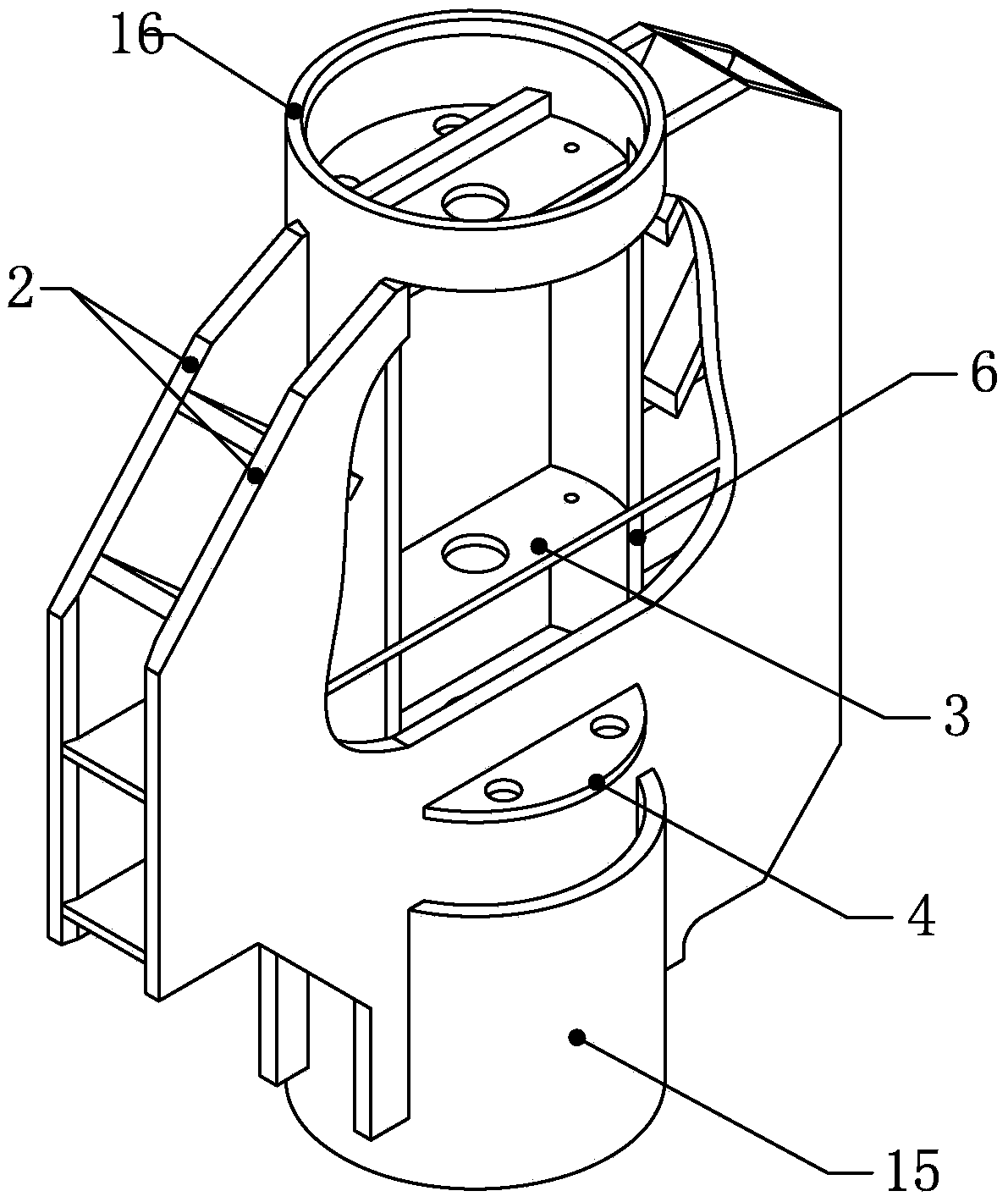

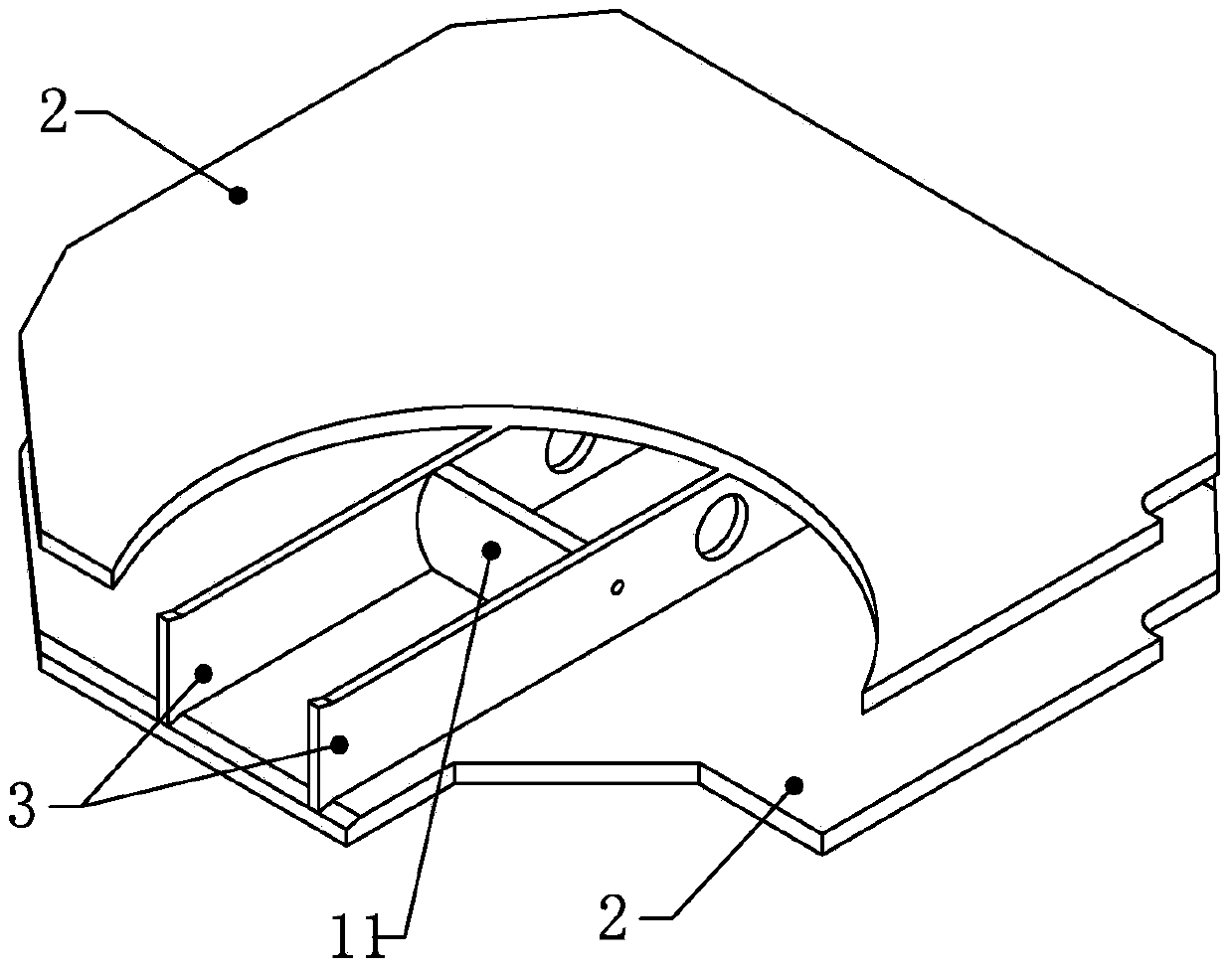

[0024] In the preferred embodiment of the present invention, the main components involved include a circular tube body 1 , two through-boards 2 with the same shape and size, a rectangular inner partition 3 and an arc-shaped inner partition 4 . The two through plates 2 are parallel to the axis of the round pipe body and pass through the round pipe body 1. A rectangular inner partition 3 perpendicular to the round pipe body 1 is arranged between the two through plates 2. Between the two through plates 2 A curved inner partition 4 is arranged outside.

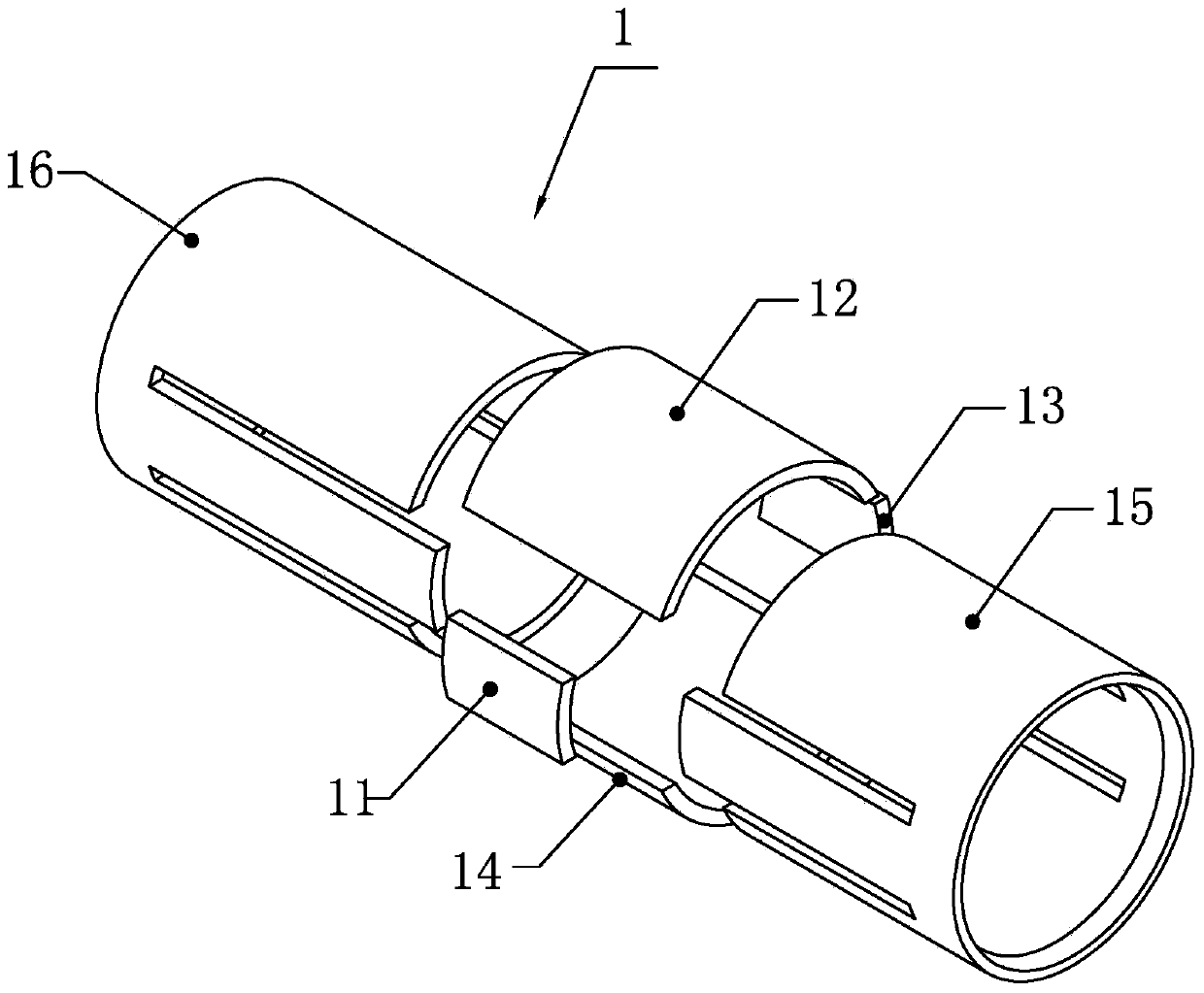

[0025] During the manufacturing process, the round pipe body 1 is first cut and disassembled into four arc-shaped tiles 11 , 12 , 13 , 14 in the middle, and special-shaped round pipe sections 15 , 16 at both ends. Wherein, when the round pipe body 1 is cut and disassembled, intersecting sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com