Patents

Literature

102results about How to "Good antibacterial and antibacterial properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ecological antibacterial high-sensitivity polyester fiber and method for producing same

ActiveCN106498541AHigh yieldSmall side effectsBiocideGroup 5/15 element organic compoundsPolyesterChemistry

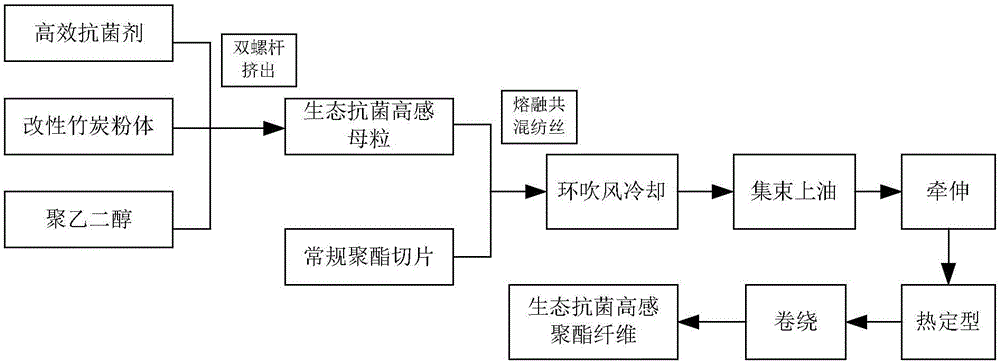

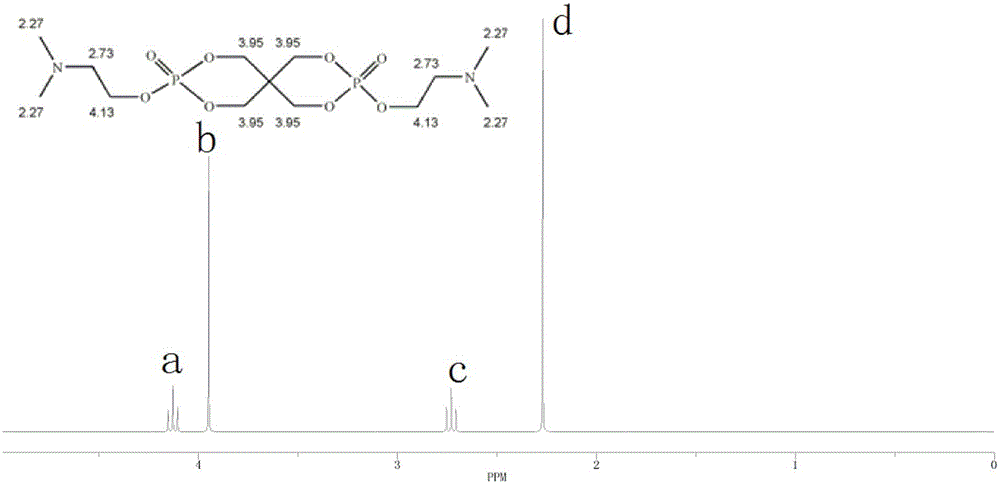

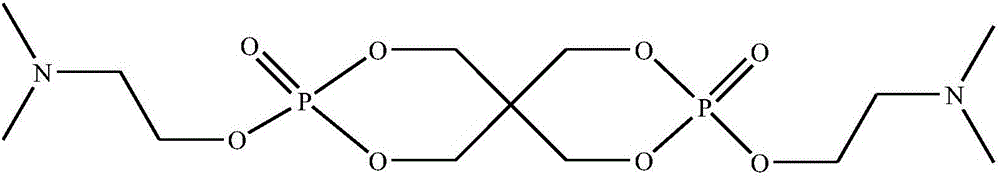

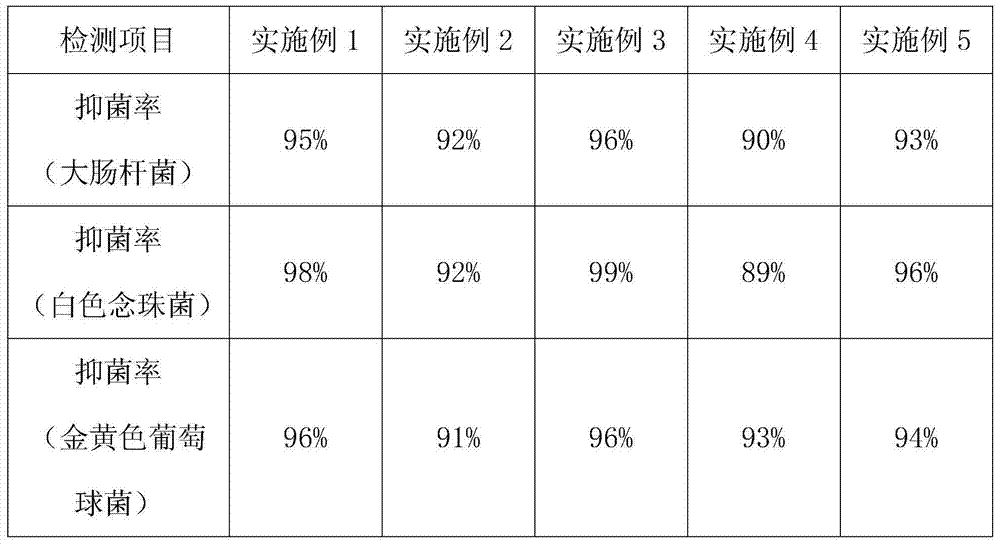

The invention relates to an ecological antibacterial high-sensitivity polyester fiber and a method for producing the same. The method includes particular steps of (1), preparing ecological antibacterial high-sensitivity master batch from efficient antibacterial agents, modified bamboo charcoal powder and polyethylene glycol by the aid of double-screw melt blending extrusion processes; (2), preparing ecological antibacterial high-sensitivity polyester fibers, to be more specific, spinning and extruding conventional polyester chips by the ecological antibacterial high-sensitivity master batch prepared at the step (1) by the aid of melt blending spinning processes via spinning assemblies, cooling virgin fibers by means of circular air blowing, applying oil to clusters and carrying out drawing, heat-setting and winding to obtain the ecological antibacterial high-sensitivity polyester fiber. The ecological antibacterial high-sensitivity master batch is used as a modification auxiliary at the step (2). The ecological antibacterial high-sensitivity polyester fiber and the method have the advantages that the antibacterial performance of the ecological antibacterial high-sensitivity polyester fiber include that the antibacterial rate of the ecological antibacterial high-sensitivity polyester fiber for staphylococcus aureus is higher than 90%, and the antibacterial rate of the ecological antibacterial high-sensitivity polyester fiber for Escherichia coli is higher than 92%; the far infrared emittance of the ecological antibacterial high-sensitivity polyester fiber is higher than 85%.

Owner:ZHEJIANG JINXIA NEW MATERIAL TECH CO LTD +1

Disposable sanitary product

InactiveCN102068715AInhibit the growth of bacteriaProtect the skinAbsorbent padsBandagesPerspirationNano zinc oxide

The invention relates to a disposable sanitary product with functions of resisting bacteria, removing peculiar smell and adjusting temperature. The surface layer of the sanitary product is made from phase change temperature adjusting fibers, moisture absorption and perspiration polyester fibers, composite fibers and bamboo fibers serving as raw materials. Because the surface layer of the sanitaryproduct contains the phase change temperature adjusting fibers and the moisture absorption and perspiration polyester fibers, sultry feeling is not produced in hot summer; meanwhile, because the moisture absorption and perspiration polyester fibers contain nano active carbon and the active carbon has good adsorption performance, the knitting wool has good peculiar smell removing function; the parallel composite fibers contain nano silver oxide granules and nano zinc oxide granules which have good antimicrobial and bacteriostatic performance, the knitting wool has good antimicrobial function so as to assist preventing the skin from being invaded by the bacteria, inhibit the propagation of the bacteria and achieve the antimicrobial and bacteriostatic effect and the skin protecting effect; and meanwhile, the bamboo fibers have antimicrobial and bacteriostatic characteristics.

Owner:亓传军

Antibacterial blended yarn and preparation method thereof

The invention discloses an antibacterial blended yarn, which is blended and woven by using wool, rabbit hairs, bamboo fibers, ultrafine polyester fibers, paper mulberry fibers and milk fibers, wherein the weight percentage of wool is 40-55 percent, the weight percentage of rabbit hairs is 3-8 percent, the weight percentage of ultrafine polyester fibers is 15-25 percent, the weight percentage of bamboo fibers is 5-10 percent, the weight percentage of paper mulberry fibers is 5-10 percent and the weight percentage of milk fibers is 10-25 percent. The antibacterial blended yarn reaches good moisture absorbing and guide, mold resistance, worm-eating resistance and antibacterial and bacteriostatic performance through proportioning of various fibers and a corresponding preparation method.

Owner:浙江龙一毛纺科技有限公司

Preparation method for antifungal and deodorized insole

ActiveCN104921406AGood antibacterial and antibacterial propertiesWide range of antibacterialSolesInsolesEmulsionChemistry

Provided is a preparation method for an antifungal and deodorized insole. The preparation method comprises the steps that firstly, essential oils of lemon fragrance, mint fragrance and orange fragrance are selected to serve as core materials, beta-cyclodextrin is selected as wall materials, fragrant microcapsules are prepared by using a wrapping method, and a preparation technology of the microcapsules is optimized; secondly, antibiotic finish is performed on a cotton fabric insole by utilizing organosilicon quaternary ammonium salt through a finishing technology with twice immersing and twice rolling at the temperature ranging from 110 DEG C to 120 DEG C; thirdly, the finished antibacterial cotton fabric insole is immersed in fragrant emulsion for two to three minutes, and through the mode of twice immersing and twice rolling, predrying is firstly performed on the cotton fabric, and then high-temperature drying is performed on the cotton fabric; finally, the antifungal and deodorized cotton fabric insole is obtained. The prepared cotton fabric insole can resist fungi and bacteria, and meanwhile has the different fragrant functions and the advantages of being good in antibacterial and deodorized effect.

Owner:SHAANXI UNIV OF SCI & TECH

Calcium alginate composite medical surgical dressing and preparation method thereof

InactiveCN105288698APromote absorptionGood biocompatibilityAdhesive dressingsAbsorbent padsFiberGlycerol

The invention belongs to the technical field of high-molecular medical biomaterials and relates to a calcium alginate composite medical surgical dressing and a preparation method thereof. The calcium alginate composite medical surgical dressing comprises an absorption core layer, a contact surface layer and a composite gel coating. The absorption core layer is a glue layer. The contact surface layer comprises chitosan fibers and active carbon fibers by blending. The composite gel coating comprises, by weight, 2-4 parts of sodium alginate, 0.5-1 part of medical glycerin, 2-4 parts of low molecular weight chitosan, 0.5-1 part of borneol and 80-100 parts of purified water. The medical surgical dressing prepared from the natural material and the synthetic high-molecular material has good absorbency, good biocompatibility, good biological activity and good mechanical properties.

Owner:GUANGDONG TAIBAO MEDICAL SCI TECH

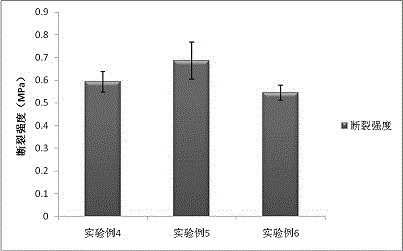

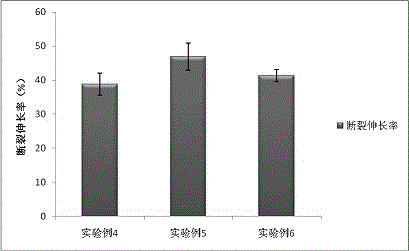

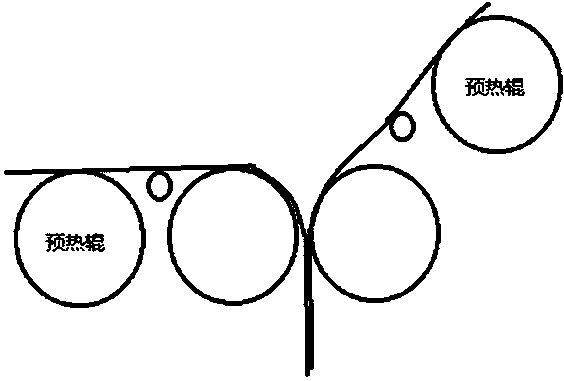

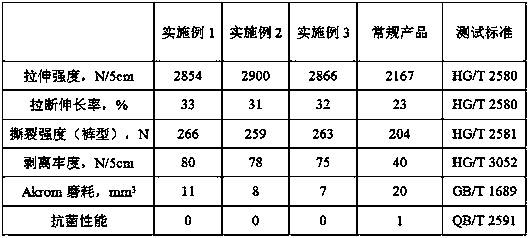

Modified TPU film fabric compound and preparation method thereof

ActiveCN108274864AImprove barrier propertiesPrevent curlingSynthetic resin layered productsChemistryPolyester

The invention discloses a modified TPU film fabric compound and a preparation method thereof. The film fabric compound comprises a modified TPU surface film layer, a PU surface adhering layer, a polyethylene fiber modified nylon base fabric, a PU bottom adhering layer and a modified TPU bottom film layer which are sequentially arranged, wherein a TPU modifying agent and polyester type TPU resin are mixed and dried based on ratio and then are extruded and cast to form a film; finally, the obtained modified TPU film layer is preheated with the nylon base fabric which is subjected to dehumidifying, pasting and drying; the modified TPU film layer and the nylon base fabric are processed by opposite pressing, laminating and winding through two mirror roller surfaces. The traditional preparationtechnology of the film fabric compound is modified, and thus a novel production method and technology is provided to a graphene oxide modified TPU film fabric compound; moreover, the prepared film fabric compound is high in tensile strength, tearing intensity and stripping fastness, and also has the bacteria resistance and bacteriostasis performances.

Owner:FUZHOU UNIVERSITY

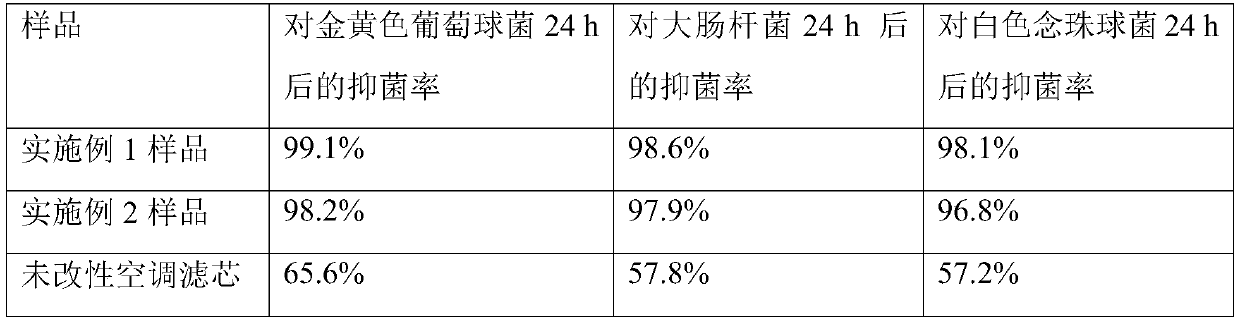

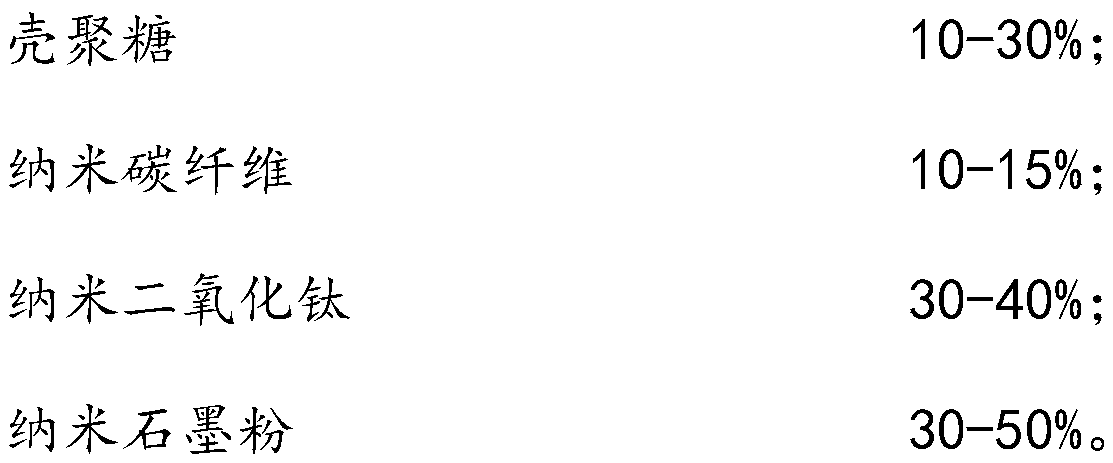

Preparation method of antibacterial air conditioner filter element material

InactiveCN109647052AImprove antibacterial propertiesStable in natureBiocideGas treatmentAir filtrationFiber

The invention discloses a preparation method of an antibacterial air conditioner filter element material, and belongs to the research field of preparation technologies of air conditioner filter element materials. The antibacterial air conditioner filter element material achieves the antibacterial purpose by contacting hydroxyl radicals on the surface of the material with bacteria, has the characteristics of safety, high efficiency, odorlessness, no residual, no corrosion, high stability, long service life and low cost, can be used for the air disinfection of confined spaces in hospitals, homes, public places and all kinds of transportation, and is especially suitable for the air filtration and disinfection in the presence of people. The preparation method of the antibacterial air conditioner filter element material adopts metal mesh fibers as a carrier, and the antibacterial air conditioner filter element material is obtained by adhering nanometer zinc oxide-silver particle compoundedbiological activated carbon containing an organosilicon quaternary ammonium salt antibacterial agent, having an antibacterial effect, to the metal surface.

Owner:SHANXI GREEN TECH CONSTR CO LTD

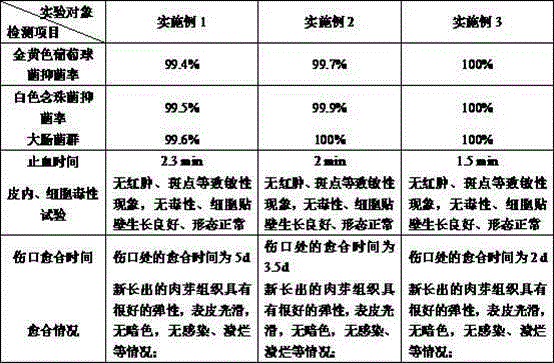

Medical antibacterial ES fiber and preparation technology thereof

ActiveCN111691006AGood antibacterial and antibacterial propertiesGood killing effectFilament/thread formingConjugated synthetic polymer artificial filamentsFiberJuniper Oil

The invention discloses medical antibacterial ES fiber and a preparation technology thereof. The medical antibacterial ES fiber is sheath core fiber, and is made of sheath layer materials and core layer materials. The sheath layer materials are prepared from 6-9 parts of sheath layer resin, 2-3 parts of addition agents, and 0.8-1.5 parts of antibacterial agents; and the core layer materials are prepared from 6-9 parts of core layer resin, 2-3 parts of addition agents, and 0.8-1.5 parts of antibacterial agents. The preparation technology comprises the steps of preparing the antibacterial agents, preparing the sheath layer materials and the core layer materials and preparing finished products through blend spinning of the sheath layer materials and the core layer materials. The antibacterialagents are prepared from modified juniper oil and nanocore-shell particles with a mass ratio of 1 to 1, and the modified juniper oil is mainly prepared from juniper oil, mesoporous silicon dioxide, 3-aminopropyl triethoxysilane and polyacrylic acid through reaction; and the nanocore-shell particles are mainly prepared from silver nitrate and ferric nitrate. The obtained medical antibacterial ES fiber is high in antibacterial activity and is enduringly antibacterial, and the problem of weak antibacterial effect brought by effumability of the juniper oil is solved.

Owner:江苏惠康特种纤维有限公司

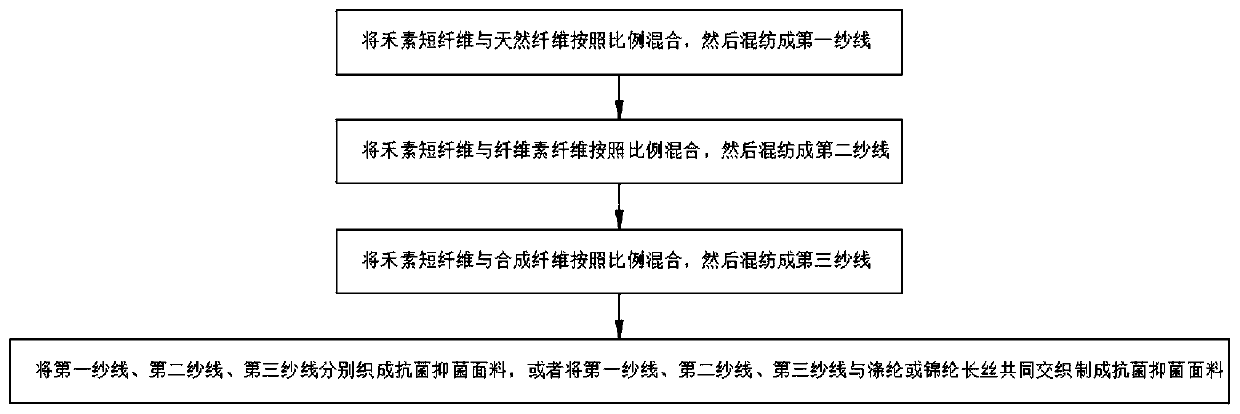

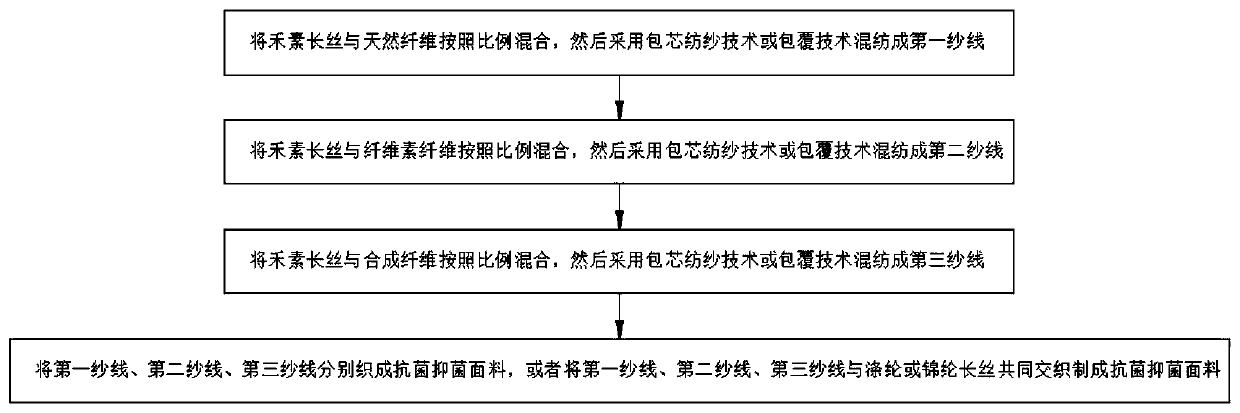

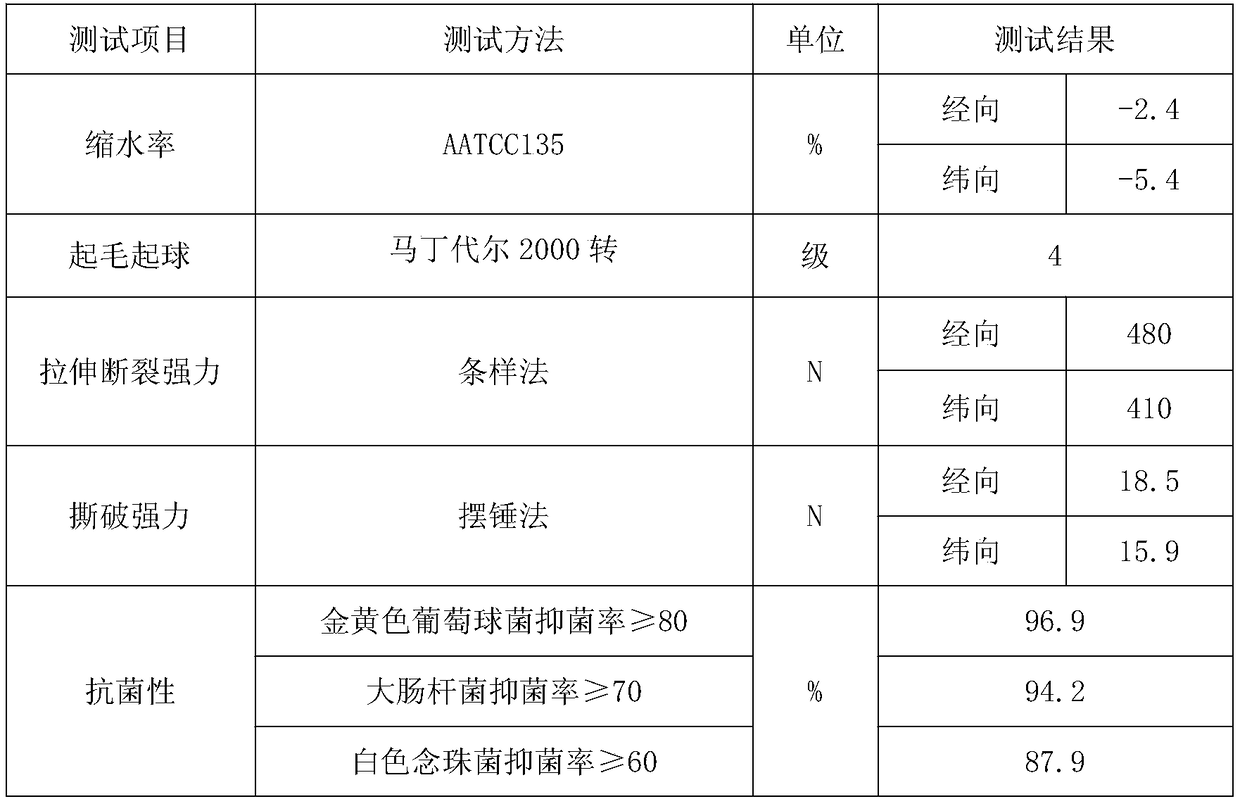

Preparing method of antibacterial and bacteriostatic fabric

InactiveCN110184718AInhibit growthGood antibacterial and antibacterial propertiesWoven fabricsYarnProtonationYarn

The invention discloses a preparing method of an antibacterial and bacteriostatic fabric. The method comprises the following steps of S1, mixing hesu fibers with natural fibers in proportion, and thenconducting blending to form first yarn; S2, mixing hesu fibers with cellulosic fibers in proportion, and then conducting blending to form second yarn; S3, mixing hesu fibers with synthetic fibers inproportion, and conducting blending to form third yarn. According to the preparing method, the feature that protonation amidogens with positive charges in the hesu fibers can adsorb germs and be combined with negative ion components on cell walls of the germs is utilized for hindering biosynthesis of the cell walls, so that the growth of microbes is inhibited, and thus the antibacterial and bacteriostatic purposes are achieved; the prepared antibacterial and bacteriostatic fabric has good antibacterial and bacteriostatic performance and cannot damage the environment at the same time.

Owner:NANJING BIOSERICA ERA ANTIBACTERIAL MATERIAL TECH CO LTD

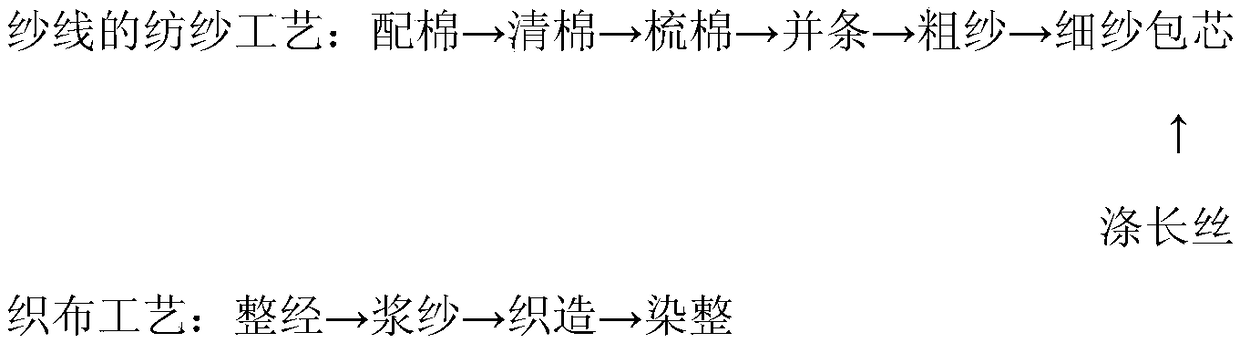

Staple-fiber corn-spun filament yarn containing natural plant antibacterial components, shirt fabric, and production method of shirt fabric

InactiveCN108866719AExtensive antibacterialImprove efficacyWoven fabricsYarnEngineeringWear resistance

The invention relates to the technical field of textiles, in particular to a staple-fiber corn-spun filament yarn containing natural plant antibacterial components, shirt fabric, and a production method of the shirt fabric. The staple-fiber corn-spun filament yarn is an Aiwei antibacterial fiber core-spun filament containing herbal natural antibacterial components, wherein wormwood extract accounts for 10% by weight of Aiwei antibacterial fiber which is bamboo fiber matrix. Core spinning is carried out in order to ensure that strength, wear resistance, wrinkle resistance, breathability, and quick drying property of the yarn are improved at the premise of ensuring that excellent functionality of bamboo fiber containing natural plant antibacterial components; shirt fabric cool, and stylish and having body texture is attained; the application limits of bamoo fiber material in shirt fabrics are broken through.

Owner:WEIQIAO TEXTILE

Manufacturing method for lasting bacterium resisting and inhibiting type leather

ActiveCN106222328ADurable and excellent antibacterial propertiesImprove antibacterial propertiesTanning treatmentLeather surface finishingLeather industryAmmonium

The invention discloses a manufacturing method for lasting bacterium resisting and inhibiting type leather. According to the manufacturing method, during pretanning, main tanning, retanning filling and dyeing, oxidization chitosan quaternary ammonium salt is used for treating the leather, formyl groups on the oxidization chitosan quaternary ammonium salt react with active groups on the leather so that the chitosan quaternary ammonium salt can be connected to the leather, and the bacterium resisting and inhibiting type leather is manufactured. The manufacturing method can be widely applied to the leather industry.

Owner:SICHUAN UNIV

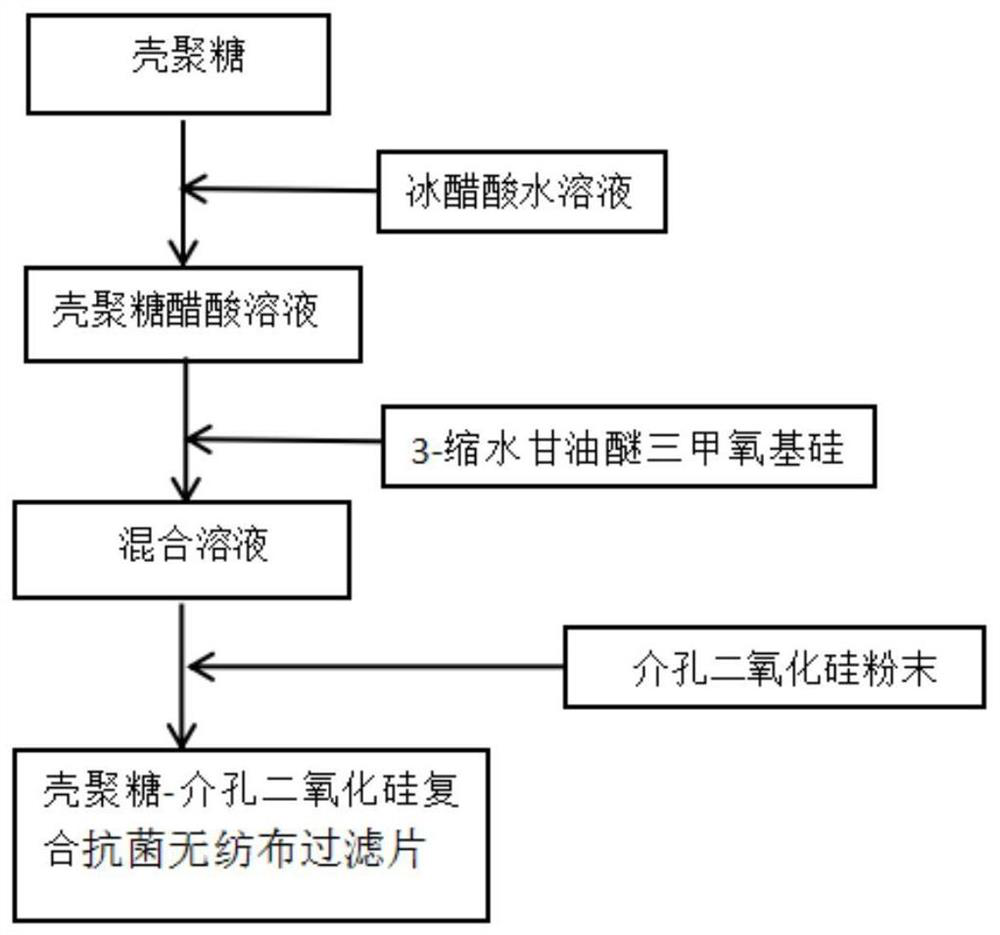

Preparation method of high-performance mesoporous silica-chitosan composite antibacterial filter

ActiveCN112007426AReduce coalescenceHigh purityDispersed particle filtrationBiochemical fibre treatmentMesoporous silicaNonwoven fabric

The invention provides a preparation method of a high-performance mesoporous silica-chitosan composite antibacterial filter. The preparation method comprises the following steps: (1) firstly, uniformly mixing a glacial acetic acid aqueous solution with chitosan to prepare a chitosan-acetic acid solution, then mixing and stirring the chitosan-acetic acid solution with 3-glycidyl ether trimethoxysilane overnight, adding mesoporous silica powder into the overnight solution, stirring and centrifuging, and then washing with ultrapure water to obtain a chitosan-mesoporous silica composite material;and (2) adding water into the chitosan-mesoporous silica composite material prepared in the step (1) to prepare a solution with the concentration of 100g / L, compounding the solution with a non-woven fabric, carrying out pre-drying and baking treatment on the composite sample, and carrying out ultraviolet curing to prepare the antibacterial filter. According to the prepared filter, the antibacterial rate reaches 90% or above, meanwhile, ultrafine particles in air can be effectively filtered out, and the effective haze prevention effect is achieved.

Owner:SHANDONG LINK SCI & TECH CO LTD

Environment-friendly sterilizing agent and preparation method thereof

InactiveCN104642325AGood antibacterial and antibacterial propertiesEasy to prepareBiocideFungicidesPolyethylene glycolCitric acid

The invention discloses an environment-friendly sterilizing agent and a preparation method thereof. The environment-friendly sterilizing agent is prepared from the following components in parts by weight: 5-8 parts of polyhistidine, 3-5 parts of chitosan, 3-5 parts of cyclodextrin, 2-3 parts of epsilon-polylysine, 0.05-0.8 part of polypyrrole, 0.01-0.04 part of citric acid, 8-12 parts of polyethylene glycol and 65-72 parts of water. The invention also provides the preparation method of the environmental-friendly sterilizing agent. The preparation method comprises the following steps: (1) weighing 3-5 parts of chitosan, 3-5 parts of cyclodextrin, 2-3 parts of epsilon-polylysine, 0.05-0.8 part of polypyrrole and 8-12 parts of polyethylene glycol; and (2) adding the components into a reaction kettle, heating, adding 65-72 parts of water under the stirring condition, slowly adding 0.01-0.04 part of citric acid, adding 5-8 parts of polyhistidine under the sunshine-shading condition, stirring till all the components are dissolved, cooling, defoaming and thus obtaining the environment-friendly sterilizing agent.

Owner:SUZHOU KANGHUA PURIFYING SYST ENG

Soybean fiber quilt

InactiveCN102327003AGood moisture absorption and moisture conductivityImprove breathabilityElectrotherapyBed-coversFiberHuman body

The invention discloses a soybean fiber quilt, which comprises a quilt cover and a quilt core. A plus material of the quilt cover is a pure cotton jacquard plus material, and the quilt core comprises 40-70% of soybean fibers and 30-60% of superfine fibers. In the invention, the soybean fibers and the superfine fibers are mixed and made into the quilt core; the warmness keeping property of the quilt core is superior to that of a common cotton quilt core; further, the quilt core has a soft tactile feeling, moisture absorption and air permeability; soybean protein fibers contain a plurality of amino acids necessary for a human body; after the soybean protein fibers are in contact with the skin, the collagens of the skin can be activated; the pruritus of the skin is restrained; and the activity of the skin is encouraged.

Owner:JIANGSU BAOMAN BEDROOM ARTICLES

Low viscosity edible antibacterial water-based ink and preparation method thereof

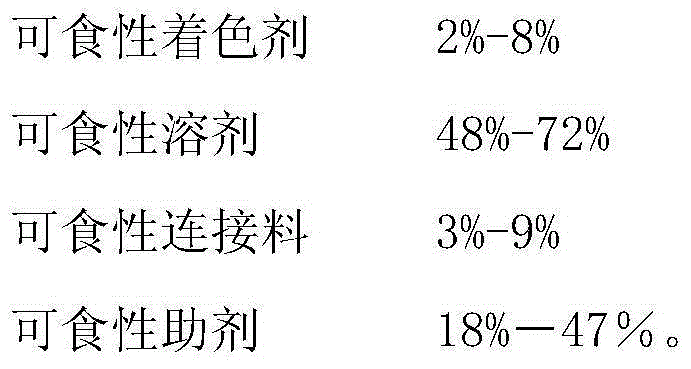

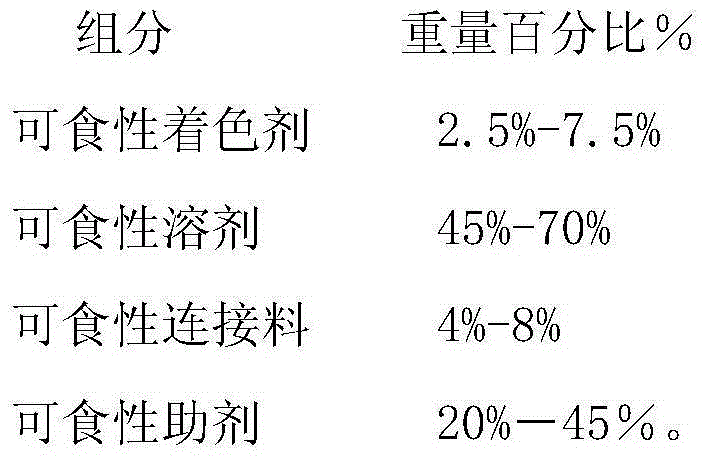

ActiveCN105062213AGood antibacterial and antibacterial propertiesGood moldabilityInksWater basedAntibacterial activity

The invention discloses a low viscosity edible antibacterial water-based ink and a preparation method thereof. The ink consists of the following components by weight percentage: 2%-8% of an edible colorant, 48%-72% of an edible solvent, 3%-9% of an edible binder and 18%-47% of an edible assistant. The preparation method includes: 1) weighing the components; 2) adding the edible assistant into the edible solvent, performing stirring to mix the edible assistant and the solvent evenly, thus obtaining a mixed solution A; 3) adding the edible binder into the mixed solution A, and conducting stirring to fully dissolve the edible binder, thus obtaining a mixed solution B; 4) adding the edible colorant into the mixed solution B, conducting stirring to fully dissolve the edible colorant, thus obtaining a mixed solution C; and 5) filtering the mixed solution C, and taking the filtrate. The ink has the advantages of low viscosity, edibility and antibacterial activity, can be directly printed on the surfaces of food and medicines, and also can be used for surface decoration of paper food packaging materials. The method has the advantages of simple process, convenient operation and low production cost.

Owner:JINGCHU UNIV OF TECH

Method for modifying natural emulsion through pulullan-alcohol soluble protein

The invention relates to a method for modifying natural emulsion through pulullan-alcohol soluble protein. The method comprises four steps of preparing organic silicon emulsion, preparing alcohol soluble protein-organic silicon compound emulsion, modifying natural emulsion by the alcohol soluble protein-organic silicon compound emulsion, and modifying the natural emulsion through pulullan-alcohol soluble protein and organic silicon compound. The natural emulsion prepared by the method has ageing resistance and antianaphylaxis.

Owner:ZHEJIANG XIANGBAN LATEX PROD

Antimicrobial blended machine knitting wool

ActiveCN102002786AGood antibacterial functionGood antibacterial effectFilament/thread formingYarnNano zinc oxideRamie

The invention relates to an antimicrobial blended machine knitting wool. The antimicrobial blended machine knitting wool is formed by blending fox velvet, tussah silk, modified ramie fibers and parallel-type composite fibers. The parallel-type composite fibers in the knitting wool of the invention comprise nano silver oxide particles and nano zinc oxide particles which both have good bacterium resisting and bacterium inhibiting performance, so the knitting wool has a good bacteria resisting function and can prevent skin from the invasion of bacteria and inhibit the growth of the bacteria; and therefore, the effects of resisting the bacteria, inhibiting the bacteria, and beautifying the skin are achieved. Simultaneously, bamboo fibers and the ramie fibers per se have the characteristics of resisting the bacteria and inhibiting the bacteria, so the addition of the bamboo fibers and the ramie fibers in the knitting wool further enhance the effects of resisting the bacteria and inhibiting the bacteria of the knitting wool.

Owner:HAITAI TEXTILE SUZHOU

Oxidized chitosan quaternary ammonium salt and collagen crosslinking method

ActiveCN106366333AGood antibacterial effectGuaranteed antimicrobial propertiesSurgical adhesivesAbsorbent padsFormyl groupBiocompatibility Testing

The invention discloses an oxidized chitosan quaternary ammonium salt and collagen crosslinking method. The method comprises the steps that oxidized chitosan quaternary ammonium salt containing active formyl groups is crosslinked with collagen under certain conditions, and chitosan quaternary ammonium salt is introduced into collagen in the mode of covalent bonds. According to the method, by means of collagen crosslinking, collagen can achieve double bacteria resistance and bacteriostasis performance on the basis of improving the use performance of collagen and keeping the biocompatibility of collagen, and a new way is created for new-generation collagen materials with good bacterium resistance and biocompatibility. The method can be used for preparing biological materials.

Owner:SICHUAN UNIV

Yarn and preparing method thereof

The invention discloses yarn formed by blending wool, cony hair, bamboo fiber, superfine polyester fiber and milk fiber. By means of matching of all kinds of fiber and a corresponding preparing method, the yarn has the good properties of absorbing moisture, guiding moisture, resisting moulding, preventing worm damages and resisting and restraining bacteria.

Owner:TIANCHANG HIGH TECH ENTREPRENEURSHIP SERVICE CENT

Anti-bacterial household paper and making method thereof

InactiveCN107524052ALow costGood antibacterial and antibacterial propertiesSpecial paperPaper/cardboardAnti bacterialDefoaming Agents

The invention discloses an antibacterial household paper, which comprises pulp, additives and antibacterial agents. The pulp comprises 45-65 parts of unbleached hardwood pulp, 10-20 parts of bamboo pulp, 15-25 parts of grass pulp, additives Including 2-4 parts of retention and drainage aid, 2-6 parts of defoamer, 1-5 parts of resin barrier remover, 2-7 parts of APAM, 3-7 parts of cationic disperse rosin, 6-10 parts of cationic starch, 2-7 parts of PPE 6 parts, 3-9 parts of surface enhancer, 2-10 parts of modified alkyd resin, 1-5 parts of amine type or quaternary ammonium cationic surfactant, antibacterial agent including 2-6 parts of quaternary ammonium salt, 3 parts of guanidine salt ~10 parts, chitosan 7~12 parts, haloamine polymer 3~8 parts; this product has the advantages of cheap price and good bactericidal effect.

Owner:YIWU YINAN PAPER IND CO LTD

Car cushion fabric easy to clean

InactiveCN107447333AAvoid deformationExtended service lifeSucessive textile treatmentsProtective fabricsPolyesterAnimal extract

The invention provides a car cushion fabric easy to clean. The car cushion fabric is characterized by comprising, by weight, 30-35 parts of polyester, 22-25 parts of polyester fiber, 20-25 parts of cotton fiber, 10-20 parts of fibrilia, 8-13 parts of modal fiber, 1-2 parts of antibacterial agent, and 0.5-0.8 part of coloring agent; the antibacterial agent is a natural plant extract or a natural animal extract. The body of the car cushion fabric easy to clean is prepared from the polyester, the polyester fiber, the cotton fiber, the fibrilia, and the modal fiber in the certain proportion and has the advantages of not only being soft, comfortable, permeable, and sweat-absorbent as a cotton fabric but also being resistant to dirt, easy to wash, not prone to deformation, long in service life and the like as a chemical fiber fabric.

Owner:安徽新创智能科技有限公司

Face cleaning cream capable of efficiently cleaning face and preparation method thereof

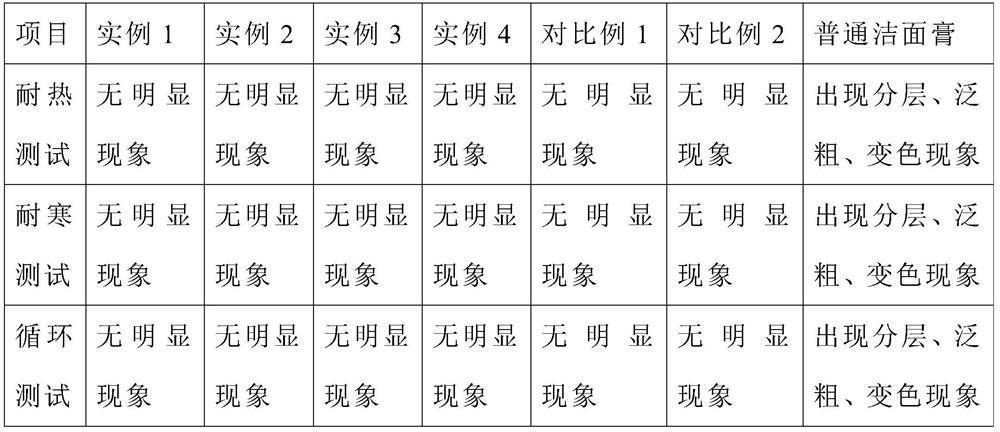

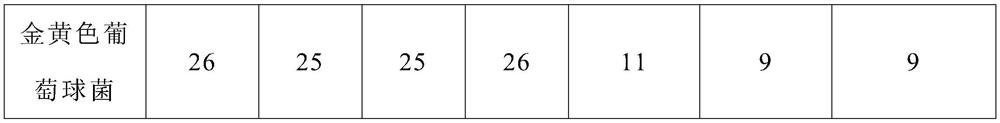

ActiveCN111671659AGood antibacterial and antibacterial propertiesEasy to cleanCosmetic preparationsToilet preparationsBiotechnologyActive agent

The invention discloses face cleaning cream capable of efficiently cleaning the face and a preparation method thereof. Sodium cocoyl glycinate is further added in the face cleaning cream, so that theface cleaning cream is mild in function and free of allergy, and can be used as an amino acid surfactant; when the face cleaning cream is prepared, glycerinum, polyethylene glycol and other componentshave a synergistic effect, meanwhile the pH value is controlled to be 5-6, the acidification degree of the sodium cocoyl glycinate is increased, and a system is crystallized, so that the finally prepared cream is exquisite in appearance, easy to extrude and apply, and excellent in crystallization temperature and stability. According to the face cleaning cream capable of efficiently cleaning the face and the preparation method thereof, the process design is reasonable, the component ratio is proper, and the prepared face cleaning cream is good in use condition and rich and exquisite in foam, makes the face feel clean, smooth, comfortable, non-irritating, non-greasy and non-tight after cleaning the face, also has excellent antibacterial performance, can clean microorganisms on the surface of the skin, and is relatively high in practicability.

Owner:前研化妆品科技(上海)有限公司

Multilayer viscose fiber composite spunlace mask base cloth and viscose fiber composite mask

InactiveCN110685070AReduce thicknessLose weightCosmetic preparationsToilet preparationsPolymer scienceMoisture permeability

The invention relates to a multilayer viscose fiber composite spunlace mask base fabric and a viscose fiber composite mask. The multilayer viscose fiber composite spunlace mask base fabric is preparedby 1) cutting raw ramie into small sections, and soaking with water to obtain a softened material; 2) carrying out steam explosion on the softened material to obtain an exploded mixture; 3) ultrasonically rinsing the exploded mixture in water, and performing impregnation modification to obtain modified ramie fibers; 4) opening and carding the modified ramie fibers to obtain a ramie fiber web; and5) opening and carding viscose fibers to obtain a viscose fiber web, cross-lapping a layer of the modified ramie fiber web between two or more layers of viscose fiber web, and performing water jet process, dewatering and drying to obtain the base fabric. The base fabric has good dry-wet strength and toughness, and the spunlace composite structure can bear the three-dimensional large-cut-number cutting and subsequent rinsing and lifting processes without damage, tearing or deformation; the base fabric has good air and moisture permeability, is soft and comfortable to touch, has good fitting property, is strong in liquid-retaining capacity and is suitable for producing a three-dimensional cut mask.

Owner:魏路平

Sound-insulation shock-absorption antibacterial coating and preparation method thereof

The invention discloses a sound-insulation shock-absorption antibacterial coating and a preparation method thereof. The formula comprises the following raw materials in parts by weight: 150-200 partsof cement, 100-150 parts of heavy calcium carbonate powder, 130-180 parts of wood fiber, 50-80 parts of sepiolite fiber, 30-60 parts of basalt fibers, 20-40 parts of micronized glass beads, 3-5 partsof hydroxypropyl methyl cellulose, 8-15 parts of redispersible latex powder, 10-20 parts of shells, 10-20 parts of medical stone, 5-10 parts of nano titanium dioxide, 1-3 parts of Octakis(trimethylsiloxy)silsesquioxane, 3-5 parts of a dispersing agent and 2-4 parts of toner. The coating provided by the invention not only has the advantages of good shock absorption, sound insulation, antibiosis, flame retardance, adhesive property, dispersibility, lower cost and the like, but also is excellent in environmental protection performance and harmless to human bodies, can purify the air and remove harmful substances such as formaldehyde in the air, and can be widely applied to the building fields such as residences, schools, hospitals, hotels and office buildings.

Owner:广西绿桂装饰材料有限公司

Nano cuprous oxide/copper oxide/silver oxide-containing emulsion for non-woven fabric and application of emulsion

ActiveCN112726219AGood antibacterial and antibacterial propertiesReduce dosageTextiles and paperAdhesiveSurgical Gowns

The invention discloses a nano cuprous oxide / copper oxide / silver oxide-containing emulsion for a non-woven fabric and application of the emulsion. The nano cuprous oxide / copper oxide / silver oxide-containing emulsion for the non-woven fabrics comprises the following solid raw material components in 100 parts of a solvent: 3 to 85 parts by mass of nano cuprous oxide / copper oxide / silver oxide, 1 to 40 parts by mass of film-forming resin, 1 to 20 parts by mass of a chain extender, 0 to 2 parts by mass of a dispersant, 0.3 to 2 parts by mass of an emulsifier, 0 to 2 parts by mass of an adhesive, 0 to 5 parts by mass of a curing agent and 0 to 3 parts by mass of an initiator. The nano cuprous oxide / copper oxide / silver oxide-containing emulsion for the non-woven fabric can be applied to the surface of a non-woven fabric base material, and is cured into a film through thermal curing or radiation curing and the like, so that good adhesion performance is achieved for the base material, and the obtained non-woven fabric has excellent antibacterial and bacteriostatic properties and is suitable for preparing masks, surgical gowns, surgical drapes, protective clothing and the like with high barrier requirements.

Owner:广东中湛融合科技研究有限公司

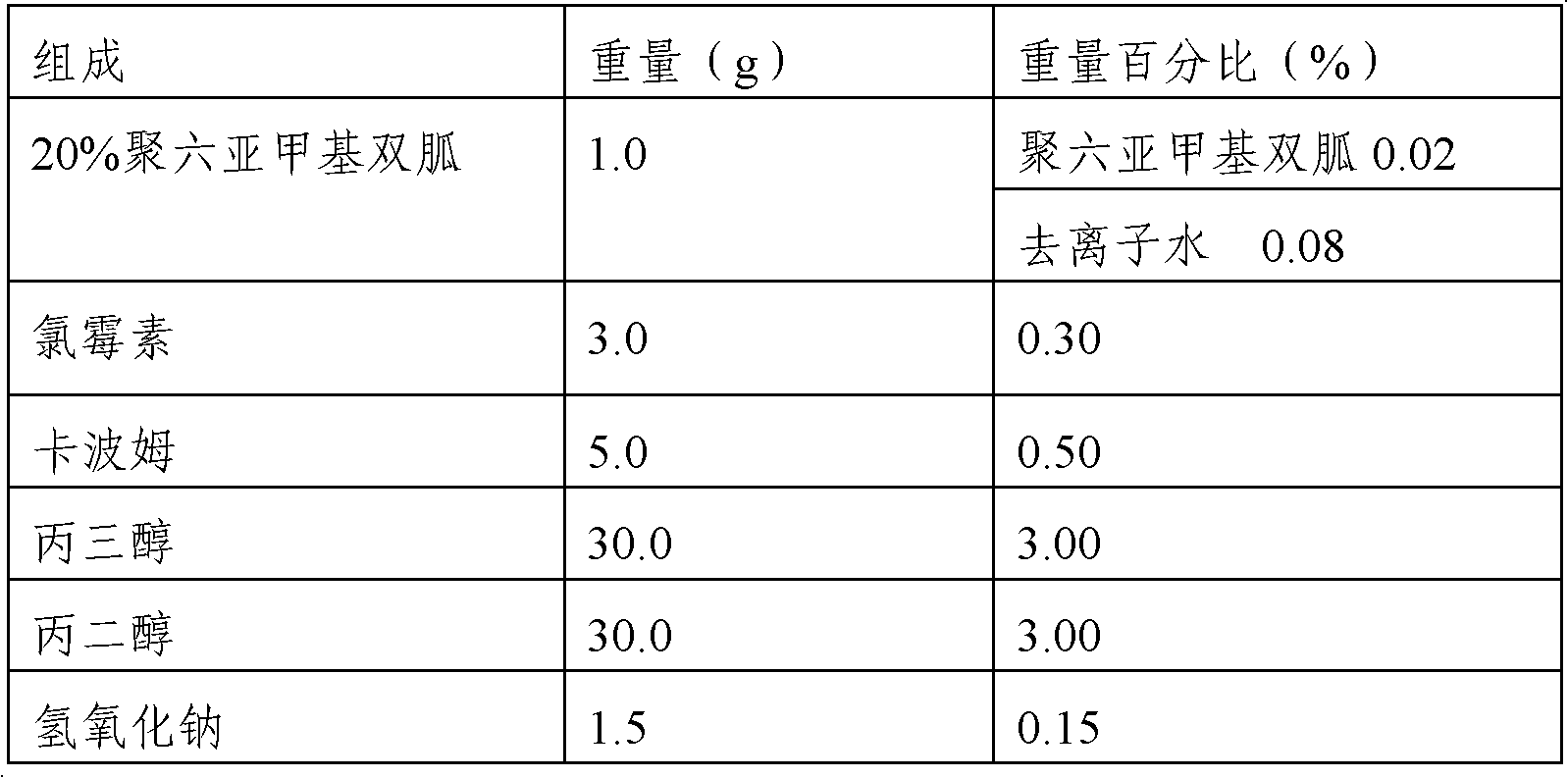

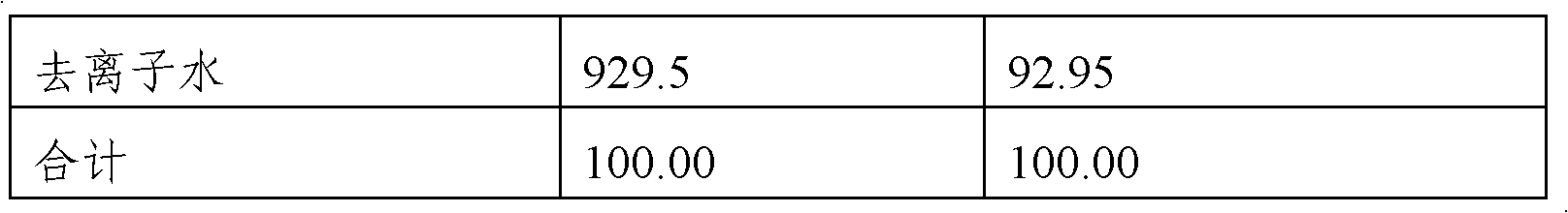

Sterilizing type medical ultrasonic coupling agent and preparation method thereof

InactiveCN102133409ABroad-spectrum bactericidalLow effective concentrationEchographic/ultrasound-imaging preparationsUltrasonographyGuanidine derivatives

The invention relates to a sterilizing type medical ultrasonic coupling agent and a preparation method thereof. The coupling agent contains the following active ingredients: polyhexamthylene guanidine-derivatives and chloramphenicol. A test proves that the coupling agent provided by the invention has the effects of transmitting sound, lubricating and preventing cross-infection, and the preparation method is simple and environment-friendly.

Owner:QINGDAO MINGYAOTANG MEDICAL TECH DEV

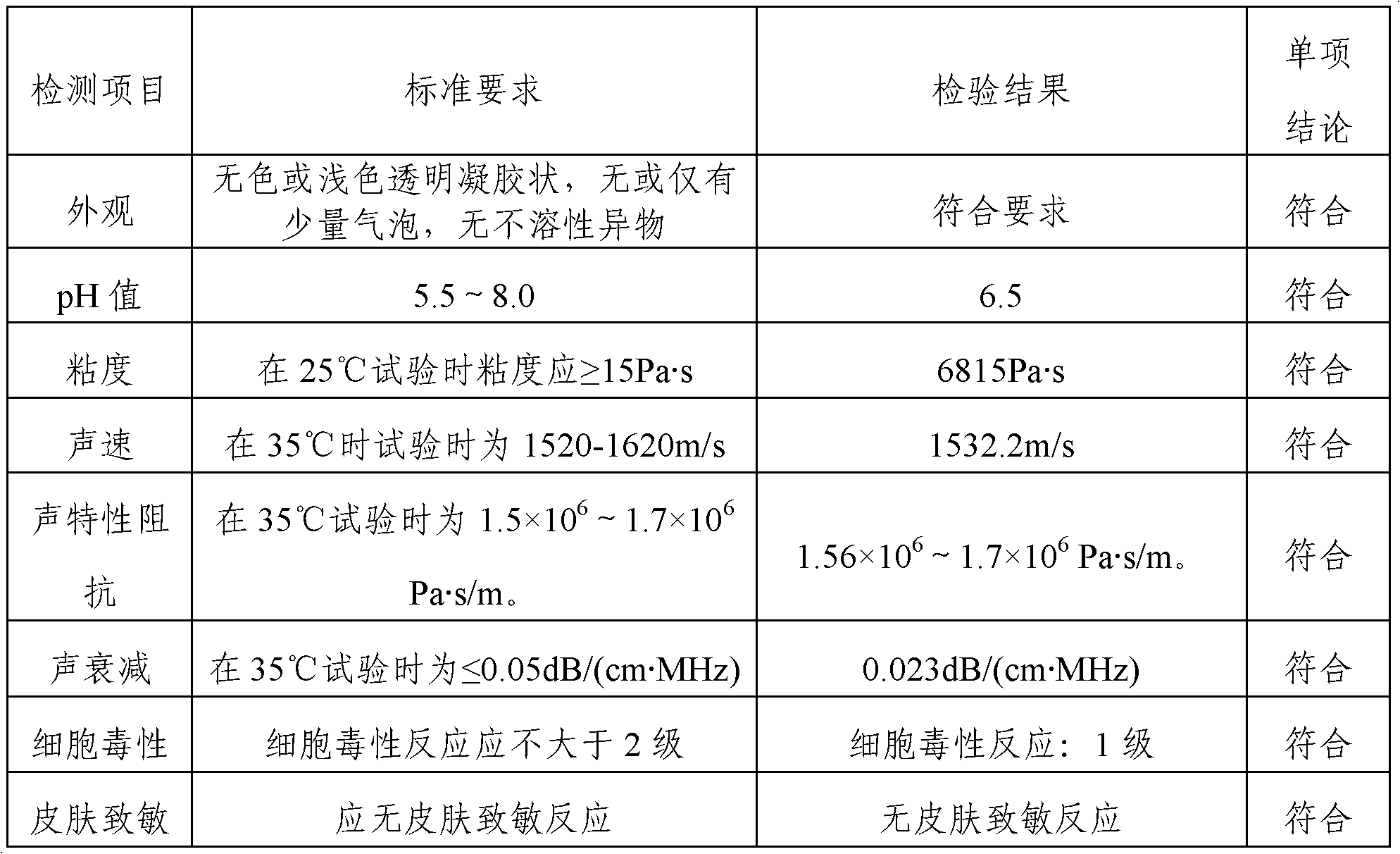

Antibacterial and deodorant sock

InactiveCN110269284AGood antibacterial and antibacterial propertiesReduce odorBiochemical fibre treatmentHandkerchiefsFiberYarn

The invention discloses an antibacterial and deodorant sock, and relates to the technical field of socks. The antibacterial and deodorant sock includes a sock body, the sock body is weaved by cotton yarn and polyester , the quality ratio of the cotton yarn and the polyester is (1-4):1, and the polyester is added with silver ions, copper ions, zinc ions and titanium dioxide particles through the ultra fine denier electrospinning technology in the spinning process. The antibacterial and deodorant sock has the effects of long-lasting elimination of sock odor, inhibition of bacteria, improvement of safety of the sock and enhancement of the sock on human health.

Owner:浙江玺润服饰有限公司

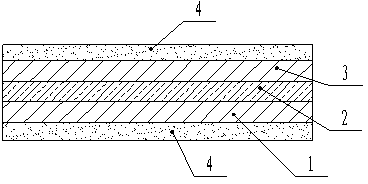

Flame-retardant non-woven fabric

InactiveCN104385730AHigh strengthImprove toughnessSynthetic resin layered productsPolyesterPolyvinyl chloride

The invention discloses flame-retardant non-woven fabric. The flame-retardant non-woven fabric comprises a first non-woven fabric layer, a reinforcing layer, a second non-woven fabric layer and flame-retardant thin film layers, wherein the reinforcing layer is positioned between the first non-woven fabric layer and the second non-woven fabric layer; both the first non-woven fabric layer and the second non-woven fabric layer are polyester fiber cloth; the reinforcing layer is an active carbon reinforcing layer; two flame-retardant thin film layers are provided, and are adhered to the outer surfaces of the first non-woven fabric and the second non-woven fabric respectively; the flame-retardant thin film layers adopt PVC (polyvinyl chloride) flame-retardant thin films. According to the technical scheme, the flame-retardant non-woven fabric has good flame retardance and antibacterial performances, has high strength and toughness, and is low in cost, safe and environment-friendly.

Owner:CHANGSHU YIXIN NONWOVEN PROD

After-finishing process for textile fabric with cooling function

InactiveCN104762778ACool to the touchGood antibacterial and antibacterial propertiesSolvent-treatmentSingeingWoven fabricYarn

The invention discloses an after-finishing process for textile fabric with a cooling function. The after-finishing process includes the technologies of scouring, singeing, flushing, soaking, dry rolling, dyeing, preshrunk shaping and drying. Warp and weft of the fabric comprise 65% to 73% of bamboo pulp fiber, 25% to 30% of polytrimethylene terephthalate fiber and 2% to 5% of medium-coarse high-elastic acrylic crease-resistant chopped fiber, wherein the density of the medium-coarse high-elastic acrylic crease-resistant chopped fiber ranges from 3.33 dtex to 5.56 dtex. The warp and the weft are twin-cord yarn, wherein the folded yarn twist is larger than or equal to 700 twists per meter. The twin-cord yarn is 27.8 tex carded yarn twin-cord yarn. The fabric is satin wave figured texture weave fabric, the warp density is 800 pieces to 900 pieces per 10 cm, and the weft density is 380 pieces to 420 pieces per 10 cm. The finished fabric has the cool touch sense, the excellent antibacterial property and the good crease-resistant performance, the fabric is soft in hand feeling compared with pure linen fabric, and meanwhile a certain body is achieved compared with chitin fabric so that the fabric can be quite suitable for being used as bedding fabric for spring and summer.

Owner:NANTONG YOUKAI TEXTILE TECH

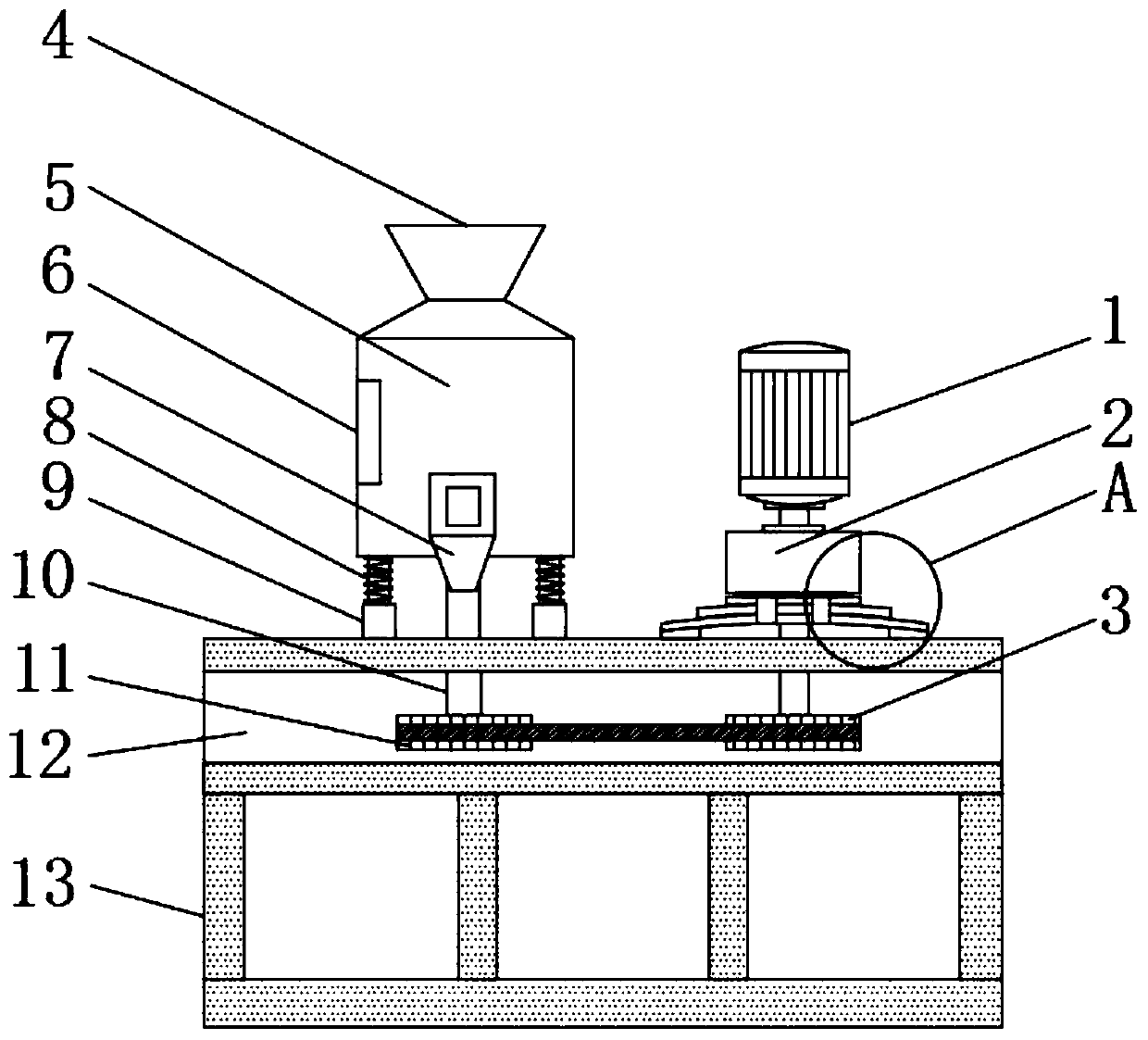

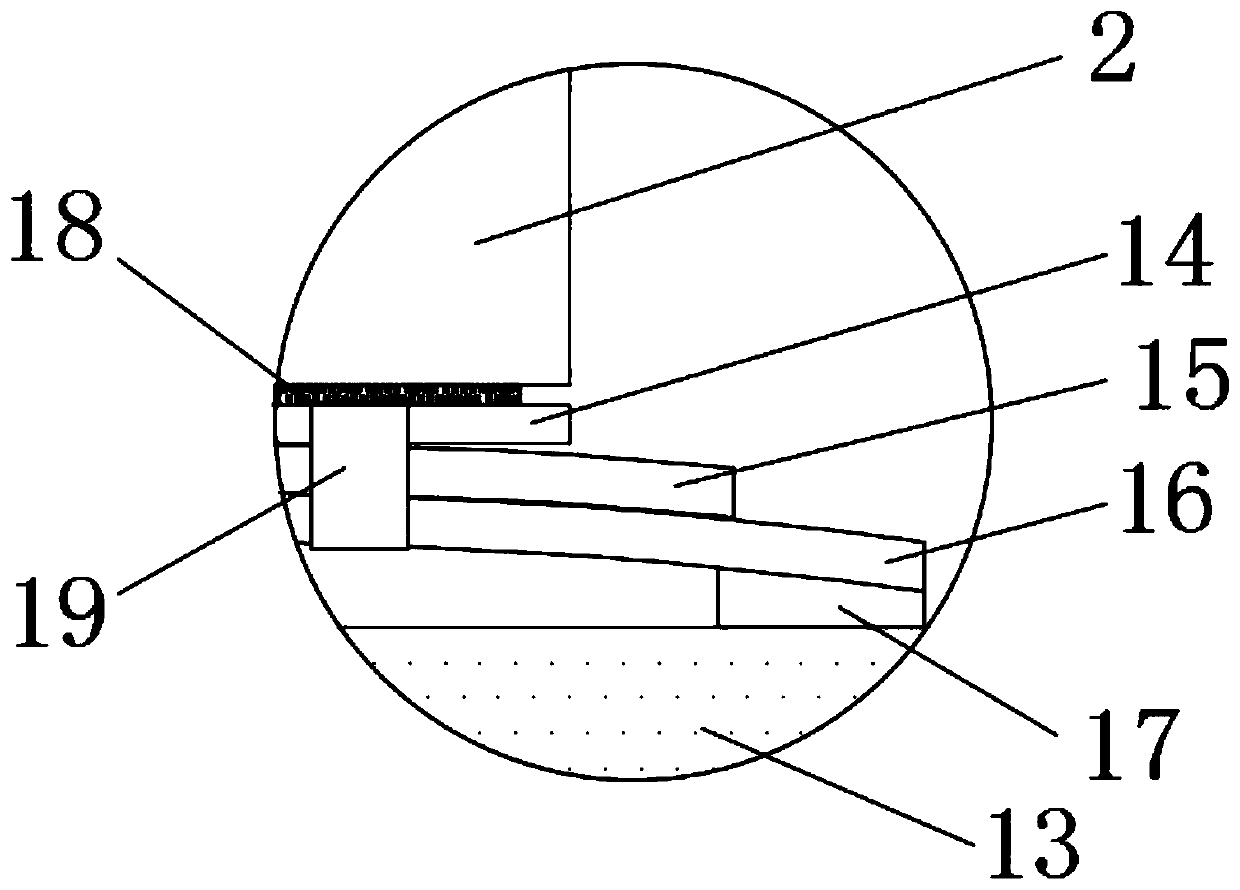

Environment-friendly coating for surface maintenance of wooden handicrafts, and preparation method of environment-friendly coating

InactiveCN110669432AImprove stain resistanceExtended service lifeAntifouling/underwater paintsTransportation and packagingVegetable oilCross linker

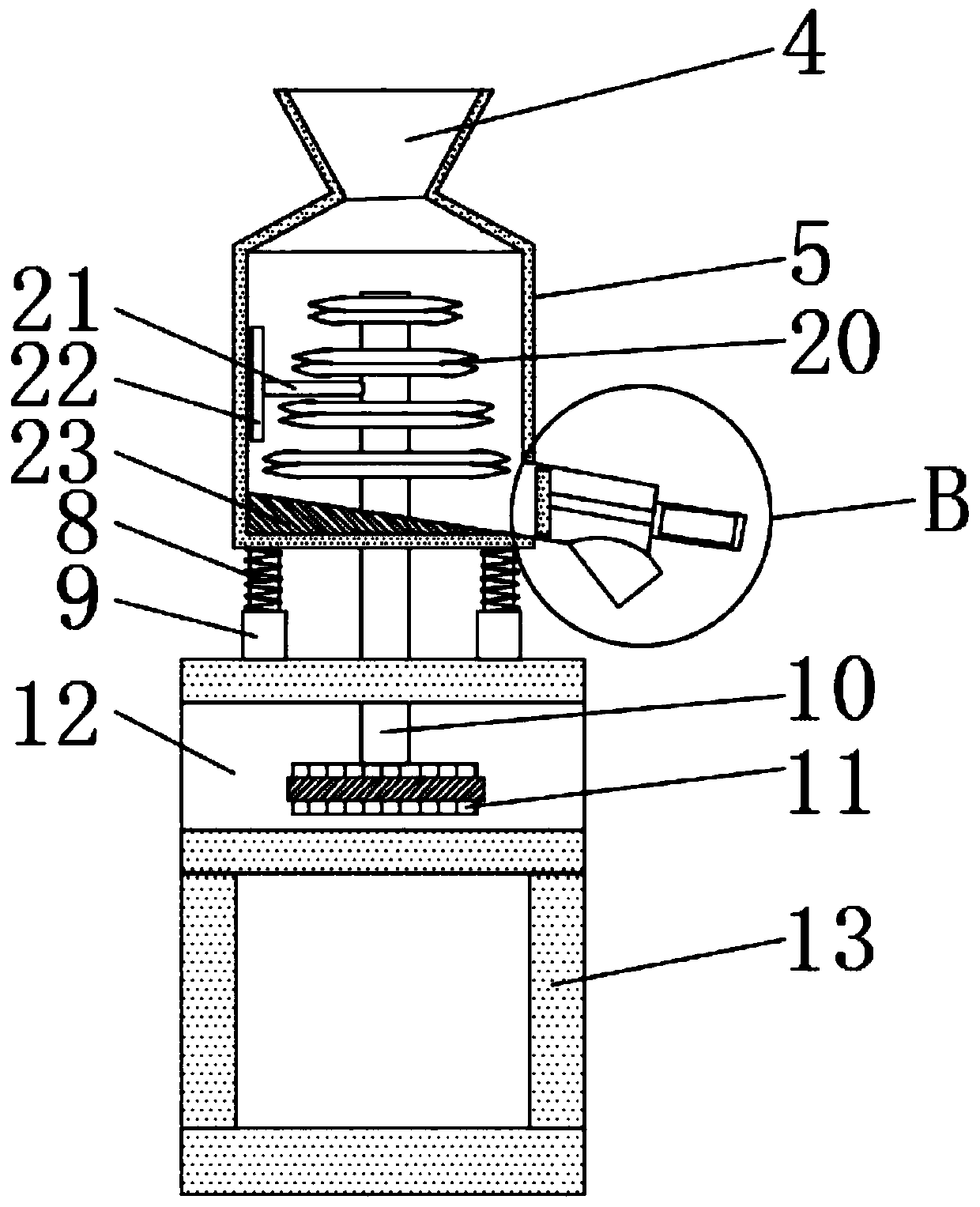

The invention discloses an environment-friendly coating for surface maintenance of wooden handicrafts, and a preparation method of the environment-friendly coating. The environment-friendly coating isprepared from the following components: natural vegetable oil, an antifouling agent, a highly reductive plant extract, a water-based fungicide, a permeable agent, a cross-linking agent and an antioxidant. The environment-friendly coating is harmless to human body health and has a good protective effect on the handicrafts; two cutting edges are mounted at the outer edges of stirring blades in an efficient mixer for mixing environment-friendly coating raw materials, so that the efficient mixer is good in mixing effect and high in mixing efficiency; by arranging a foam plate, a first elastic plate, a second elastic plate and a rubber pad, a certain cushioning effect is achieved so that vibration generated when a servo motor operates can be reduced; by connecting coil springs to telescopic rods in a sleeving mode, vibration of a mixing tank can be reduced, thus the vibration reduction effect of the efficient mixer is good, and noise generation is reduced; and through contraction of an aircylinder, a baffle gets away from the side wall of the mixing tank, thus automatic discharging is achieved, and the discharging process is simple and convenient.

Owner:安徽阜南县向发工艺品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com