Calcium alginate composite medical surgical dressing and preparation method thereof

A technology of calcium alginate and sodium alginate, applied in dressings, viscous dressings, medical science, etc., can solve the problems of poor mechanical properties and poor absorption properties, achieve good absorption capacity, prolong action time, and durable and stable antibacterial effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

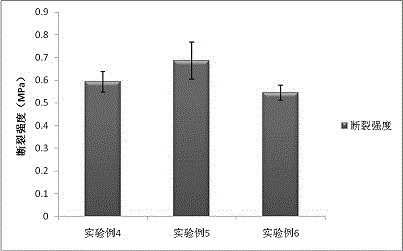

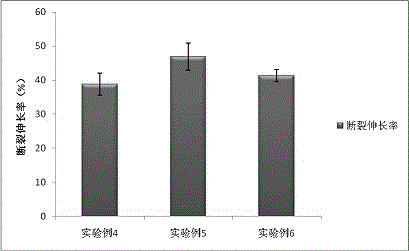

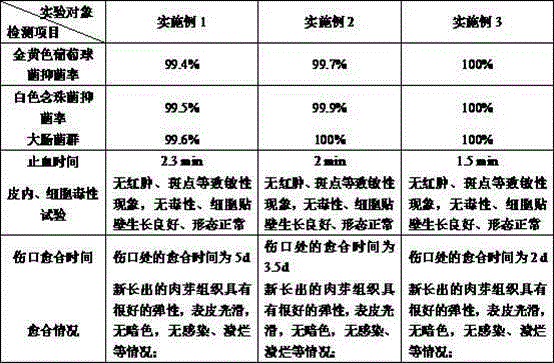

Embodiment 1

[0027] A calcium alginate composite medical dressing, which is composed of an absorbent core layer, a contact surface layer and a composite gel coating; the absorbent core layer is an adhesive layer, and the described contact surface layer is made of chitosan Fiber and activated carbon fiber are blended, and the composite gel coating is composed of the following components in parts by weight: 2 parts of sodium alginate, 0.5 part of medical glycerin, 3 parts of low molecular weight chitosan, 0.5 part of borneol, purified 94 parts of water, the molecular weight of the low molecular weight chitosan is 5000Da, the degree of deacetylation is 70%~85%, and the purity of the medical glycerin is greater than 99.8%. Chitosan fiber has good antibacterial and antibacterial properties, and the hollow and porous structure of activated carbon fiber makes it have good adsorption properties. Combined with the composite gel coating, it can achieve antibacterial, moisturizing, and hemostatic and ...

Embodiment 2

[0030] A calcium alginate composite medical dressing, which is composed of an absorbent core layer, a contact surface layer and a composite gel coating; the absorbent core layer is an adhesive layer, and the described contact surface layer is made of chitosan Fiber and activated carbon fiber are blended, and the composite gel coating is composed of the following components in parts by weight: 3 parts of sodium alginate, 0.8 part of medical glycerin, 2 parts of low molecular weight chitosan, 0.8 part of borneol, purified 93.4 parts of water, the molecular weight of the low molecular weight chitosan is 8000Da, the degree of deacetylation is 70%~85%, and the purity of the medical glycerin is greater than 99.8%. Chitosan fiber has good antibacterial and antibacterial properties, and the hollow and porous structure of activated carbon fiber makes it have good adsorption properties. Combined with the composite gel coating, it can achieve antibacterial, moisturizing, and hemostatic an...

Embodiment 3

[0033] A calcium alginate composite medical dressing, which is composed of an absorbent core layer, a contact surface layer and a composite gel coating; the absorbent core layer is an adhesive layer, and the described contact surface layer is made of chitosan Fiber and activated carbon fiber are blended, and the composite gel coating is composed of the following components in parts by weight: 3.5 parts of sodium alginate, 1 part of medical glycerin, 4 parts of low molecular weight chitosan, 1 part of borneol, purified 90.5 parts of water, the molecular weight of the low molecular weight chitosan is 10000Da, the degree of deacetylation is 70%~85%, and the purity of the medical glycerin is greater than 99.8%. Chitosan fiber has good antibacterial and antibacterial properties, and the hollow and porous structure of activated carbon fiber makes it have good adsorption properties. Combined with the composite gel coating, it can achieve antibacterial, moisturizing, and hemostatic and a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com