Face cleaning cream capable of efficiently cleaning face and preparation method thereof

A technology for cleansing the face and cleansing cream, which is applied in the directions of medical preparations containing active ingredients, preparations for skin care, pharmaceutical formulas, etc. Delicate, clean-feeling, mild-functioning results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

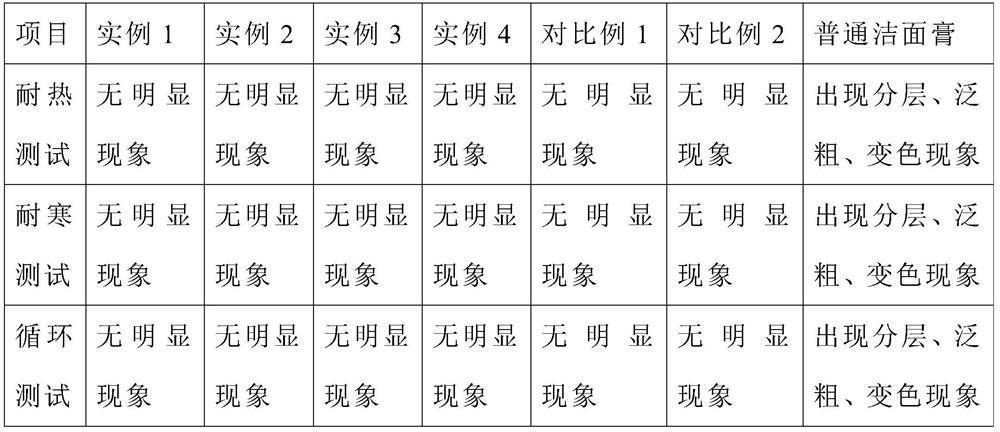

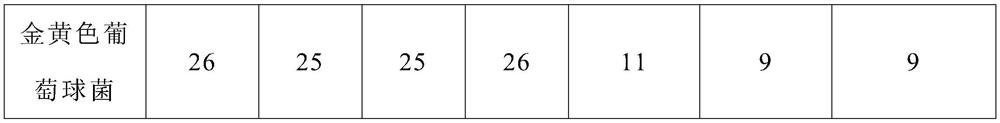

Examples

example 1

[0044] S1: Prepare materials;

[0045] S2: Prepare the first additive:

[0046] Get carboxymethyl chitosan, dissolve in deionized water, stir for 10min, and obtain chitosan solution;

[0047] Take n-octane and Span-80, stir for 10 minutes, heat up to 45°C, then add chitosan solution, emulsify for 30 minutes, then add glutaraldehyde, solidify for 4 hours, wash with acetone for 10 minutes after the reaction, and wash with absolute ethanol for 5 minutes , washed with deionized water for 5 minutes, and dried in vacuum to obtain material A;

[0048] Mix 3-aminopropyltriethoxysilane with deionized water, heat up to 45°C, stir for 4 hours, add material A, continue stirring for 5 hours, then add silver nitrate solution, continue stirring for 1 hour, wash and dry to obtain the first addition material;

[0049] S3: preparing the second additive:

[0050] Take bamboo, soak in distilled water for 1-2 days, air-dry naturally, crush to 40 mesh, vacuum-dry at 100°C, place in pyrophosphoric...

example 2

[0057] S1: Prepare materials;

[0058] S2: Prepare the first additive:

[0059] Get carboxymethyl chitosan, dissolve in deionized water, stir for 15min, and obtain chitosan solution;

[0060] Take n-octane and Span-80, stir for 13 minutes, heat up to 48°C, then add chitosan solution, emulsify for 35 minutes, then add glutaraldehyde, solidify for 4.5 hours, wash with acetone for 13 minutes after the reaction, and wash with absolute ethanol 8 minutes, washed with deionized water for 7 minutes, and dried in vacuum to obtain material A;

[0061] Mix 3-aminopropyltriethoxysilane and deionized water, heat up to 46°C, stir for 4.5 hours, add material A, continue stirring for 7 hours, then add silver nitrate solution, continue stirring for 1.5 hours, wash and dry to obtain the first One add material;

[0062] S3: preparing the second additive:

[0063] Take bamboo, soak in distilled water for 1.5 days, air-dry naturally, crush to 40 mesh, vacuum-dry at 100°C, place in pyrophosphor...

example 3

[0070] S1: Prepare materials;

[0071] S2: Prepare the first additive:

[0072] Get carboxymethyl chitosan, dissolve in deionized water, stir for 18min, and obtain chitosan solution;

[0073] Take n-octane and Span-80, stir for 12 minutes, heat up to 49°C, then add chitosan solution, emulsify for 34 minutes, then add glutaraldehyde, solidify for 4.2 hours, wash with acetone for 12 minutes after the reaction, and wash with absolute ethanol 9min, washed with deionized water for 7min, and vacuum-dried to obtain material A;

[0074] Mix 3-aminopropyltriethoxysilane and deionized water, heat up to 46°C, stir for 4.9 hours, add material A, continue stirring for 7 hours, then add silver nitrate solution, continue stirring for 1.8 hours, wash and dry to obtain the first One add material;

[0075] S3: preparing the second additive:

[0076] Take bamboo, soak in distilled water for 2 days, air-dry naturally, crush to 40 mesh, vacuum-dry at 100°C, place in pyrophosphoric acid after d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com