Environment-friendly coating for surface maintenance of wooden handicrafts, and preparation method of environment-friendly coating

A technology for handicrafts and environmentally friendly coatings, applied in coatings, chemical instruments and methods, antifouling/underwater coatings, etc., can solve the problems of reducing the number of wiping times, easy to be stained with dust, difficult to remove, etc., to reduce the cost of wiping The number of times, antibacterial and antibacterial properties are good, and the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

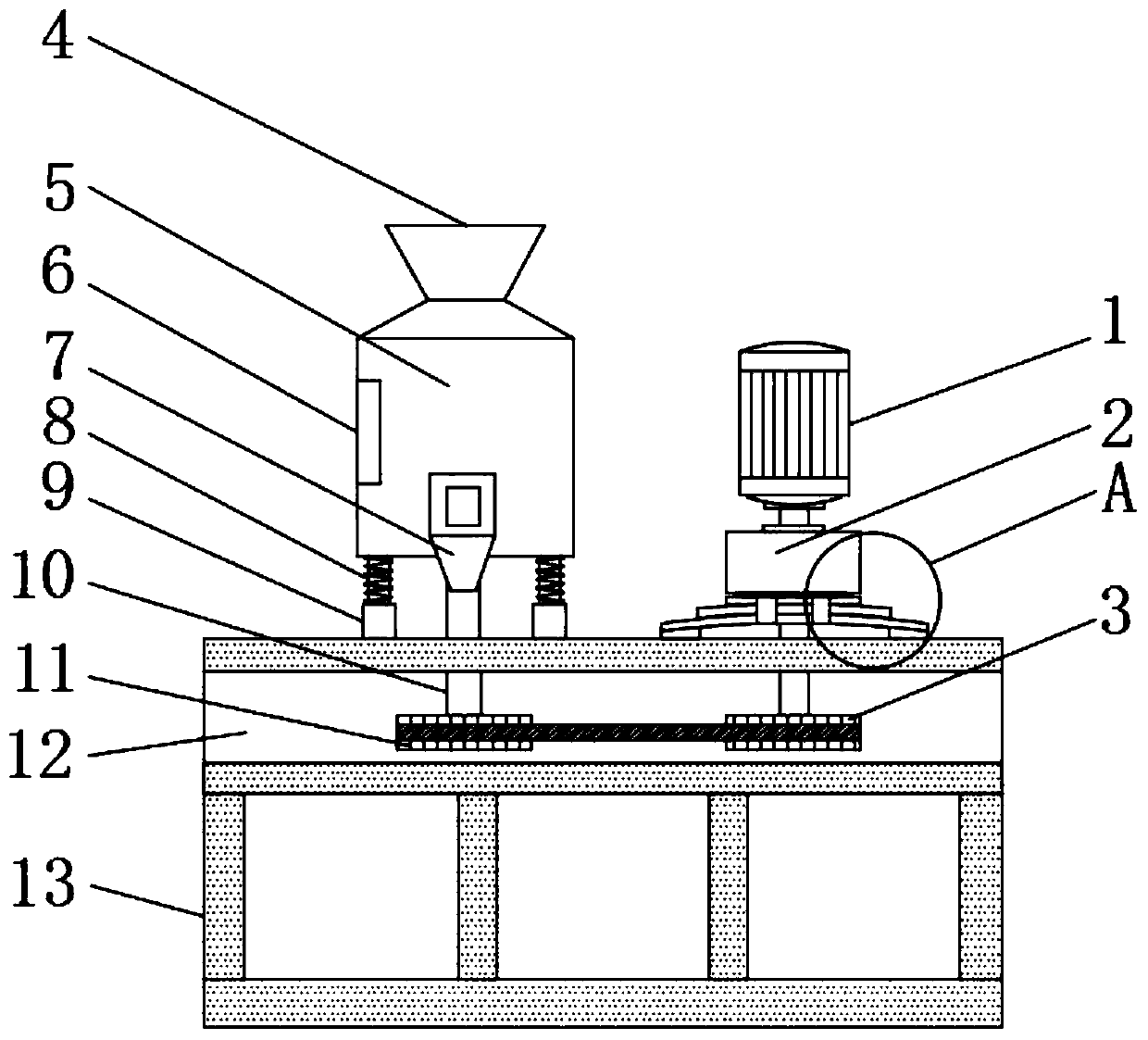

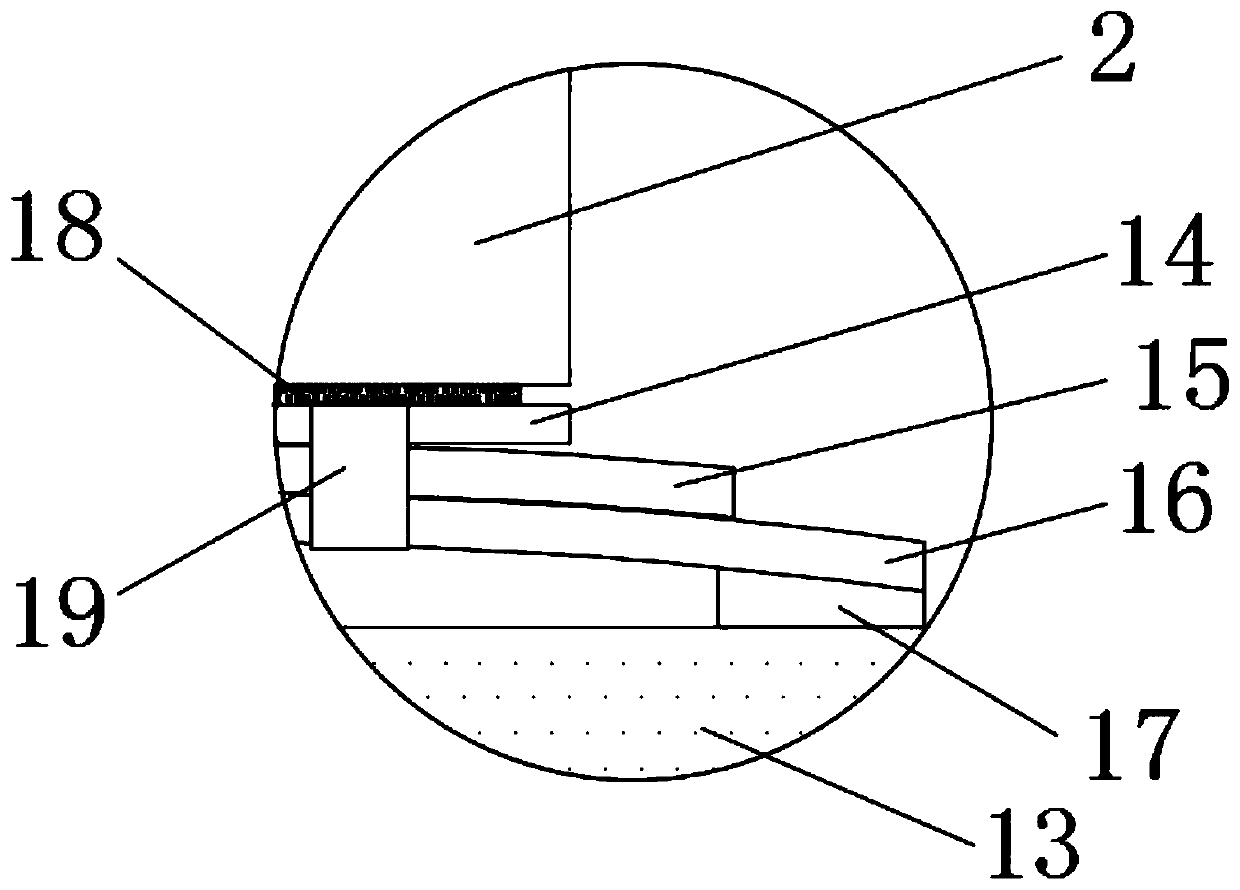

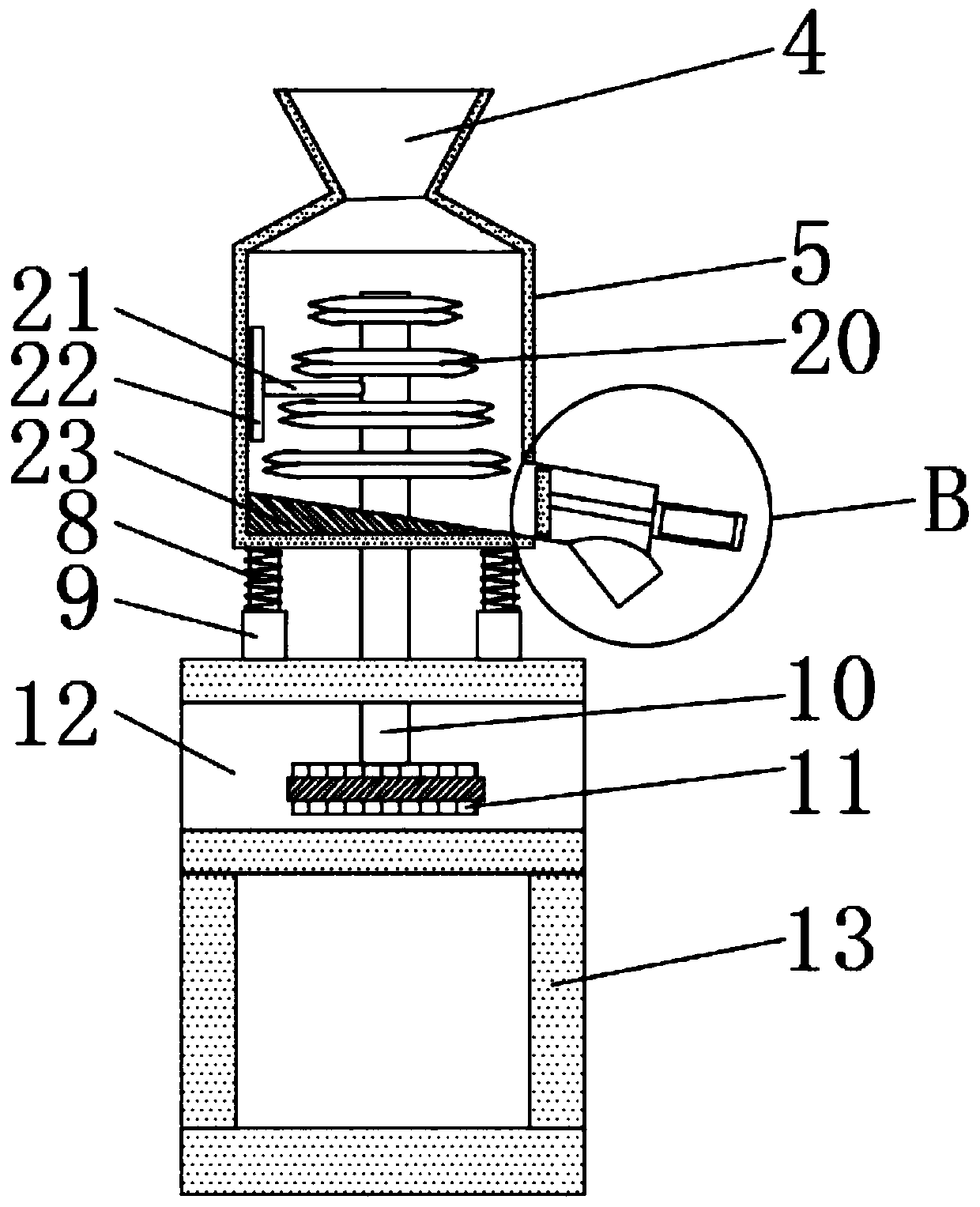

[0047] see Figure 1-5 As shown, the present embodiment is an environmentally friendly coating for the surface maintenance of wooden handicrafts, including the following components by weight: 100 parts of natural vegetable oil, 25 parts of antifouling agent, 5 parts of highly reducing plant extract, 3 parts of water-based fungicide 3 parts, 3 parts of penetrating agent, 1.0 part of crosslinking agent, 0.8 part of antioxidant;

[0048] The preparation method of this environment-friendly coating comprises the following steps:

[0049] S1: After the surface of the wooden handicraft after molding is polished by the sandpaper of 400#, the sandpaper of 1500# is used for grinding, and it is set aside;

[0050] S2: Weigh the raw materials in parts by weight, put the raw materials into a high-efficiency mixer and mix them for 5-10 minutes, and after mixing evenly, an environmentally friendly coating is obtained and set aside;

[0051] S3: Evenly paint the environmentally friendly pai...

Embodiment 2

[0068] see Figure 1-5 As shown, the present embodiment is an environmentally friendly coating for the surface maintenance of wooden handicrafts, comprising the following components by weight: 110 parts of natural vegetable oil, 32 parts of antifouling agent, 12 parts of highly reducing plant extract, 4 parts of water-based fungicide 6 parts, 6 parts of penetrating agent, 1.2 parts of crosslinking agent, 1.2 parts of antioxidant;

[0069] The preparation method of this environment-friendly coating comprises the following steps:

[0070] S1: After the surface of the wooden handicraft after molding is polished by the sandpaper of 400#, the sandpaper of 1500# is used for grinding, and it is set aside;

[0071] S2: Weigh the raw materials in parts by weight, put the raw materials into a high-efficiency mixer and mix them for 5-10 minutes, and after mixing evenly, an environmentally friendly coating is obtained and set aside;

[0072] S3: Evenly paint the environmentally friendly...

Embodiment 3

[0083] see Figure 1-5 As shown, the present embodiment is an environmentally friendly coating for the surface maintenance of wooden handicrafts, comprising the following components in parts by weight: 120 parts of natural vegetable oil, 40 parts of antifouling agent, 20 parts of highly reducing plant extract, 6 parts of water-based fungicide 9 parts, 9 parts of penetrating agent, 1.5 parts of crosslinking agent, 1.6 parts of antioxidant;

[0084] The preparation method of this environment-friendly coating comprises the following steps:

[0085] S1: After the surface of the wooden handicraft after molding is polished by the sandpaper of 400#, the sandpaper of 1500# is used for grinding, and it is set aside;

[0086] S2: Weigh the raw materials in parts by weight, put the raw materials into a high-efficiency mixer and mix them for 5-10 minutes, and after mixing evenly, an environmentally friendly coating is obtained and set aside;

[0087] S3: Evenly paint the environmentally...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com