Multilayer viscose fiber composite spunlace mask base cloth and viscose fiber composite mask

A viscose fiber and spunlace technology, applied in fiber processing, plant fibers, non-woven fabrics, etc., can solve problems such as difficulty in meeting 3D cutting processing requirements, soft and low-strength viscose fiber mask base fabric, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

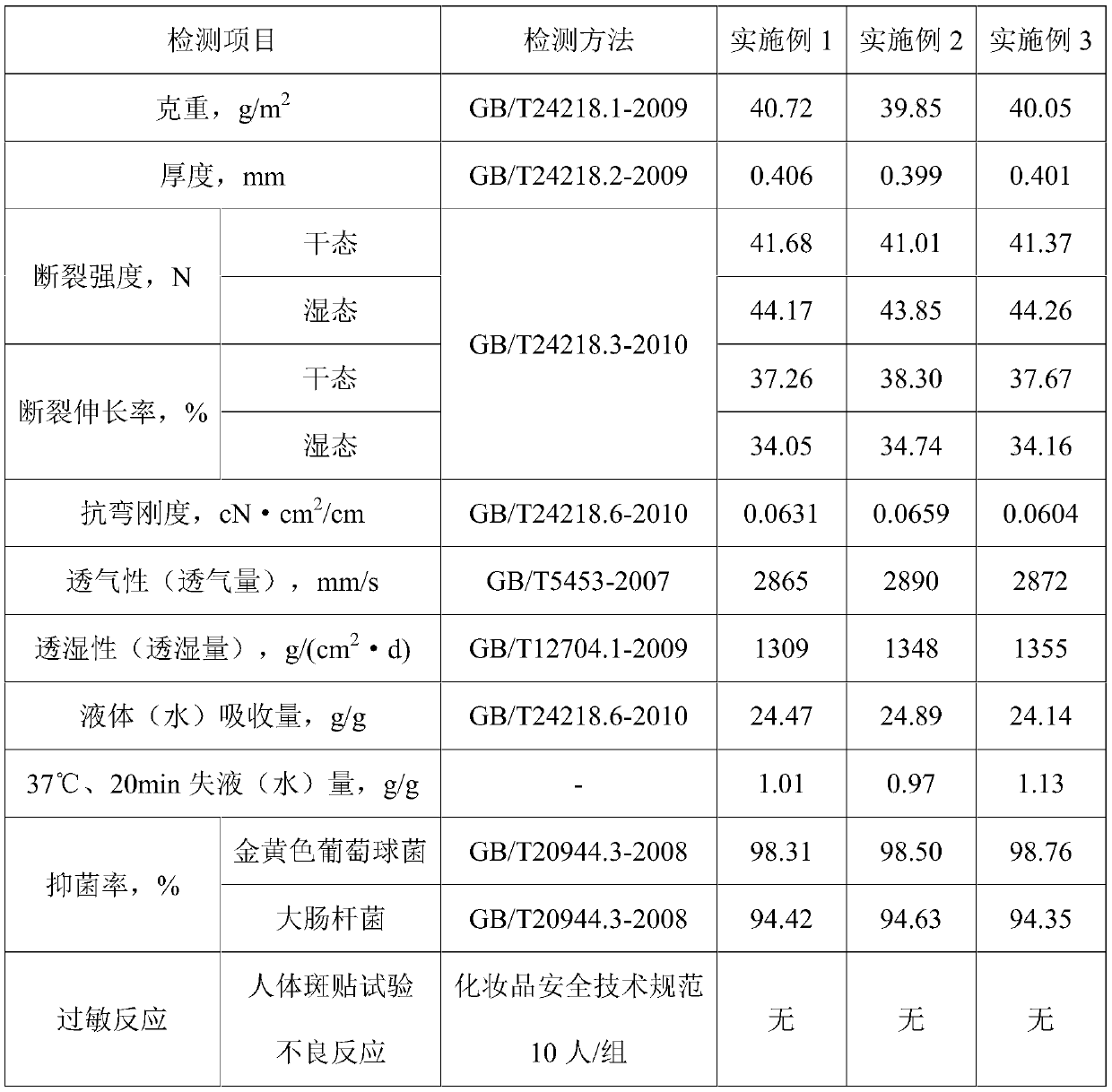

Examples

Embodiment 1

[0036] The multi-layer viscose fiber composite spunlace mask base cloth of the present embodiment is prepared by the following method:

[0037] 1) Cut the raw ramie into small pieces with a length of 30-50 mm, soak in water at a temperature of 55° C. for 60 minutes, then take it out, extrude and dehydrate until the water content is 48%, to obtain a softening material;

[0038] 2) Put the softened material obtained in step 1) into a steam explosion device for steam explosion, the steam temperature is 220°C, the explosion pressure is 2.2MPa, the heat preservation and pressure are maintained for 3.0min, the pressure is released and the material is discharged, and the explosion mixture is obtained;

[0039] 3) Immediately place the blasting mixture obtained in step 2) in water at 55°C for ultrasonic dipping to dissolve the colloid. The ultrasonic frequency is 40kHz, and the ultrasonic dipping time is 1.5h. During the dipping process, the agglomerated fibers are broken up , sorting...

Embodiment 2

[0044] The multi-layer viscose fiber composite spunlace mask base cloth of the present embodiment is prepared by the following method:

[0045] 1) Cut the raw ramie into small sections with a length of 30-50mm, place it in water at a temperature of 60°C and soak it for 40 minutes, then take it out, extrude and dehydrate it until the water content is 48%, to obtain a softened material;

[0046] 2) Put the softened material obtained in step 1) in a steam explosion device for steam explosion, the steam temperature is 230°C, the explosion pressure is 1.8MPa, the heat preservation and pressure are kept for 3.5min, and the pressure is released to obtain the explosion mixture;

[0047] 3) Immediately place the blasting mixture obtained in step 2) in water at 60°C for ultrasonic dipping to dissolve the colloid. The ultrasonic frequency is 30 kHz, and the ultrasonic dipping time is 1.5 hours. During the dipping process, the agglomerated fibers are broken up , sorting and removing the r...

Embodiment 3

[0052] The multi-layer viscose fiber composite spunlace mask base cloth of the present embodiment is prepared by the following method:

[0053] 1) Cut the raw ramie into small sections with a length of 30-50 mm, place it in water at a temperature of 55° C. and soak it for 50 minutes, then take it out, extrude and dehydrate it until the water content is 48%, to obtain a softened material;

[0054] 2) Put the softened material obtained in step 1) in a steam explosion device for steam explosion, the steam temperature is 225°C, the explosion pressure is 2.0MPa, the heat preservation and pressure are maintained for 3.5min, and the pressure is released to obtain the explosion mixture;

[0055] 3) Immediately place the blasting mixture obtained in step 2) in water at 60°C for ultrasonic dipping to dissolve the colloid. The ultrasonic frequency is 40 kHz, and the ultrasonic dipping time is 1.0 h. During the dipping process, the fiber agglomerates are broken up , sorting and removing t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com