Sound-insulation shock-absorption antibacterial coating and preparation method thereof

An antibacterial coating and wood fiber technology, applied in the field of coatings, can solve the problems of poor environmental performance, easy volatility, and poor dispersibility, and achieve the effects of excellent environmental performance, improved dispersibility, and improved weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

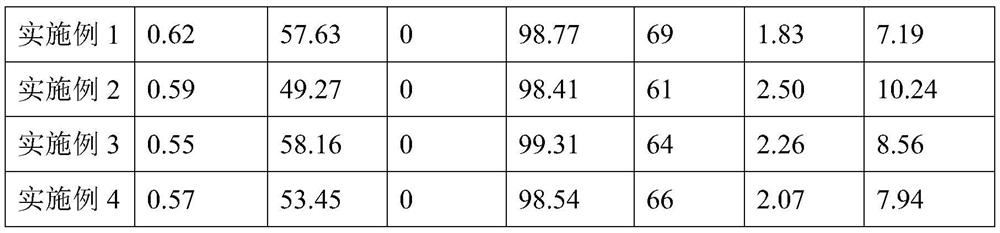

Examples

Embodiment 1

[0028] A sound-insulating, shock-absorbing and antibacterial coating, comprising the following raw materials in parts by weight: 175 parts of cement, 125 parts of Shuangfei powder, 165 parts of wood fiber, 70 parts of sepiolite fiber, 45 parts of basalt fiber, 30 parts of micronized glass beads, hydroxyl 4 parts of propyl methylcellulose, 12 parts of redispersible latex powder, 15 parts of shell, 12 parts of medical stone, 6 parts of nano titanium dioxide, 2.5 parts of trimethylsilyl clathrate polysilsesquioxane, dispersant 4 parts and 2.5 parts of toner. The dispersant is composed of titanate coupling agent, polysiloxane quaternary ammonium salt and maleic rosin octylphenol polyoxyethylene ether diester carboxylate sodium with a mass ratio of 5:2:3.

[0029] Its preparation method comprises the following steps:

[0030] (1) Wooden fiber, sepiolite fiber, basalt fiber, micronized glass beads, shells and medical stone are pulverized to 250 orders respectively;

[0031] (2) Th...

Embodiment 2

[0034] A sound-insulating, shock-absorbing and antibacterial coating, comprising the following raw materials in parts by weight: 150 parts of cement, 138 parts of Shuangfei powder, 150 parts of wood fiber, 60 parts of sepiolite fiber, 35 parts of basalt fiber, 25 parts of micronized glass beads, hydroxyl 3.5 parts of propyl methylcellulose, 10 parts of redispersible latex powder, 12 parts of shell, 18 parts of medical stone, 8 parts of nano-titanium dioxide, 1.5 parts of trimethylsilyl clathrate polysilsesquioxane, dispersant 3.5 parts and toner 2.8 parts. The dispersant is composed of titanate coupling agent, polysiloxane quaternary ammonium salt and maleic rosin octylphenol polyoxyethylene ether diester carboxylate sodium with a mass ratio of 4:2:1.

[0035] Its preparation method comprises the following steps:

[0036] (1) Wooden fiber, sepiolite fiber, basalt fiber, micronized glass beads, shells and medical stone are pulverized to 200 orders respectively;

[0037] (2) T...

Embodiment 3

[0040] A sound-insulating, shock-absorbing and antibacterial coating, comprising the following raw materials in parts by weight: 170 parts of cement, 130 parts of Shuangfei powder, 145 parts of wood fiber, 65 parts of sepiolite fiber, 50 parts of basalt fiber, 30 parts of micronized glass beads, hydroxyl 4 parts of propyl methylcellulose, 10 parts of redispersible latex powder, 15 parts of shell, 15 parts of medical stone, 7 parts of nano-titanium dioxide, 3 parts of trimethylsilyl clathrate polysilsesquioxane, dispersant 4.5 parts and 3.2 parts of toner. The dispersant is composed of titanate coupling agent, polysiloxane quaternary ammonium salt and maleic rosin octylphenol polyoxyethylene ether diester carboxylate sodium with a mass ratio of 6:3:1.

[0041] Its preparation method comprises the following steps:

[0042] (1) Wooden fiber, sepiolite fiber, basalt fiber, micronized glass beads, shells and medical stone are pulverized to 250 orders respectively;

[0043] (2) Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com