Preparing method of antibacterial and bacteriostatic fabric

A technology of fabric and yarn, which is applied in the field of preparation of antibacterial and antibacterial fabrics, can solve the problems of harming human health, increasing pollution emission, energy consumption, heavy metal non-degradable pollution of the environment, etc., and achieves good antibacterial and antibacterial effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

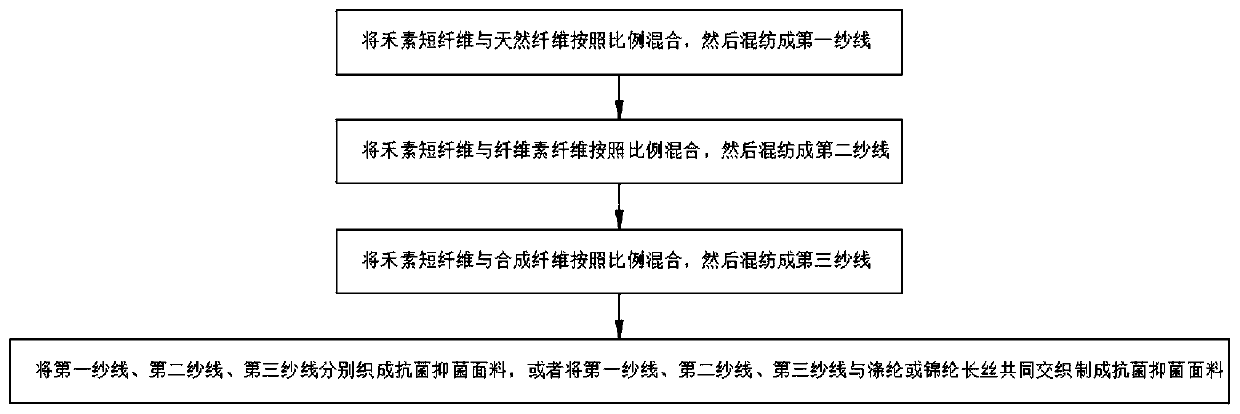

[0031] refer to figure 1 , a preparation method of antibacterial antibacterial fabric, the method comprises the following steps:

[0032] S1. mixing grass fiber and natural fiber in proportion, and then blending into the first yarn;

[0033] S2. mixing grass fiber and cellulose fiber in proportion, and then blending into the second yarn;

[0034] S3. mixing grass fiber and synthetic fiber in proportion, and then blending into the third yarn;

[0035] S4. Weave the first yarn, the second yarn, and the third yarn into antibacterial and antibacterial fabrics respectively, or interweave the first yarn, the second yarn, and the third yarn with polyester or nylon filaments into antibacterial and antibacterial fabrics.

[0036] When the grass fiber is mixed with the natural fiber, the proportion of the grass fiber is 20%-60%, when the grass fiber is mixed with the cellulose fiber, the proportion of the grass fiber is 20%-60%. When the fibers are mixed, the proportion of grass fib...

Embodiment 2

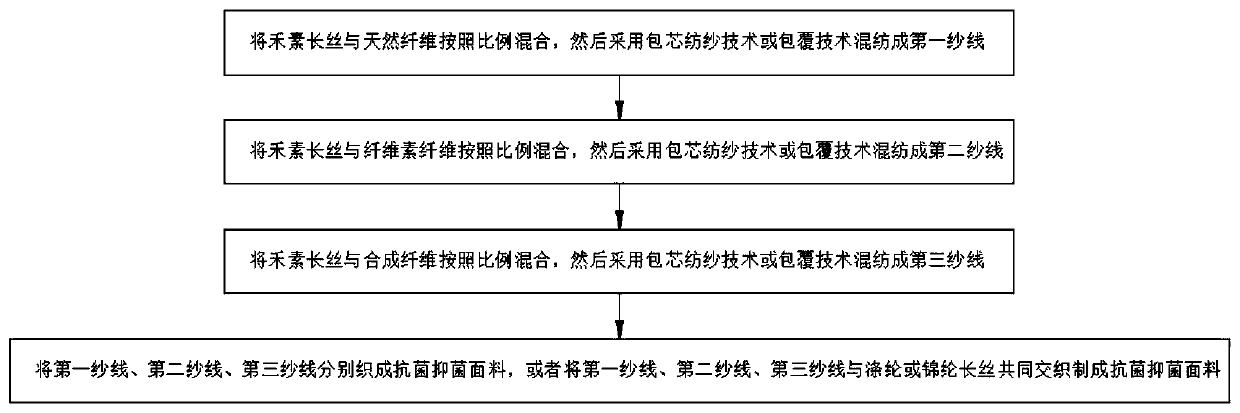

[0038] refer to figure 2 , a preparation method of antibacterial antibacterial fabric, the method comprises the following steps:

[0039] S1. mixing grass filaments with natural fibers in proportion, and then blending into the first yarn by core spinning technology or covering technology;

[0040] S2. mixing grass filaments and cellulose fibers in proportion, and then blending them into second yarns using core spinning technology or covering technology;

[0041] S3. mixing grass filaments and synthetic fibers in proportion, and then blending into a third yarn by core spinning technology or covering technology;

[0042] S4. Weave the first yarn, the second yarn, and the third yarn into antibacterial and antibacterial fabrics respectively, or interweave the first yarn, the second yarn, and the third yarn with polyester or nylon filaments into antibacterial and antibacterial fabrics.

[0043] When the grass filaments are mixed with natural fibers, the proportion of grass fila...

Embodiment 3

[0045] A preparation method of antibacterial and antibacterial fabric, the method is:

[0046] Antibacterial and antibacterial fabrics are formed by directly interweaving graminoid filaments with viscose filaments, polyester filaments or nylon filaments in proportion.

[0047] When the grass filament is mixed with viscose filament or polyester filament or nylon filament, the proportion of grass filament is 20%-60%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com