Preparation method of high-performance mesoporous silica-chitosan composite antibacterial filter

A technology of mesoporous silica and chitosan, which is applied in chemical instruments and methods, filtration and separation, membrane filters, etc., can solve the problems of low ability to prevent solid particles and cumbersome preparation, and achieve good results and simple reaction system , The effect of mild reaction and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

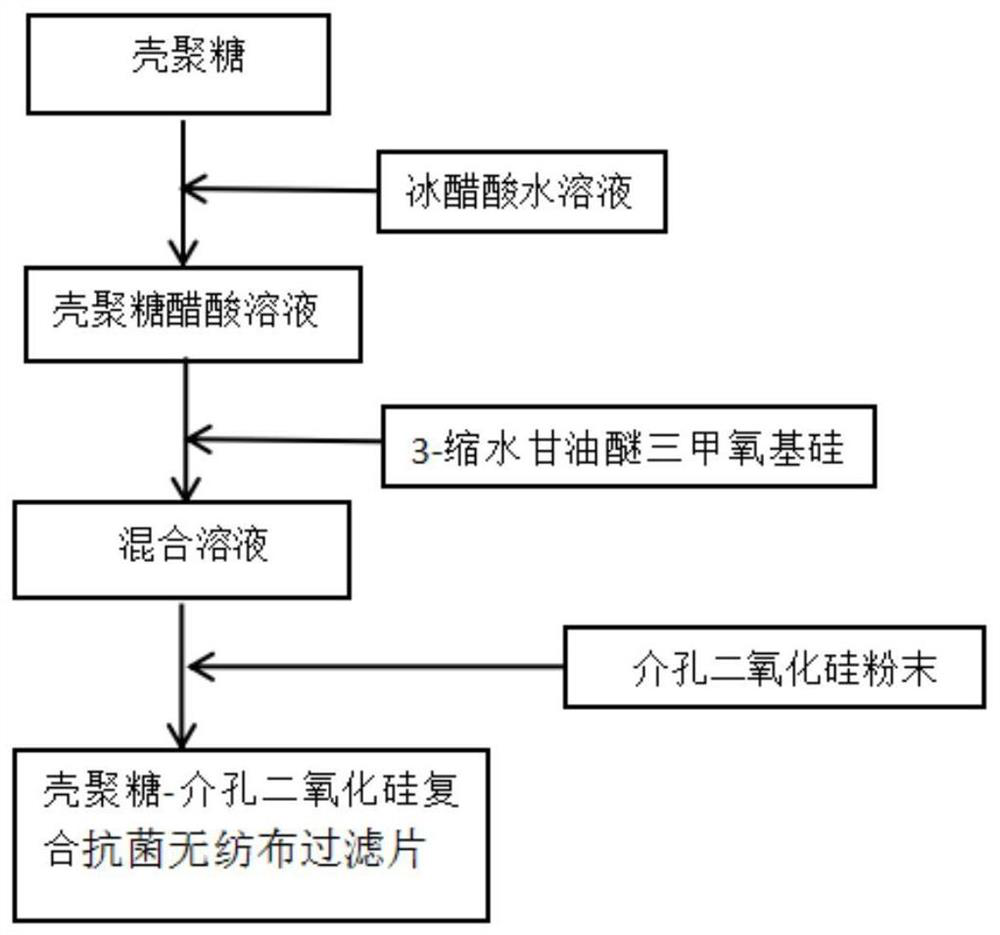

Method used

Image

Examples

Embodiment 1

[0037] Dissolve 150mg of the template agent cetyltrimethylammonium bromide (abbreviation: CTAB) in 15ml of ultrapure water, stir and mix in the reaction kettle, and at the same time, control the temperature at 40°C to dissolve it, and dissolve 5mL of NaOH Add 4.0mL of the template additive ethyl acetate (abbreviation: EtOAC) dropwise into the CTAB solution, and after stirring at a constant speed for 5min, add 1.0mL of the silicon oxide precursor orthosilicate (abbreviation: TEOS) to the mixed solution. During the stirring process, the mixed solution changed from colorless and transparent to a milky white solution. After continuous stirring for 24 hours, the solution was transferred to a centrifuge for centrifugation at a speed of 6000r / min. After centrifugation for 10 minutes, the supernatant suspension was removed to obtain a solid white precipitate.

[0038] Add 50ml of absolute ethanol to the obtained solid white precipitate and sonicate for 8 minutes, centrifuge at a speed...

Embodiment 2

[0041] Dissolve 100mg of template agent CTAB in 15ml of ultrapure water, stir and mix in the reaction kettle, and at the same time, control the temperature at 45°C to dissolve it, add 2mL of ammonia water and 3.0mL of template aid EtOAC to the CTAB solution dropwise , after stirring at a constant speed for 5 minutes, add 0.5 mL of silicon oxide precursor TEOS to the mixed solution. During the stirring process, the mixed solution turns from colorless and transparent to a milky white solution. After continuous stirring for 24 hours, the solution is transferred to a centrifuge for further Centrifuge at a speed of 6000r / min. After centrifuging for 10 minutes, remove the supernatant suspension to obtain a solid white precipitate.

[0042] Add 50ml of absolute ethanol to the obtained solid white precipitate and sonicate for 5 minutes, centrifuge at a speed of 4000r / min for 3 minutes, dry the white precipitate obtained by centrifugation at 75-85°C to obtain mesoporous silica powder. ...

Embodiment 3

[0045] Firstly, mix 2% glacial acetic acid aqueous solution with chitosan to prepare chitosan-acetic acid solution with 0.5% mass fraction. Get 50ml of chitosan-acetic acid solution and 2ml of 3-glycidyl ether trimethoxysilane and mix, after stirring overnight, get the white powdery mesoporous silica powder prepared in Example 1 and add in the overnight liquid, stir and centrifuge, Then use ultrapure water to wash, and finally obtain the chitosan-mesoporous silica composite material. Wherein, the mass ratio of chitosan to mesoporous silica is 5:0.08.

[0046] Cut the non-woven fabric into a size of 40cm×30cm, prepare the prepared chitosan-mesoporous silica composite solution with a concentration of 100g / L, impregnate the chitosan-mesoporous silica composite solution and the non-woven fabric Composite, pre-bake the composite sample at 50°C for 3 minutes, bake at 120°C for 3 minutes, put the sample under a 3kw ultraviolet high-pressure mercury lamp for 20s, and cure the sample ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com