Nano cuprous oxide/copper oxide/silver oxide-containing emulsion for non-woven fabric and application of emulsion

A technology of nano-cuprous oxide and copper oxide, which is applied in textiles and papermaking, and can solve the problems of high proportion of silver nanoparticles, high cost, and poor compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

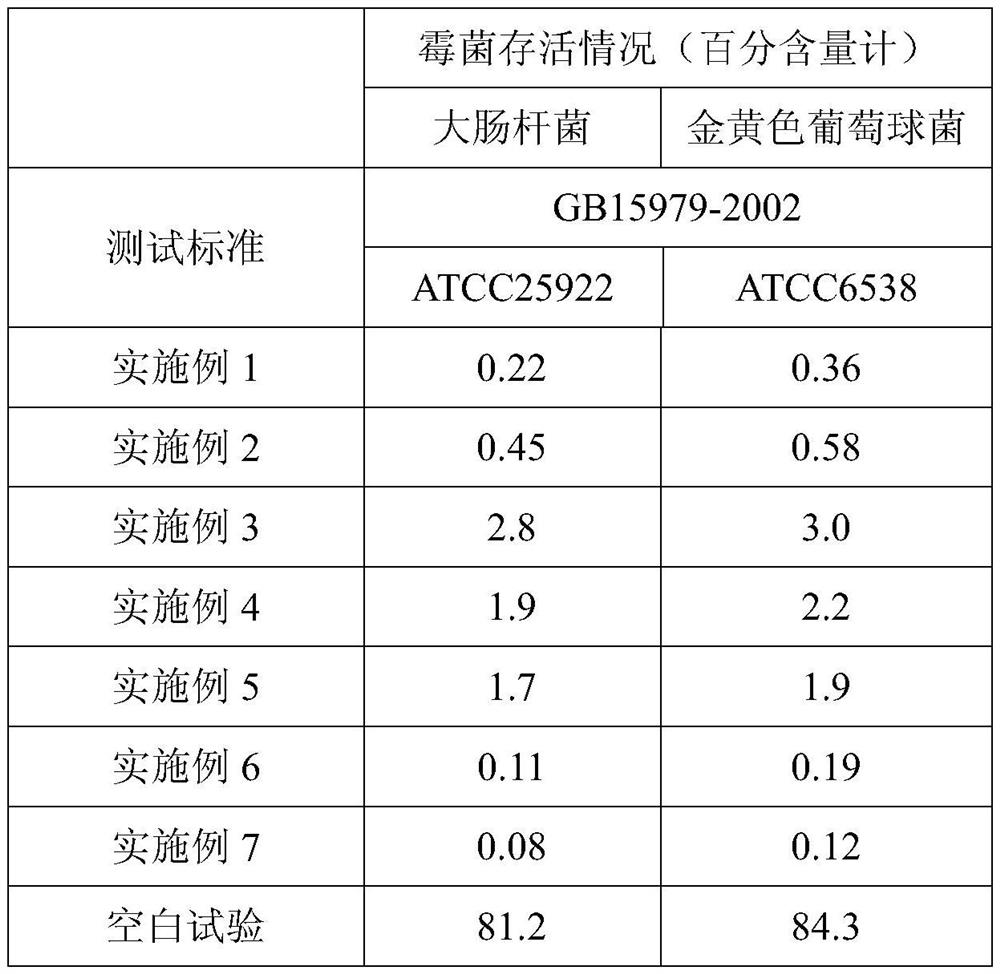

Examples

Embodiment 1

[0031] Add ethanol solution 100g to the batching tank, then add the following materials: nano cuprous oxide / copper oxide (nano cuprous oxide 20.3g, nano copper oxide 2g) (50-80nm), epoxy resin ( Jiangsu Sanmu E44) 16.2g, butyl acrylate (Jiangsu Sanmu) 6.2g, hydroxymethyl cellulose (Hebei Renqiu Jinyu Chemical Co., Ltd.) 3.6g, sodium lignosulfonate (Shanghai Tingruo Chemical Co., Ltd.) 0.3 g, polycarboxylate (Dongguan Rongxie Chemical Materials Co., Ltd. RX-504) 0.3g, biuret polyisocyanate (Wanhua Chemical HB-100) 0.1g, N-dodecyldimethylamine 0.3g, azobisisobutyronitrile 0.1g, after the addition is complete, use a high-speed shearer to stir at a high speed of 4800-5000r / min for 50min, stop stirring, and use the emulsion for later use .

[0032] Spread the non-woven fabric on the metal plate, spray the emulsion on the surface of the non-woven fabric at a rate of 1.5g per square meter with a spray gun, let it stand for 2 minutes, and place it together with the metal plate in an...

Embodiment 2

[0034] Add ethanol solution 100g to the batching tank, then add the following materials: nano-cuprous oxide / copper oxide (nano-cuprous oxide 26.3g, nano-cupric oxide 4g) (50-80nm), epoxy resin ( Jiangsu Sanmu E51) 12.2g, hydroxypropyl acrylate (Jiangsu Sanmu) 5.2g, polyvinyl alcohol (Shanghai Petrochemical PVA088-20) 2.6g, fatty amine polyoxyethylene ether (Jiangsu Haian Petrochemical AC-1800) 0.3g, tea soap Su (Wenzhou Shoucheng Chemical Technology Co., Ltd.) 0.3g, amino-terminated epoxy amine adduct (Xi'an Qiyue Biotechnology Co., Ltd. HBP-NH2) 0.1g, benzoyl peroxide (Jiangyin Wanqian Chemical) 0.1g, After the addition is complete, use a high-speed shearer to stir at a high speed of 4800-5000r / min for 50 minutes, stop stirring, and use the emulsion for later use.

[0035] Spread the non-woven fabric on the metal plate, spray the emulsion on the surface of the non-woven fabric at a rate of 1g per square meter with a spray gun, let it stand for 2 minutes, and put it in an oven...

Embodiment 3

[0037] Add 100 g of ethanol solution to the batching tank, then add the following materials: nano-cuprous oxide / copper oxide (nano-cuprous oxide 10.3 g, nano-cuprous oxide 1.8 g) (50-80 nm), epoxy resin containing 12.1 grams of active ingredients (Polyethylene glycol diglycidyl ether, Anhui Xinyuan Technology Co., Ltd. XY215) 22.2, polyether polyurethane acrylate (Kaiphos Ruiyang RY2201) 8.2g, polyethylene glycol (Jiangsu Haian Petrochemical PEG1000) 3.6g, Fatty amide polyoxyethylene ether (Jiangsu Haian Petrochemical AC-1200) 0.3g, polyethylene sulfonate (Shanghai Guduo Biotechnology Co., Ltd.) 0.3g, xanthan gum (Hubei Zijingyuan Biotechnology Co., Ltd.) 0.1g, HDI trimer (Wanhua Chemical HT-100) 0.1g, benzoyl peroxide (Jiangyin Wanqian Chemical) 0.1g / N, N-diethylaniline 0.1g, stir with a high-speed shearer at a high speed of 4800-5000r / min for 50min after adding, stop Stir and set aside the emulsion.

[0038] Spread the non-woven fabric on the metal plate, spray the emulsi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com