Low viscosity edible antibacterial water-based ink and preparation method thereof

A water-based ink, low-viscosity technology, used in the preparation of low-viscosity edible antibacterial water-based ink, low-viscosity edible antibacterial water-based ink, can solve the problem that the dispersed particle size cannot reach the nano-level, food safety protection effect, The inkjet quality is not good enough to achieve good antibacterial and bacteriostatic properties, significantly inhibit spoilage bacteria, and improve liver and cardiopulmonary function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

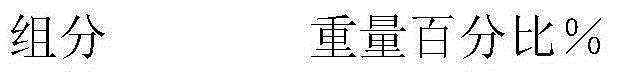

[0038] A kind of low-viscosity edible antibacterial water-based ink, comprises the component of following percentage by weight:

[0039]

[0040] Wherein the mass percentage concentration of vitamin C is 5.24%, and the volume percentage of edible alcohol is 25%.

[0041] The preparation method of above-mentioned low-viscosity edible antibacterial water-based ink, comprises the steps:

[0042] 1) Weigh natural gardenia blue pigment, deionized water, vitamin C powder, chitosan oligosaccharide, edible alcohol and isopropanol according to the above ratio;

[0043] 2) Add vitamin C powder into deionized water, stir evenly, and prepare a vitamin C solution, then add edible alcohol and isopropanol into the vitamin C solution, stir for 20 minutes with a magnetic stirrer at a speed of 10000r / min, and make edible Mix alcohol, isopropanol and vitamin C solution evenly to obtain mixed solution A;

[0044] 3) Add the chitosan oligosaccharide into the mixed solution A, stir it with a m...

Embodiment 2

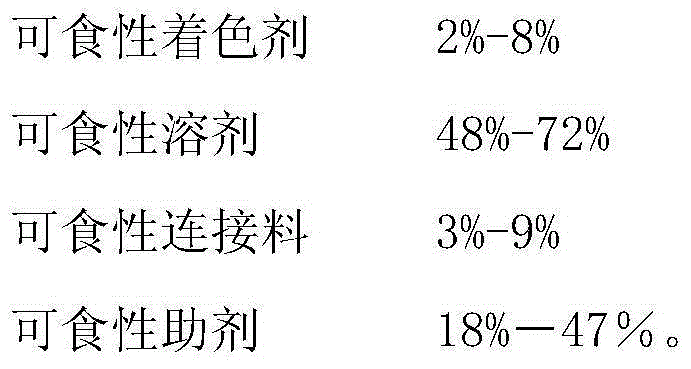

[0052]A kind of low-viscosity edible antibacterial water-based ink, comprises the component of following percentage by weight:

[0053]

[0054] Wherein the mass percentage concentration of glucose is 8.06%, and the volume percentage of edible alcohol is 20%.

[0055] The preparation method of above-mentioned low-viscosity edible antibacterial water-based ink, comprises the steps:

[0056] 1) Take by weighing natural gardenia blue pigment, deionized water, glucose powder, chitosan oligosaccharide, edible alcohol and isopropanol according to the above ratio;

[0057] 2) Add glucose powder into deionized water, stir evenly, and prepare a glucose solution, then add edible alcohol and isopropanol to the glucose solution, stir with a magnetic stirrer for 20 minutes, and the rotating speed is 10000r / min, so that the edible alcohol, isopropanol Mix propanol and glucose solution evenly to obtain mixed solution A;

[0058] 3) Add the chitosan oligosaccharide into the mixed solutio...

Embodiment 3

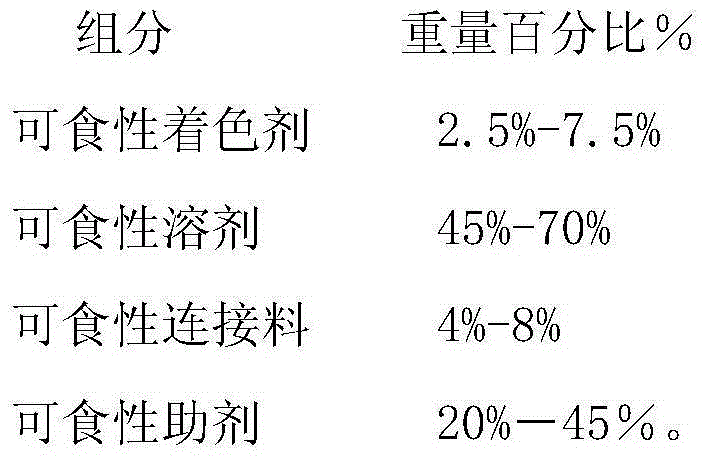

[0067] A kind of low-viscosity edible antibacterial water-based ink, comprises the component of following percentage by weight:

[0068]

[0069] Wherein the mass percentage concentration of vitamin C is 5.36%, and the volume percentage of edible alcohol is 27%.

[0070] The preparation method of above-mentioned low-viscosity edible antibacterial water-based ink, comprises the steps:

[0071] 1) Take by weighing natural gardenia yellow pigment, deionized water, vitamin C powder, chitosan oligosaccharide and edible alcohol according to the above ratio;

[0072] 2) Add vitamin C powder into deionized water, stir evenly, and prepare a vitamin C solution, then add edible alcohol into the vitamin C solution, and stir for 20 minutes with a magnetic stirrer at a speed of 10000r / min to make edible alcohol and vitamin C The solutions are mixed evenly to obtain mixed solution A;

[0073] 3) Add the chitosan oligosaccharide into the mixed solution A, stir it with a magnetic stirrer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com