Staple-fiber corn-spun filament yarn containing natural plant antibacterial components, shirt fabric, and production method of shirt fabric

An antibacterial ingredient, natural plant technology, applied in yarns, fabrics, protective clothing, etc., can solve the problems of poor wear resistance, no wear resistance, easy to pilling, etc., achieve excellent strength, excellent antibacterial and bacteriostatic properties, and meet health needs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

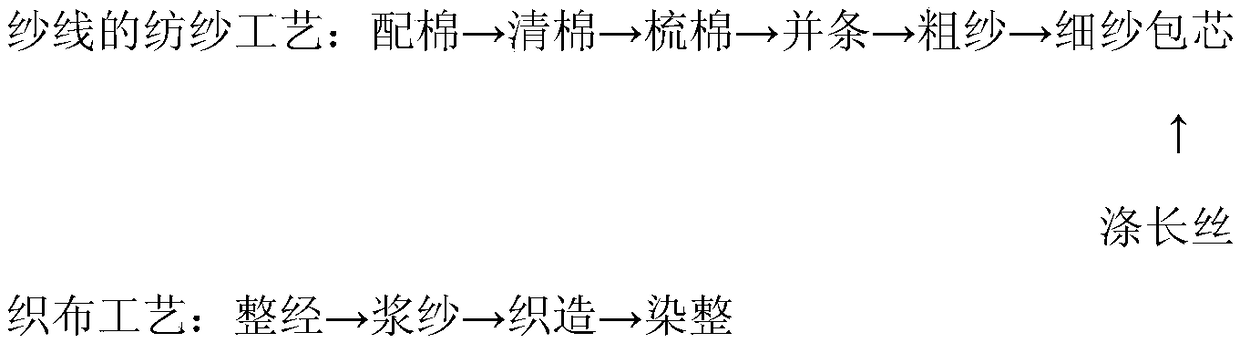

Method used

Image

Examples

Embodiment 1

[0035] The bamboo fiber core-spun classic grid yarn-dyed jacquard shirt fabric containing natural plant antibacterial components of the present invention has a specification of 32 pieces of Aviary fiber core-spun polyester filament 30D+stock solution dyed bamboo fiber 32 pieces (color number a) of warp combing, and the ratio 21:2, weft combed 32 Aviary core-spun polyester filament 30D + stock solution dyed bamboo fiber 32 (color number b), the ratio is 23:2. The warp yarn density is 100 threads / inch, and the weft thread density is 80 threads / inch. The used weave is plain ground jacquard weave A.

[0036] The Aiwei fiber is bamboo fiber containing wormwood extract, wherein the weight ratio of the wormwood extract in the Aiwei antibacterial fiber is 10%, and the Aiwei fiber is made by adding the wormwood extract to the bamboo fiber spinning solution It is prepared by spinning and forming, and the specification of the Aiwei antibacterial fiber is 1.56dtex×38mm.

[0037] Routing...

Embodiment 2

[0053] The bamboo fiber core-spun classic stripe yarn-dyed jacquard shirt fabric containing natural plant antibacterial components of the present invention has a specification of 32 bamboo fiber core-spun polyester filaments 30D+stock solution dyed bamboo fibers (color) of warp combed 32 No. a), the ratio is 21:2; the weft yarn is combed with 32 counts of bamboo fiber core-spun polyester filament 30D containing natural plant antibacterial ingredients. The warp yarn density is 100 threads / inch, and the weft thread density is 80 threads / inch. The used weave is plain ground jacquard weave B.

[0054] The difference between this embodiment and embodiment 1 is:

[0055] Weaving process: take out the dope dyed bamboo fiber in the weft direction, adopt jacquard weave B, and other process parameters are the same as Example 1.

[0056] Spinning process, dyeing and finishing process parameters are the same as example 1.

Embodiment 3

[0058] The bamboo fiber core-spun classic lattice jacquard shirt fabric containing natural plant antibacterial components of the present invention has a specification of 32 pieces of bamboo fiber core-spun polyester filament 30D containing natural plant antibacterial components combed in the warp and 32 pieces of combed weft yarns containing natural plant antibacterial components Composition of bamboo fiber core-spun polyester filament 30D. The warp yarn density is 92 threads / inch and the weft thread density is 80 threads / inch. The used weave is plain ground jacquard weave A.

[0059] The difference between this embodiment and embodiment 1 is:

[0060] Weaving process: warp and weft direction stock solution dyed bamboo fiber is drawn out, and other process parameters are the same as example 1.

[0061] Spinning process, dyeing and finishing process parameters are the same as example 1.

PUM

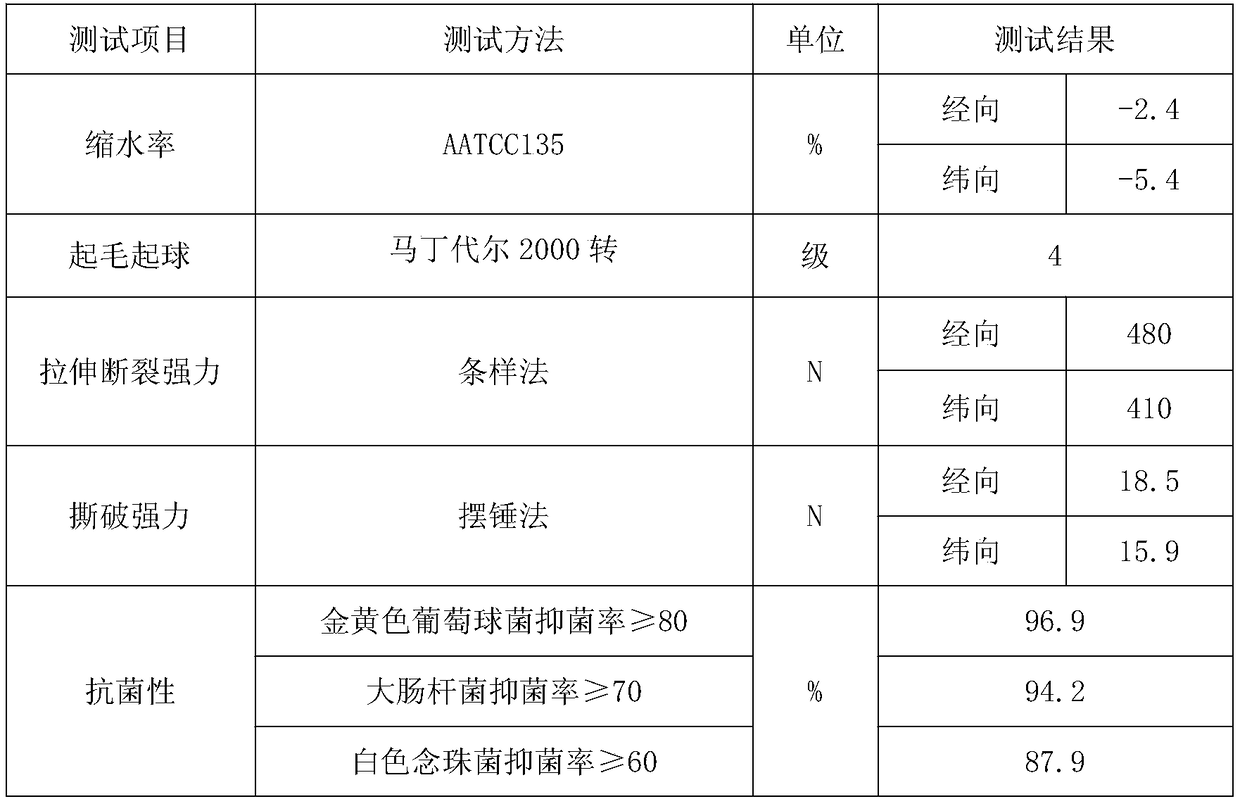

| Property | Measurement | Unit |

|---|---|---|

| antibacterial rate | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com