Special tool clamp for wind driven generator one-piece bearing pedestal casting and machining technology

A technology of wind power generators and fixtures, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., and can solve problems such as difficult to guarantee accuracy, many turning times, unstable quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

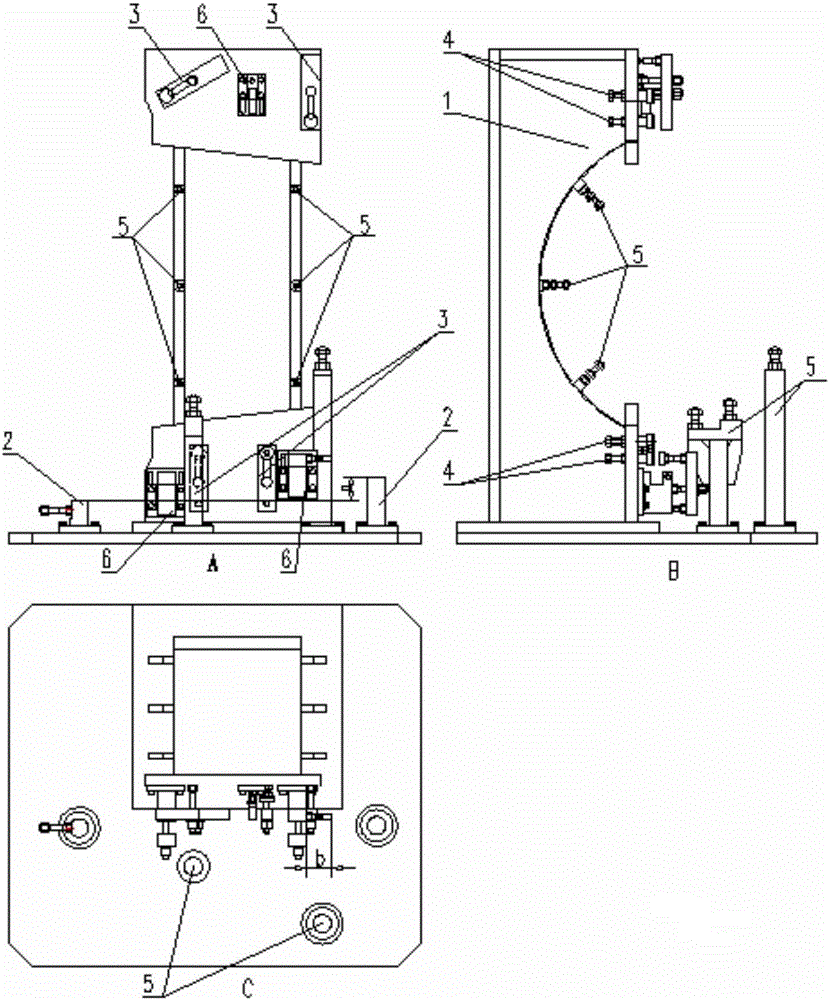

[0040] Disclosed is a special tooling and fixture for castings of one-piece bearing housings of wind power generators, comprising a box body 1, a positioning device 2, a pressing device 3, an adjusting device 4, and a supporting device 5.

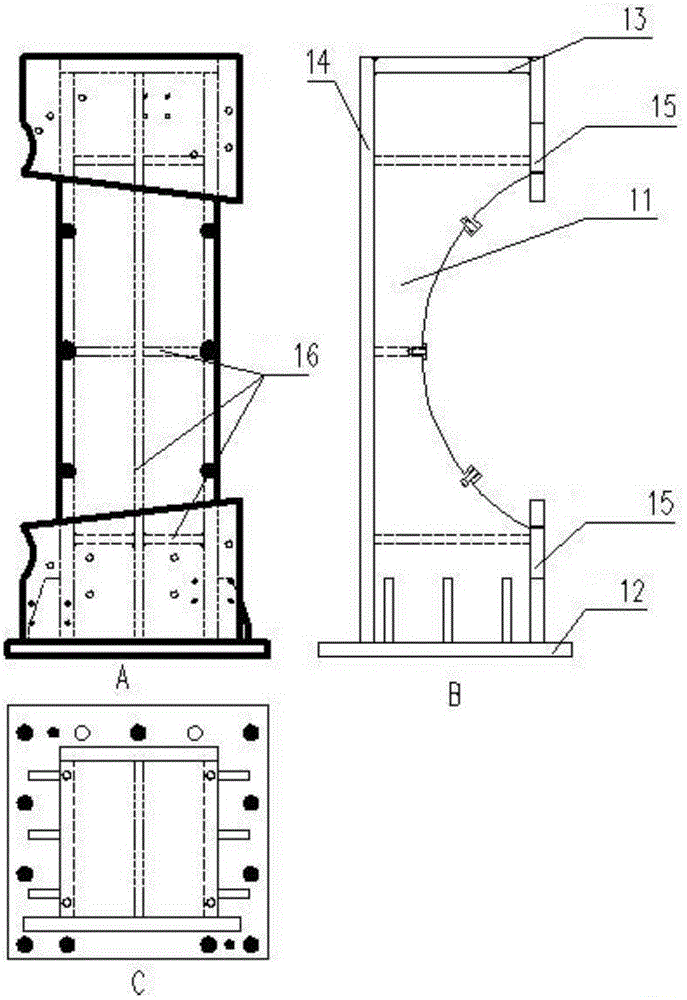

[0041]Among them, the box body 1 is welded by the steel plate of 45 materials, and the box body 1 is composed of two semicircular arc-shaped side panels 11, a bottom panel 12, a top panel 13, a rear wall panel 14, and two symmetrical upper and lower front wall panels 15. And some bracing ribs 16 form in the middle. After welding, the bottom surface and the front wall are required to be processed, the two sides are required to be vertical, the bottom plate is drilled, and it is positioned and connected with the machine tool workbench to achieve the function of fixing the fixture (such as figure 2 ).

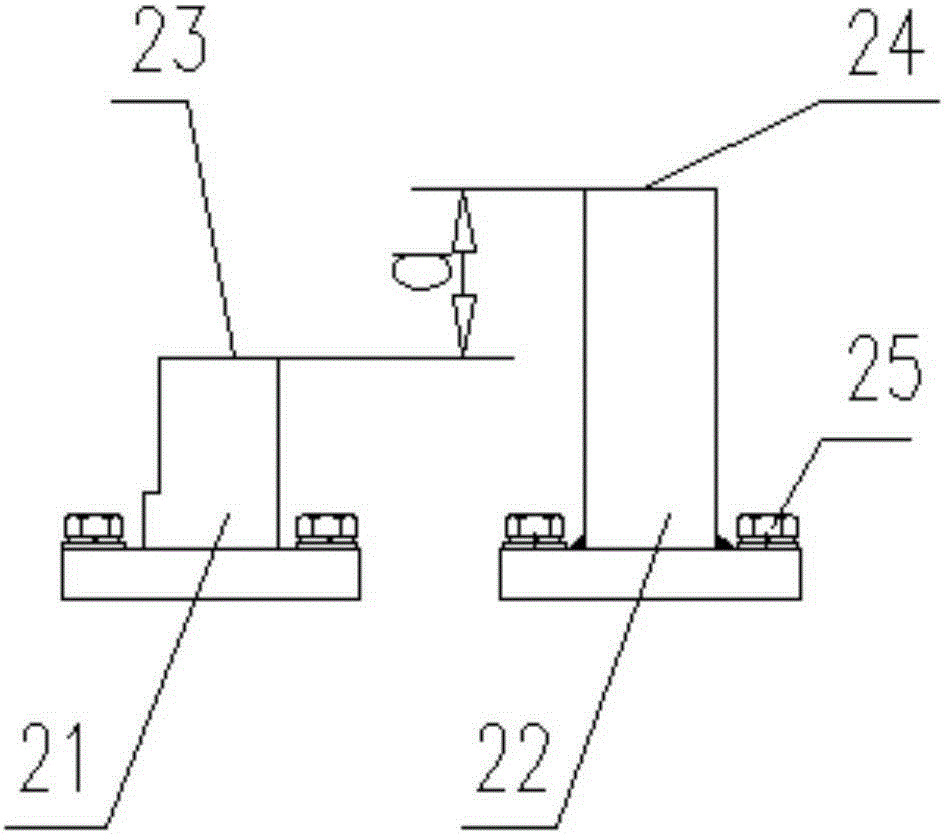

[0042] The positioning device 2 is composed of a positioning seat I21 and a positioning seat II22. There is a positioning surface I23 on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com