Patents

Literature

50results about How to "Achieve machining accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

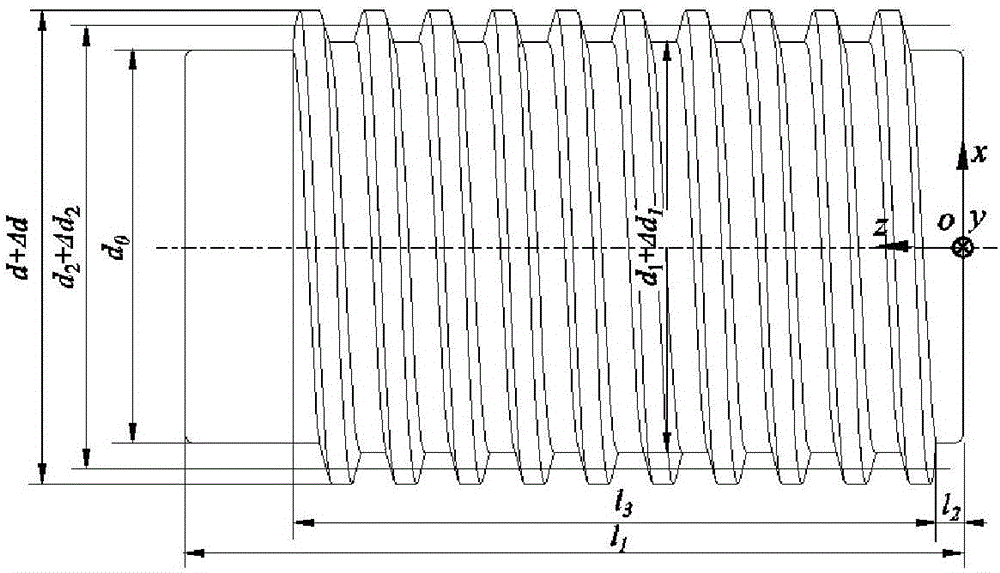

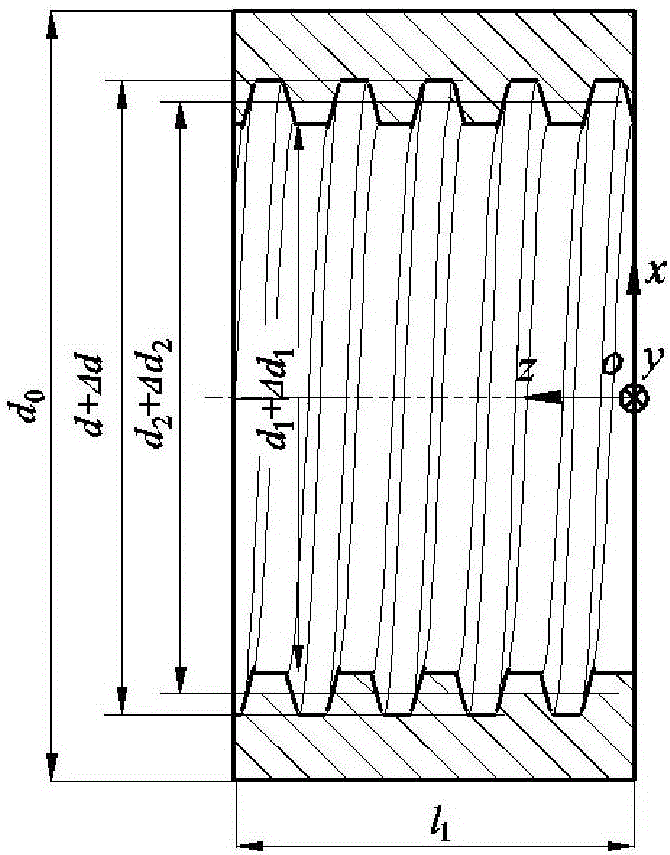

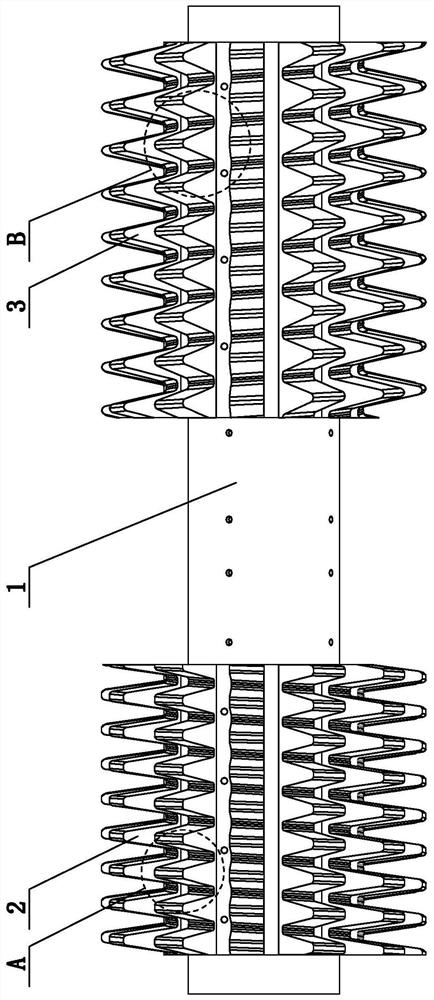

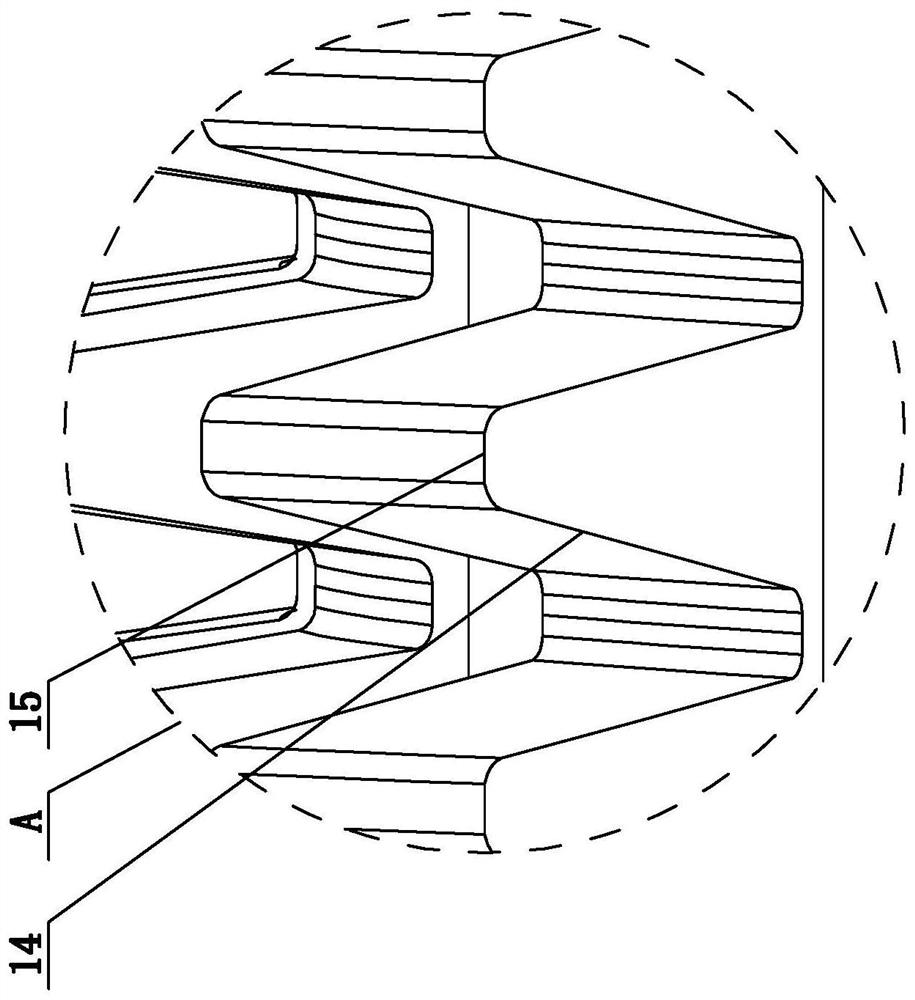

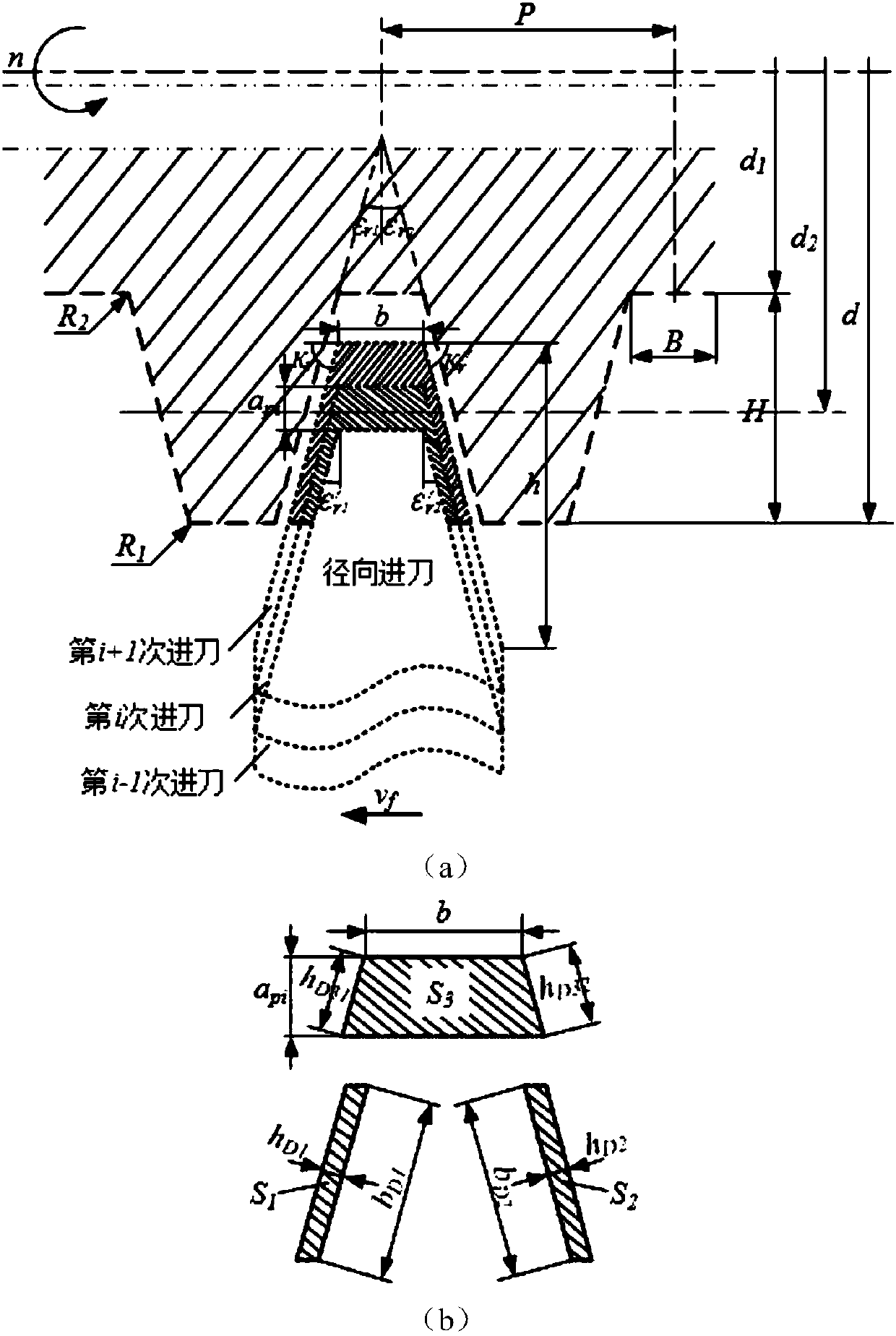

Coarse-pitch external thread layered turning process

InactiveCN105537695AImprove rough machining efficiencyReduce geometric errors in rough machiningThread cutting machinesTurning toolsEngineeringMachining process

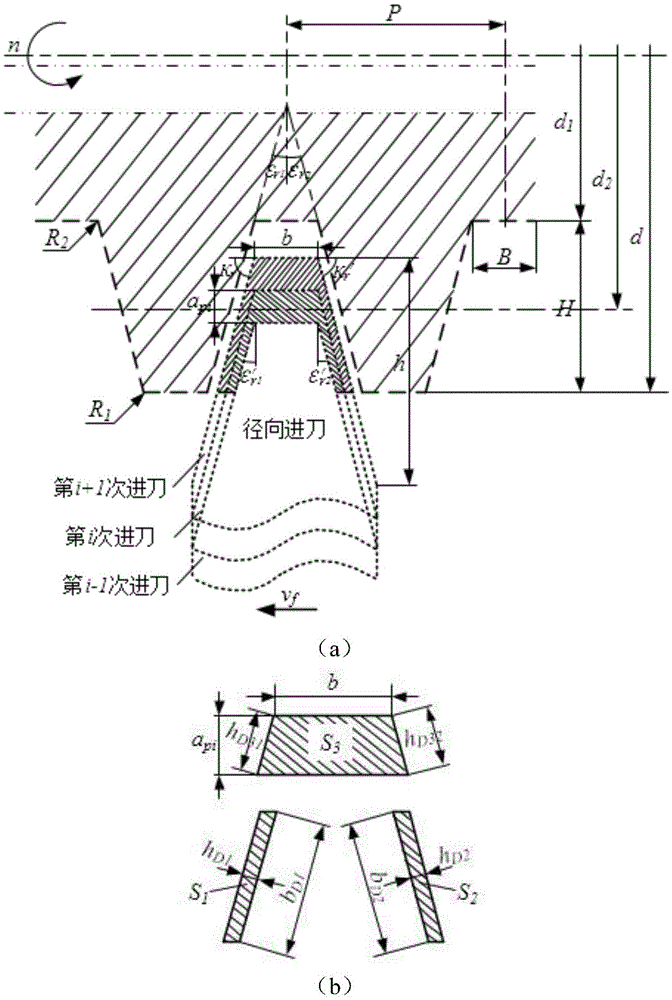

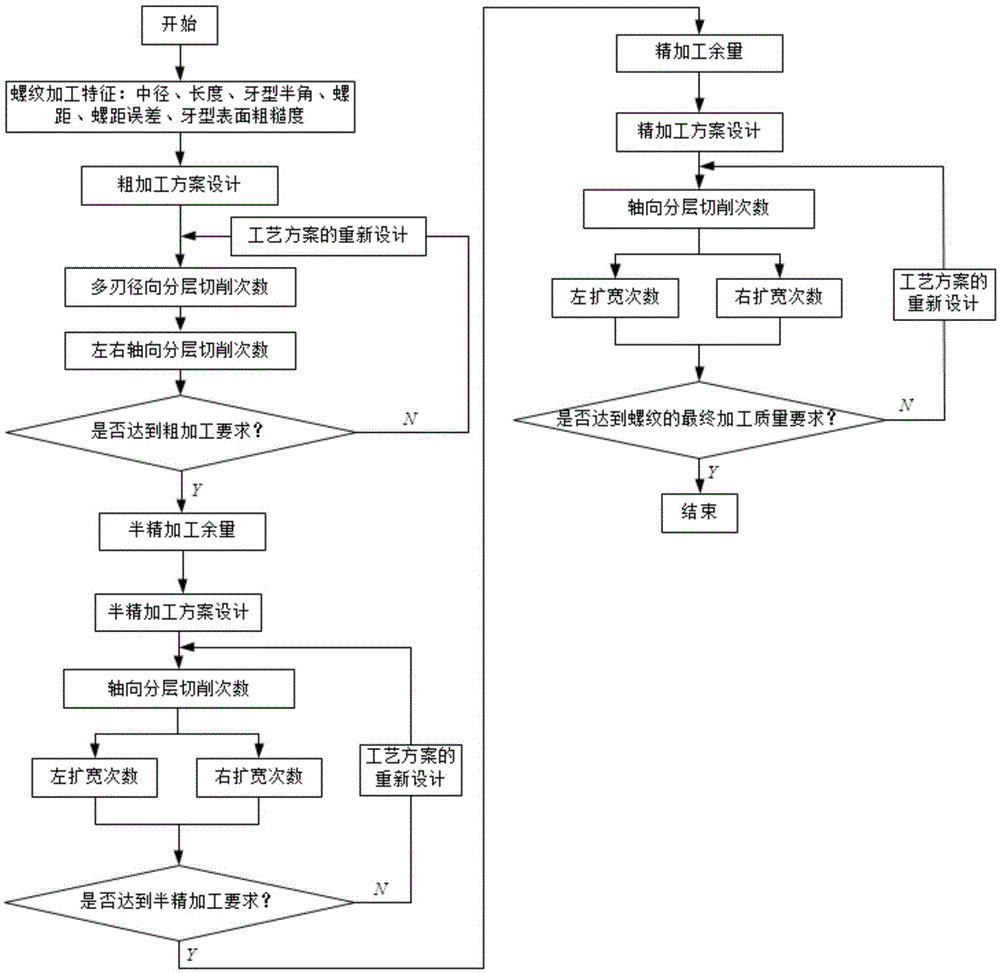

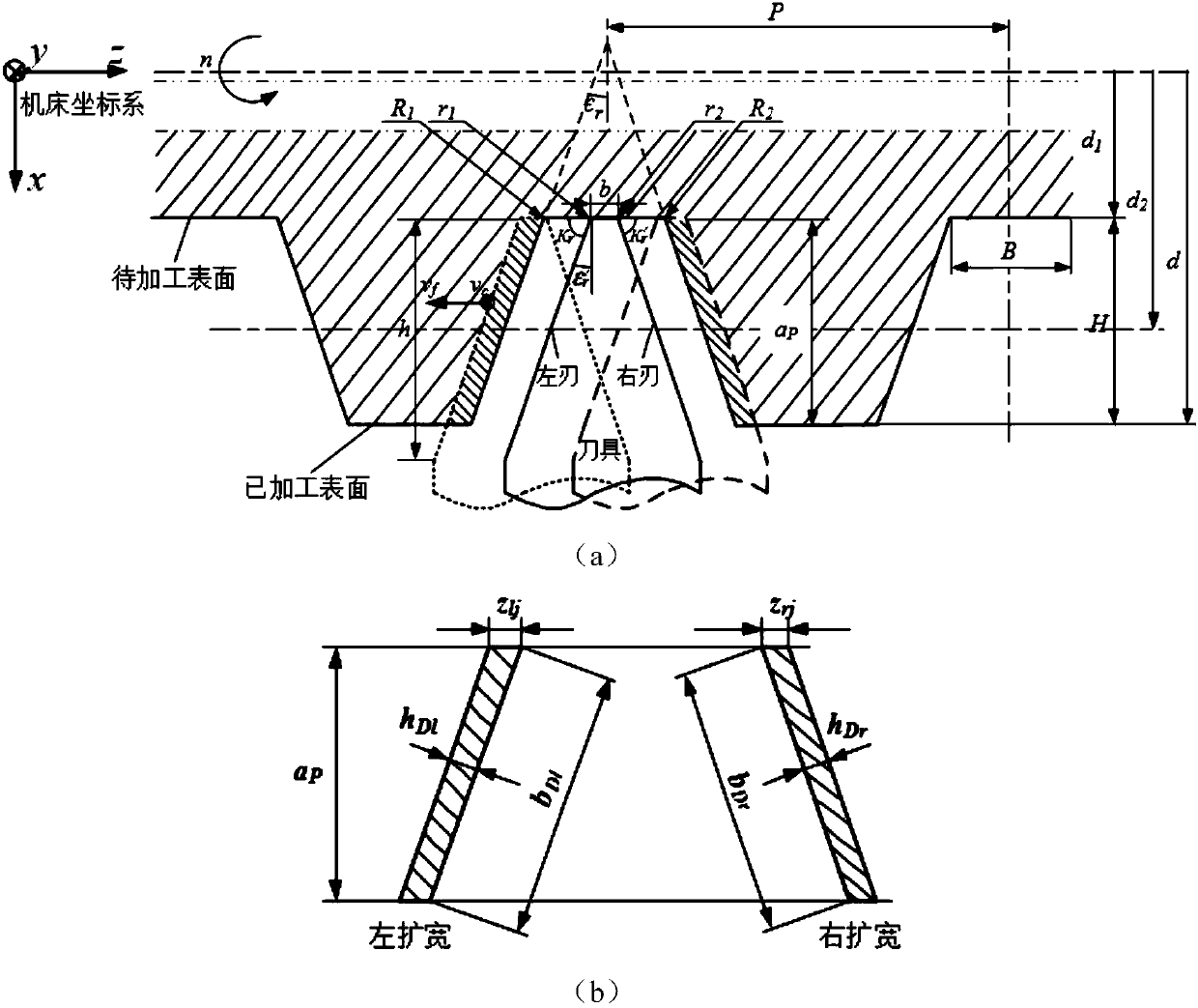

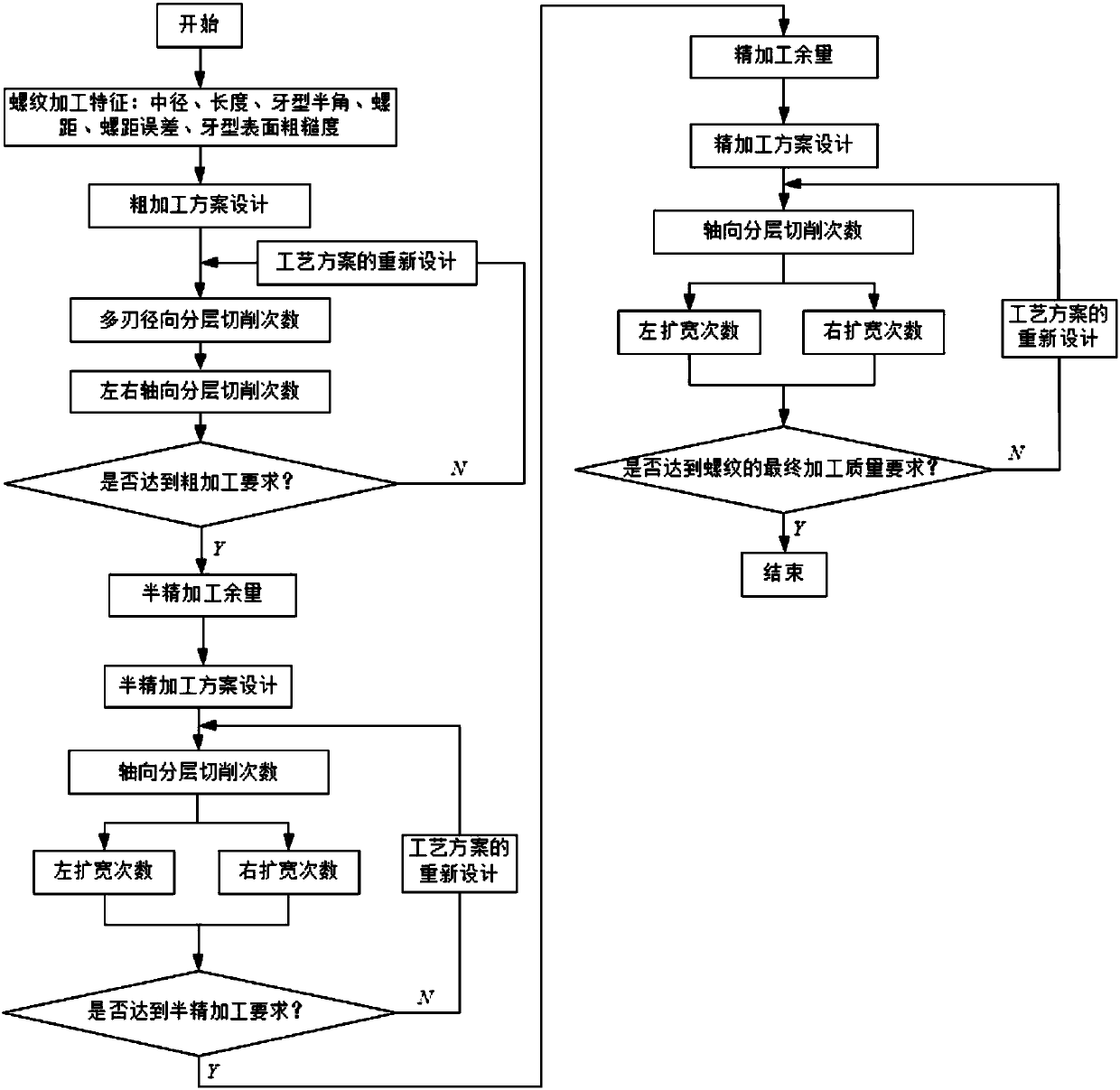

The invention relates to an external thread turning process, in particular to a coarse-pitch external thread layered turning process. The process aims at solving the problem that by means of existing thread turning methods, because the requirements for massive removal and high-precision machining of coarse-pitch external threads can not be met, thread surface machining principle errors and cutter marks exist in coarse-pitch external thread turning, the problem that because of the overlarge cutting load, cutter abrasion is quick, and the problem that because of staggered threads and an excessively large number of layered cutting times caused by cutter starting point error accumulation, the machining efficiency is low is solved. The process includes the process of conducting rough machining by removing thread rough machining allowance through multiple cutting edges in a radial continuous multi-time feed layered cutting mode and a left-right axial multi-time layered cutting mode, and the process of conducting semi fine machining and fine machining in a layered cutting mode by feeding the left cutting edge and the right cutting edge alternately multiple times in the axial direction. The requirements for the machining precision and the machining surface quality of external threads are met, obtained left and right threaded faces are free of cutter marks, the problem that threads are meshed in disorder is solved, and the requirement for efficiently turning coarse-pitch external threads in a high-quality mode is met.

Owner:HARBIN UNIV OF SCI & TECH

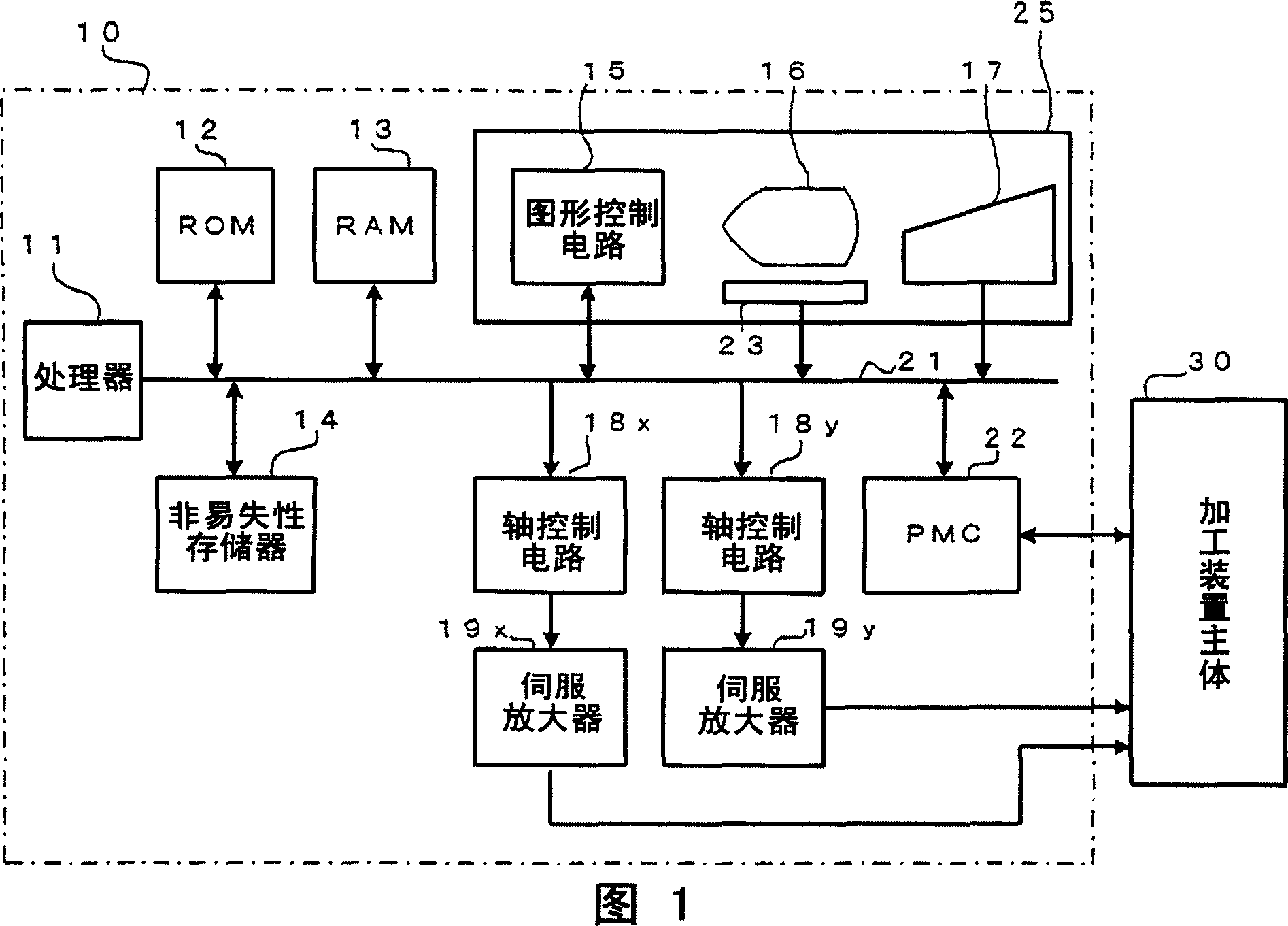

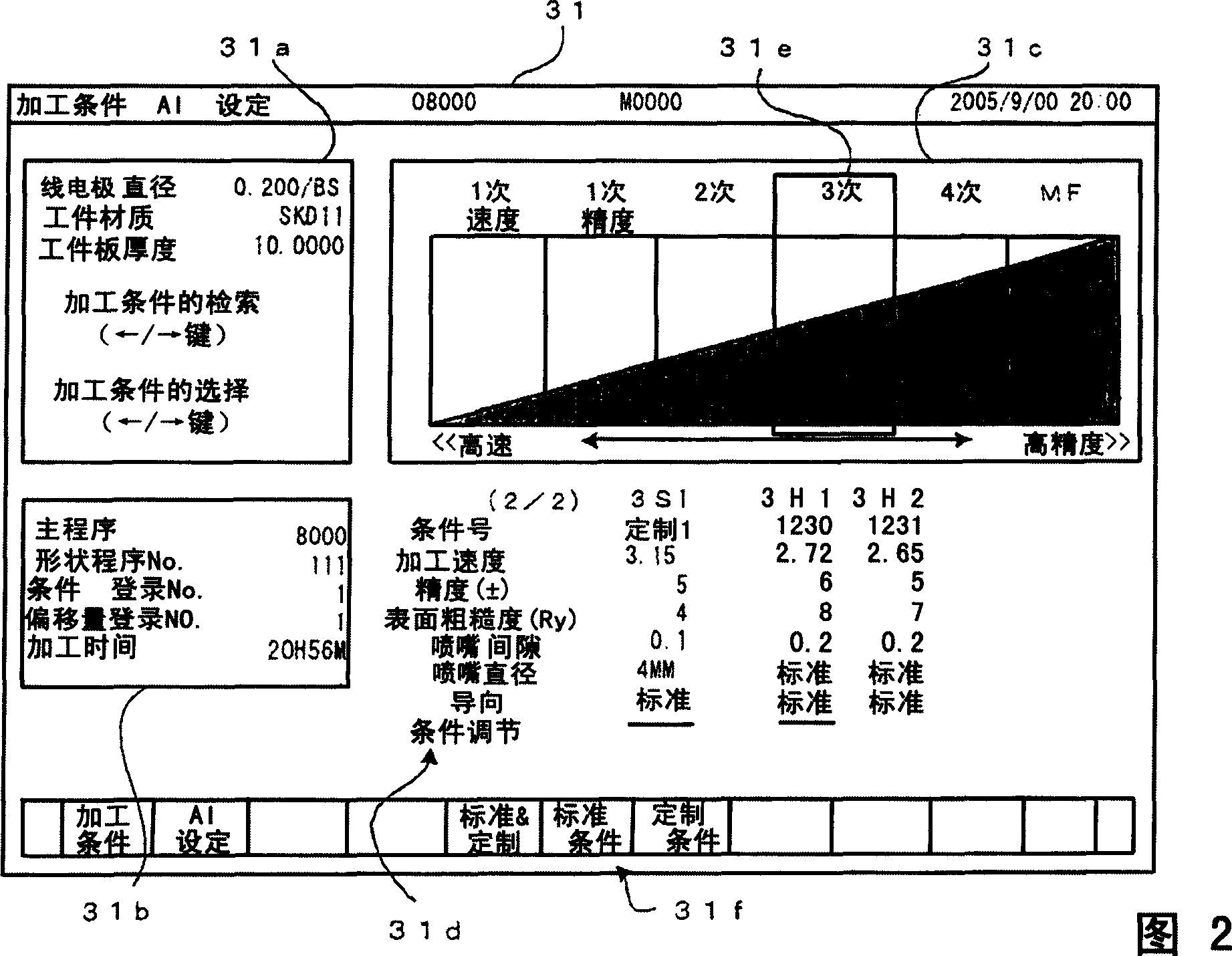

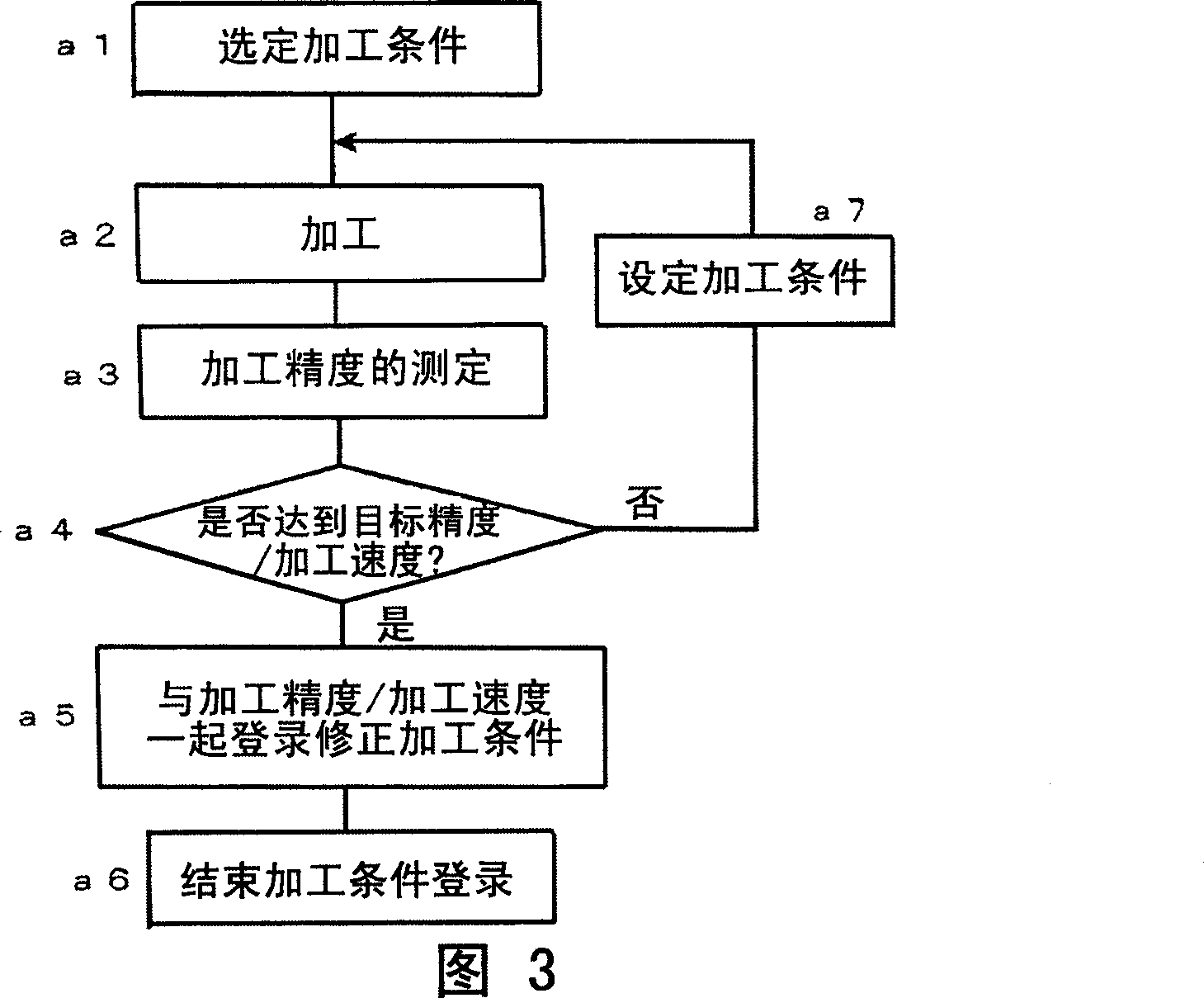

Machining condition setting method for electrical discharge machines

InactiveCN1931495AReach the target processing speedAchieve machining accuracyProgramme controlAutomatic control devicesMachining processMachining time

Standard machining conditions are registered in advance for each workpiece material and other factors in correspondence to machining speed and precision. The standard machining conditions are selected for execution of machining. The machining precision is measured to determine whether or not the measured machining precision and machining speed (machining time) fall within an allowable target range. If they are not within the range, the machining conditions are modified and machining is executed again. This procedure is repeated until the machining speed and precision fall within the allowable range, at which point the machining conditions are additionally registered and stored. The added machining conditions can be used in the next machining process.

Owner:FANUC LTD

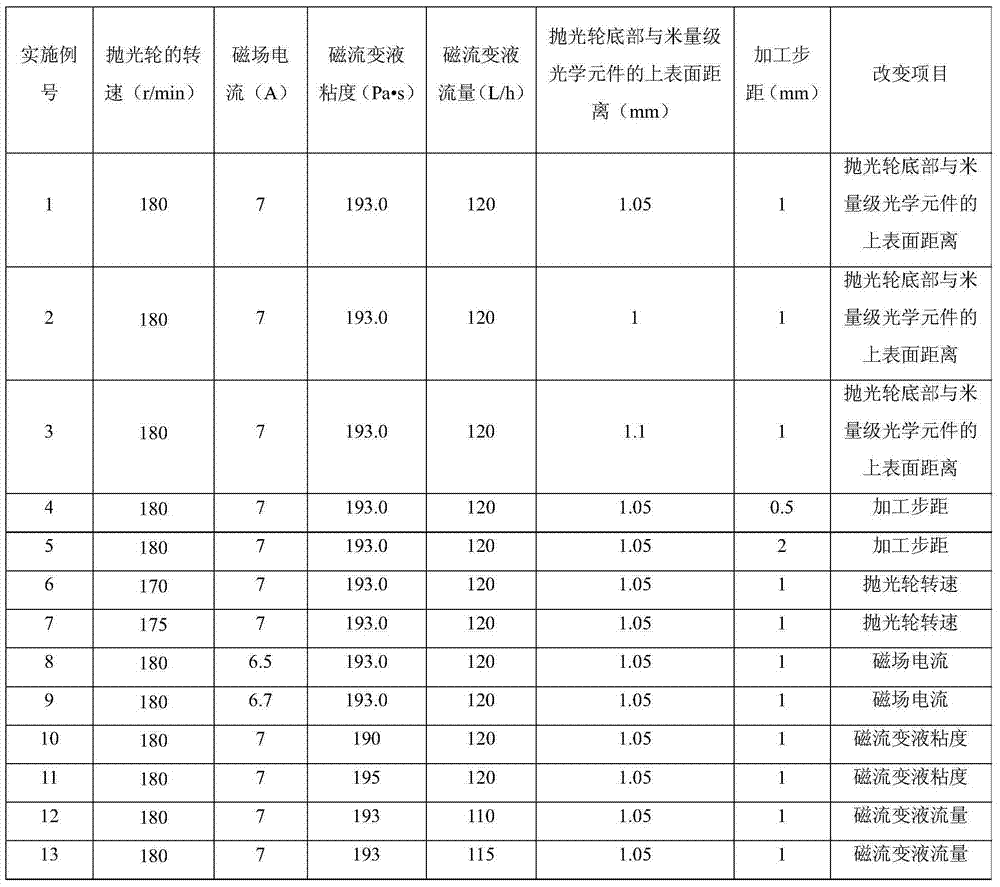

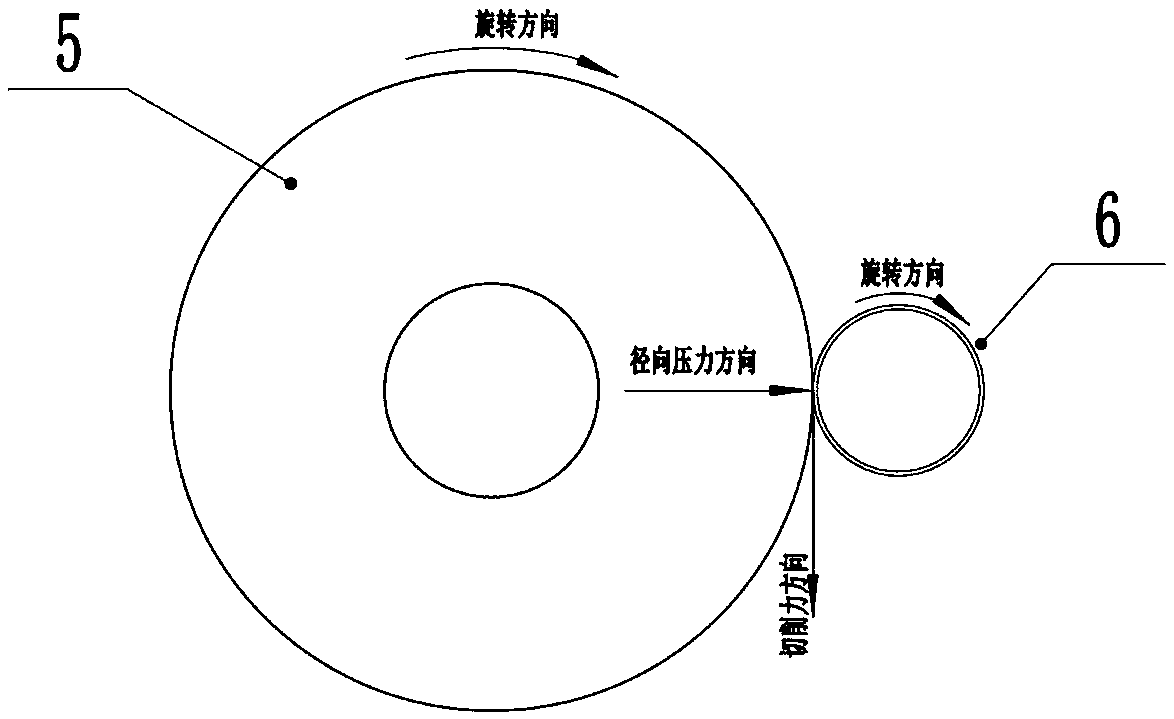

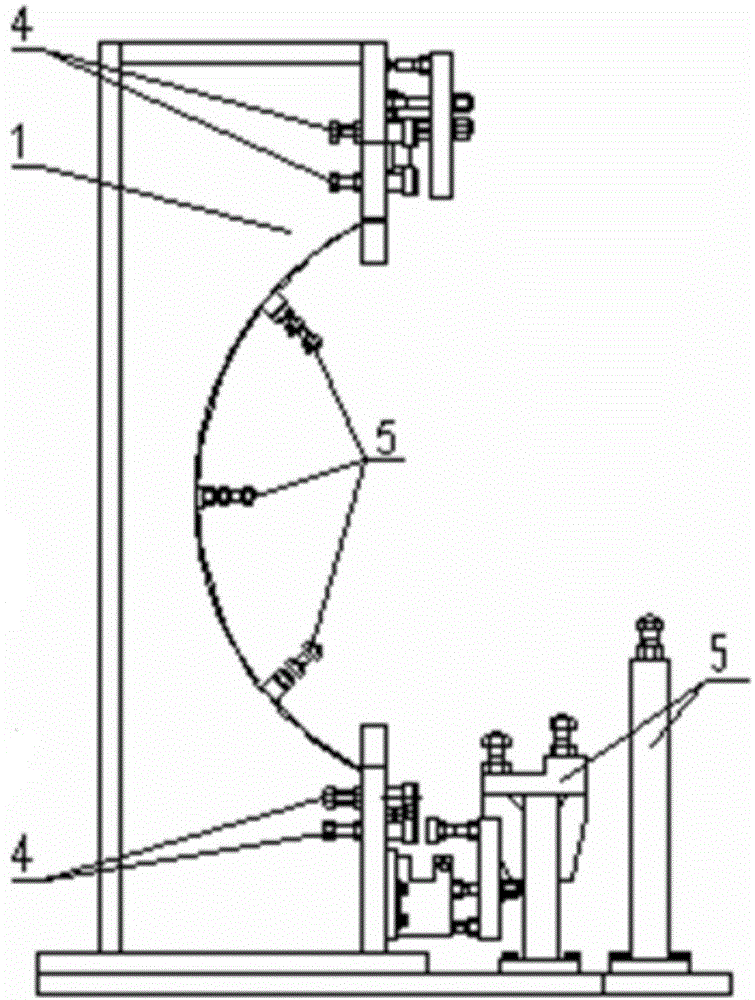

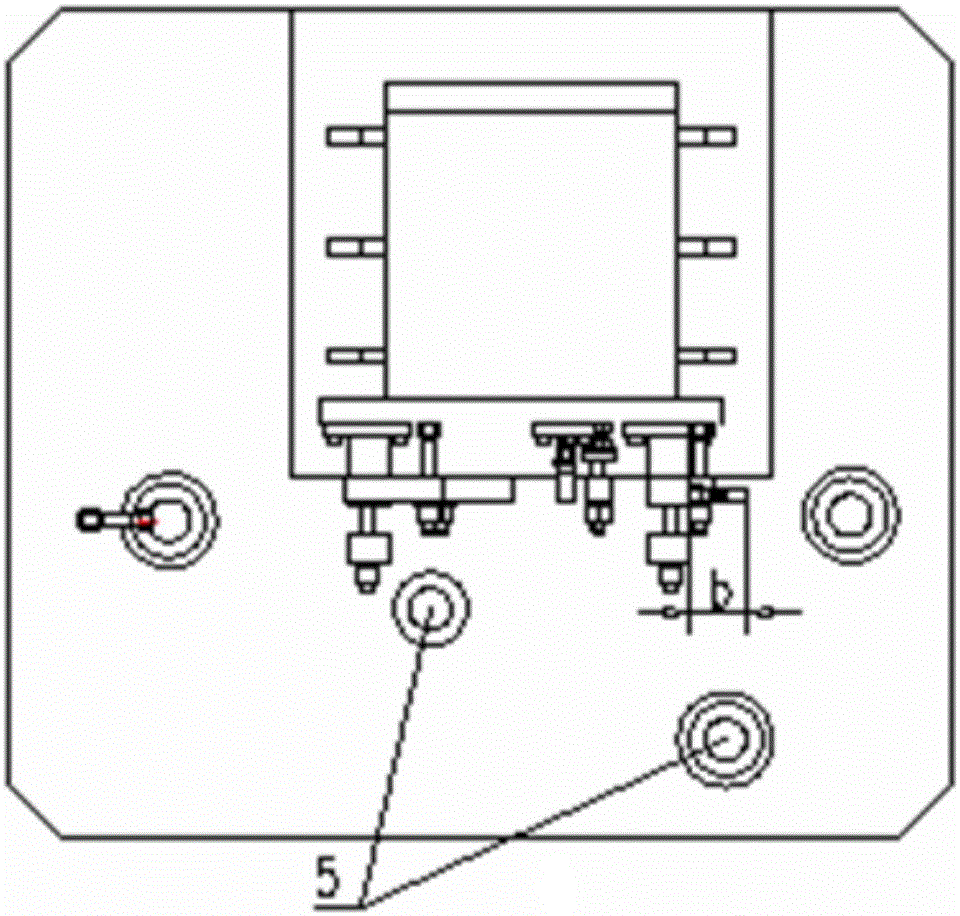

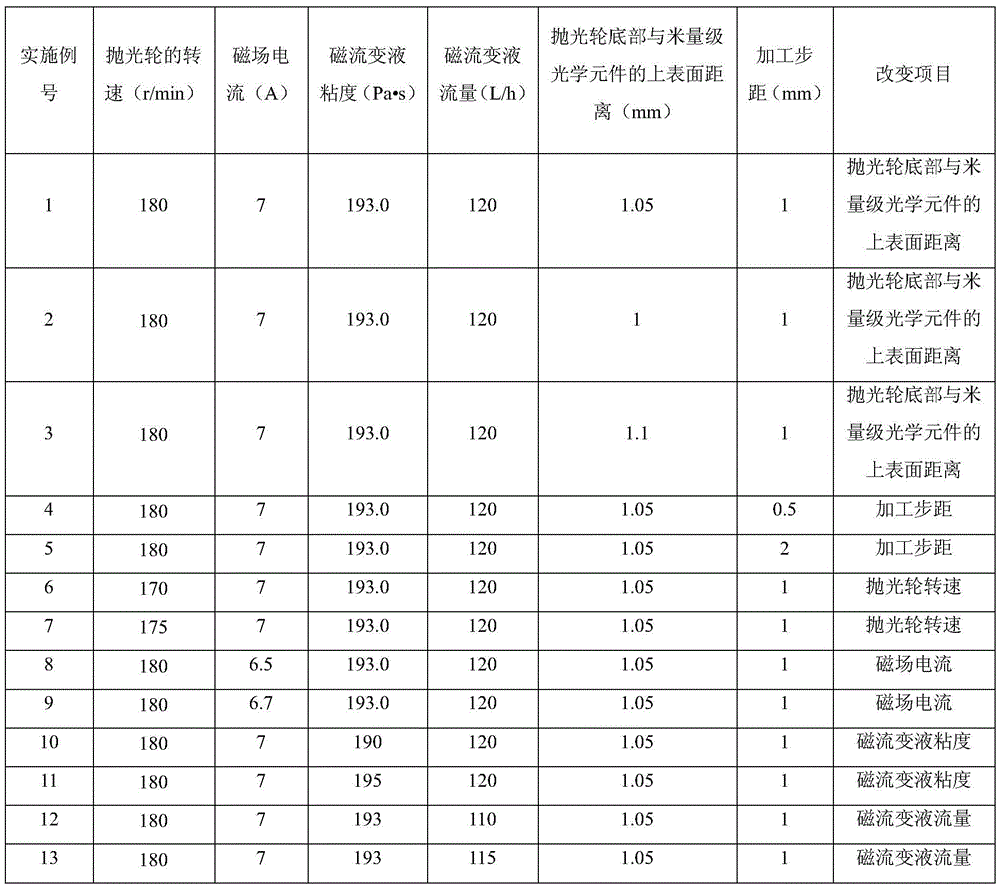

Ultrahigh precision processing method for meter-scale optical element

ActiveCN103692294AAchieve machining accuracyOptical surface grinding machinesLength waveMagneto rheological

The invention discloses an ultrahigh precision processing method for a meter-scale optical element. According to the method, an annular polishing technology and a magneto-rheological polishing technology are combined, and different processing technical parameters are subjected to optimal combination to realize the ultrahigh precision processing of the meter-scale optical element. According to the method, the meter-scale optical element of which the PV (pageviews) value of surface figure accuracy is 1 / 8 wavelength and the RMS (rate-monotonic scheduling) value is 1 / 50 wavelength is processed.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

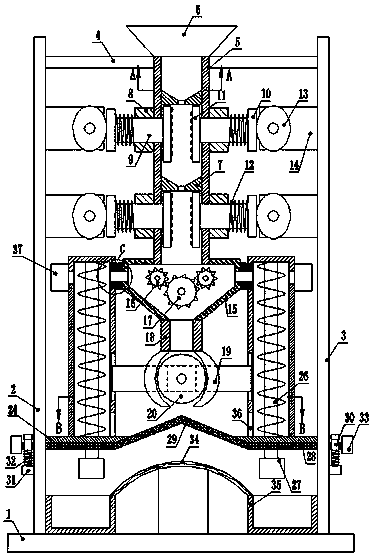

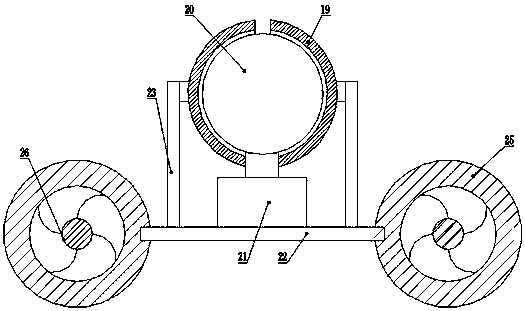

Grain processing smashing device for agricultural machine

InactiveCN108607631ASimple structureEasy to useGrain treatmentsAgricultural engineeringPre treatment

The invention provides a grain processing smashing device for an agricultural machine. The grain processing smashing device comprises a rack. A pretreatment system and a finish processing system are sequentially arranged in the rack from top to bottom. The pretreatment system comprises multiple levels of extruding mechanisms arranged side by side. The finish processing system comprises a smashingand grinding mechanism, a screening mechanism, a spiral conveying mechanism and a material receiving mechanism. The grain processing smashing device for the agricultural machine is simple in structureand convenient to use, grain raw materials enter the multiple levels of extruding mechanisms from a feeding pipe to be subjected to extruding pretreatment, then the grain raw materials are subjectedto finish processing through the smashing and grinding mechanism and the screening mechanism, the grain raw materials are fully smashed, ground and screened, the screening efficiency is high, the grinding effect is good, the ground grain raw materials are collected through a collecting tank, the labor intensity of workers is reduced, the working efficiency is improved, the grain raw materials which are obtained after finish processing and do not conform to the standard are returned to the smashing and grinding mechanism through the spiral conveying mechanism to be subjected to secondary smashing and grinding until the grain raw materials conform to the standard, and then grain raw materials fall into the collecting tank through the screening mechanism to be collected.

Owner:HENAN UNIV OF SCI & TECH

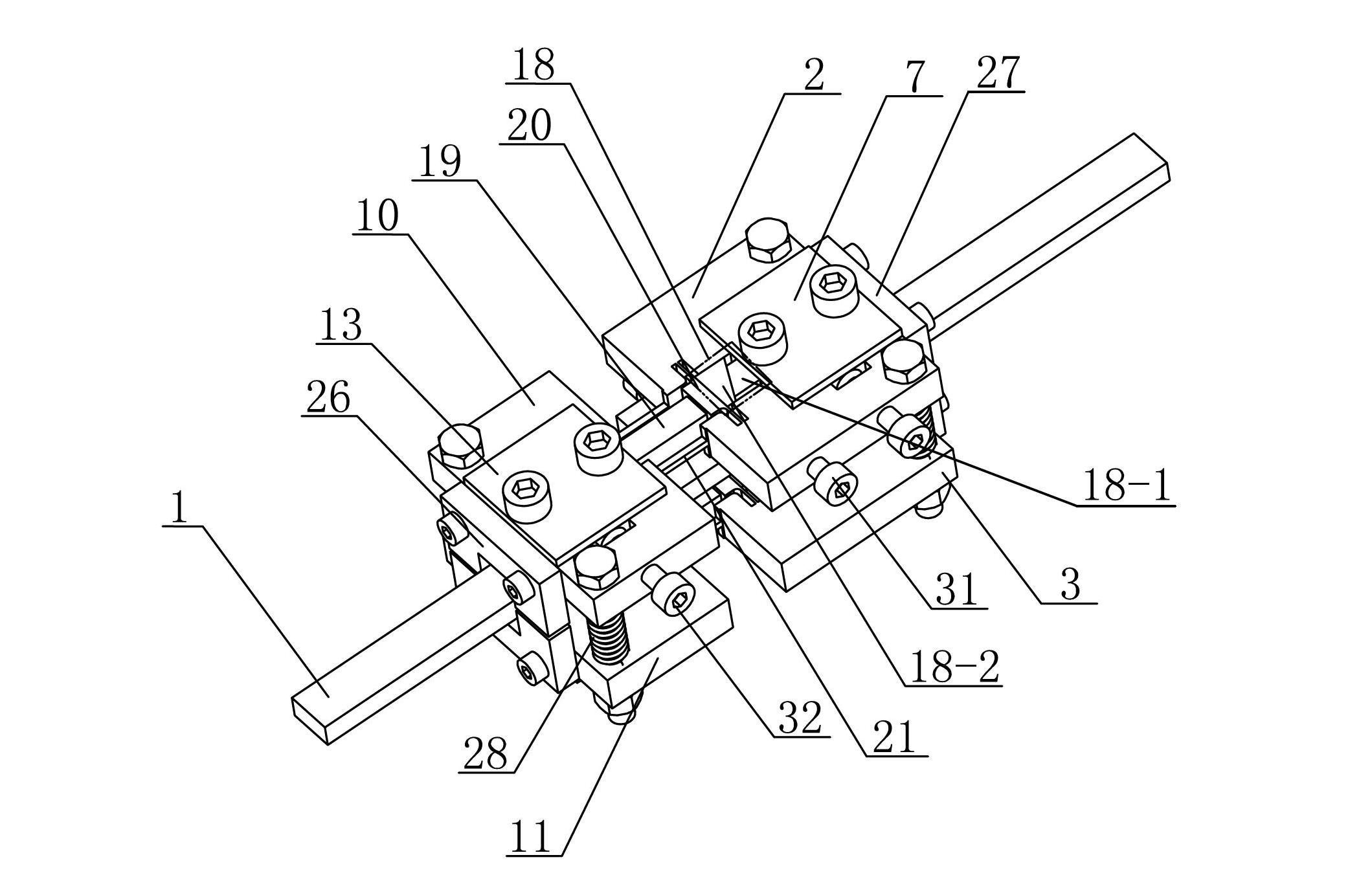

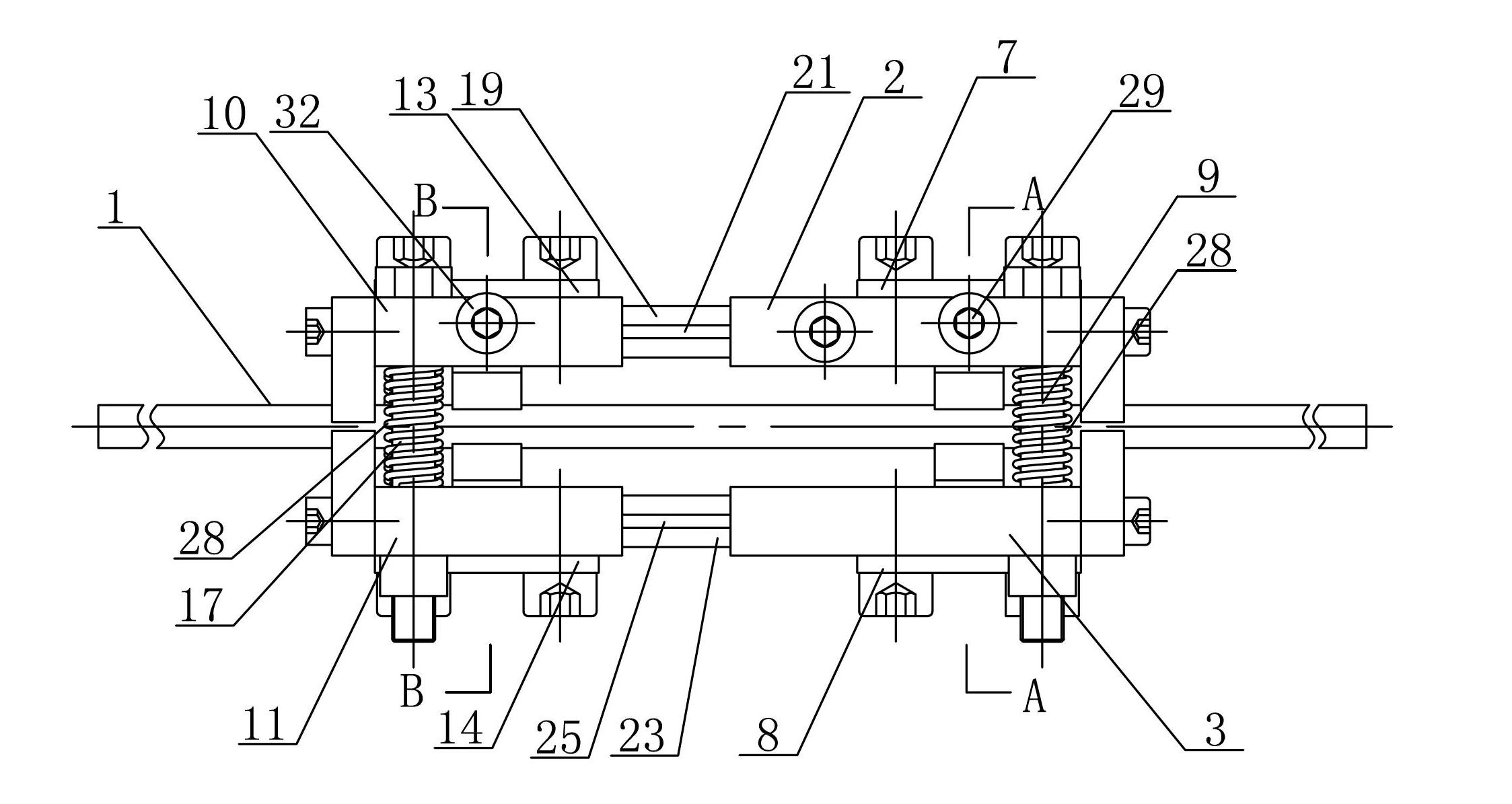

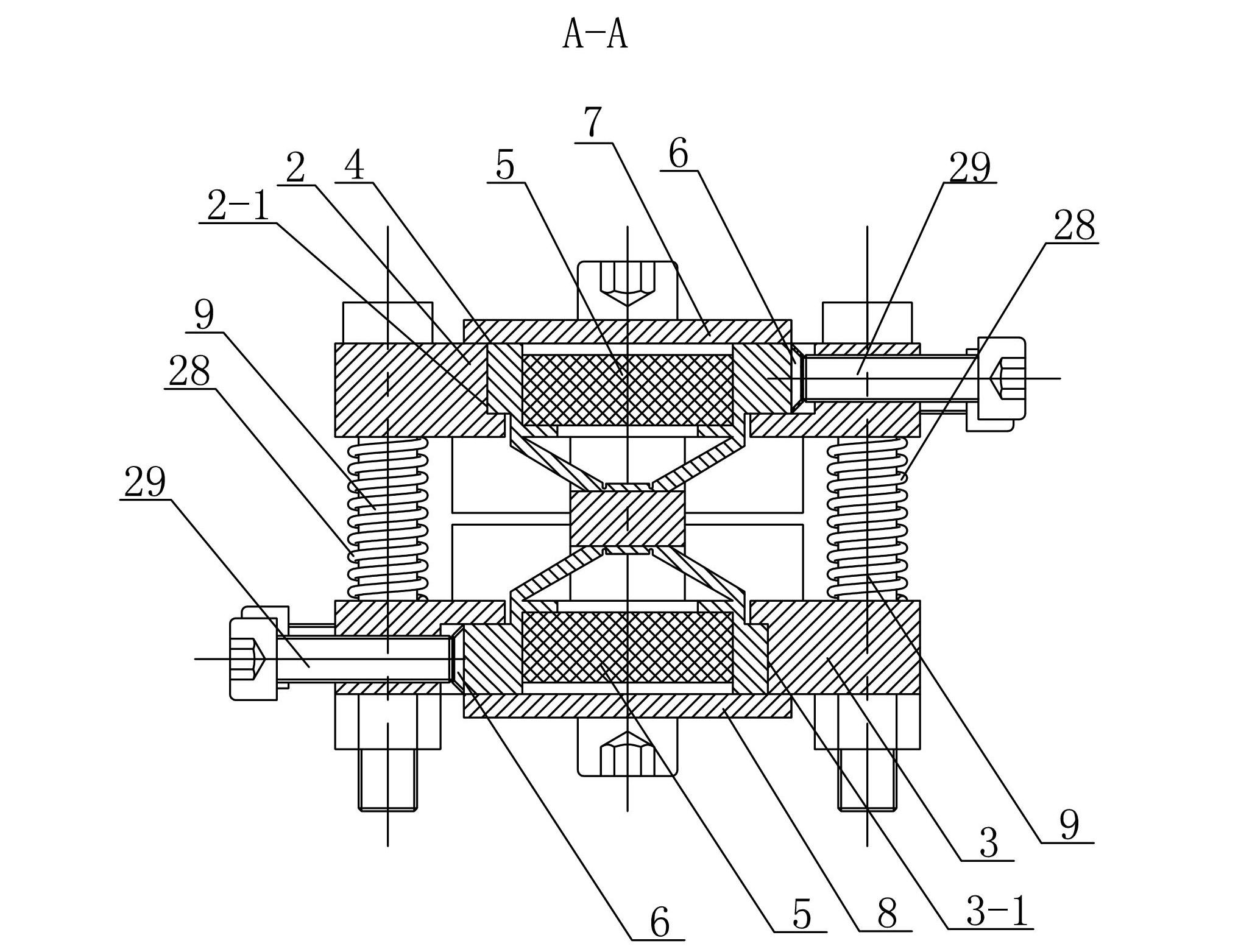

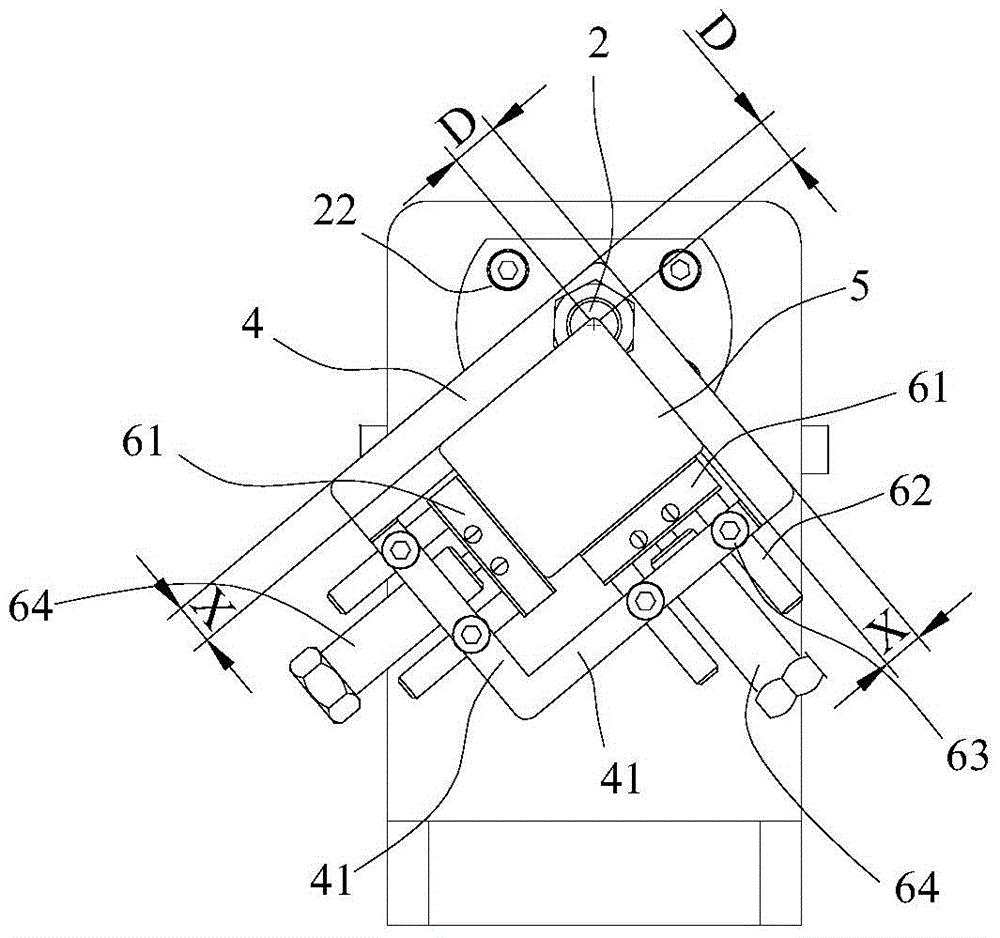

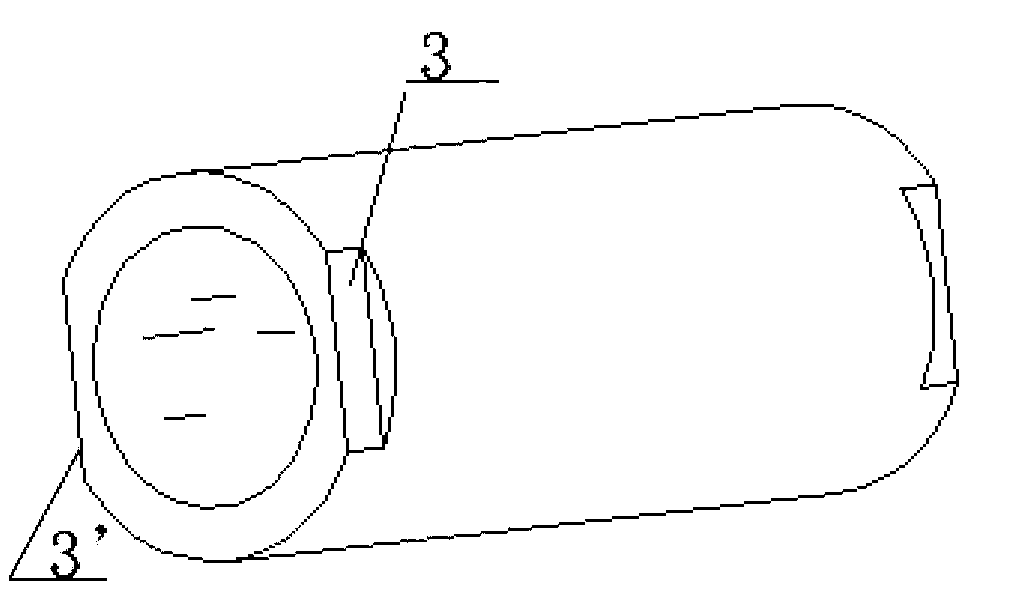

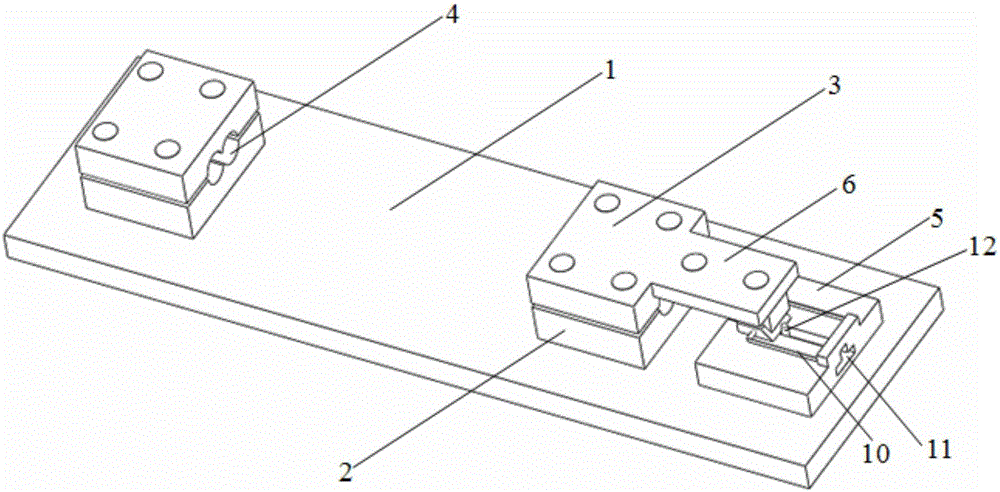

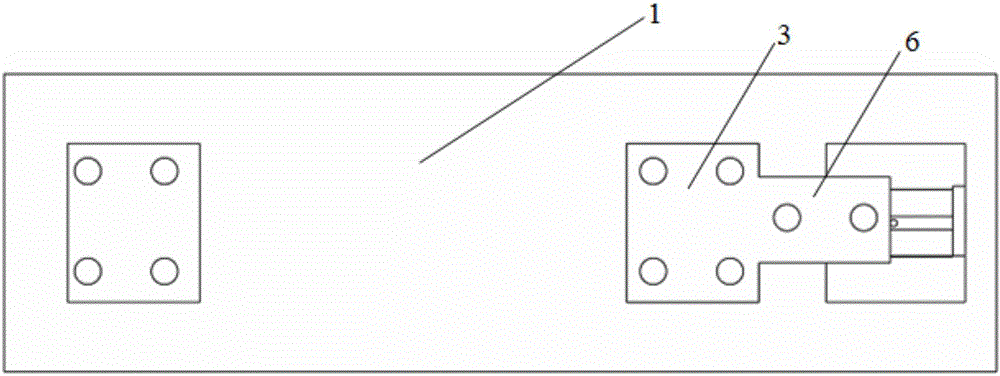

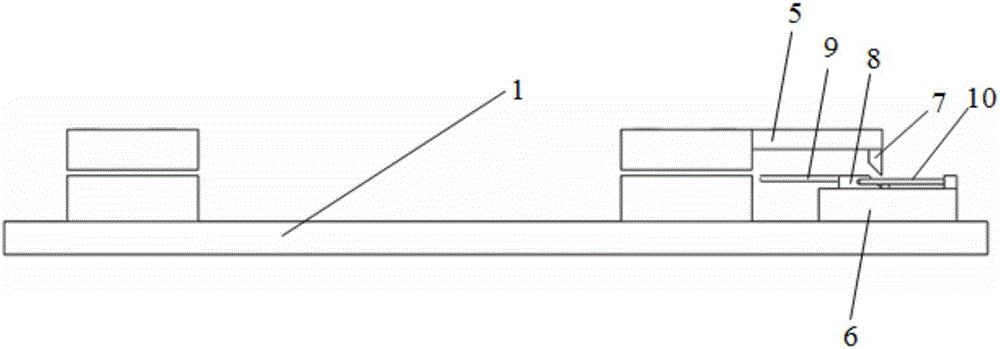

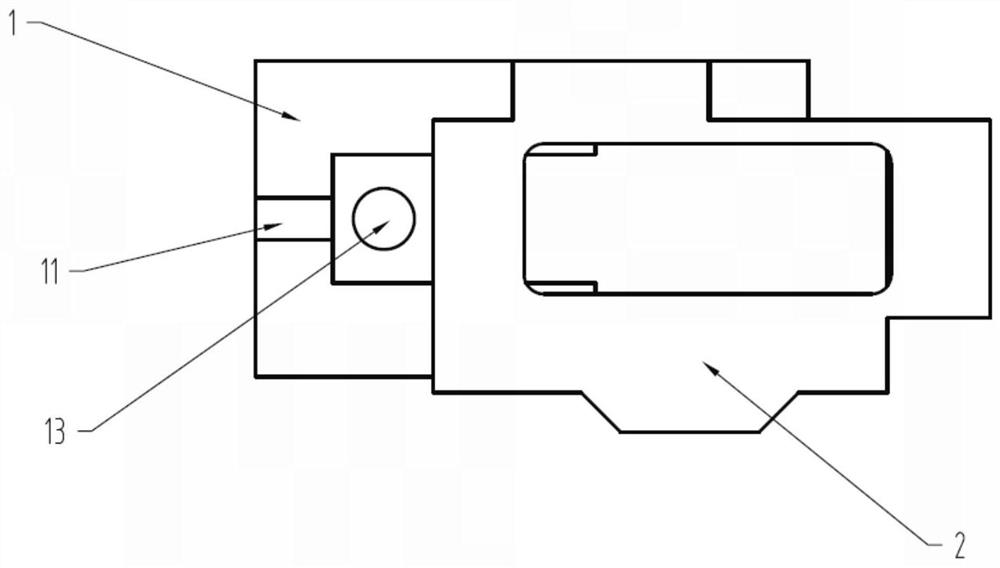

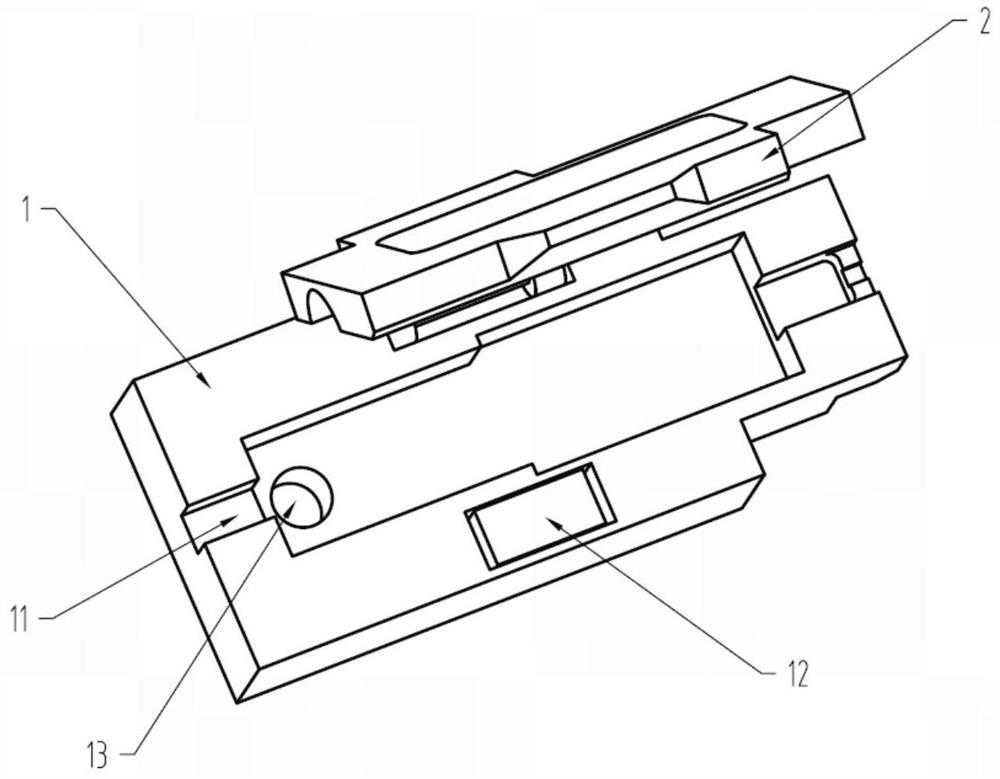

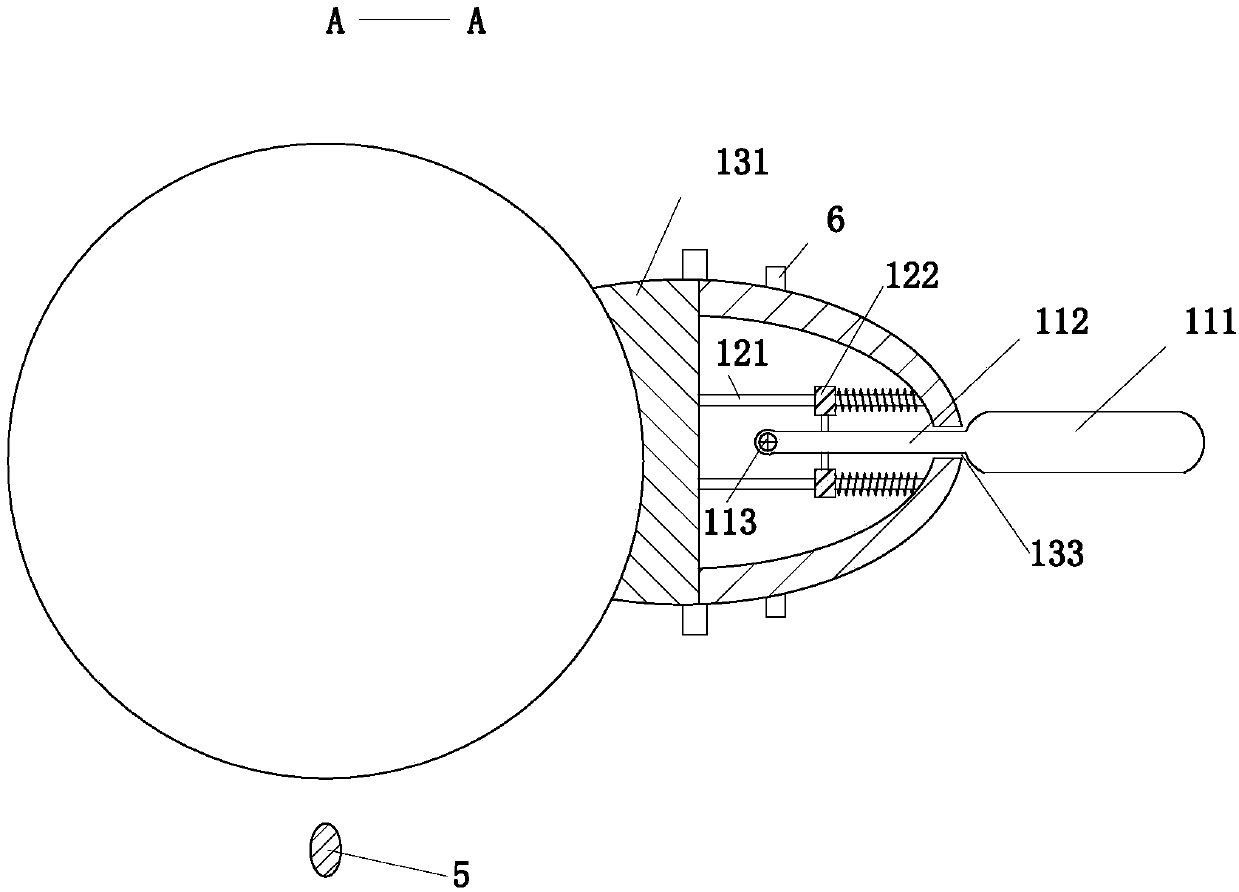

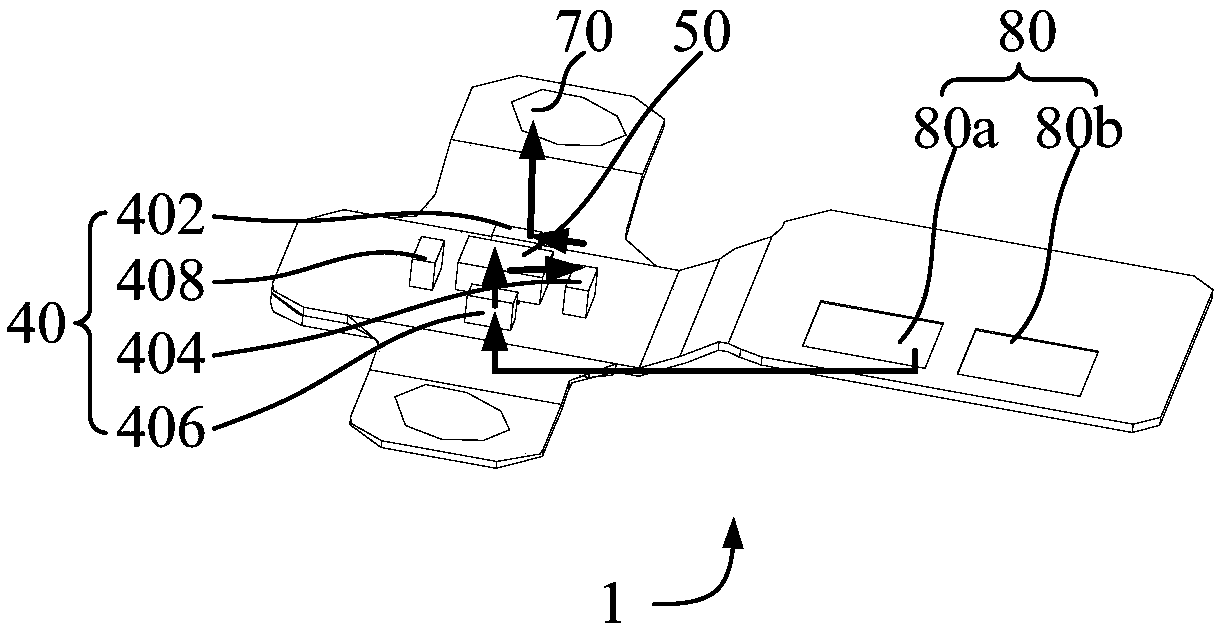

Passive clamping type piezoelectric actuator

ActiveCN102664554AReduce volumeIncrease flexibilityPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric actuatorsEngineering

The invention provides a passive clamping type piezoelectric actuator and relates to a piezoelectric actuator. The invention aims to solve the problems that the adjustment of the pretightening force of the existing passive clamping type piezoelectric actuator is controlled in cooperation with interference, so the control flexibility is poor, and the structural type of the clamping amplification structure is complex. The passive clamping type piezoelectric actuator provided by the invention comprises a first clamping mechanism, an actuating mechanism, a second clamping mechanism and a guide rail, wherein the first clamping mechanism and the second clamping mechanism are arranged in sequence from right to left, and the guide rail penetrates through the middle parts of the first clamping mechanism and the second clamping mechanism in sequence, and the actuating mechanism connects the first clamping mechanism and the second clamping mechanism. The passive clamping type piezoelectric actuator provided by the invention has small size and can realize self-locking when a power failure occurs, a clamping device is provided with a triangle amplifying mechanism, which can amplify the displacement of a clamping piezoelectric stack, thus reducing the difficulties of processing and assembling. The passive clamping type piezoelectric actuator is applied to the micro drive process.

Owner:HARBIN INST OF TECH

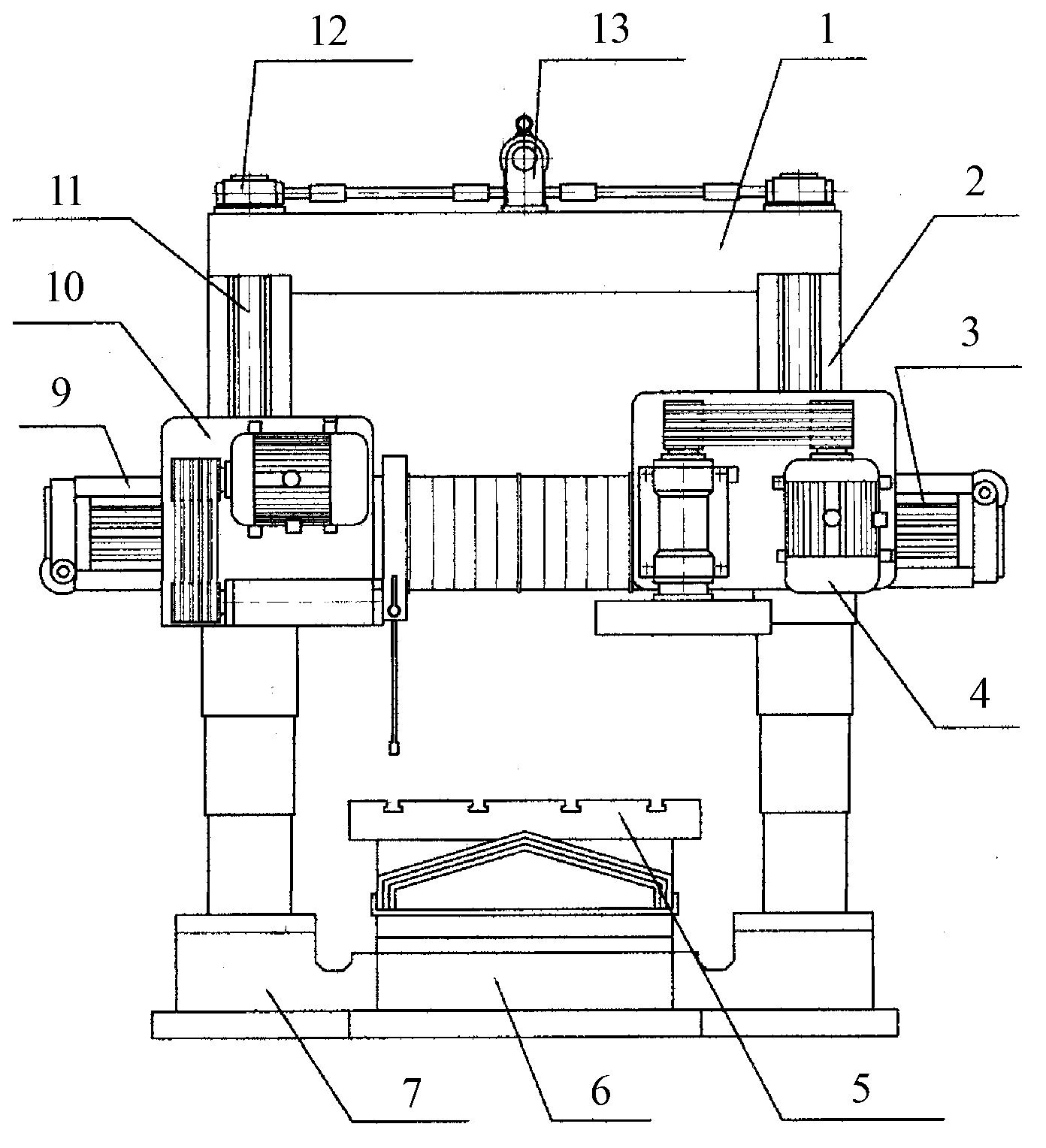

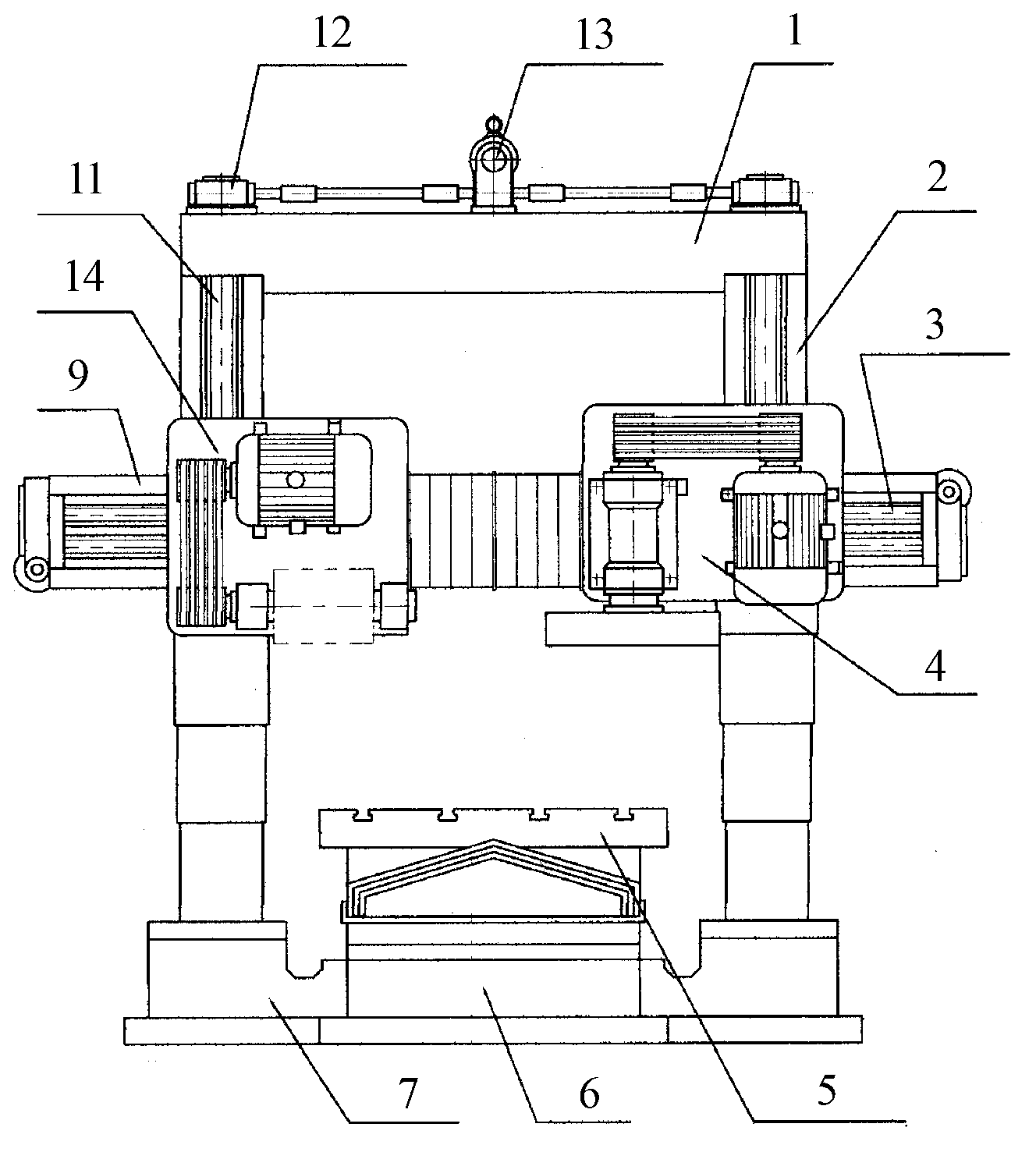

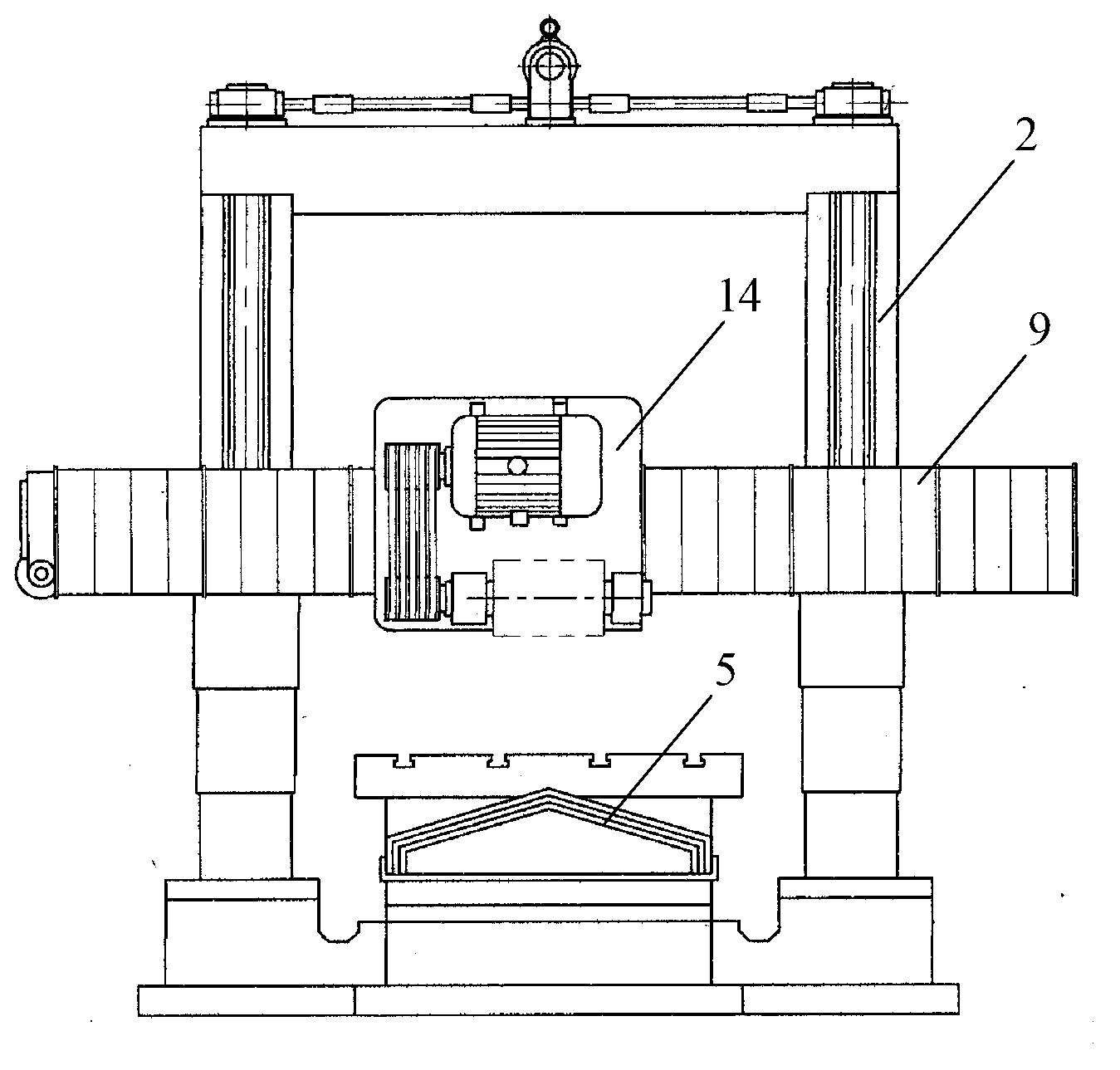

Never-worn milling machine

ActiveCN103302499ASimple structureGuaranteed machining and grinding accuracyOther manufacturing equipments/toolsLarge fixed membersWear resistantAgricultural engineering

The invention relates to the field of machining machinery, in particular to a never-worn milling machine, and belongs to machining equipment for machining refractory materials and nonmetallic materials. The milling machine comprises a gantry framework, a milling head mechanism and a worktable guide rail, wherein one side of a cross beam on the gantry framework is connected with the a lifting transmission mechanism in an upright post; a sliding plate base connected on the other side of the cross beam through a left-and-right transmission mechanism is connected with the milling head mechanism; the lower part of the milling head mechanism corresponds to a workpiece on the worktable guide rail mechanism; replaceable wear-resistant belts are installed at sliding fit positions of the upright post and the cross beam, the cross beam and the sliding plate base, and a worktable and a guide rail respectively; the replaceable wear-resistant belts can be wear-resistant soft belts, wear-resistant steel belts or wear-resistant nodular iron castings. The never-worn milling machine solves the problems that the conventional milling machine has certain wear at work and thus the accuracy cannot meet technical requirements; the never-worn milling machine can reduce the maintenance cost and can ensure the machining accuracy for a long time.

Owner:沈阳鹏程非金属设备有限公司

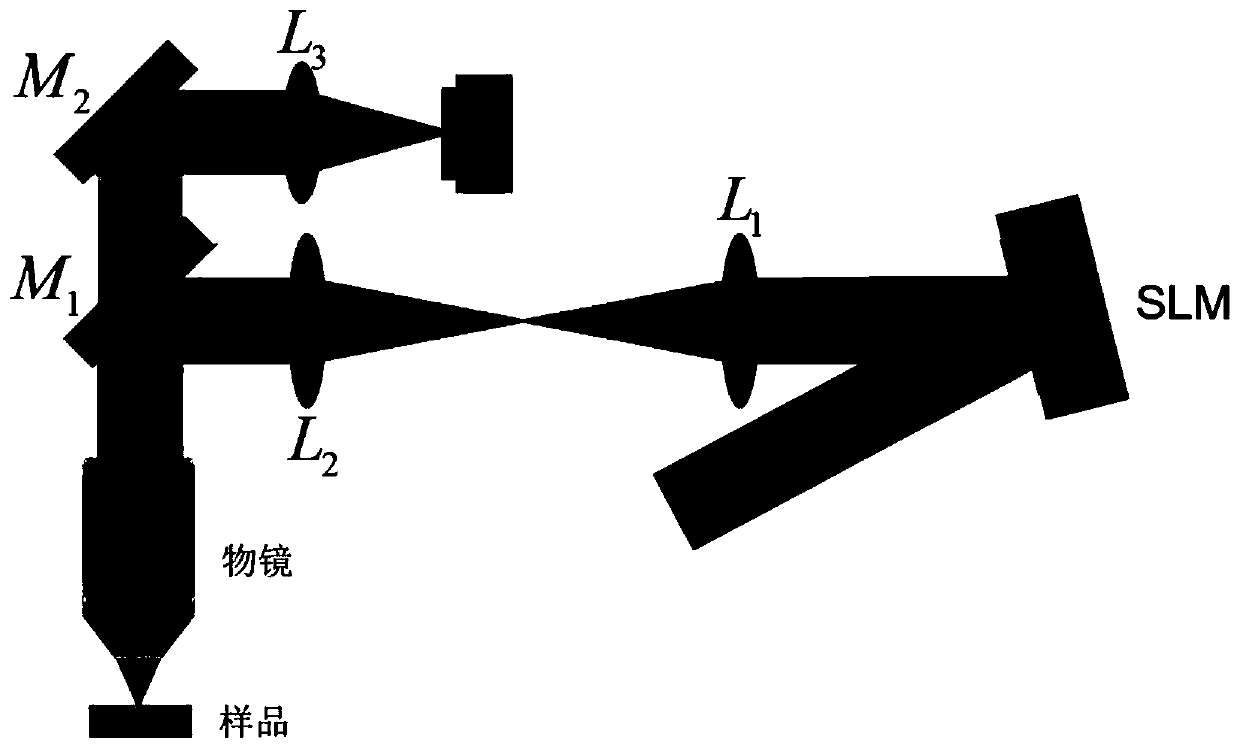

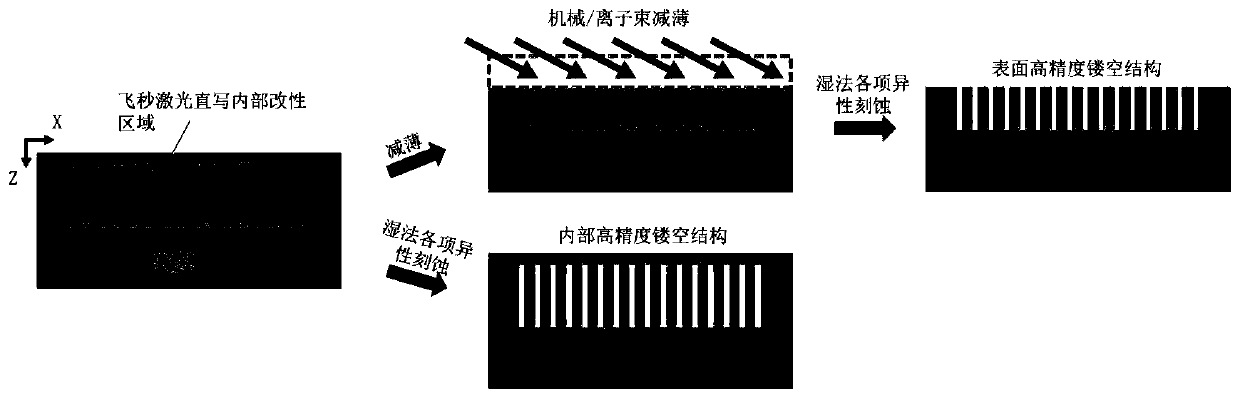

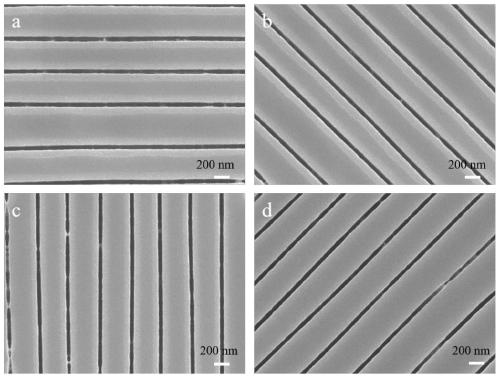

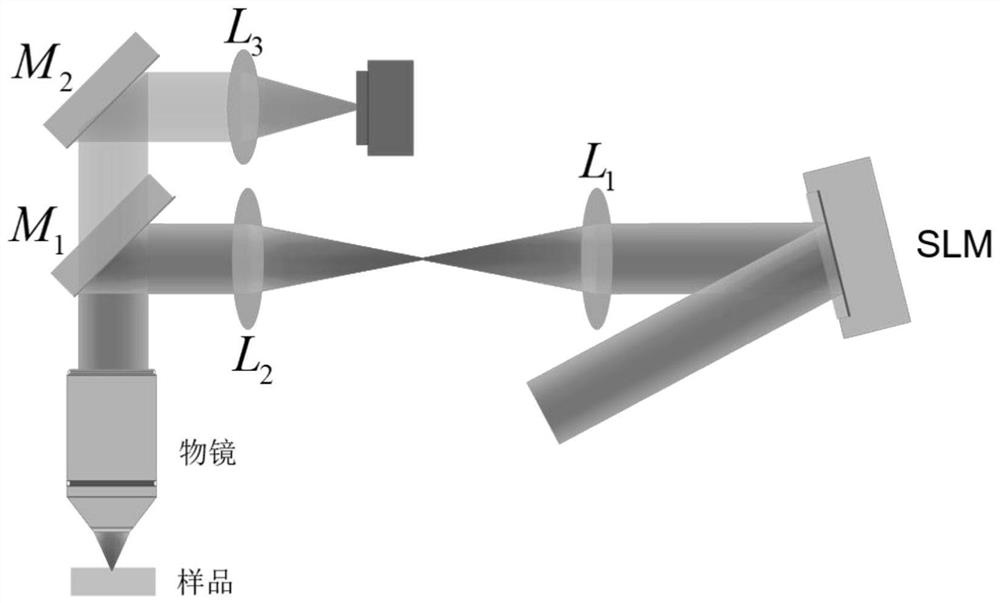

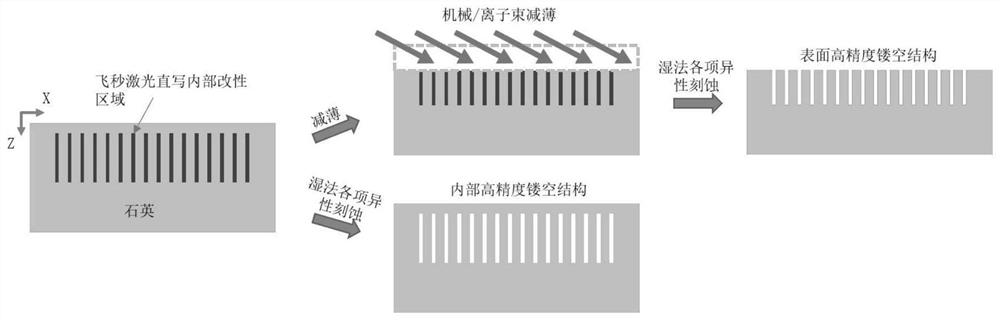

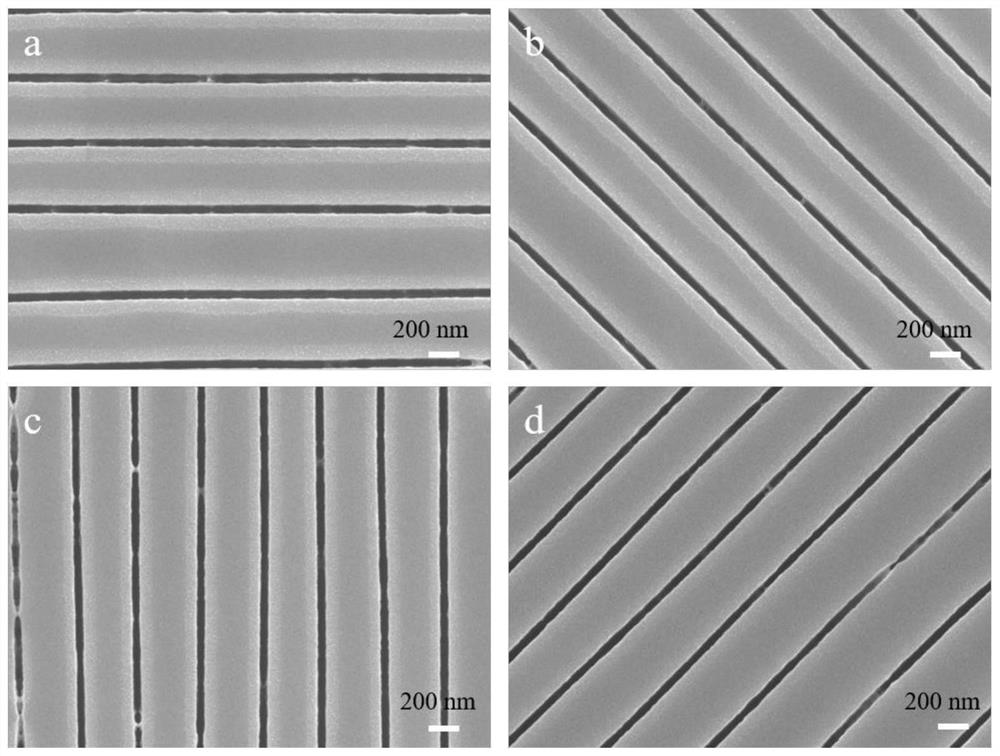

Method for preparing hollowed structure on surface of transparent material and in transparent material

ActiveCN111185678AAbility to realize three-dimensional processingAchieve machining accuracyCleaning using liquidsLaser beam welding apparatusEtchingFemto second laser

The invention discloses a method for preparing a hollowed structure on the surface of a transparent material and in the transparent material, and belongs to the technical field of femtosecond laser micro-nano machining. According to the method, the polarization and machining power is precisely controlled, a modified area with the precision of hundreds of nano is directly written in the transparentmaterial in a femtosecond laser direct writing manner, then the surface of the transparent is thinned to the machining area position (surface machining) in a mechanical / ion beam thinning manner, finally the material is etched through a wet etching process, and preparation of the hollowed structure with high precision, any patterned structure and the precision of hundreds of nano is achieved. According to the method, efficient high-precision machining of multiple common transparent materials can be achieved in a vacuum environment, and the problems that in the prior art, the requirement for the environment is high, and the machining efficiency is low are solved.

Owner:JILIN UNIV

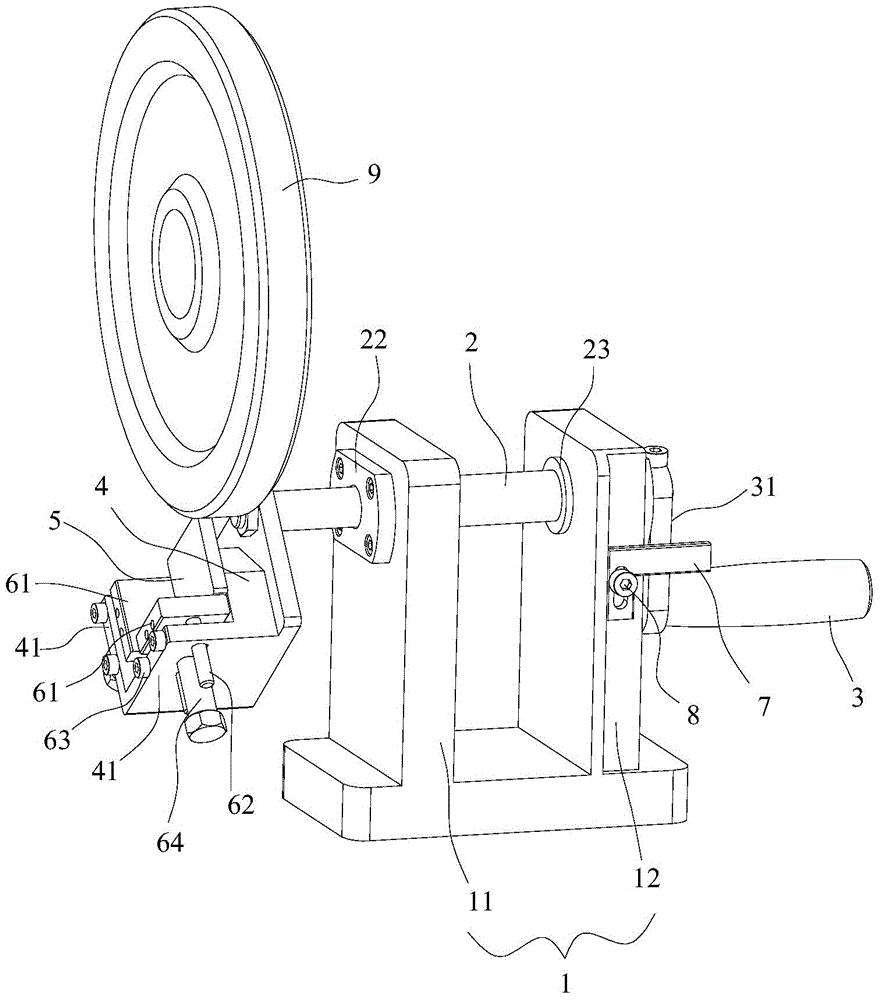

Manual rounding device

ActiveCN104369063AEasy to operateAvoid instabilityEdge grinding machinesPortable grinding machinesRoundingInstability

The invention discloses a manual rounding device. The device comprises a supporting base, a rotary shaft installed on the supporting base, a handle and a positioning block, wherein the handle and the positioning block are installed at the two ends of the rotary shaft respectively, the front surface of the positioning block is flat, two positioning plates which are perpendicular to the positioning block and extend forwards are formed on the edge of the front surface of the positioning block, an angle is formed between the two positioning plates, an installation site which deviates from the rotary shaft and is used for accommodating a workpiece to be machined is formed on the front side of the positioning block by the two positioning plates, and a positioning mechanism used for fastening the workpiece to be machined is arranged in the installation site. The manual rounding device is used in cooperation with a widely used flat grinder, and after the workpiece is well positioned on the installation site, the position of a grinding wheel of the flat grinder is adjusted and the workpiece is made to rotate around the rotary shaft, so that rounding is achieved easily. By the adoption of the device, the machining precision of current professional equipment can be realized, instability caused by manual rounding is avoided, no professional rounding equipment is needed, and increase of machining cost is avoided.

Owner:GUANGZHOU HONSUN OPTOELECTRONICS

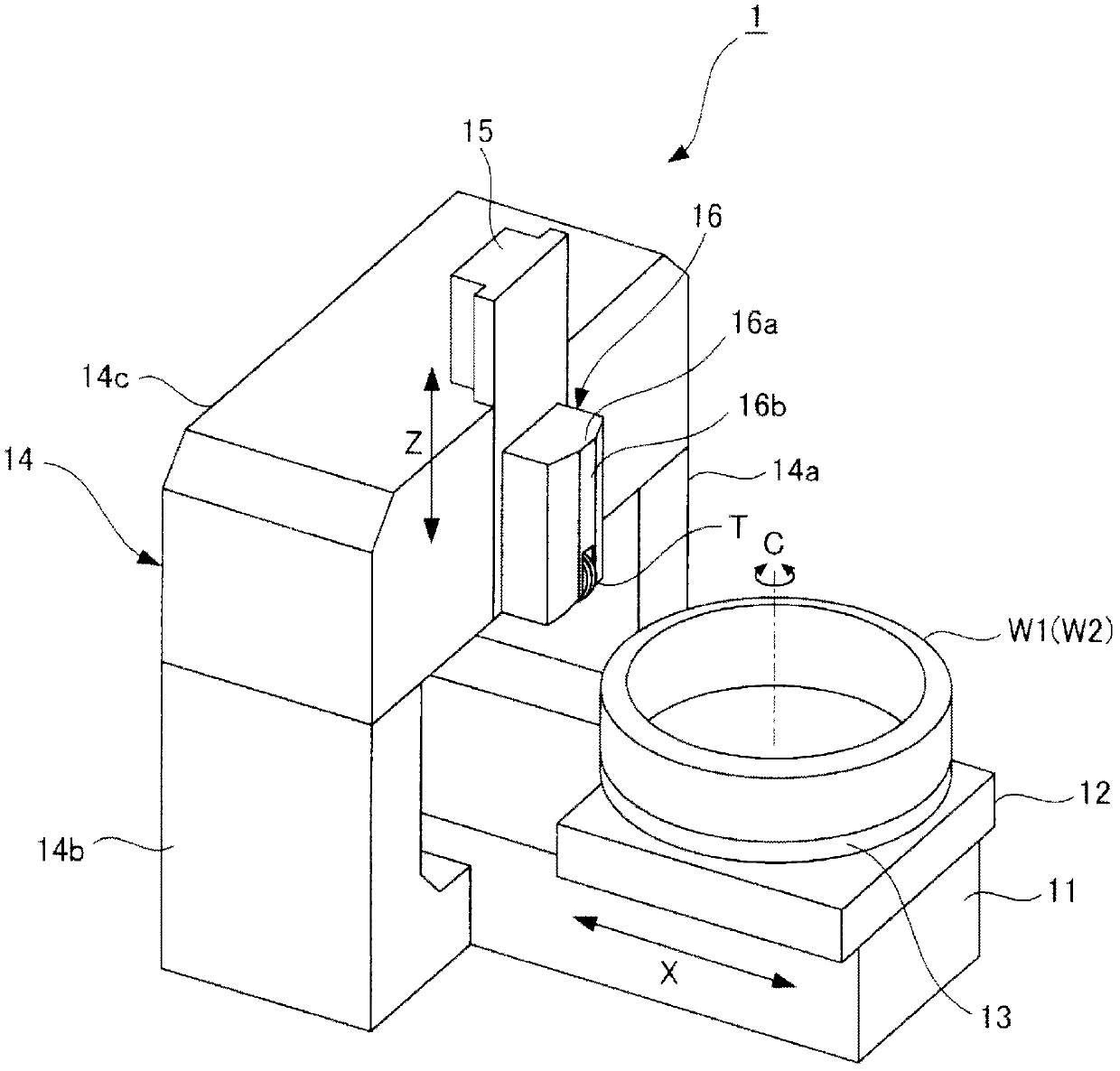

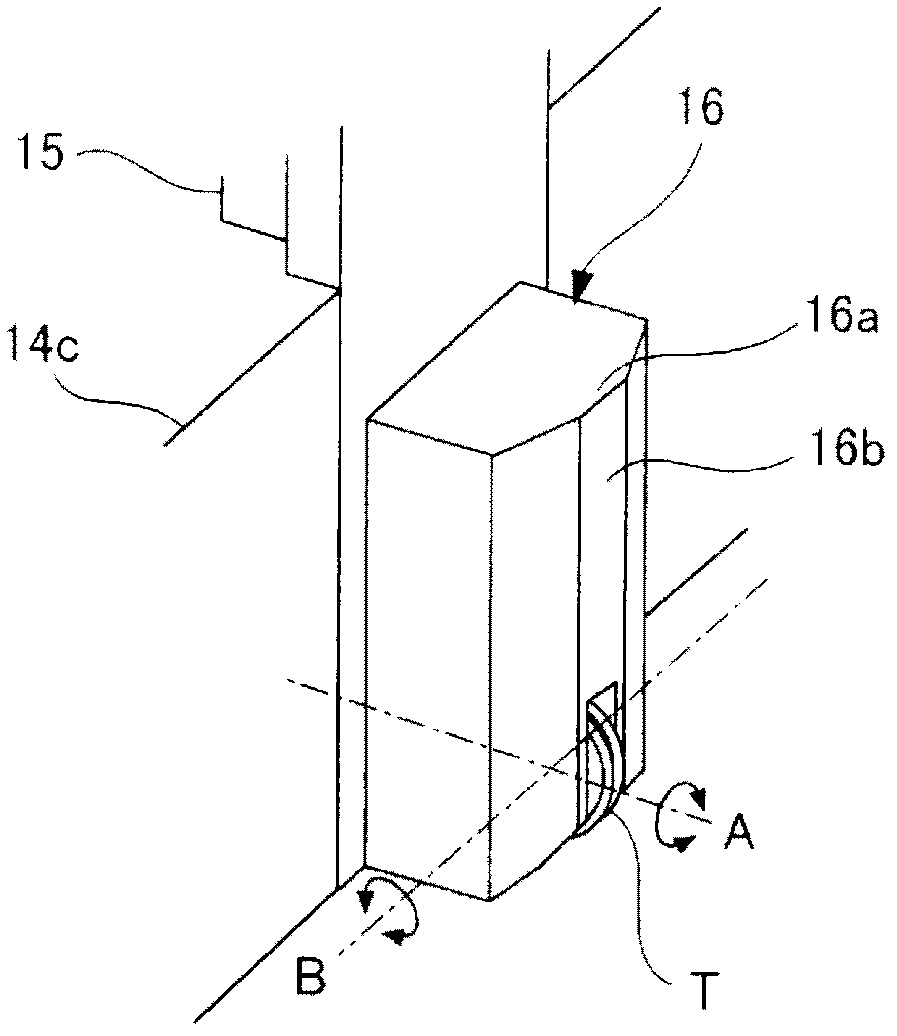

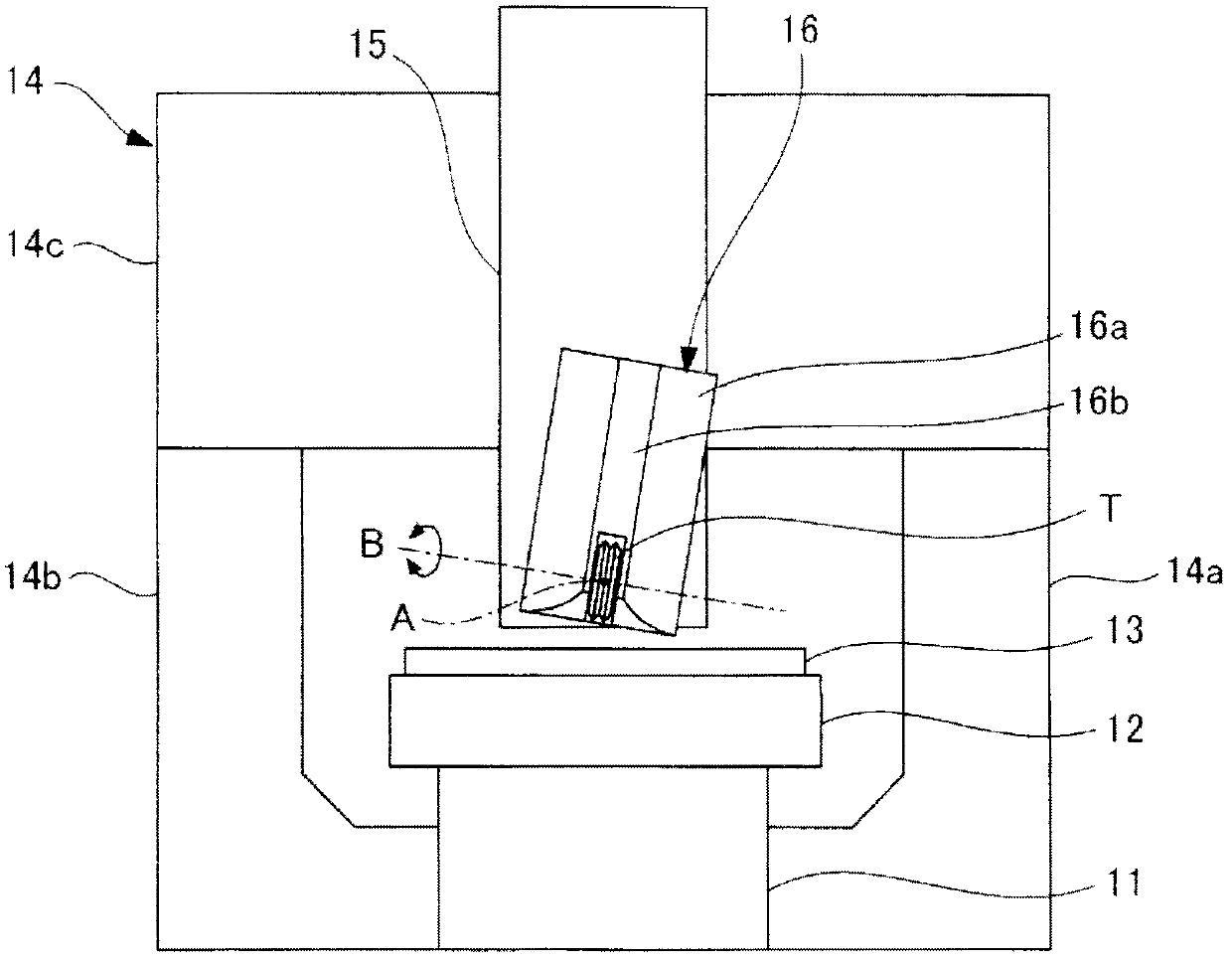

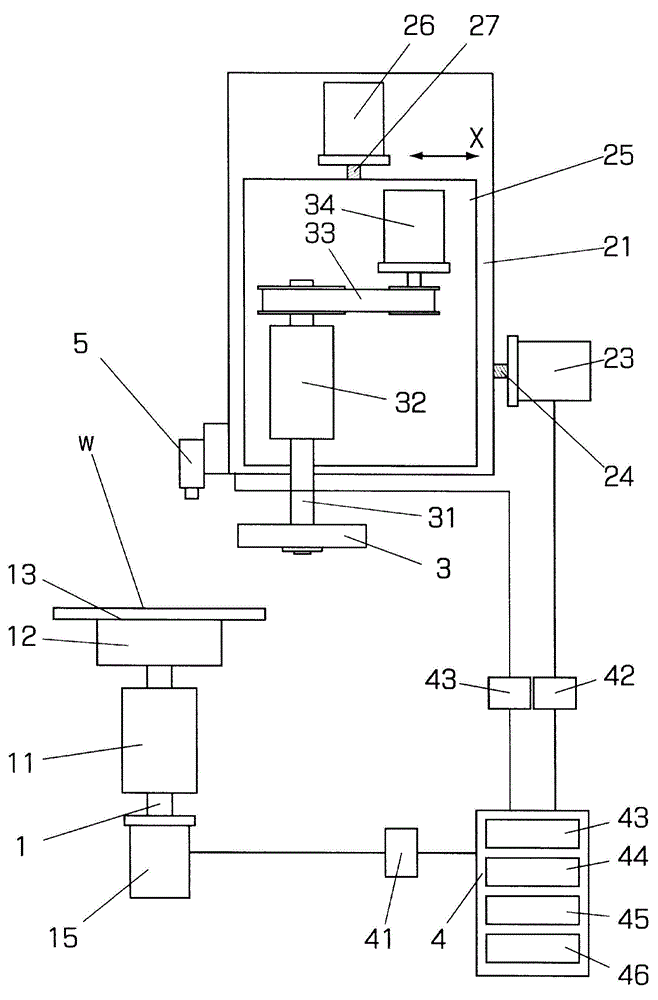

Gear machining machine

InactiveCN102596470AImprove rigidityAchieve machining accuracyLarge fixed membersGear teethEngineeringWorkbench

Provided is a gear machining machine which has a cutter head with improved rigidity, and contributes to improving machining accuracy and making quality uniform when either an external gear or an internal gear has been machined. For this purpose, the gear machining machine is equipped with a movement base (12) that is movably supported and rotatably supports a rotation table (13) on which an external gear (W1) or an internal gear (W2) is mounted; a bridge section (14c) of a gate-shaped column (14) provided at a location above the movement base (12); a saddle (15) which is supported by the bridge section (14c) in a vertically movable manner; and a cutter head (16) which is provided on the front surface of the saddle (15), and the lower end of which rotatably supports a tool (T). A protrusion (16a) which projects forward is provided on the front surface of the cutter head (16). The tool (T) is disposed in such way that the front thereof protrudes further forward of an end surface (16b) which is the most forward projecting portion of the protrusion (16a).

Owner:MITSUBISHI HEAVY IND LTD

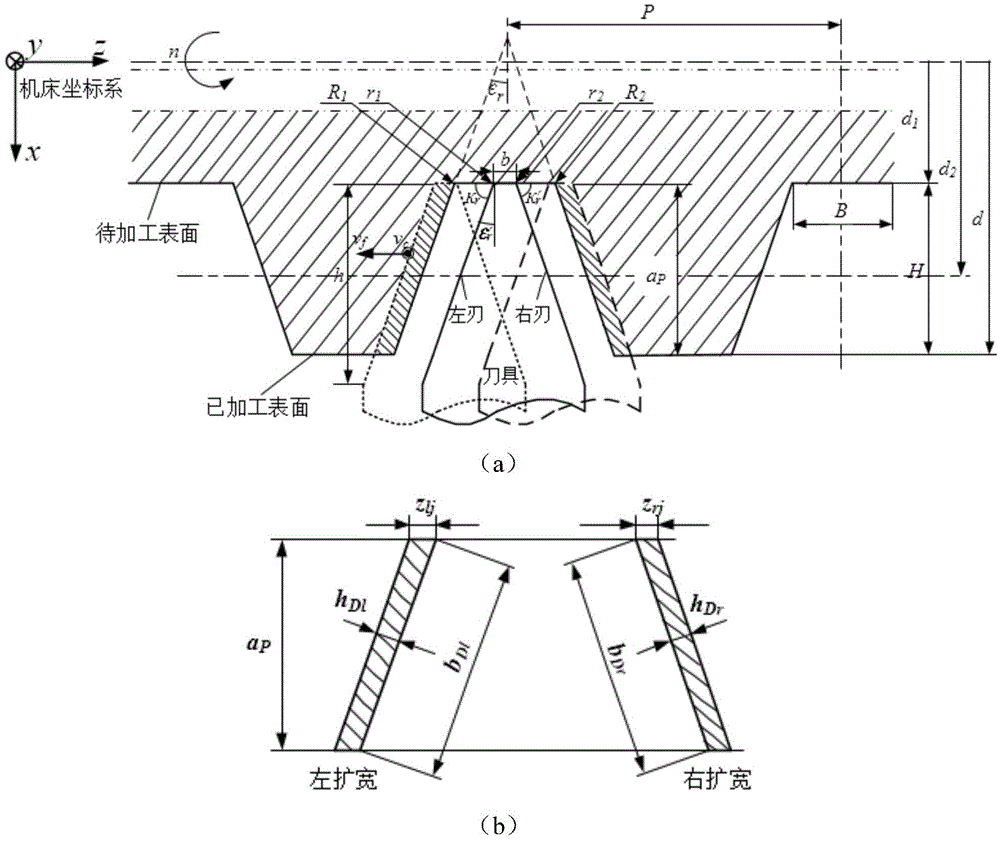

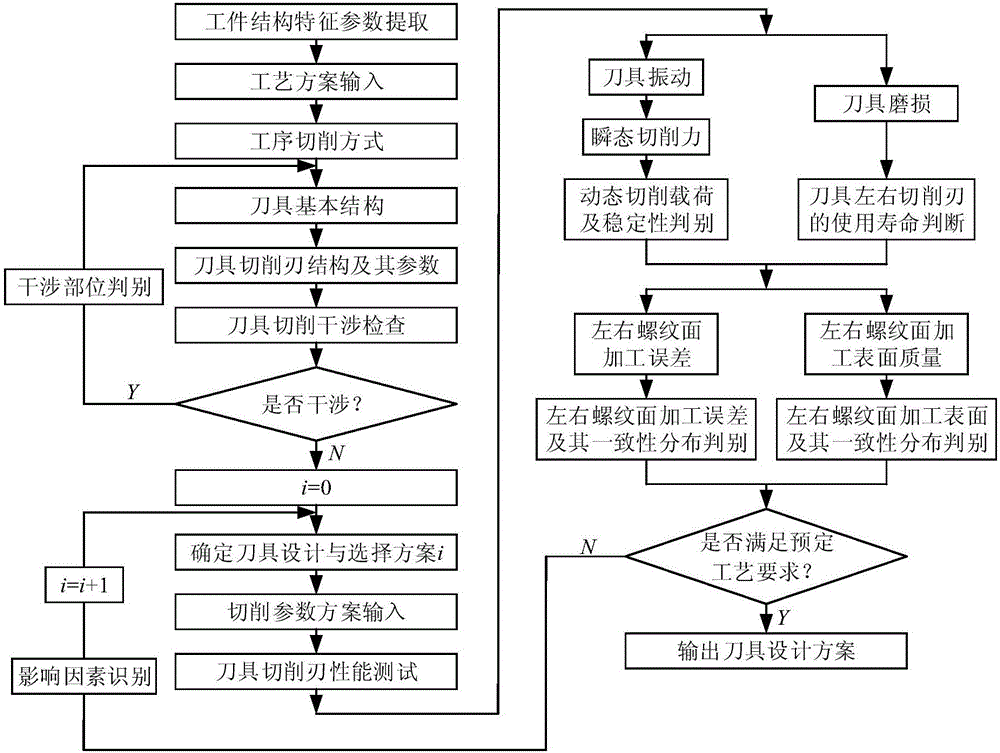

Large-pitch thread turning tool design method

ActiveCN106407622AImprove processing qualityAvoid deformation and rapid wearGeometric CADTurning toolsDesign objectiveEngineering

The invention provides a large-pitch thread turning tool design method. According to the technical main points, the method comprises the steps of (1) determining a process scheme and a procedure cutting method according to structure characteristics of a processed large-pitch thread workpiece and setting a cutting tool with a basic tool structure suitable for turning the large-pitch thread workpiece, wherein the basic tool structure of the cutting tool comprises a tool cutting edge structure and parameters thereof; (2) carrying out tool cutting interference checking, if interference does not exist, determining a cutting experiment on the workpiece by using the cutting tool; (3) inputting a cutting scheme to turn the workpiece and obtaining a tool vibration signal and a rear tool surface abrasion image of the tool; and (4) evaluating the cutting scheme of the cutting tool by taking the dynamic load consistency of left and right edges of the cutting tool, the left, right and back tool surface abrasion consistency of the cutting tool, the processing precision of left and right thread surfaces of the workpiece and the processing surface quality consistency as design objectives. According to the large-pitch thread turning tool design method, the loads of the left and right edges of the tool are improved; the abrasion is reduced; the consistency is good; and the processing quality of the workpiece is improved.

Owner:HARBIN UNIV OF SCI & TECH

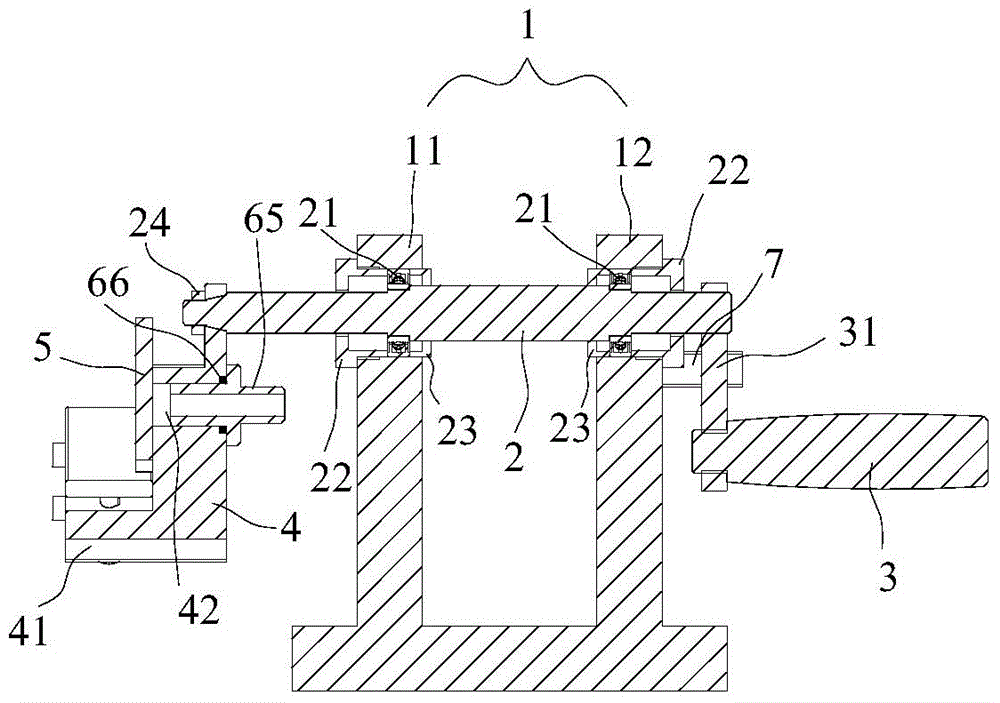

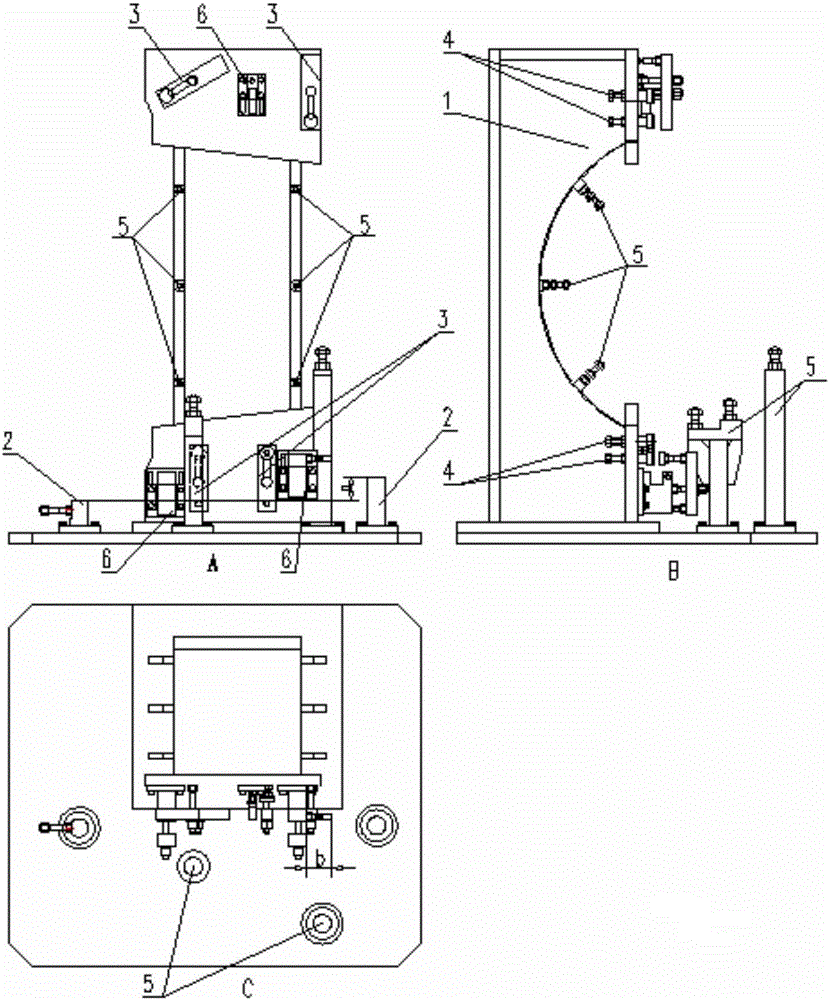

Special tool clamp for wind driven generator one-piece bearing pedestal casting and machining technology

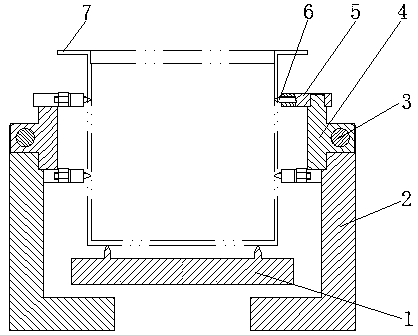

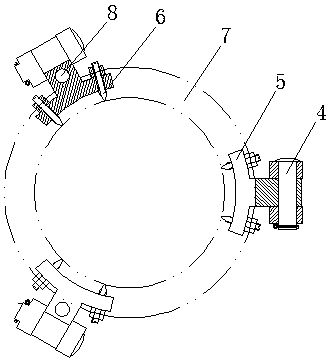

ActiveCN105234701AReduce turning timesGuaranteed cylindricityPositioning apparatusMetal-working holdersUltimate tensile strengthMechanical engineering

The invention relates to a special tool clamp for a wind driven generator one-piece bearing pedestal casting and a machining technology and belongs to the technical field of mechanical part machining. The special tool clamp comprises a box, a positioning device, a pressing device, an adjusting device and a supporting device. According to the special tool clamp for the wind driven generator one-piece bearing pedestal casting, a one-piece bearing pedestal lies one side to be clamped on the special tool clamp, a rotating workbench, bearing pedestal holes, a blast hole, an end face and peripheral faces complete finish machining through one time of clamping, the cylindricity and the coaxiality of the bearing pedestal holes in the two ends are guaranteed, the overturning frequency of the casting is reduced, the machining precision required in graph paper is achieved, production efficiency is improved, and production cost and labor intensity of workers are reduced.

Owner:JIANGSU JIXIN WIND ENERGY TECH

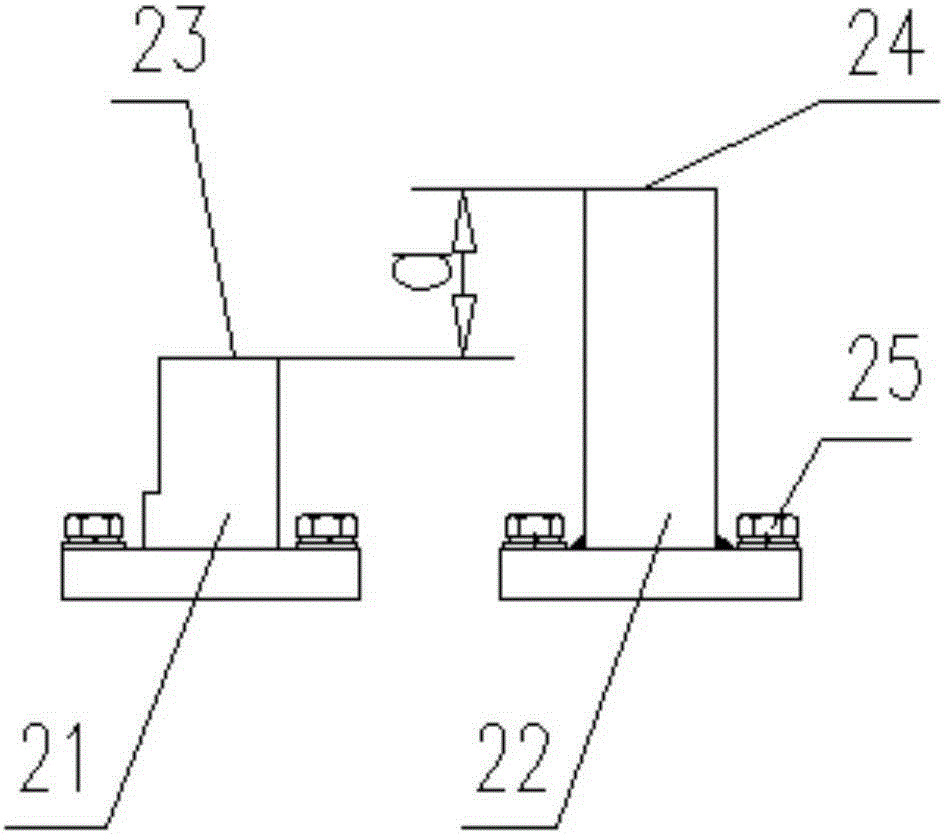

Reverse machining method and positioner for flat-shoulder sleeve

InactiveCN102794494AAchieve machining accuracyEasy to processPlaning/slotting machinesPositioning apparatusEngineeringMachining process

The invention discloses a reverse machining method for a flat-shoulder sleeve. The reverse machining method comprises the following steps: blanking, clamping a positioner with a rectangular block positioning part on a planer vice clamp and arranging a first positioning shoulder on one end of the cylindrical long blank, wherein the first positioning shoulder is used for positioning the cylindrical long blank or the flat-shoulder sleeve, and the first positioning shoulder comprises a first flat shoulder and a second flat shoulder which are respectively formed on one end of the cylindrical long blank, correspondingly; starting a bullnose plane to machine the first flat shoulder on one end of the cylindrical long blank; pulling out a plug pin to rotate the cylindrical long blank by 180 degrees; using the plug pin to lock the radial rotation of the cylindrical long blank; machining the second flat shoulder corresponding to the first flat shoulder on one end of the cylindrical long blank, namely machining the flat shoulder on the symmetrical side of the first flat shoulder; and then, machining the flow positioning shoulder on the rest sections of the cylindrical long blank; and breaking the blank into small-section cylindrical solid barrel, machining and smoothening the solid barrels to be hollow barrels, namely the flat-shoulder sleeves. The reversing machining method uses processes and manners reverse to those in the field so as to achieve a machining process for simultaneously forming a plurality of workpieces, thereby achieving high processing precision and improving the processing efficiency.

Owner:BAOSTEEL STAINLESS STEEL

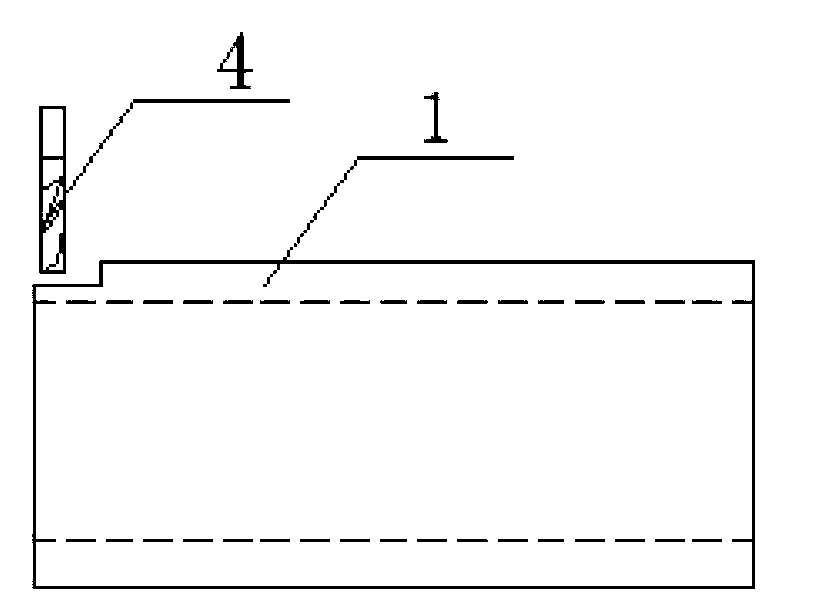

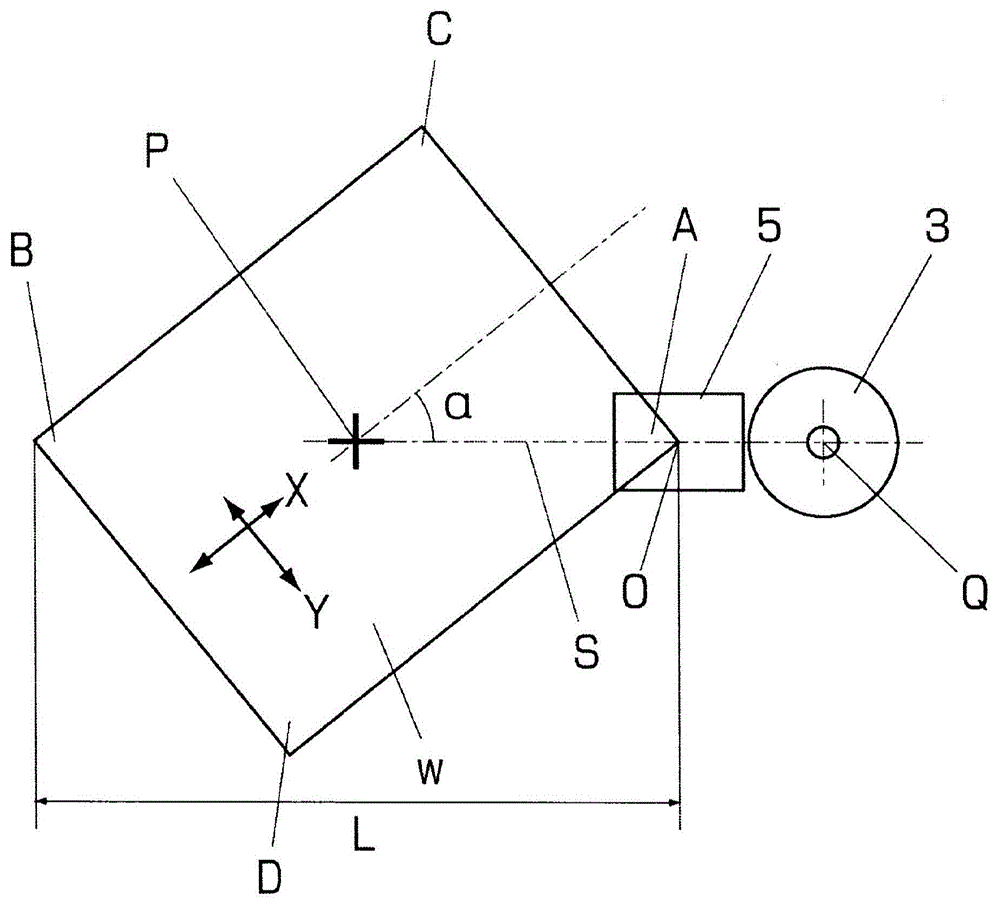

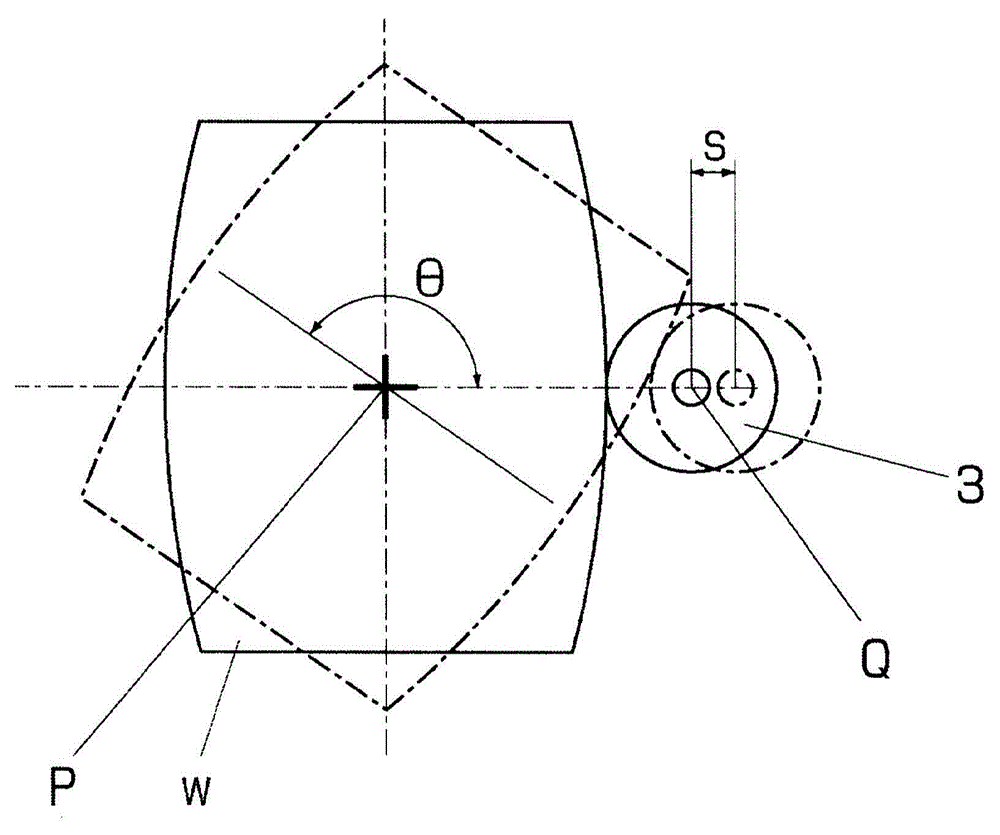

Homogenization method of chipping allowance and periphery grinding apparatus of plate

InactiveCN104339241AAchieve machining accuracyReduce the number of man-hours for measurementEdge grinding machinesGrinding feed controlMotor driveEngineering

The invention provides a homogenization method of chipping allowance and a periphery grinding apparatus of a plate, and relates to an apparatus for grinding a glass substrate of a display panel of a portable terminal and peripheries of other plates, even in a polar coordinate system, the grinding apparatus can automatically set a corrected value for homogenizing chipping allowance of a workpiece at the whole periphery of the workpiece. Before processing and after processing the workpiece held on a workbench, images of predefined periphery portions at more than three positions of the workpiece are acquired by using a camera, differences of positions of sides of the workpiece before processing and after processing at the periphery portions of each position are detected, a corrected value for homogenizing the differences of the positions of the sides at the periphery portions at more than three positions is calculated, and the corrected value is set to a controller. The controller uses the set corrected value to correct instruction values provided to a spindle motor driving the workbench to rotate and a feed motor of a grinding wheel.

Owner:NAKAMURATOME SEIMITSU IND

Punching and flattening die for producing automobile covering parts

InactiveCN105665523AAchieve machining accuracy and productivityAchieve machining accuracyShaping toolsPerforating toolsEngineeringChinese characters

The invention relates to a stamping die in the field of machinery, in particular to a punching and flattening die for producing automobile covering parts. The punching and flattening die comprises a base plate, a clamping-punching device and a flattening device, wherein the clamping-punching device and the flattening device are arranged on the base plate, the clamping-punching device comprises upper die plates and lower die plates which are vertically arranged, the upper die plate and the lower die plate are each provided with a semicircular groove, and a puncher pin is arranged on the upper die plate. The flattening device comprises a lower die, an upper die, a stamping slide block, a flattening slide block, a flattening puncher pin and a spring, a sliding way in a shape of a Chinese character 'ao' is formed in the lower die, the flattening slide block is movably fixed to the sliding way in the shape of the Chinese character 'ao', one end of the spring is connected to the flattening slide block, the other end of the spring is fixed to the lower die, and the stamping slide block is arranged on the upper die. The punching and flattening are simultaneously performed through a set of the die, and the machining precision and production efficiency of products are greatly improved.

Owner:合肥亿恒智能科技有限公司

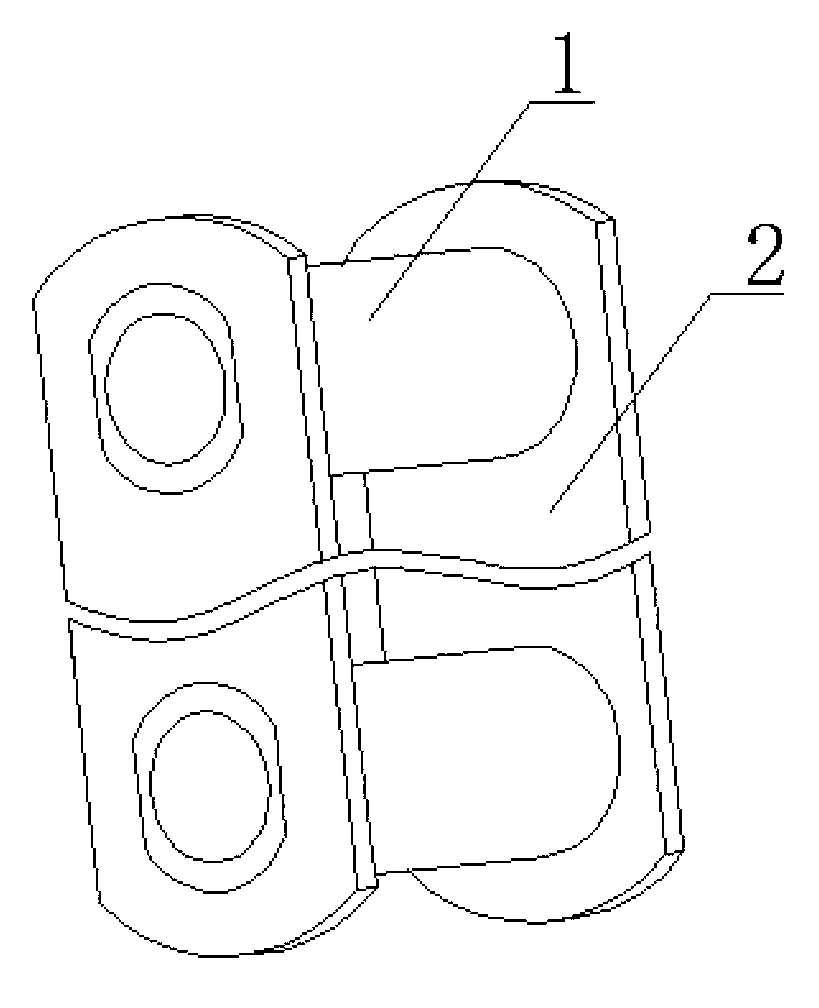

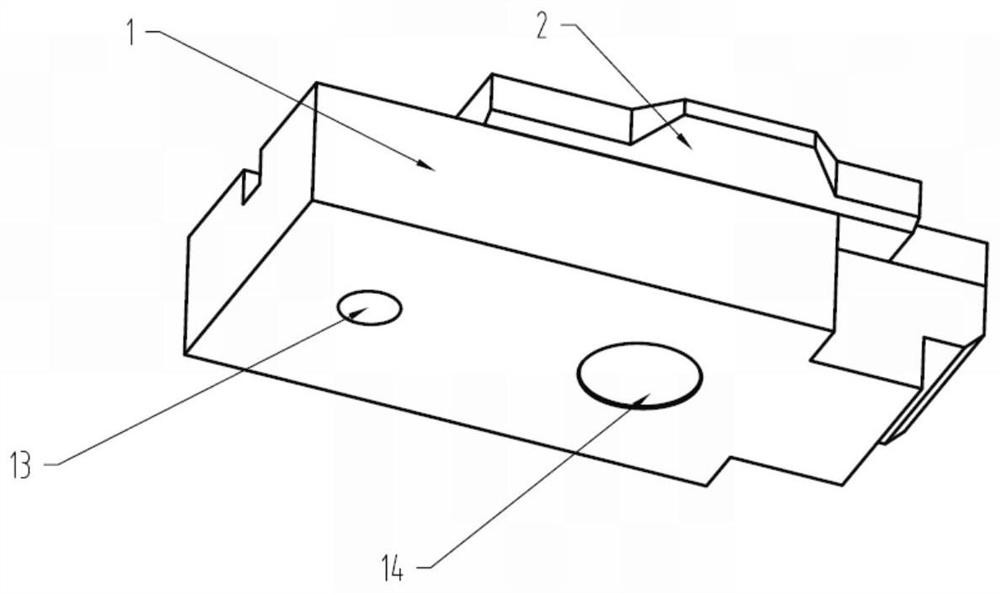

Optical fiber clamp and fusion splicer

PendingCN113376745AMeet the needs of reliable positioningQuick slotCoupling light guidesEngineeringOptical fiber connector

The invention discloses an optical fiber clamp and a fusion splicer, and belongs to the field of optical fiber fusion splicers. The optical fiber clamp comprises a pressing plate cover and a base, the pressing plate cover is hinged to the base, the upper end face of the base is provided with an optical fiber groove penetrating through the end faces of the two sides of the base, the middle of the pressing plate cover is provided with a special-shaped hole suitable for a special optical fiber connector, and the pressing plate cover covers the upper side of the optical fiber groove of the base; a magnet capable of being attracted with the pressing plate cover is embedded in the position, corresponding to the pressing plate cover, of the upper end face of the base, and a limiting hole is further formed in one side of the base; and the optical fiber clamp is installed on the base of the optical fiber fusion splicer, the second magnet of the clamp base is integrally attracted to the base of the optical fiber fusion splicer, and the limiting hole of the clamp base is matched with the limiting pin of the base of the optical fiber fusion splicer. The requirement for reliable positioning of the special connector optical fiber is met, the optical fiber can enter the groove quickly, and it is guaranteed that the optical fiber is not dislocated.

Owner:中电科思仪科技(安徽)有限公司

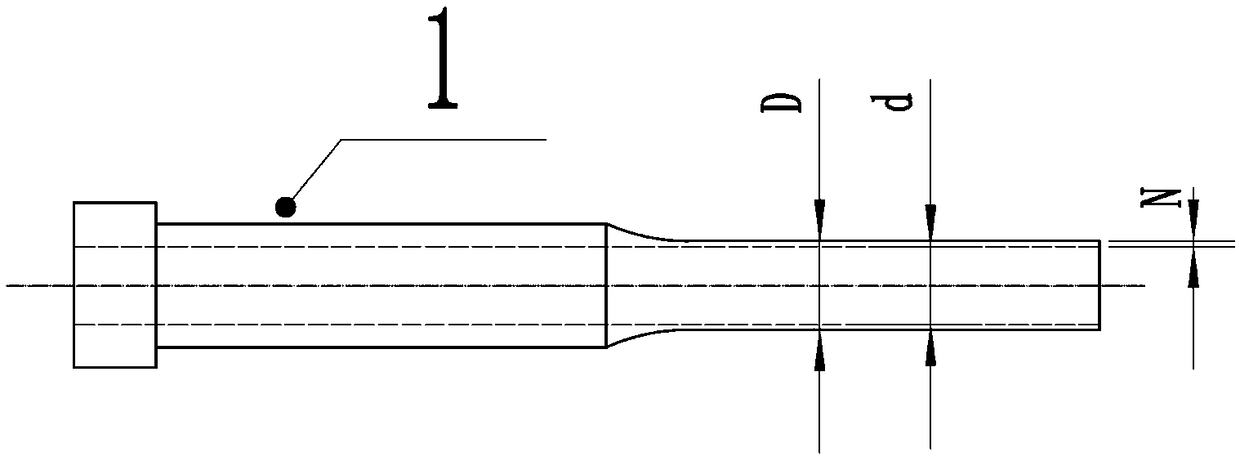

High-precision thin-wall push pipe machining technology and casing tool

InactiveCN109176179AAchieve machining accuracyImprove processing efficiencyRevolution surface grinding machinesGrinding work supportsEngineeringMechanical engineering

The invention belongs to the technical field of push pipe machining and particularly relates to a high-precision thin-wall push pipe machining technology and a casing tool. During rough machining, thegrinding amount is normally reserved in a hole of a thin-wall push plate, the outer diameter is thickened, an inner hole is subjected to finish machining after heat treatment, finally, the outer diameter is machined with the inner hole serving as the benchmark, and the precision of the thin-wall push pipe is finally ensured. The machining special casing pipe suitable for the high-precision thin-wall push pipe and the matched machining technology are adopted, the machining efficiency is high, the quality is stable, and the requirements for the machining precision and form and location precision of the high-precision thin-wall push pipe can be met.

Owner:PUNCH IND DALIAN

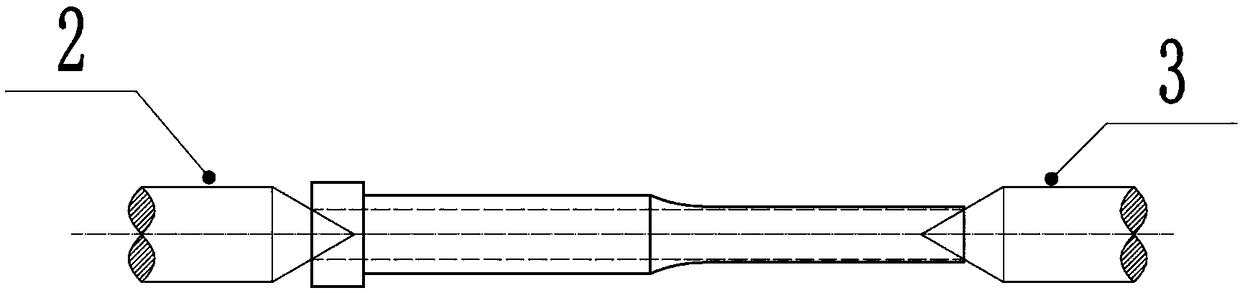

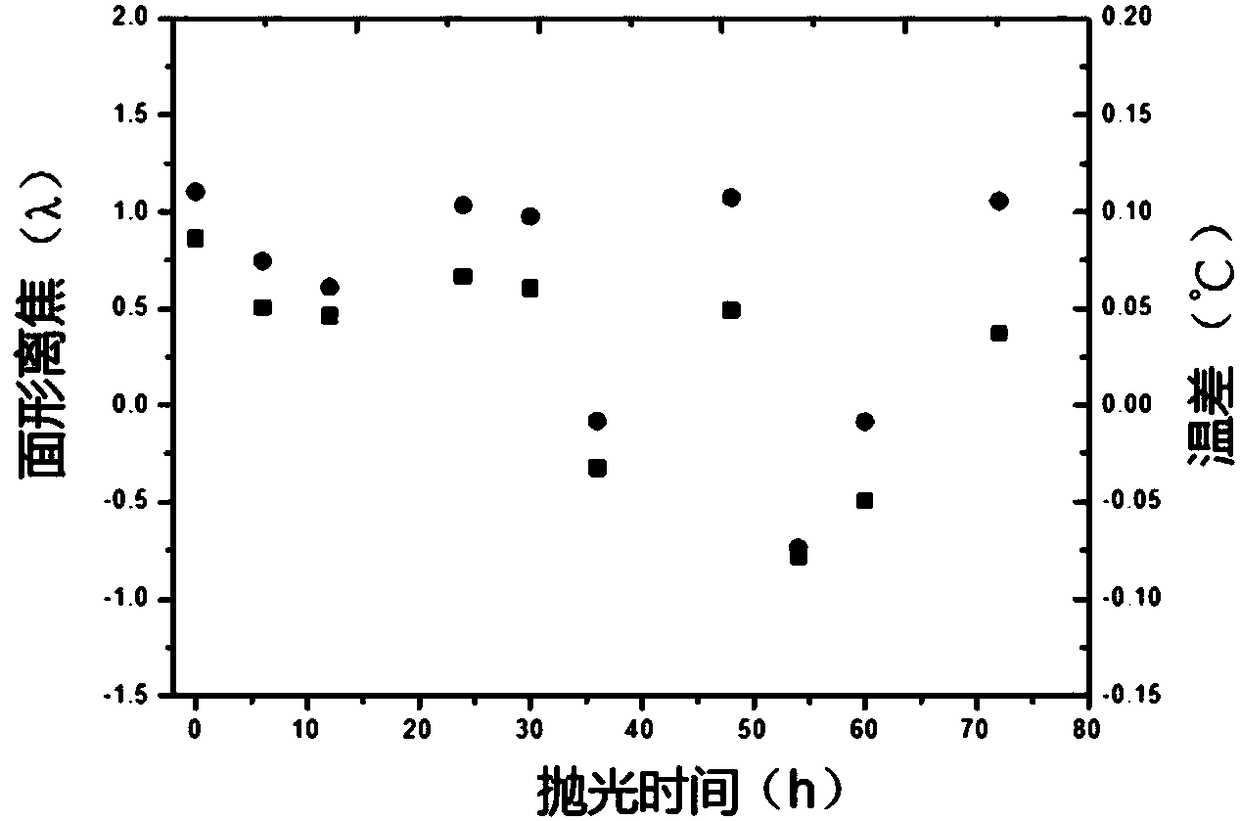

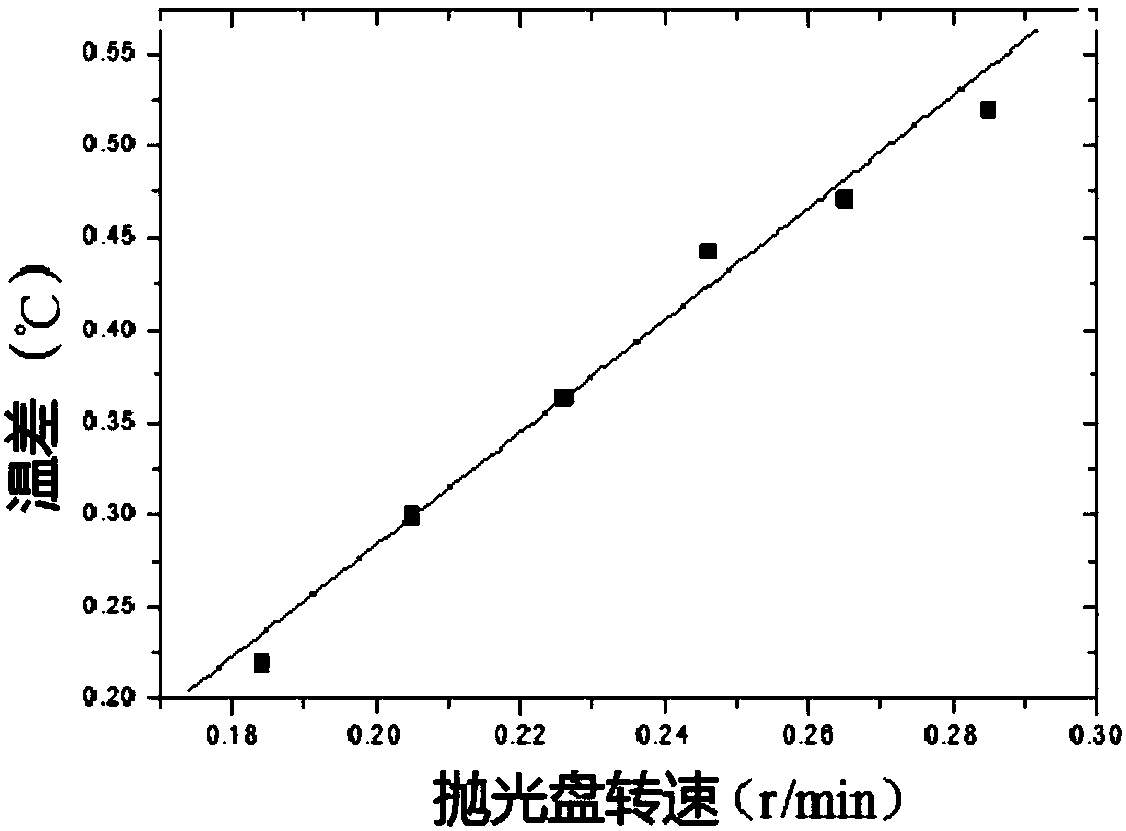

Annular polishing surface shape accurate adjustment method for plate type optical components

ActiveCN108177027AAchieve machining accuracyImprove controllabilityOptical surface grinding machinesWavefrontDistribution control

The invention discloses an annular polishing surface shape accurate adjustment method for plate type optical components. According to the annular polishing surface shape accurate adjustment method forthe plate type optical components, the variation of reflection / transmission surface shapes is adjusted by using the thermal deformation of the plate type optical components during the course of annular polishing and accordingly the rapid and controllable conversion of the heights of the surface shapes of the components can be made during the surface shape preserving period of a polishing mould, so that the annular polishing reflection / transmission wavefront distribution control efficiency of the plate type components can be greatly improved. The method is particularly applicable to the platetype optical components which are large in thermal expansivity and prone to deform, such as laser neodymium glass sheet-shaped components with the caliber of 400 mm, so that the uncertainty of surfaceshape control can be effectively overcome during the annular polishing course of the plate type components, the machining accuracy of the meter-scale plate type optical components can be realized, the surface shape PV is superior to 1 / 5 lambda (lambda=632.8 nm) and GRMS is superior to 1 / 90 lambda.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

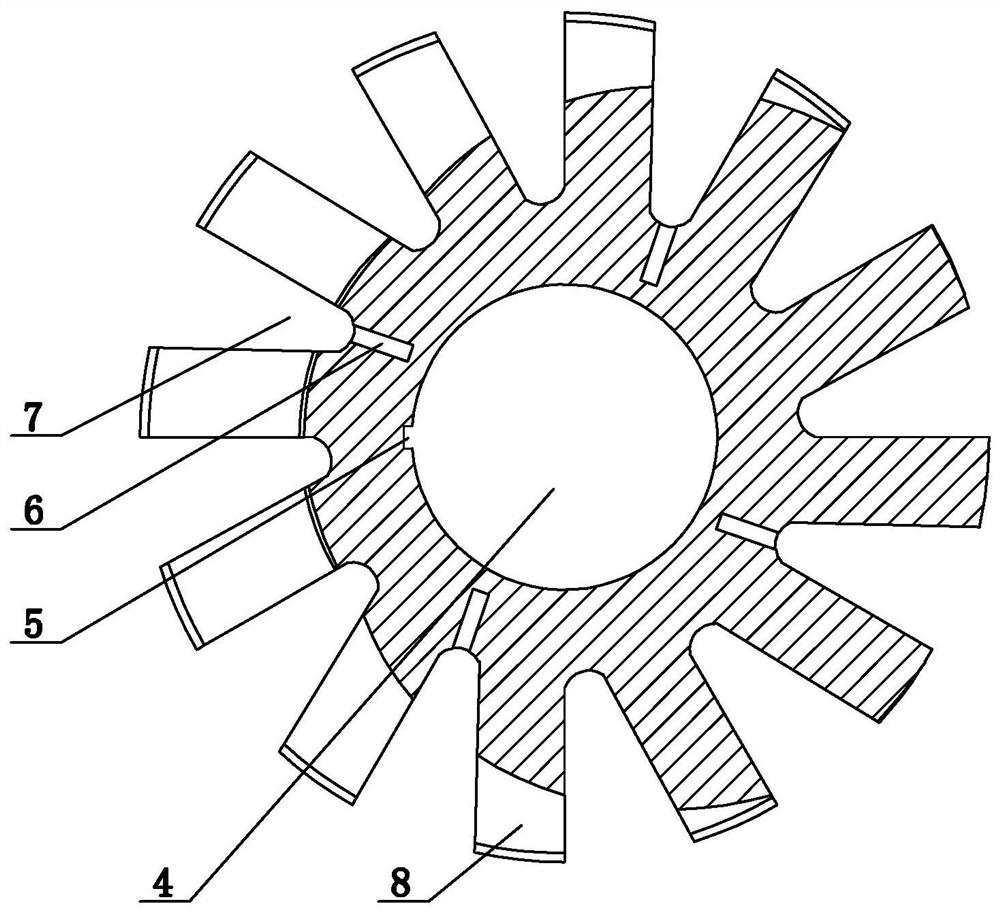

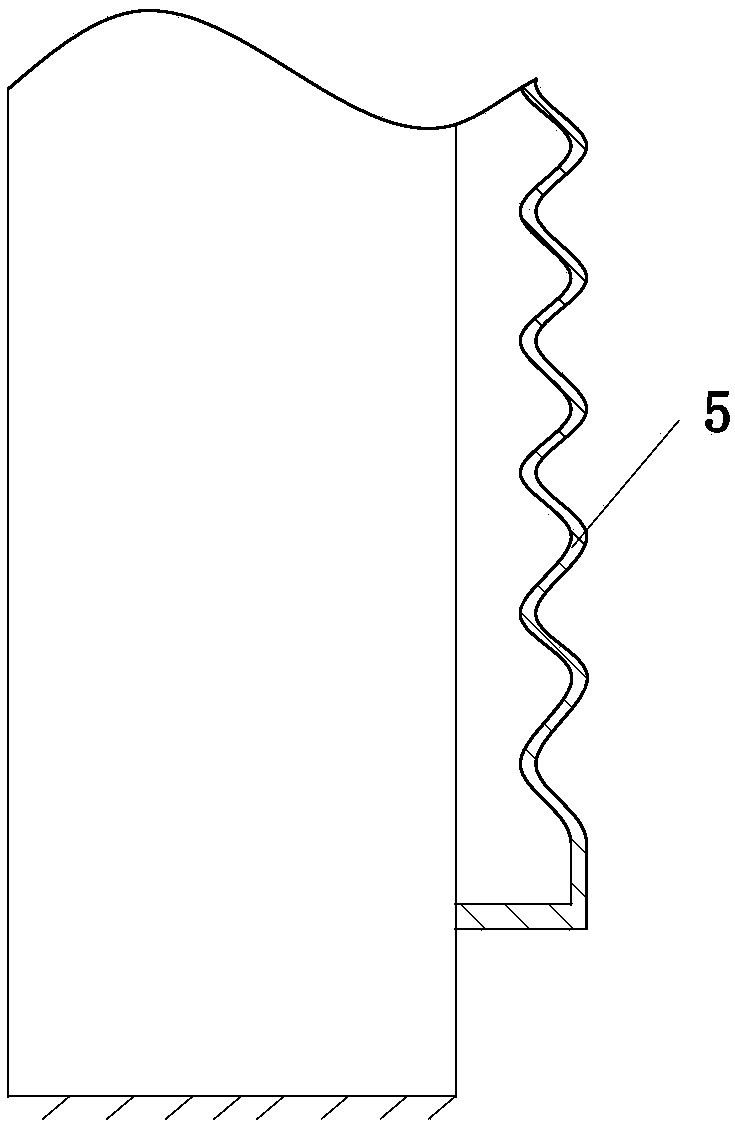

Roughing and finishing integrated hard alloy dry-cutting hob

InactiveCN111922448AImprove machining accuracyShort processGear teeth manufacturing toolsGear teethGear wheelAlloy

The invention discloses a roughing and finishing integrated hard alloy dry-cutting hob and belongs to the technical field of gear machining tools. The roughing and finishing integrated hard alloy dry-cutting hob comprises a hob body, a roughing hob set and a finishing hob set, wherein the center of the hob body is provided with a hob locating hole in the axial direction; the hob body, the roughinghob set and the finishing hob set are all made of hard alloy, the inner wall of the hob locating hole is provided with a key groove in key connection with a hobbing machine tool spindle, the roughinghob set and the finishing hob set are detachably and fixedly connected to the hob body respectively, multiple V-shaped roughing hob chip containing grooves are uniformly distributed in the outer circle surface of the roughing hob set, multiple V-shaped finishing hob chip containing grooves are uniformly distributed in the outer circle surface of the finishing hob set, a roughing front cutting edge and a roughing side cutting edge are arranged on the front surface of each roughing hob blade in the roughing hob set, and a finishing front cutting edge and a finishing side cutting edge are arranged on the front surface of each finishing hob blade in the finishing hob set. The hob is used for roughing and finishing of a gear.

Owner:HARBIN UNIV OF SCI & TECH

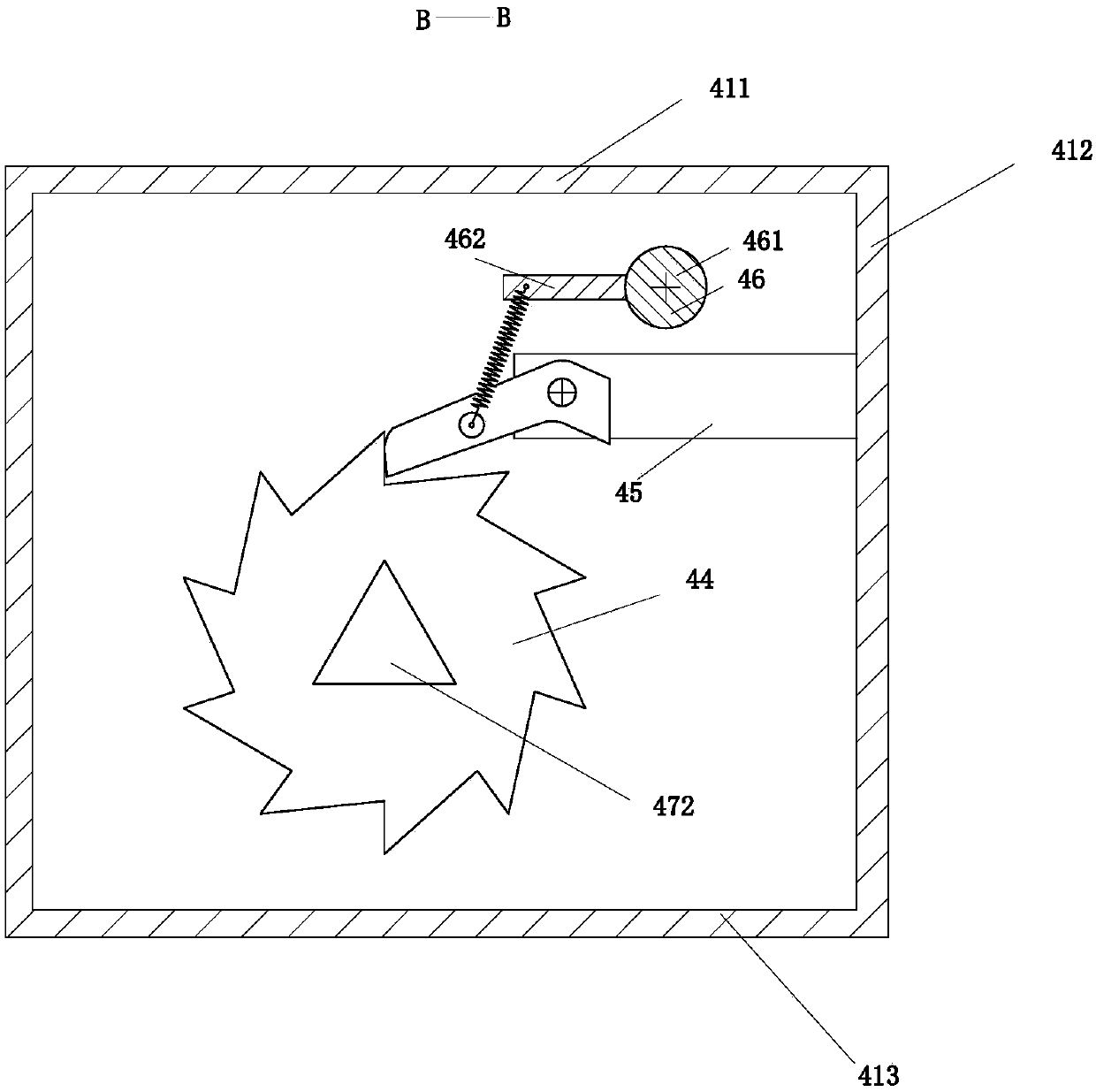

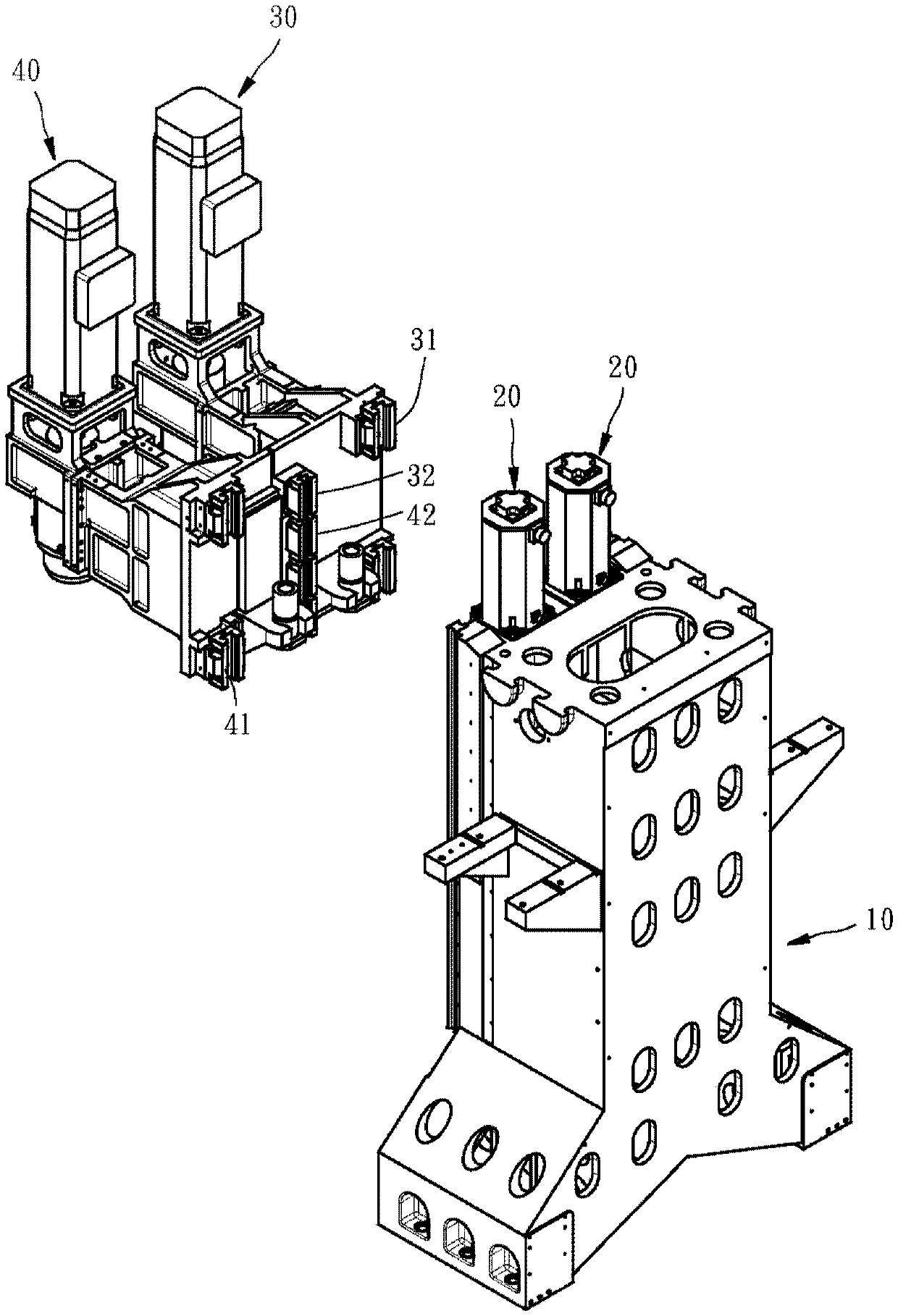

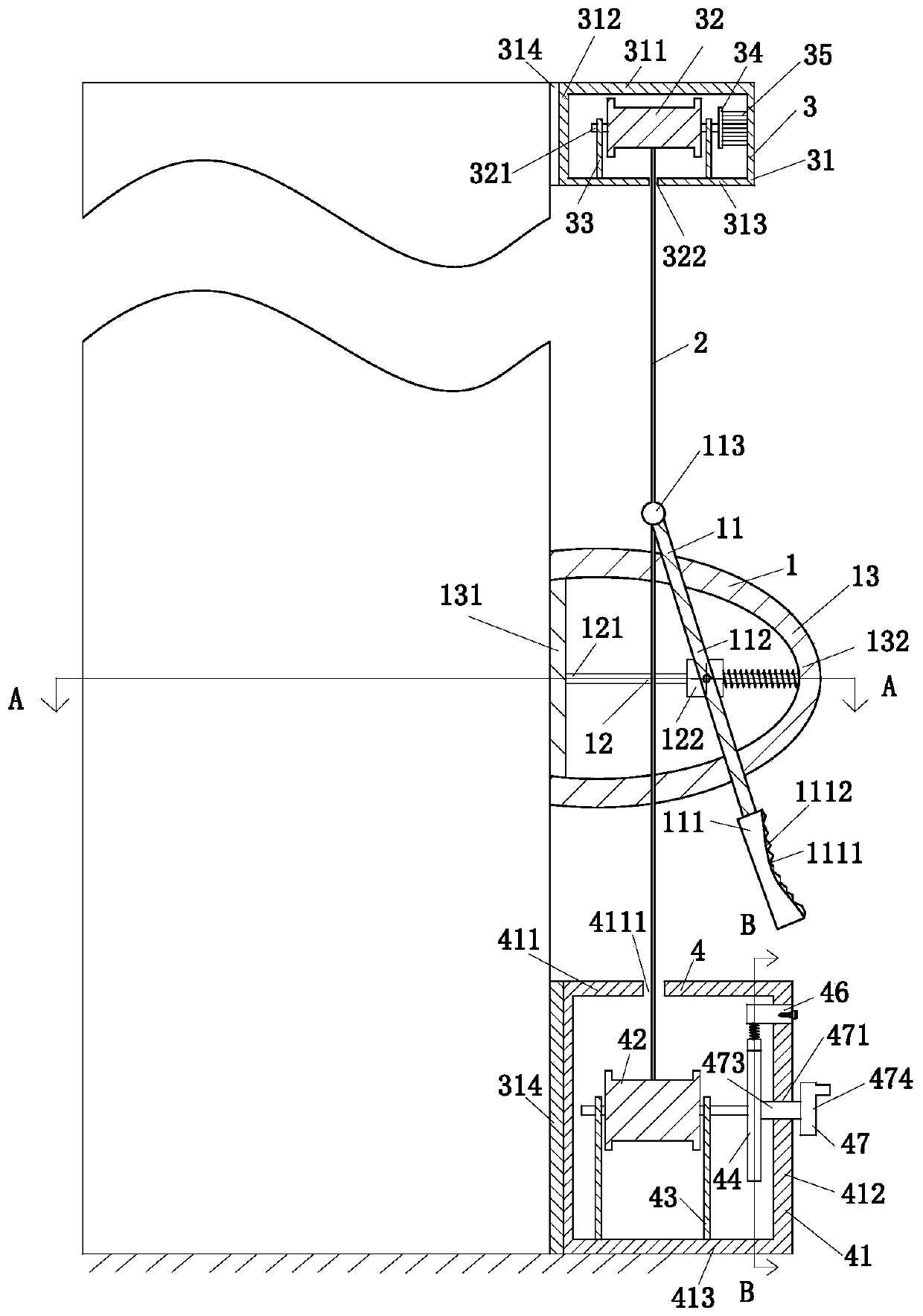

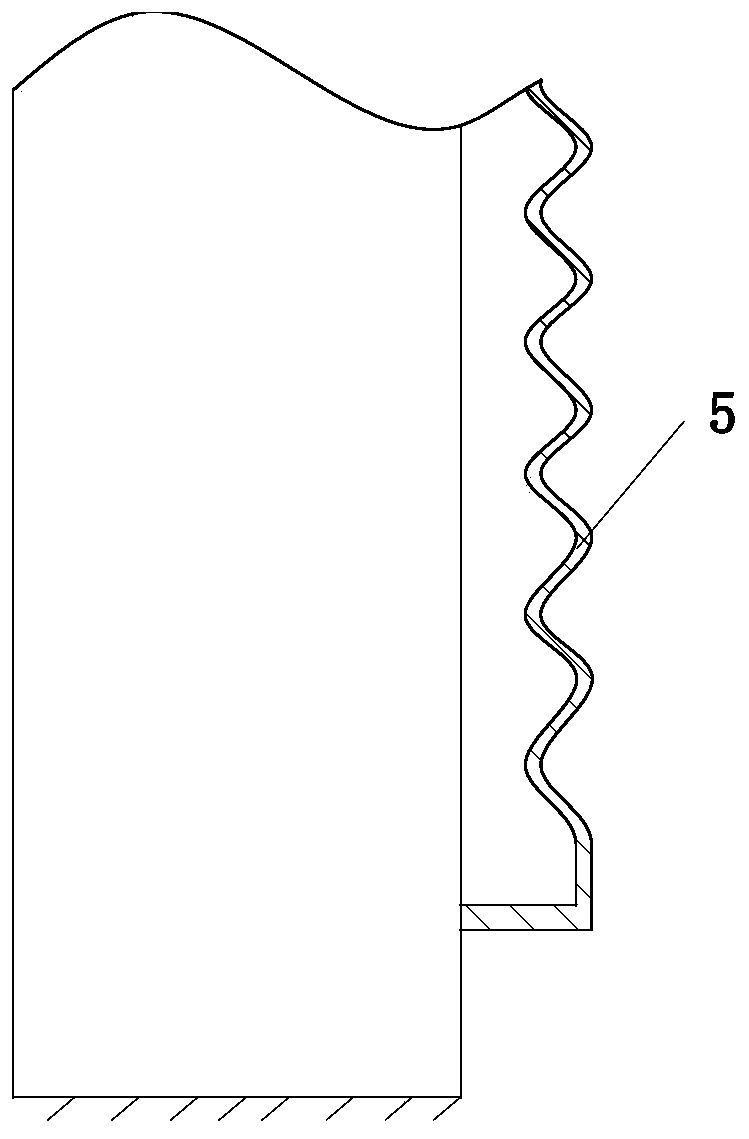

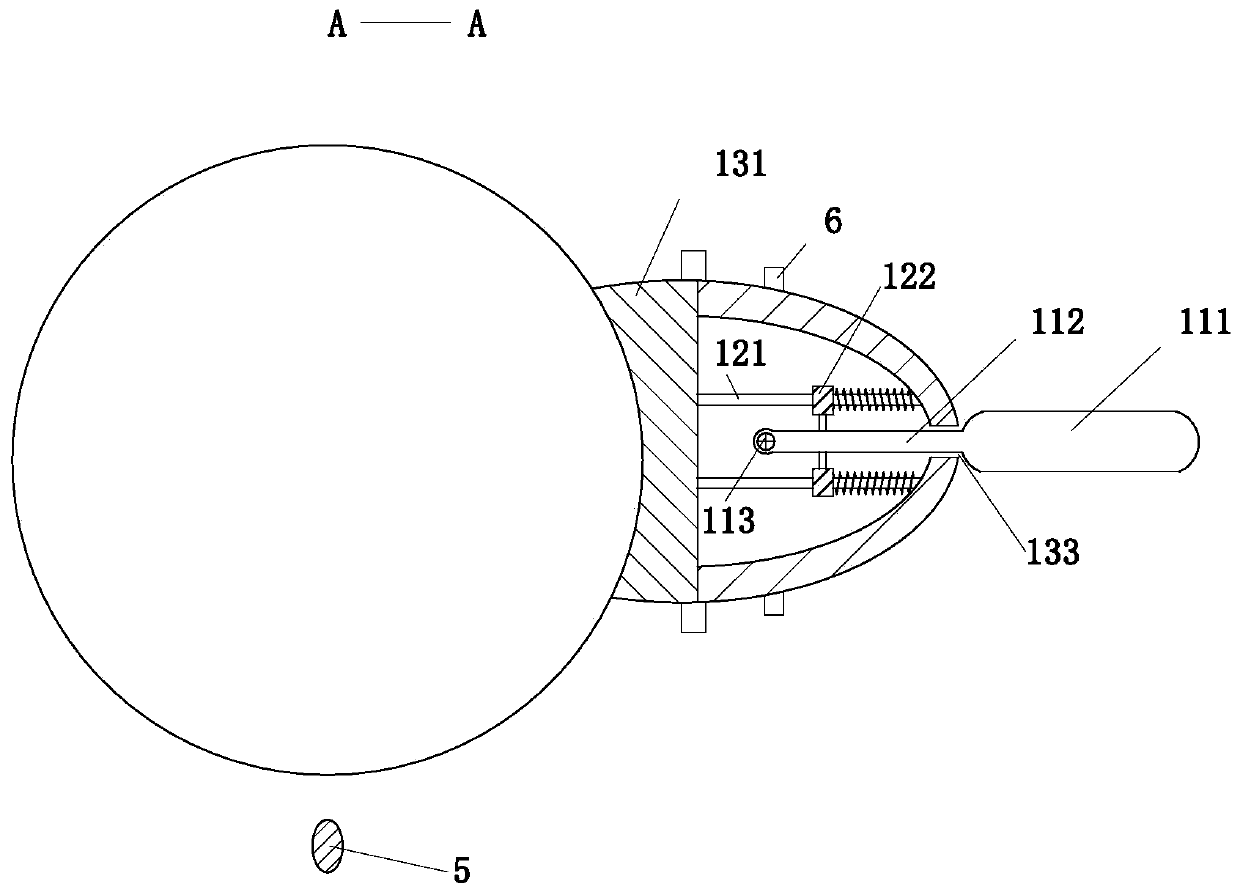

Anti-climbing signal tower

The invention belongs to the field of signal communication towers and particularly relates to an anti-climbing signal tower. The anti-climbing signal tower comprises a climbing unit, a steel wire rope, a tensioning unit and a winding unit, wherein the tensioning unit, the climbing unit and the winding unit are sequentially arranged on the right side of the signal tower from top to bottom. The steel wire rope is connected between the tensioning unit and the climbing unit, and the climbing unit comprises a climbing plate, a limiting unit and a first box. The winding unit is fixedly connected with a fixed head through the steel wire rope; the tensioning unit is used for automatically tightening the steel wire rope; the winding unit is used for downwards pulling the steel wire rope; the steelwire rope drives the fixed head to downwards move to enable a connecting rod to push a sliding block to rightwards move; and a locking unit in the winding unit can limit working of the winding unit. The anti-climbing signal tower is mainly used for climbing of the cylindrical signal tower, the climbing unit can be controlled in a hand-operated mode, and meanwhile a constructor controls the lockingunit to lock the climbing unit through a key to prevent climbing of the signal tower by non-staff.

Owner:安徽明辉电气有限公司

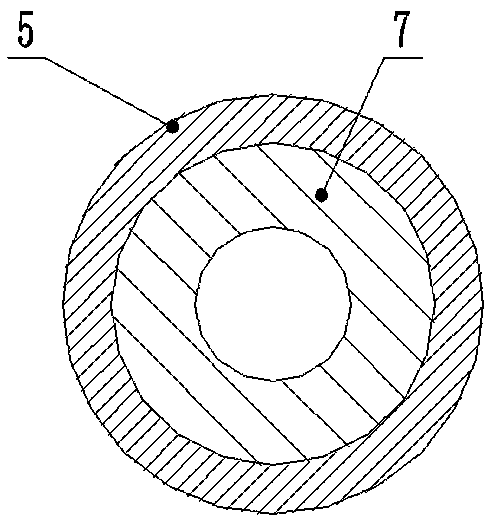

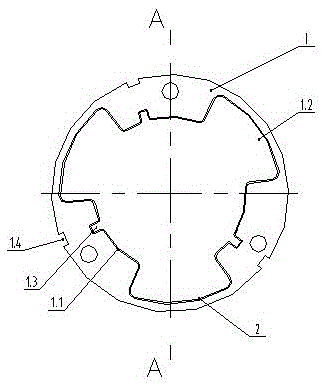

Powder metallurgy automobile engine stator and manufacturing methods thereof

InactiveCN105610251AIncrease profitSave man hoursMagnetic circuit stationary partsManufacturing stator/rotor bodiesRare earthEngineering

The invention discloses a powder metallurgy automobile engine stator. The stator is a circular ring component taking powder metallurgy as a main body. The stator comprises an annular main body. An inner hole of the main body is formed by several embossments and grooves which are arranged with intervals along a circumference direction. Inner walls of the embossments are provided with technology grooves. A main body outer wall corresponding to a radial direction of the technology grooves is provided with an oil groove. Improved points are characterized in that a hole wall of the inner hole of the main body is provided with a wear-resisting composite layer; and the wear-resisting composite layer is a rare earth compound composite layer. The invention also discloses three kinds of manufacturing methods of the powder metallurgy automobile engine stator. Structure intensity is high, a material utilization rate is high, wear-resisting performance is good and a lubricity is good.

Owner:TAIZHOU KECHENG AUTOMOBILE PARTS

A method for preparing a hollow structure on the surface and inside of a transparent material

ActiveCN111185678BAbility to realize three-dimensional processingAchieve machining accuracyCleaning using liquidsLaser beam welding apparatusEtchingFemto second laser

The invention discloses a method for preparing a hollow structure on the surface and inside of a transparent material, which belongs to the technical field of femtosecond laser micro-nano processing. The invention uses a femtosecond laser direct writing method to write inside a transparent material through precise control of polarization and processing power. Directly write the modified area with an accuracy of hundreds of nanometers, then use mechanical / ion beam thinning to thin the surface of the transparent material to the position of the processed area (surface processing), and finally use wet etching to etch the material, Finally, the preparation of a hollow structure with a precision of hundreds of nanometers and an arbitrary patterned structure was realized. The method of the invention can realize high-efficiency and high-precision processing of various common transparent materials in a vacuum-free environment, and solves the problems of relatively high environmental requirements and low processing efficiency in the prior art.

Owner:JILIN UNIV

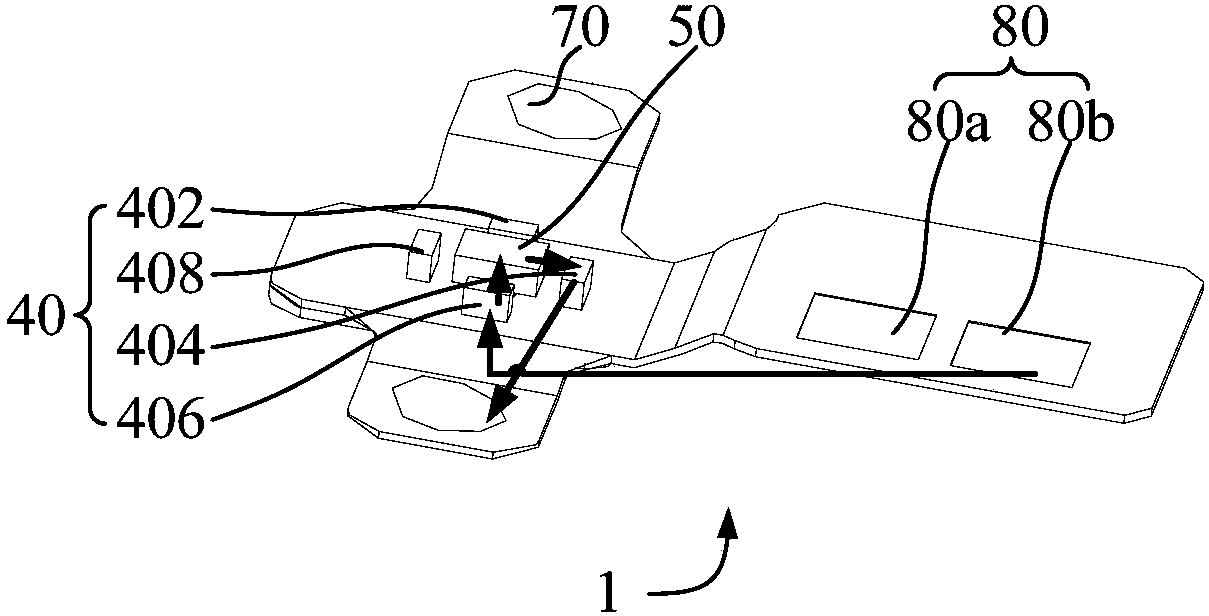

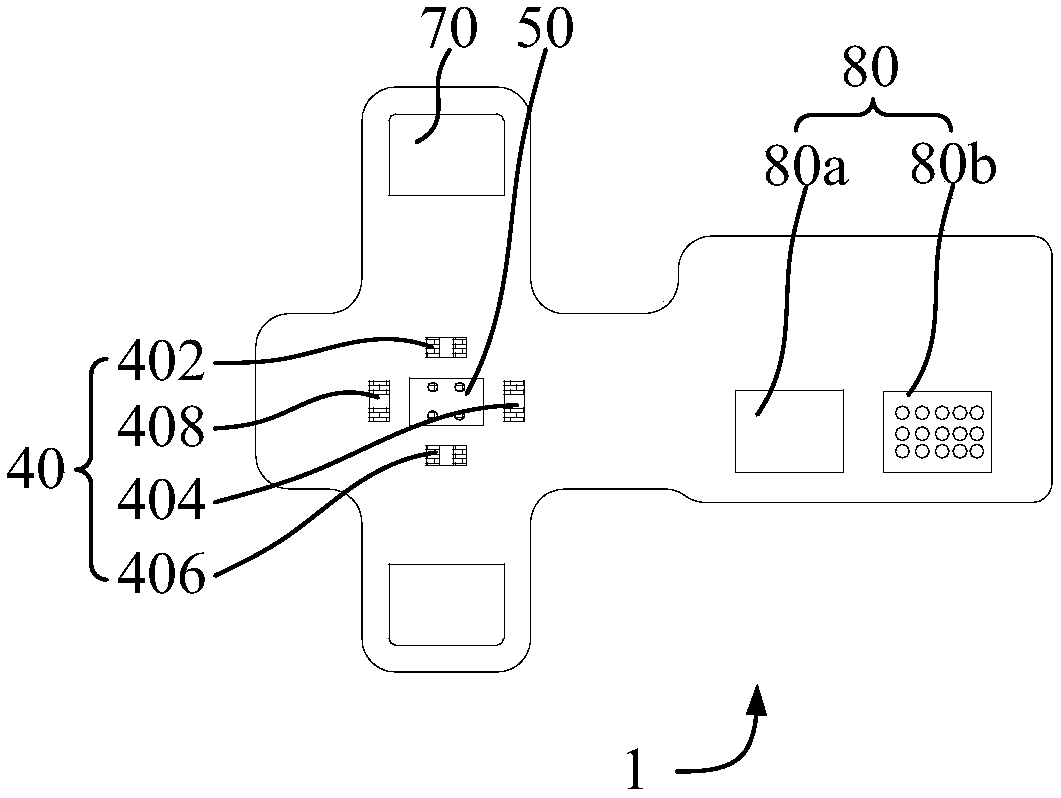

Antenna assembly and terminal

PendingCN107834213ASmall sizeGuaranteed reliabilityAntenna supports/mountingsRadiating elements structural formsStructural engineeringMechanical engineering

The invention provides an antenna assembly which is used for a terminal, and the terminal is provided with a battery cover and a mainboard. The antenna assembly comprises a first antenna body, of which one end is connected with the battery cover; a second antenna body, which is opposite to the first antenna body; a connecting assembly, of which the two opposite ends are connected with the first antenna body and the second antenna body respectively; at least one connecting hole penetrating through the first antenna body, the connecting assembly and the second antenna body; and a conduction layer which is arranged on the hole wall of the at least one connecting hole; wherein the first antenna body and the second antenna body are conducted through the conduction layer. According to the structure of the antenna assembly, the size of the antenna assembly is reduced., so that the impedance value is reduced, the use reliability of the product is ensured. One end of the first antenna body is directly connected with a battery cover, so that the occupation rate of the antenna assembly in the internal space of the terminal is reduced, and the lightening and thinning of the product are realized.

Owner:MEIZU TECH CO LTD

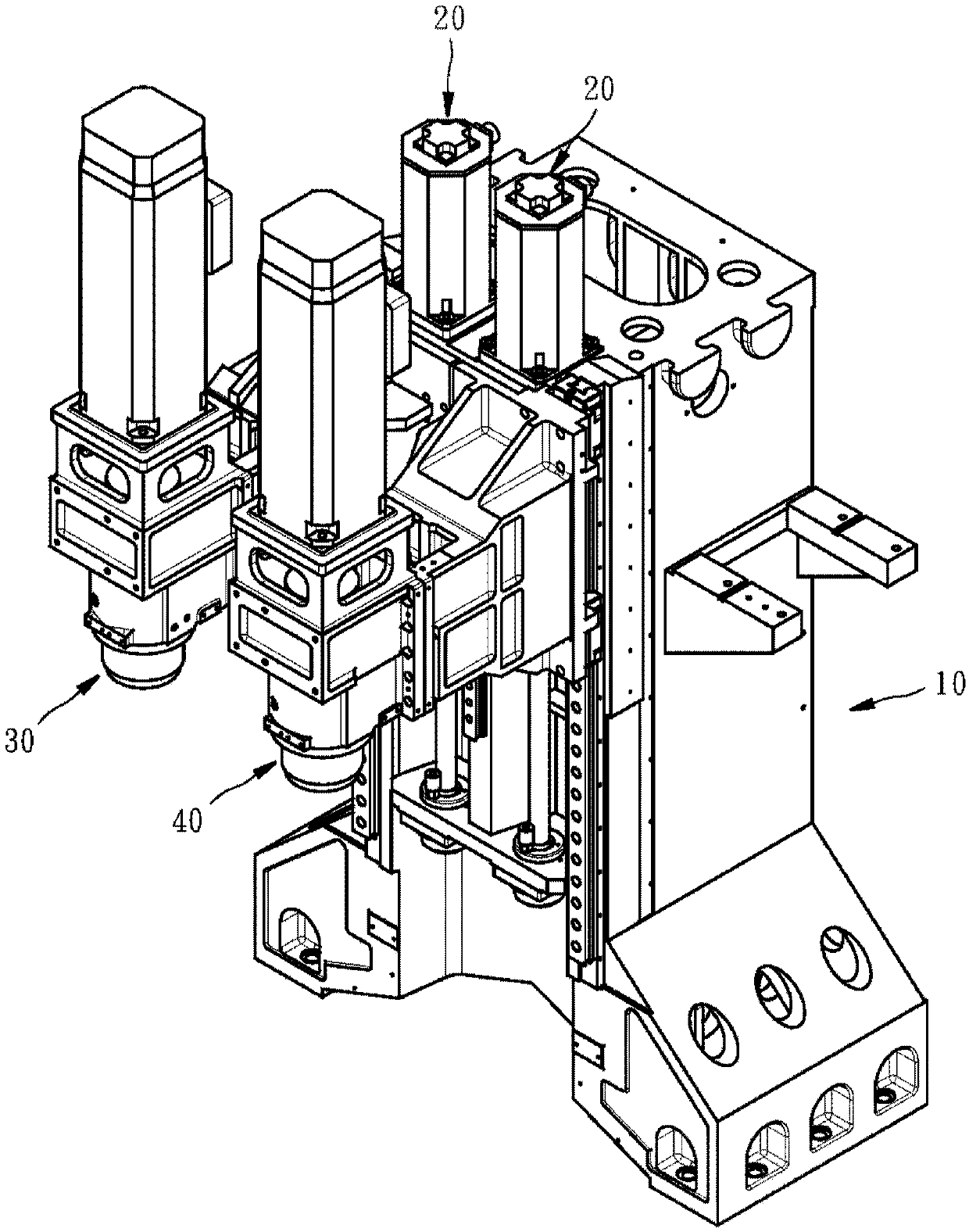

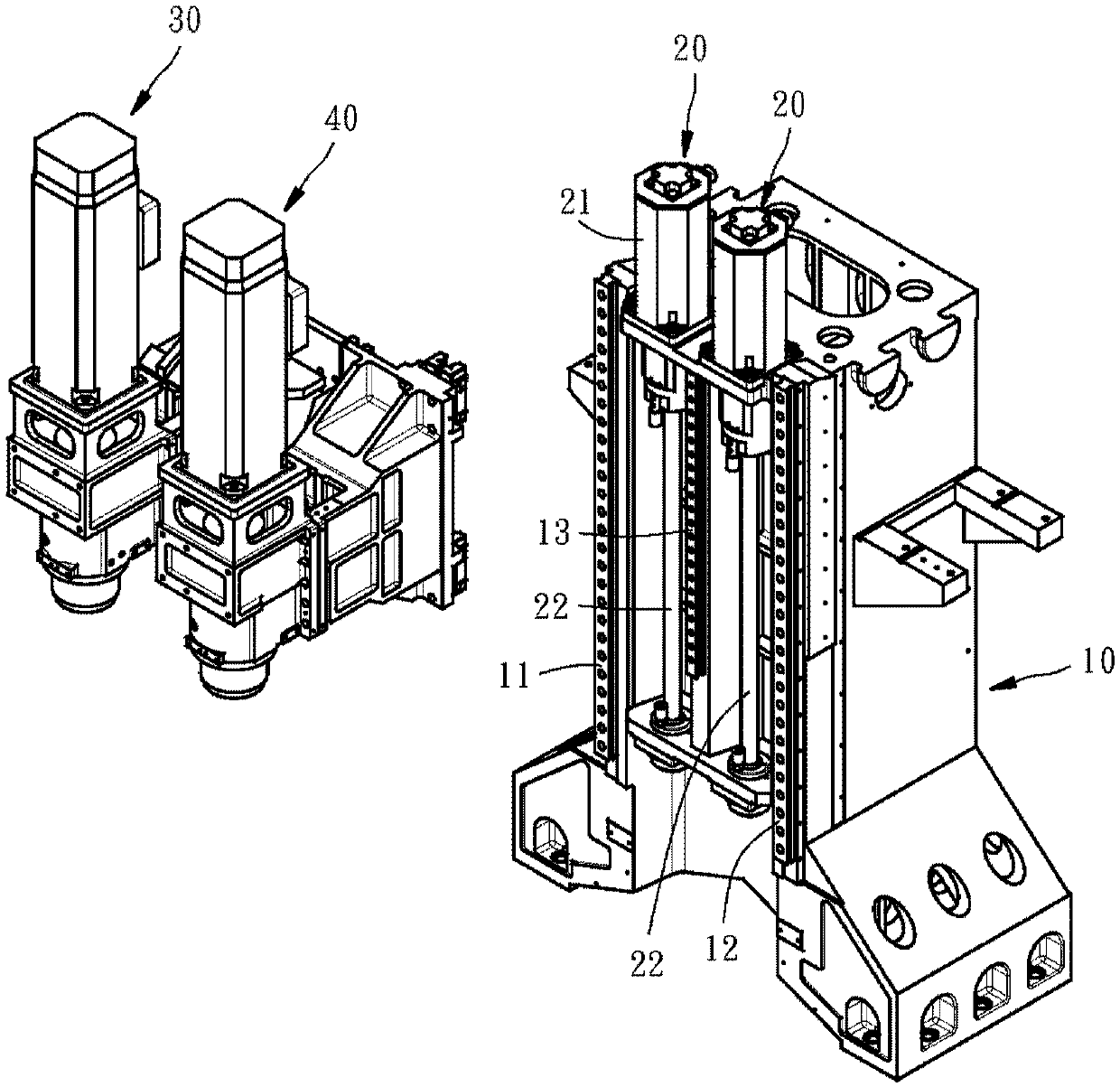

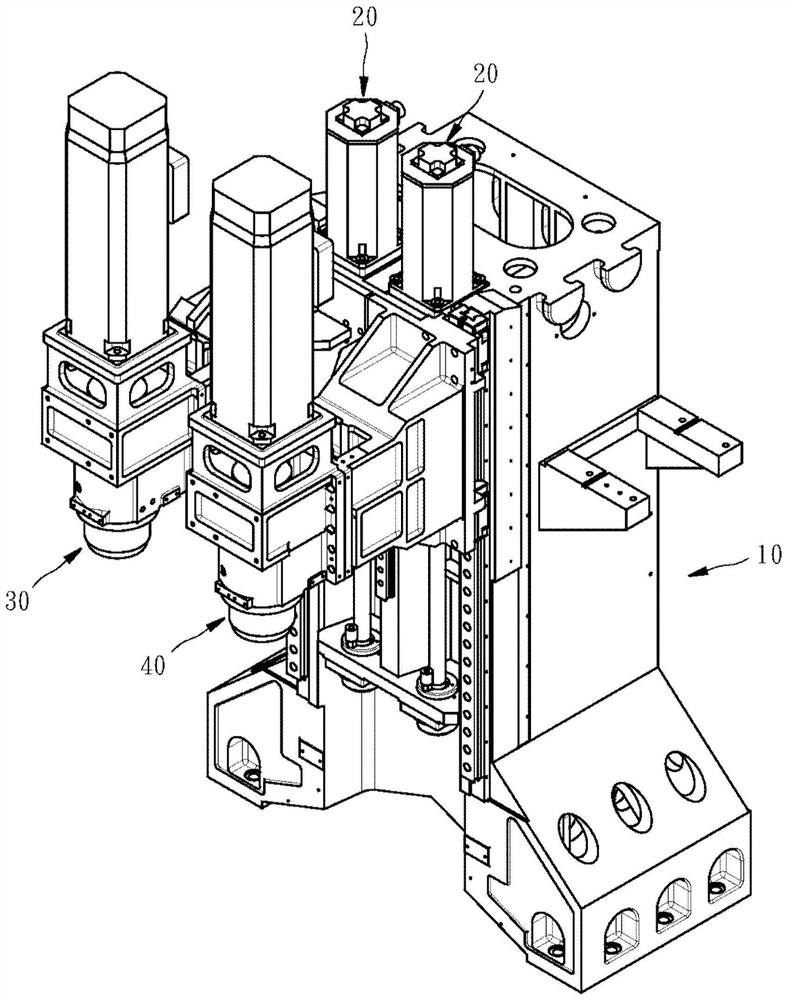

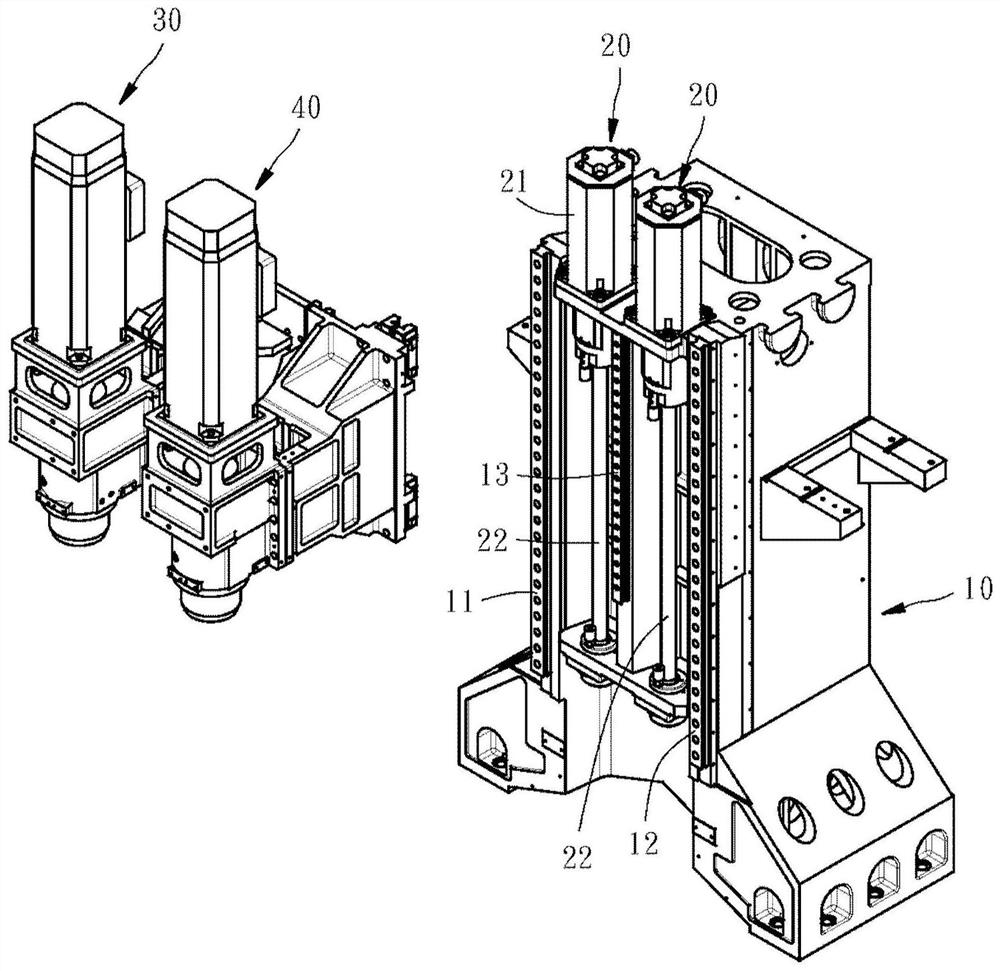

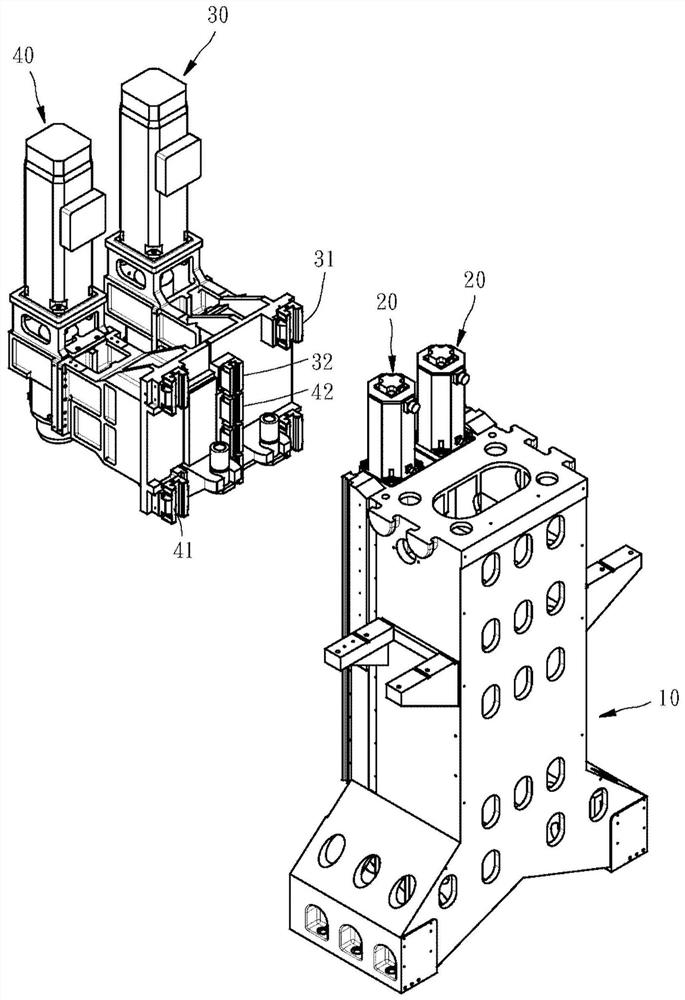

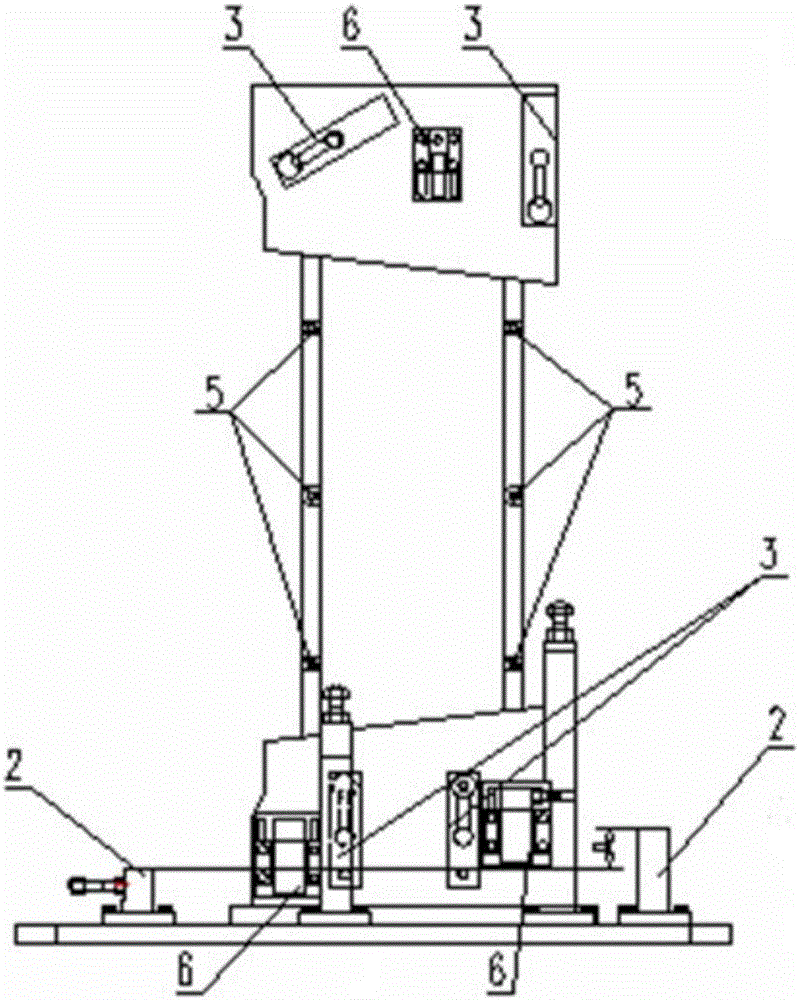

Double-headed machine tool

ActiveCN110270848AReduce distortionImprove rigidityLarge fixed membersMetal working apparatusDrive motorBlock match

A double-headed machine tool comprises a stand column machine base set which is provided with a first linear rail, a second linear rail and a third linear rail arranged between the first linear rail and the second linear rail; two feeding driving sets arranged on the stand column machine base set, each feeding driving set being provided with a driving motor and a screw rod which is driven by the motor to rotate; a first head provided with a first sliding block matched with the first linear rail in a sliding manner, a second sliding block matched with the third linear rail in a sliding manner, a screw barrel matched with the screw of one feeding driving set in a threaded manner, and a main shaft unit; a second head provided with a first sliding block which is matched with the second linear rail in a sliding mode, a second sliding block which is matched with the third linear rail in a sliding mode, a screw barrel which is matched with the screw rod of the other feeding driving set in a threaded mode, and a main shaft unit.

Owner:艾格玛科技股份有限公司

anti-climbing signal tower

The invention belongs to the field of signal communication towers and particularly relates to an anti-climbing signal tower. The anti-climbing signal tower comprises a climbing unit, a steel wire rope, a tensioning unit and a winding unit, wherein the tensioning unit, the climbing unit and the winding unit are sequentially arranged on the right side of the signal tower from top to bottom. The steel wire rope is connected between the tensioning unit and the climbing unit, and the climbing unit comprises a climbing plate, a limiting unit and a first box. The winding unit is fixedly connected with a fixed head through the steel wire rope; the tensioning unit is used for automatically tightening the steel wire rope; the winding unit is used for downwards pulling the steel wire rope; the steelwire rope drives the fixed head to downwards move to enable a connecting rod to push a sliding block to rightwards move; and a locking unit in the winding unit can limit working of the winding unit. The anti-climbing signal tower is mainly used for climbing of the cylindrical signal tower, the climbing unit can be controlled in a hand-operated mode, and meanwhile a constructor controls the lockingunit to lock the climbing unit through a key to prevent climbing of the signal tower by non-staff.

Owner:安徽明辉电气有限公司

Double head machine tool

ActiveCN110270848BReduce distortionImprove rigidityLarge fixed membersMetal working apparatusFeed driveControl engineering

A double-head machine tool, including a column base group, with a first line rail, a second line rail, and a third line rail arranged between the first line rail and the second line rail; two feed drive groups , installed on the column machine base group, each feed drive group has a drive motor and a screw driven by the motor to rotate; a first machine head has a first slider slidingly fitted on the first line rail, a The second slider is slidably fitted on the third line rail, a screw barrel is screw-fitted to one of the screw rods of the feed drive group, and a main shaft unit; a second machine head has a first slider slidably fitted to the first Two line rails, a second slide block slidingly fitted on the third line rail, a screw barrel threaded on the other screw rod of the feed drive group, and a main shaft unit.

Owner:艾格玛科技股份有限公司

Special tooling and fixture for castings of one-piece bearing seat of wind power generator

ActiveCN105234701BReduce turning timesGuaranteed cylindricityPositioning apparatusMetal-working holdersWind drivenEngineering

The invention relates to a special tool clamp for a wind driven generator one-piece bearing pedestal casting and a machining technology and belongs to the technical field of mechanical part machining. The special tool clamp comprises a box, a positioning device, a pressing device, an adjusting device and a supporting device. According to the special tool clamp for the wind driven generator one-piece bearing pedestal casting, a one-piece bearing pedestal lies one side to be clamped on the special tool clamp, a rotating workbench, bearing pedestal holes, a blast hole, an end face and peripheral faces complete finish machining through one time of clamping, the cylindricity and the coaxiality of the bearing pedestal holes in the two ends are guaranteed, the overturning frequency of the casting is reduced, the machining precision required in graph paper is achieved, production efficiency is improved, and production cost and labor intensity of workers are reduced.

Owner:JIANGSU JIXIN WIND ENERGY TECH

Ultra-high-precision processing method for meter-level optical components

ActiveCN103692294BAchieve machining accuracyOptical surface grinding machinesLength waveMagneto rheological

The invention discloses an ultrahigh precision processing method for a meter-scale optical element. According to the method, an annular polishing technology and a magneto-rheological polishing technology are combined, and different processing technical parameters are subjected to optimal combination to realize the ultrahigh precision processing of the meter-scale optical element. According to the method, the meter-scale optical element of which the PV (pageviews) value of surface figure accuracy is 1 / 8 wavelength and the RMS (rate-monotonic scheduling) value is 1 / 50 wavelength is processed.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

Layered Turning Technology of Large Pitch External Thread

InactiveCN105537695BImprove rough machining efficiencyReduce geometric errors in rough machiningThread cutting machinesTurning toolsEngineeringMachining process

The invention relates to an external thread turning process, in particular to a coarse-pitch external thread layered turning process. The process aims at solving the problem that by means of existing thread turning methods, because the requirements for massive removal and high-precision machining of coarse-pitch external threads can not be met, thread surface machining principle errors and cutter marks exist in coarse-pitch external thread turning, the problem that because of the overlarge cutting load, cutter abrasion is quick, and the problem that because of staggered threads and an excessively large number of layered cutting times caused by cutter starting point error accumulation, the machining efficiency is low is solved. The process includes the process of conducting rough machining by removing thread rough machining allowance through multiple cutting edges in a radial continuous multi-time feed layered cutting mode and a left-right axial multi-time layered cutting mode, and the process of conducting semi fine machining and fine machining in a layered cutting mode by feeding the left cutting edge and the right cutting edge alternately multiple times in the axial direction. The requirements for the machining precision and the machining surface quality of external threads are met, obtained left and right threaded faces are free of cutter marks, the problem that threads are meshed in disorder is solved, and the requirement for efficiently turning coarse-pitch external threads in a high-quality mode is met.

Owner:HARBIN UNIV OF SCI & TECH

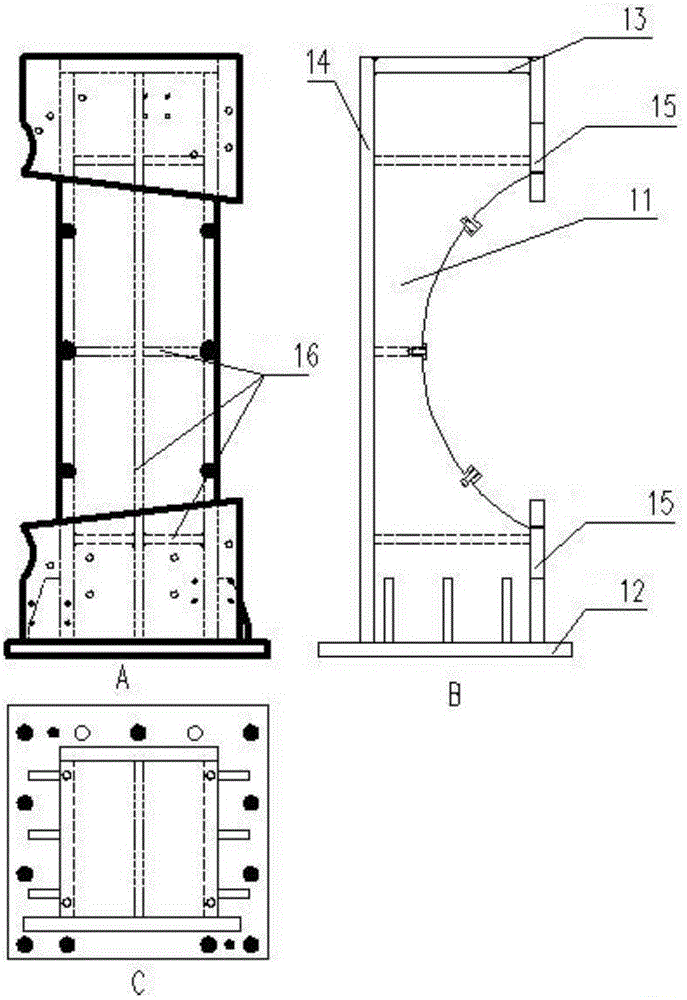

Workpiece clamping device

InactiveCN109128235AStable positionAchieve machining accuracyChucksMachining processMechanical engineering

The invention provides a workpiece clamping device. The workpiece clamping device comprises a bottom plate and bases and is characterized in that the periphery of the bottom plate is equidistantly provided with three sets of the bases in a same circumference, the upper end of each base is provided with a built-in connection rod, each connection rod is provided with upper and lower two pairs of support seats, each support seat is provided with left and right two pairs of clamping heads, the bases are connected with the corresponding connection rods through circumferential base connection shafts, and the connection rods are connected with the corresponding support seats through axial support seat connection shafts. By means of the workpiece clamping device, the problems that present lathe clamping devices are strenuous to align workpieces and low in efficiency are solved, and the workpiece clamping device particularly adapts to assembly and use for clamping cylindrical workpieces in thenumerical control lathe machining process.

Owner:郑鑫

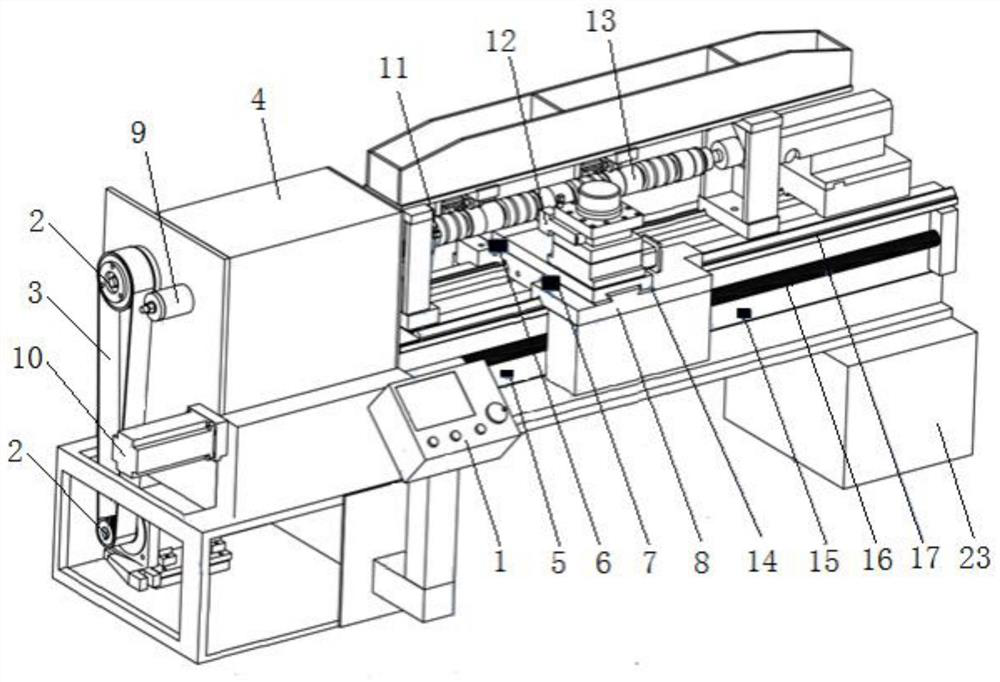

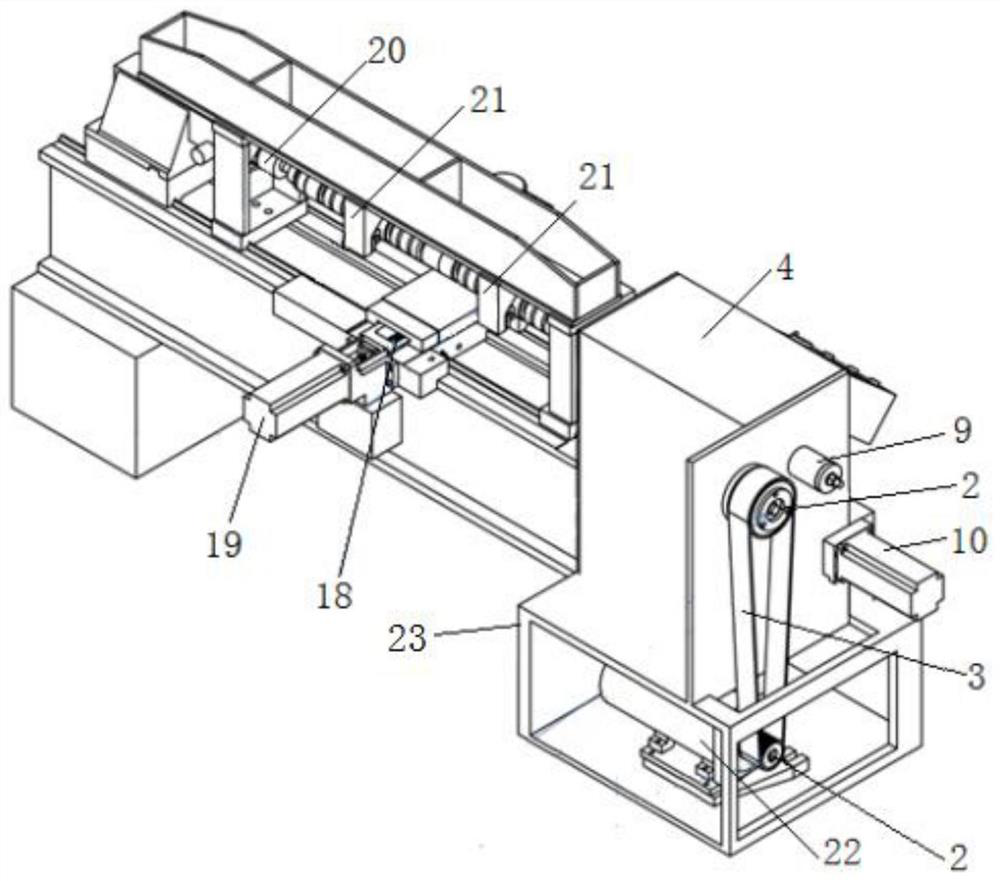

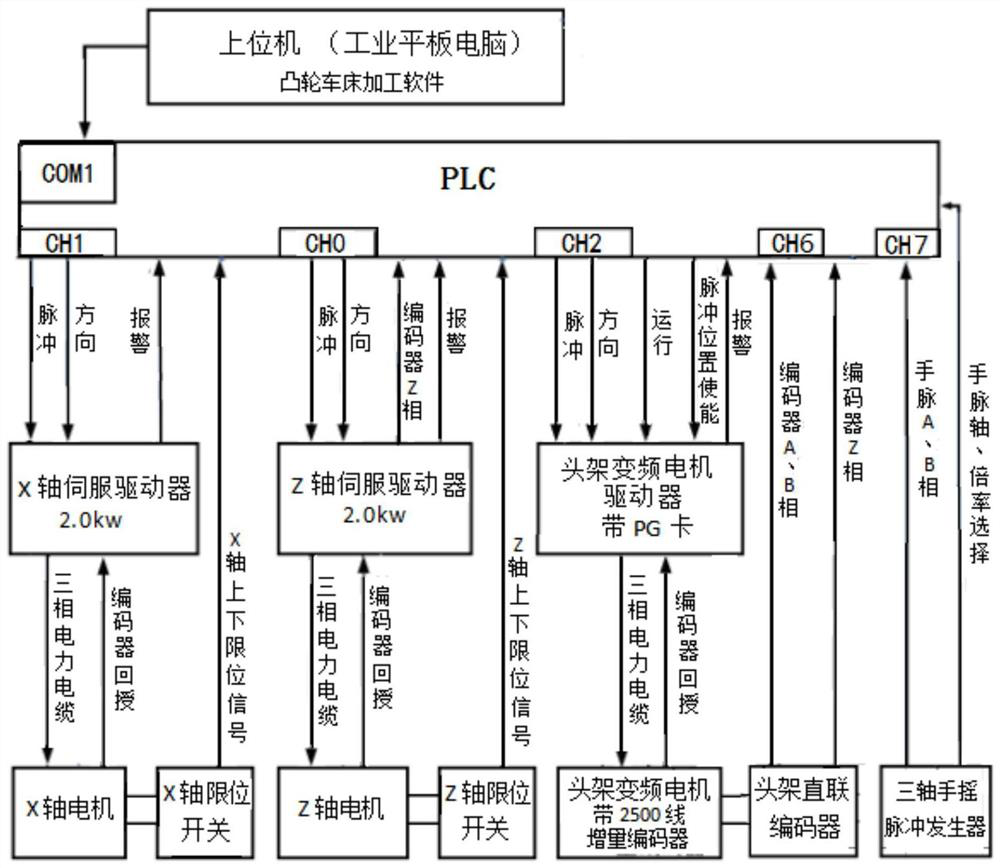

A cam lathe numerical control system

ActiveCN112327747BThere will be no split processingProcessing efficiency is similarNumerical controlFrequency changerCam

Owner:荆州环球汽车零部件制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com