Punching and flattening die for producing automobile covering parts

An automobile cover and punching technology, applied in the field of stamping die, can solve the problems of low processing efficiency and precision, high labor intensity, etc., and achieve the effect of realizing processing precision and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

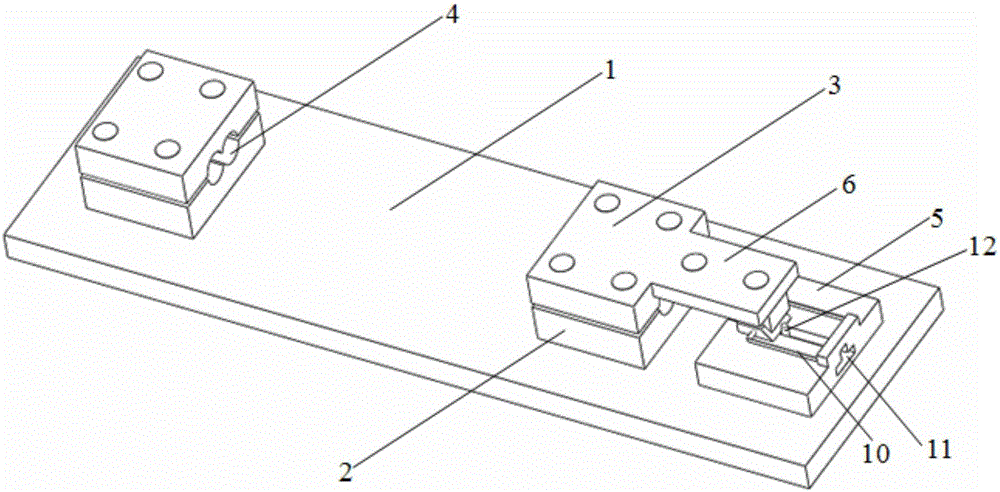

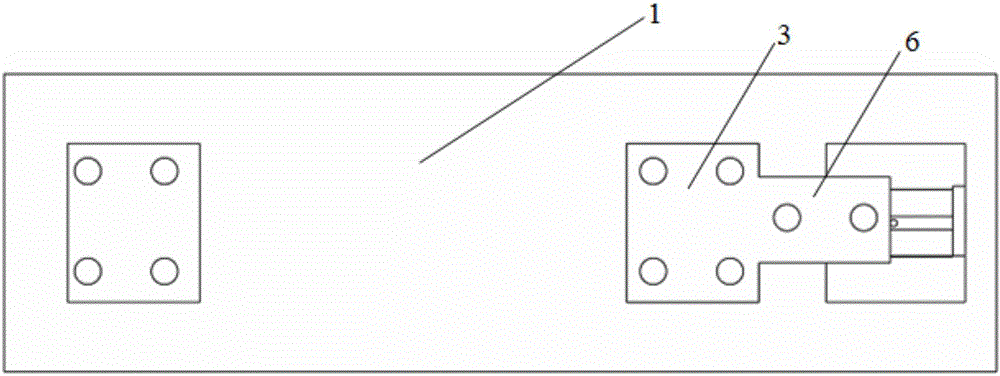

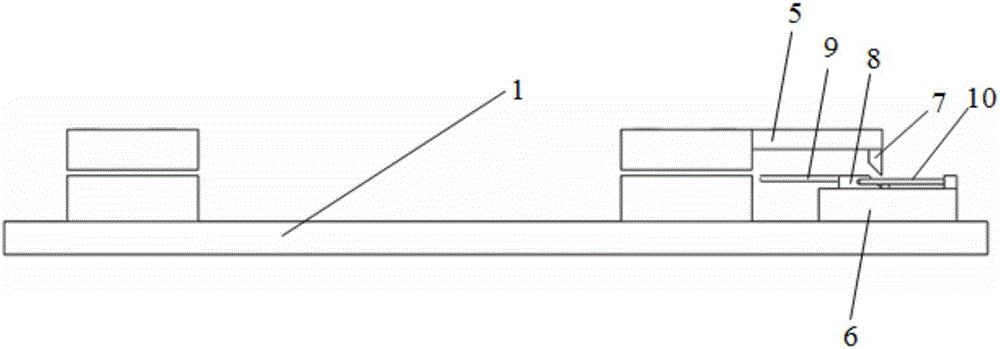

[0015] See attached Figure 1-Figure 5 As shown, a punching and flattening die for the production of automobile panels includes a base plate 1 and a clamping and punching device and a flattening device arranged on the base plate 1, and the clamping and punching device includes a clamping and punching device in the form of The upper template 2 and the lower template 3 arranged on the upper and lower sides are respectively provided with semicircular grooves 4 for clamping steel pipes, and the upper template 2 is provided with punches. The flattening device includes a lower die 5, an upper die 6, a stamping slider 7, a flattening slider 8, a flattening punch 9 and a spring 10, and the lower die 5 is provided with a "concave" slideway 11. The flattening slider 8 is movably fixed in the "concave"-shaped slideway 11, the flattening punch 9 is fixed on the flattening slider 8, and the spring 10 One end is connected to the flattening slider 8 and the other end is fixed on the lower d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Rockwell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com