Ultra-high-precision processing method for meter-level optical components

A technology of optical components and processing methods, which is applied in the direction of optical surface grinders, metal processing equipment, manufacturing tools, etc., can solve the problem of unstable properties of magnetorheological fluids, difficulty in realizing ultra-high-precision processing of meter-level optical components, and processing time long wait question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

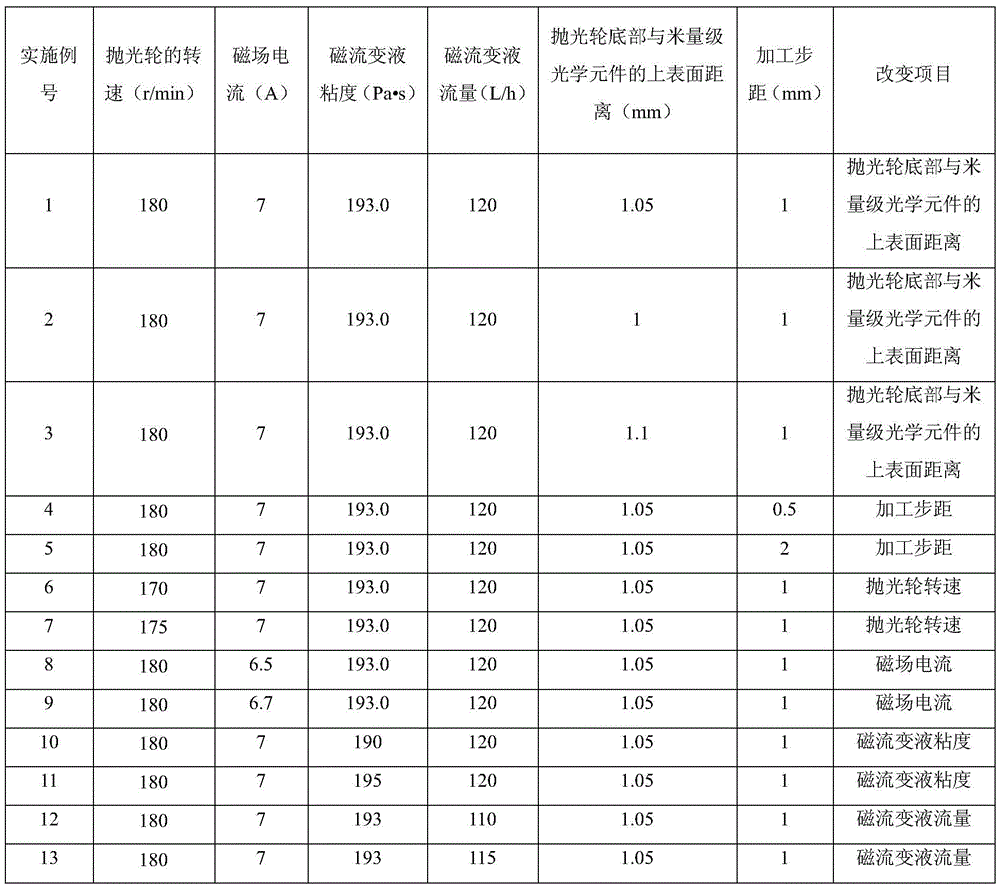

Embodiment 1

[0026] An ultra-high-precision processing method for a meter-level optical element, the processing steps of which are as follows:

[0027] 1) Ring polishing:

[0028] Use a ring polishing machine to pre-process the meter-level optical components, and use a Φ300mm interferometer to measure the PV value of the surface shape accuracy of the meter-level optical components during the processing until the surface shape accuracy of the meter-level optical components is less than 1 wavelength;

[0029] 2) Magnetorheological processing:

[0030] ①Set the polishing parameters of the magnetorheological machine tool: the speed of the polishing wheel is 180r / min, the magnetic field current is 7A, the viscosity of the magnetorheological fluid is 193.0Pa·s, the flow rate is 120L / h, the bottom of the polishing wheel is at the level of meters The distance between the upper surface of the optical element is 1.05mm;

[0031] ② Calibrate the removal efficiency of magnetorheological fluid:

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com