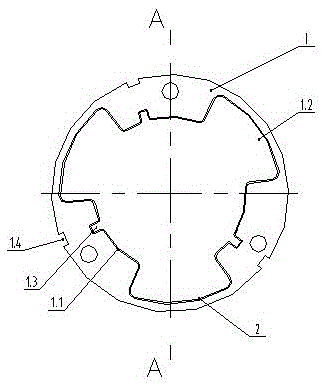

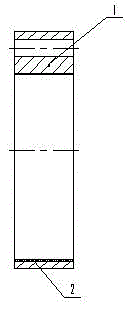

Powder metallurgy automobile engine stator and manufacturing methods thereof

An automobile engine, powder metallurgy technology, applied in the manufacture of stator/rotor body, magnetic circuit shape/style/structure, magnetic circuit static parts, etc., can solve the problems of stress concentration, large difference in wall thickness, stator damage, etc. Achieve the effect of increased yield strength, high material utilization, and increased hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] By weight, nickel powder 1.75, molybdenum powder 0.5, copper powder 1.5, chromium powder 1.7, manganese powder 1.0, graphite powder 0.8, cerium dioxide 0.2, stearic acid Zinc 0.05%, the rest is iron powder, the sum of each component is 100%; the corresponding process is green density 7.5g / cm3, sintering temperature 1200-1240℃, without tempering treatment.

[0032] After testing, the yield strength of the prepared powder metallurgy alloy is 575MPa, the tensile strength reaches 955MPa, the hardness is 98HRB, and the impact toughness is 31.3J / cm 2 .

Embodiment 2

[0034] The chromium and part of iron in the formula of Example 1 are achieved by adding fine particle Cr-Fe alloy powder with an average particle size of 4.65 μm to achieve the weight ratio.

[0035] After testing, the tensile strength of the prepared powder metallurgy alloy reaches 1212MPa, and the hardness is 31HRC.

Embodiment 3

[0037] By weight, nickel powder 1.75, molybdenum powder 0.5, copper powder 1.5, chromium powder 1.7, manganese powder 1.0, graphite powder 0.8, cerium dioxide 0.2, stearic acid Zinc 0.05%, molybdenum disulfide 0.5%, rare earth element La 0.6%, the rest is iron powder, the sum of each component is 100%; the corresponding process is green density 7.5g / cm 3 , Sintering temperature 1200-1240 ℃, without tempering treatment.

[0038] After testing, the yield strength of the prepared powder metallurgy alloy is 578MPa, the tensile strength reaches 962MPa, the hardness is 80-85HRA, and the impact toughness is 58J / cm 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com