Homogenization method of chipping allowance and periphery grinding apparatus of plate

A cutting allowance, homogenization technology, applied in the direction of grinding machine parts, grinding/polishing equipment, machine tools suitable for grinding workpiece edges, etc. Errors and other problems, to achieve the effect of improving machining accuracy, stable product quality, and prolonging life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

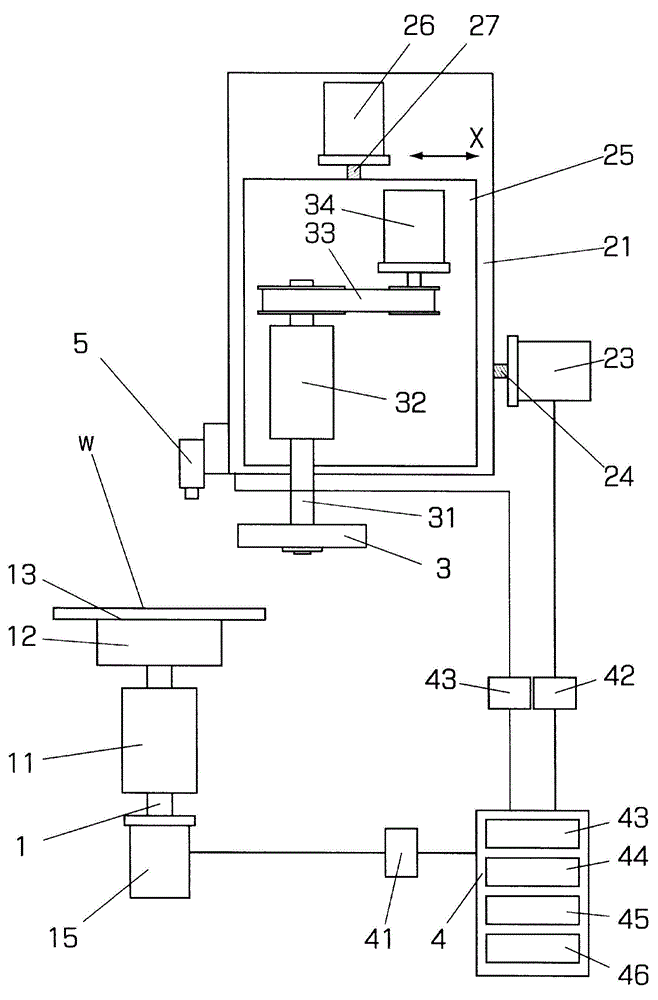

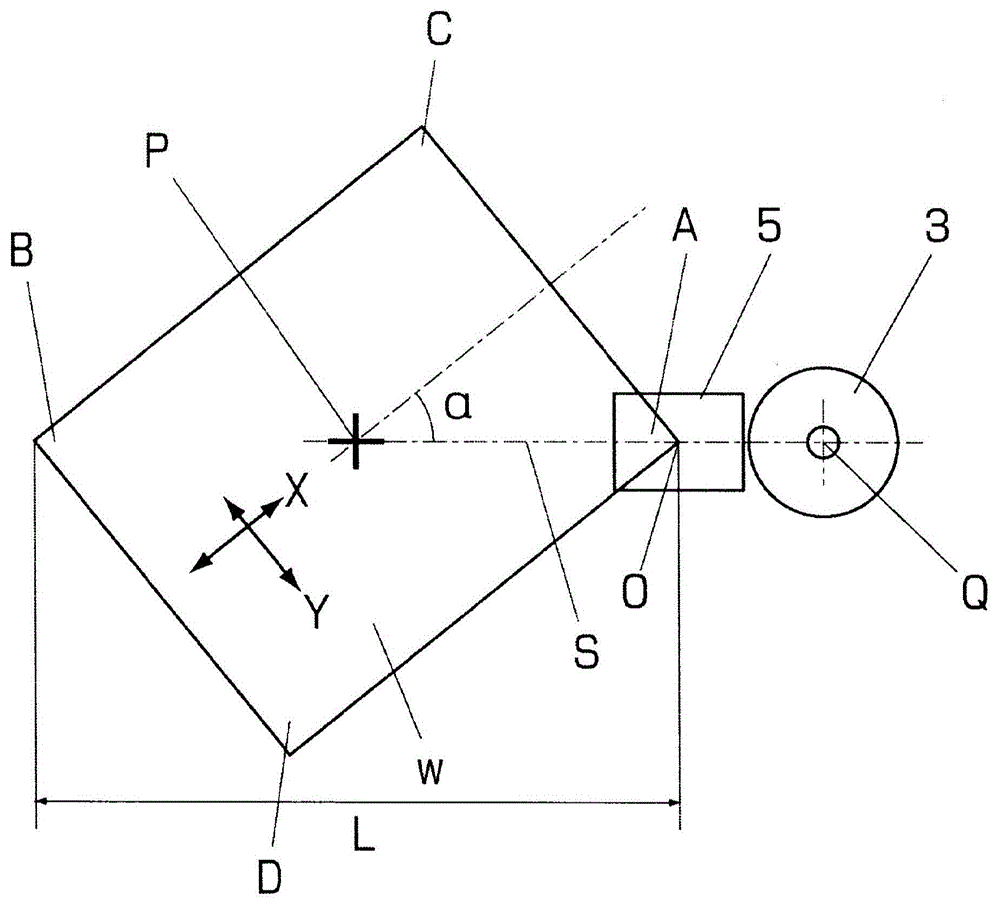

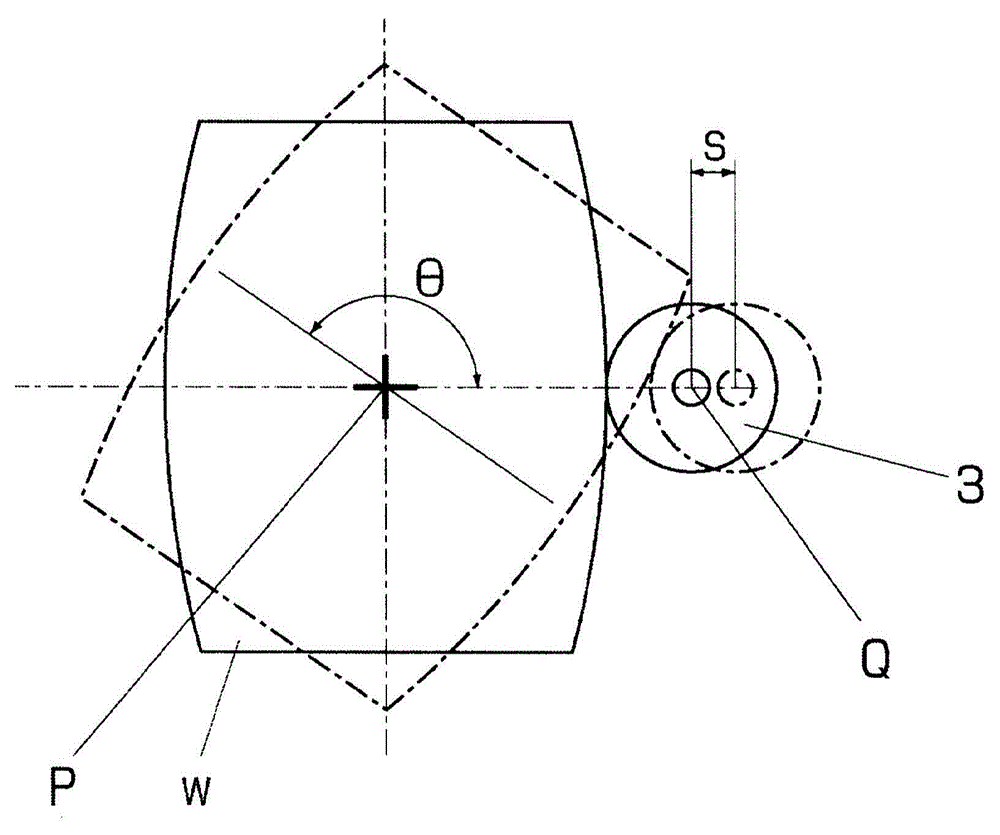

[0049] Hereinafter, embodiments of the peripheral edge grinding device of the present invention will be described with reference to the drawings. figure 1 is a schematic side view of the peripheral grinding device in polar coordinates, figure 2 is a plan view showing the configuration of the device.

[0050] In the figure, the workpiece shaft 1 is a hollow shaft in the vertical direction, and is rotatably supported by a bearing 11 on an unillustrated machine frame. A table 12 is fixed to the upper end of the workpiece shaft 1 , and the upper surface of the table serves as a horizontal workpiece holding surface 13 . Negative pressure is supplied to the workpiece holding surface 13 through the hollow hole of the workpiece shaft 1 , and the workpiece w placed on the workpiece holding surface 13 is vacuum-adsorbed by the lower surface and fixed to the table 12 . A spindle motor (servo motor) 15 is connected to the lower end of the workpiece shaft 1 . The spindle motor 15 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com