Large-pitch thread turning tool design method

A cutting tool design and large pitch technology, applied in turning equipment, cutting tools for lathes, calculations, etc., can solve problems such as inability to solve the problem of consistency in the distribution of left and right thread surfaces, cutting quality problems that cannot be solved, and cutting efficiency that cannot be guaranteed. , to achieve the effect of improving the processing accuracy and the consistency of the processing surface quality, avoiding deformation and excessive wear, and improving the processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

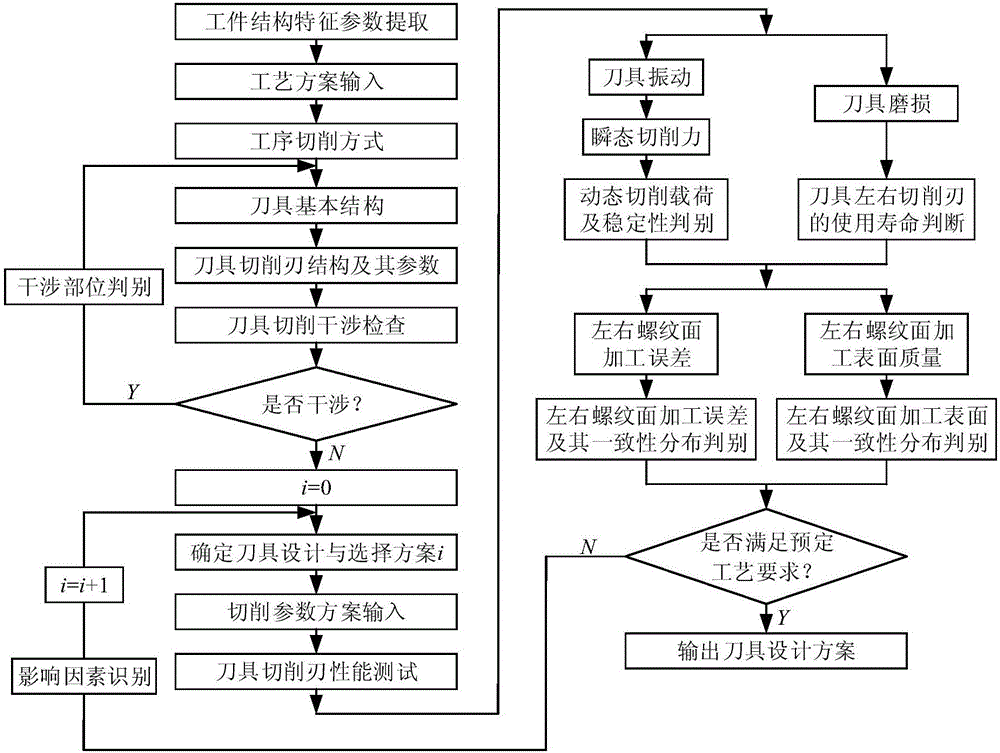

[0032] refer to figure 1 , the large-pitch thread turning tool design method of the present invention comprises the following steps:

[0033] 1. Determine the process plan and process cutting method according to the structural characteristics of the processed large-pitch thread workpiece, and set the cutting tool suitable for the basic structure of the tool for turning the large-pitch thread workpiece according to the process plan and process cutting method. The basic structure includes the tool cutting edge structure and its parameters;

[0034] 2. Check the tool cutting interference. If there is interference, judge the interference position of the cutting tool; if there is no interference, determine to use the cutting tool to perform cutting experiments on the workpiece;

[0035]3. Input the cutting plan to turn the workpiece, and obtain the tool vibration signal and the wear image of the tool flank during the cutting process;

[0036] 4. Judging the cutting plan of the cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com