Coarse-pitch external thread layered turning process

A technology of external thread and large pitch, which is applied in the field of external thread turning process and large pitch external thread layered turning process, which can solve the problems of large cutting load, joint tool marks, and too many layered cutting times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

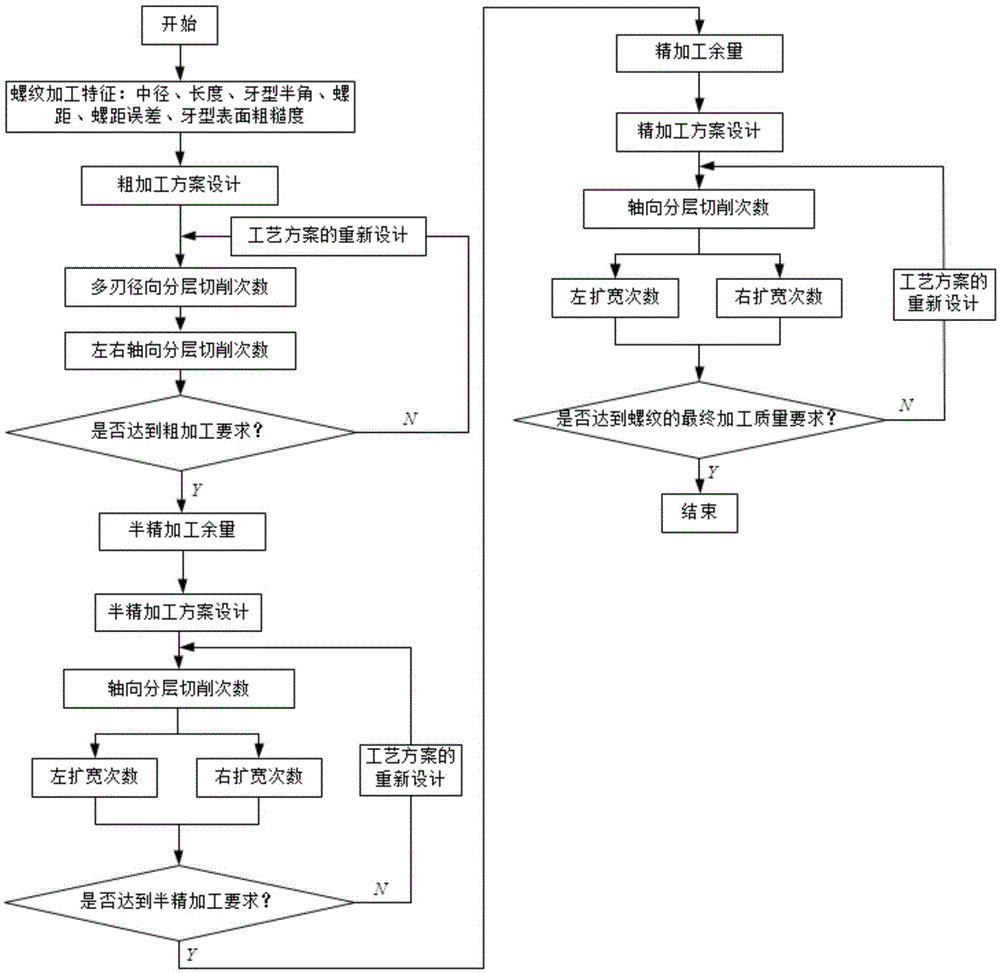

[0031] The specific embodiment of the present invention is described in conjunction with the accompanying drawings. The large-pitch external thread layered turning process of this embodiment, turning a 35CrMo trapezoidal screw with a pitch of 16mm and an outer diameter of 120mm, specifically includes the following steps:

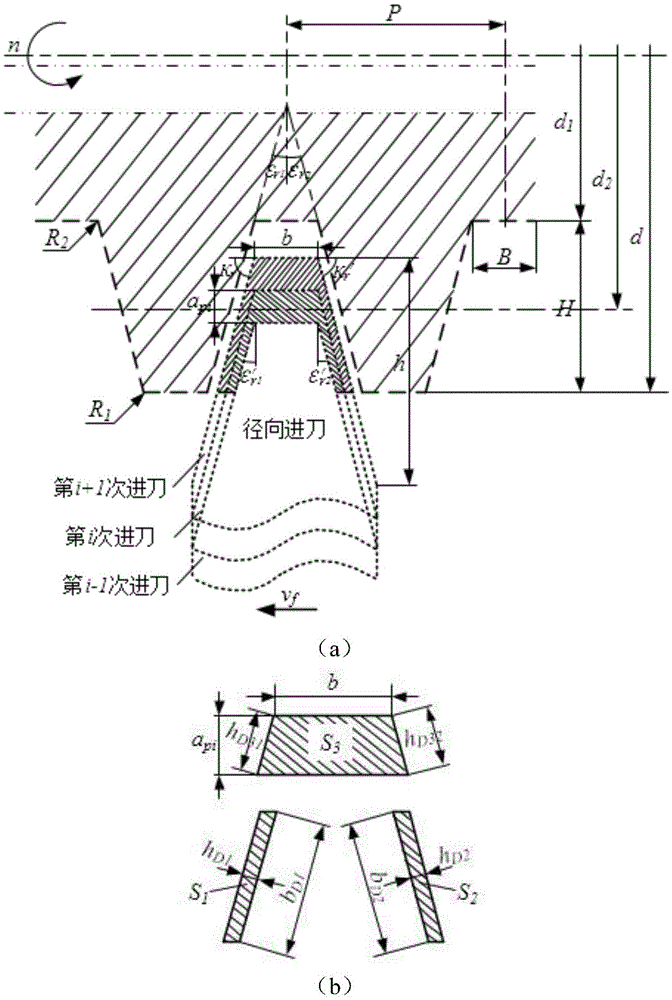

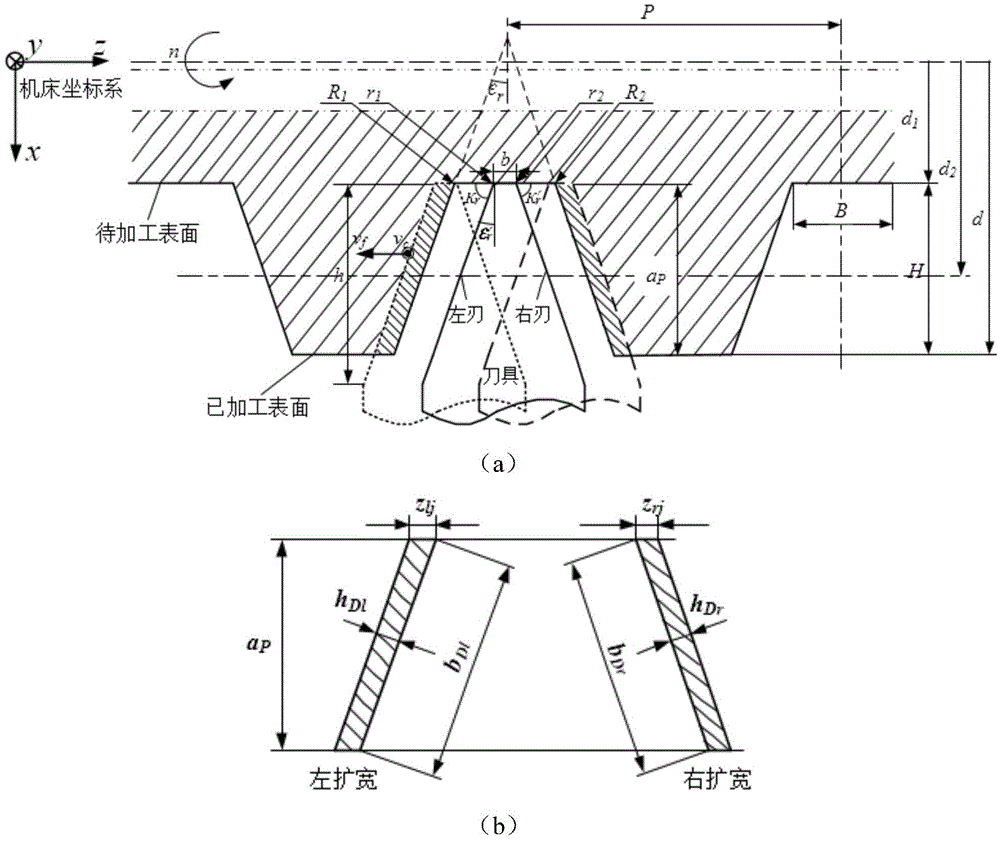

[0032] Step 1. Rough machining process: The rough machining allowance of the external thread is removed by means of continuous multi-feed layered cutting along the radial direction, so that the radial dimension of the external thread meets the requirements, specifically as follows figure 1 As shown; the left and right blades are used to remove the cutting marks during the radial layered cutting by adopting the method of continuous multi-layered cutting of the left and right blades along the axial direction, forming the basic tooth structure of the external thread and the left and right thread surfaces, reducing the geometric error of the rough machining of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com