Clamping apparatus for rough machining of rotor

A rotor and fixture technology, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of increasing the rough machining cost of air compressor rotors, achieve easy and fast processing, improve rough machining efficiency, and overcome rough machining. The effect of processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

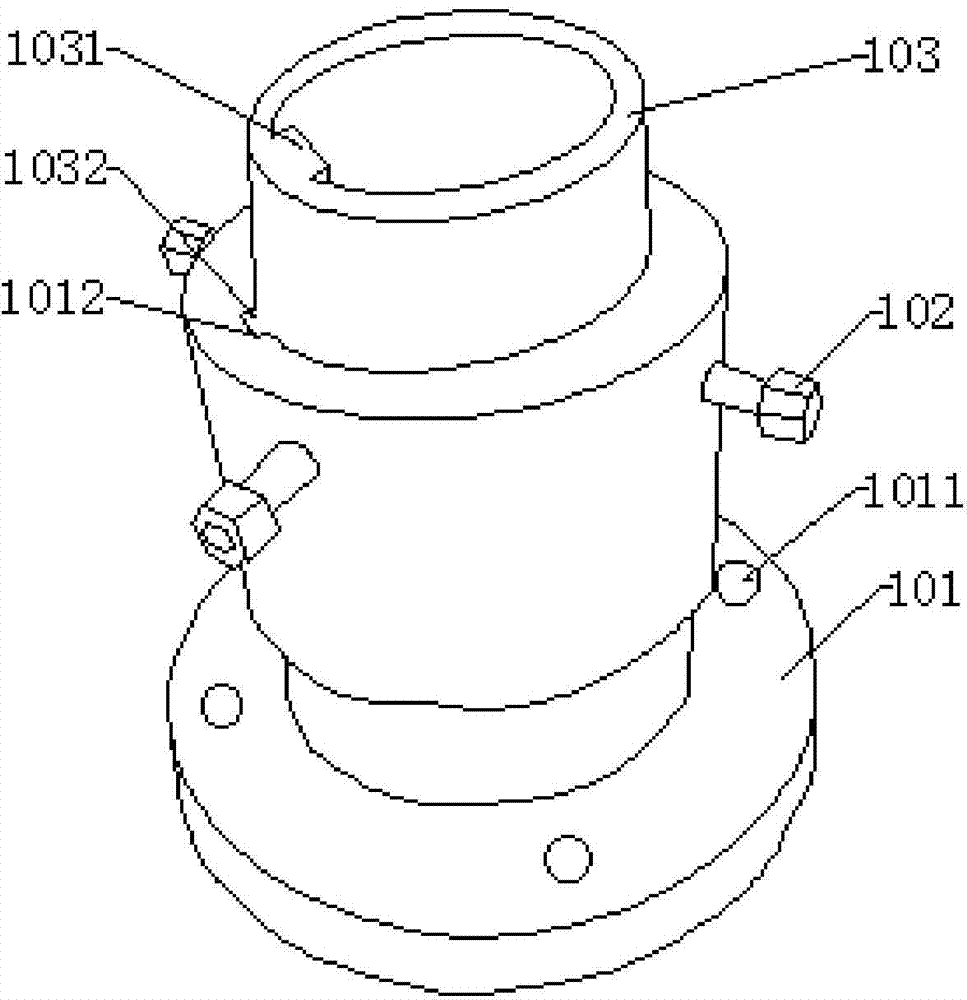

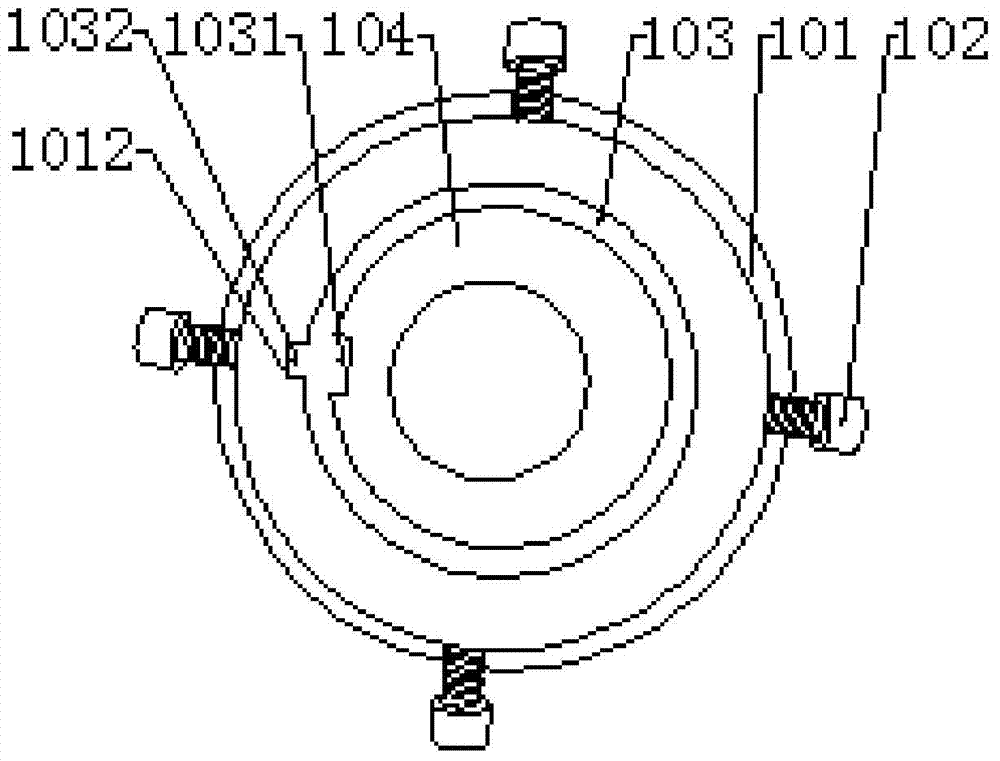

[0024] figure 1 It is a schematic structural diagram of the tool and fixture in the rough machining of the rotor provided by Embodiment 1 of the present invention; as shown in the figure, figure 1 It is a schematic structural diagram of the tool and fixture in the rough machining of the rotor provided by Embodiment 1 of the present invention; figure 2 It is a top view of the jig in the rough machining of the rotor provided by Embodiment 1 of the present invention; as shown in the figure, the jig in the rough machining of the rotor provided in Embodiment 1 of the present invention includes: a clamping body 101 for installation, for The screw 102 for auxiliary clamping, the fixed ring 103 for fixing the rotor and the lining ring 104 for positioning, the side inner wall of the clamping body 101 has a vertical groove 1012, and the side outer wall of the fixed ring 103 is integrally formed with a vertical The outer boss 1032, through the mutual matching of the vertical outer boss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com