Casting mold and casting process for gearbox case

A casting process and casting mold technology are applied in the field of casting molds and casting processes of gearbox casings, which can solve the problems of large temperature drop in the cavity, product leakage and scrap, easy shrinkage at the transition, etc., so as to improve the gate. Insufficient height, high machining accuracy, reducing the effect of rough machining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

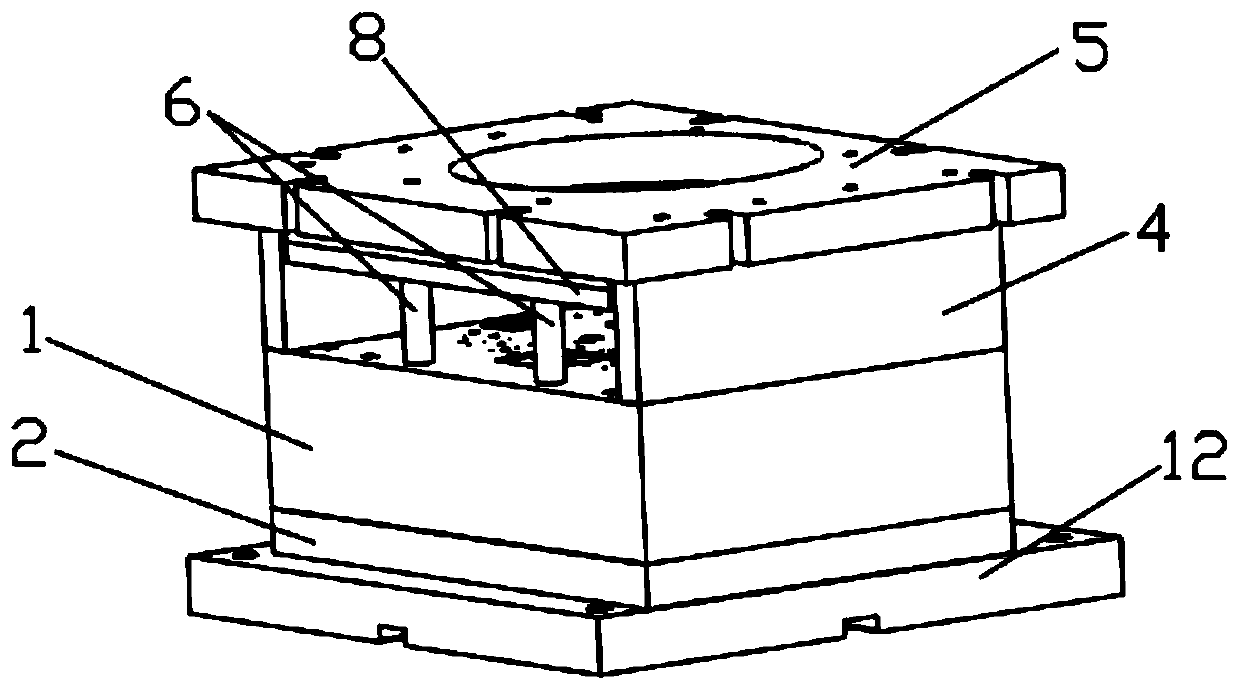

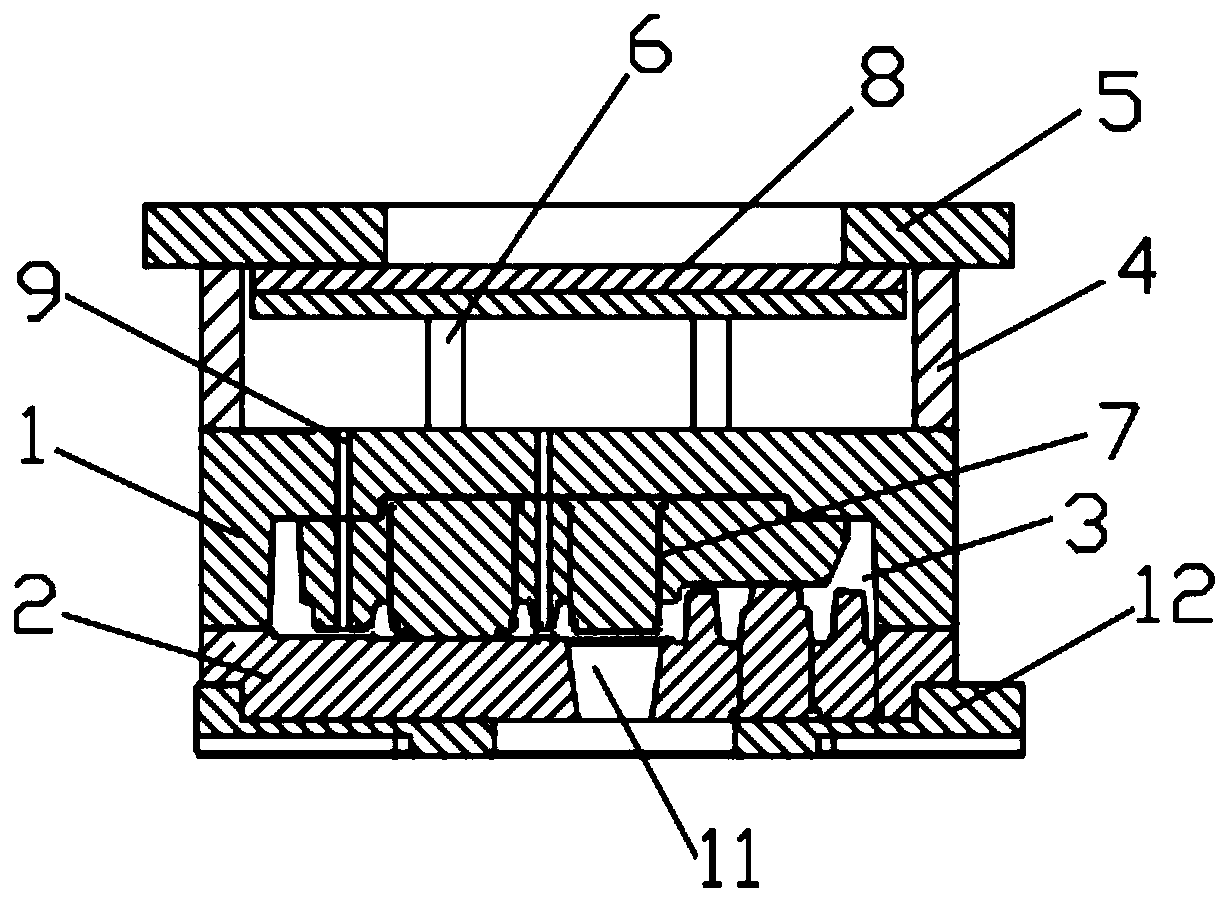

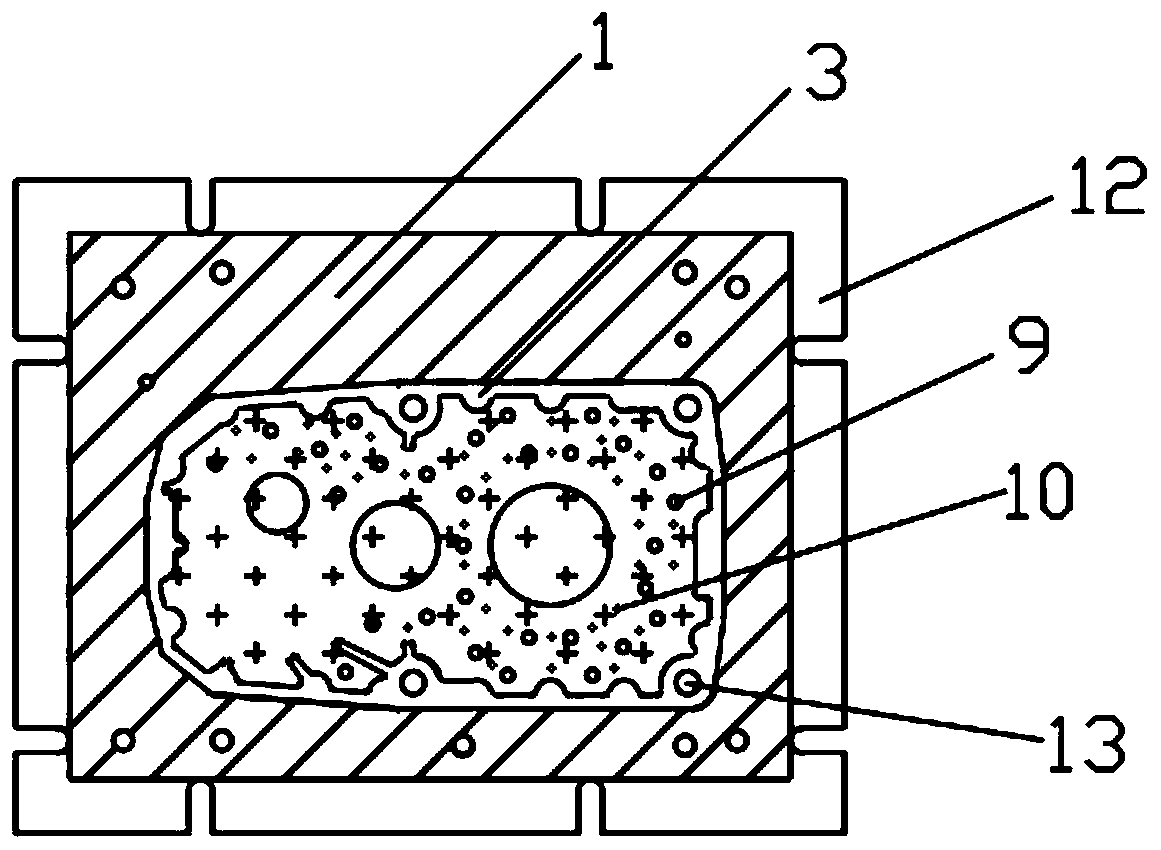

[0038] Please refer to figure 1 , figure 2 and image 3 As shown, this embodiment provides a casting mold for a gearbox case, including an upper mold 1, a lower mold 2, and a casting cavity 3 formed by the cooperation of the upper mold 1 and the lower mold 2. The upper end of the upper mold 1 passes through a spacer 4 An upper die connecting plate 5 is installed, and an ejector mechanism is provided between the upper die connecting plate 5 and the upper die 1. The ejector mechanism includes a thimble fixing plate 8 and a plurality of thimbles evenly installed on the thimble fixing plate 8. It is detachably connected with the thimble fixing plate 8, and the thimble fixing plate 8 is provided with a threaded hole for the thimble to be installed; The diameters are all 11 to 13 mm, and the diameter of the plurality of thimble through holes 9 in this embodiment is preferably 12 mm; and the upper die connecting plate 5 and the upper die 1 are fixedly connected with a sleeve colum...

Embodiment 2

[0045] please combine figure 1 , figure 2 and image 3 As shown in the figure, this embodiment provides a casting process for a gearbox case. The casting mold of the gearbox case in the above-mentioned embodiment 1 is used to cast the LYP315.2 traveling gearbox case. Made of aluminum alloy with composition: Si: 6.5%, Mg: 0.3%, Ti: 0.1%, Cu: 2.1%, Mn: 0.2%, Fe: 0.65%, Ni: 0.25%, Zn: 0.08%, Pb : 0.15%, Sn: 0.05%, Cr: 0.12%, the balance is Al and inevitable impurities, the casting process specifically includes the following process steps:

[0046] Step (a): batching, according to above-mentioned component batching, select corresponding elemental raw material and Al to carry out batching;

[0047] Step (b): alloy smelting, the aluminum furnace is baked, and the metal alloy prepared in step (a) is put into the aluminum furnace for smelting, and the melting temperature is 780 ° C, and refining, deoxidation, and slag removal are carried out. , refining alloy solution;

[0048] ...

Embodiment 3

[0057] please combine figure 1 , figure 2 and image 3 As shown in the figure, this embodiment provides a casting process for a gearbox case. The casting mold of the gearbox case in the above-mentioned embodiment 1 is used to cast the LYP315.2 traveling gearbox case. Made of aluminum alloy with composition: Si: 7.5%, Mg: 0.4%, Ti: 0.2%, Cu: 3.5%, Mn: 0.5%, Fe: 0.55%, Ni: 0.15%, Zn: 0.06%, Pb : 0.12%, Sn: 0.08%, Cr: 0.15%, the balance is Al and inevitable impurities, the casting process specifically includes the following process steps:

[0058] Step (a): batching, according to above-mentioned component batching, select corresponding elemental raw material and Al to carry out batching;

[0059] Step (b): alloy smelting, the aluminum furnace is baked, and the metal alloy prepared in step (a) is put into the aluminum furnace for smelting, and the smelting temperature is 790 ° C, and refining, deoxidation, and slag removal are carried out. , refining alloy solution;

[0060]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com