Optical fiber clamp and fusion splicer

A technology of optical fiber fusion splicer and optical fiber joint, which is applied in the direction of light guide, optics, optical components, etc., and can solve the problems of affecting welding effect, optical fiber position, and inability to clamp.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

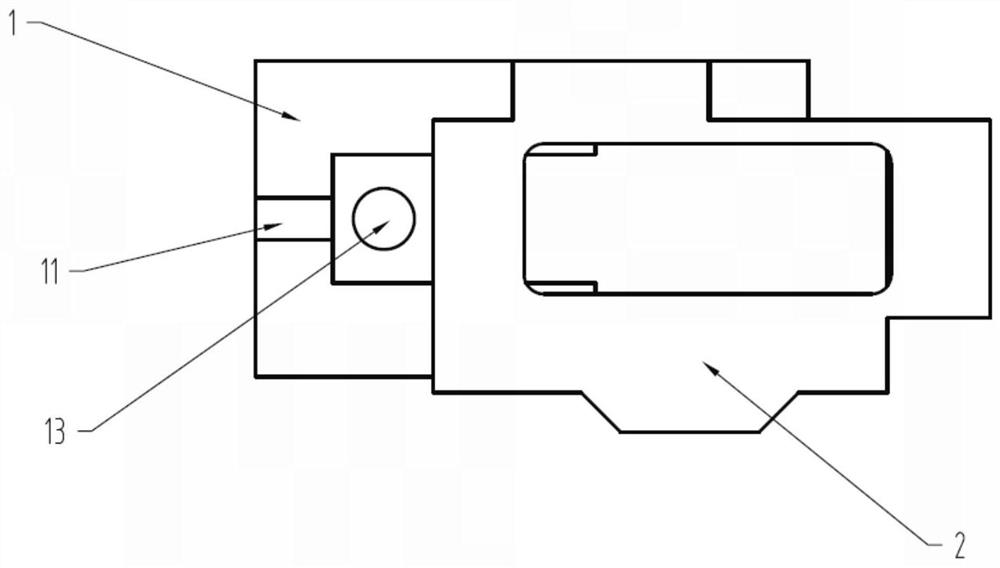

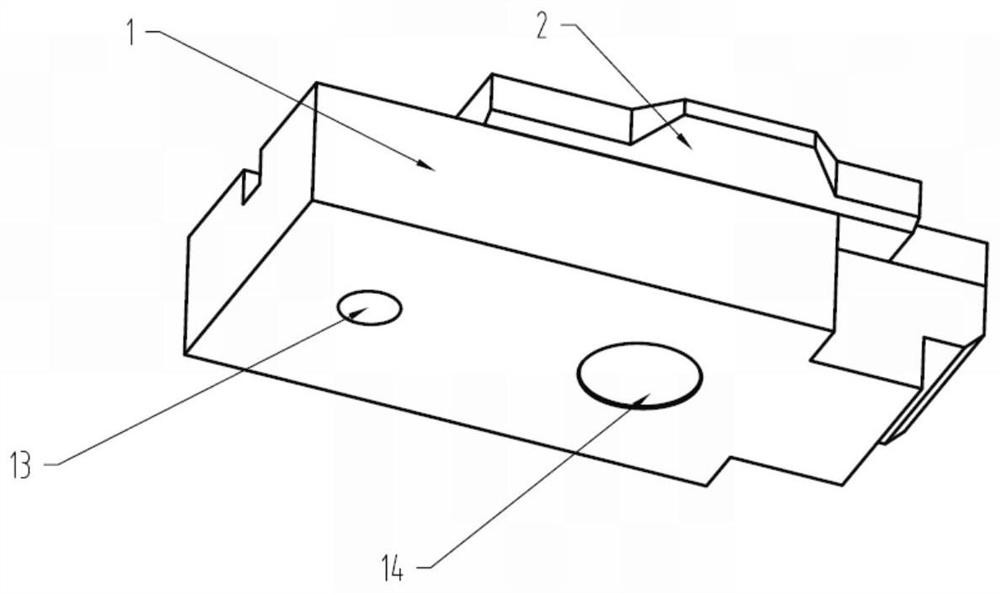

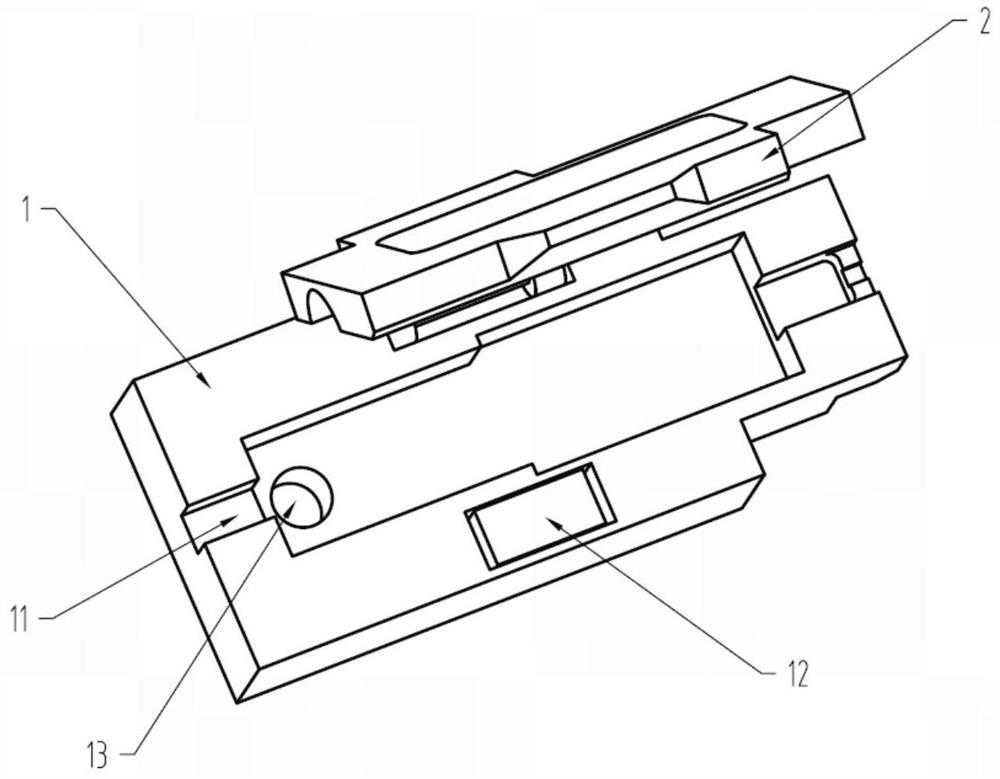

[0026] Such as Figures 1 to 4 As shown, the optical fiber clamp of the present invention includes a clamp base 1 and a platen cover 2, which are hinged to each other.

[0027] The fixture base 1 is roughly in the shape of a cuboid, and the fixture base 1 is made of metal. The upper end surface of the fixture base 1 is near the middle position and has an optical fiber groove 11 that runs through its vertical two sides. The outer contour of the fixture base 1 is embedded with a first magnet 12 at the right and front positions of the upper end surface of the fixture base 1, and the first magnet 12 can be attracted to the pressure plate cover 2;

[0028] The fixture base 1 is provided with a circular limit hole 13 that matches the limit pin of the base of the optical fiber fusion splicer. A second magnet 14 that can be attracted to the base of the optical fiber fusion splicer is embedded in the lower end surface of the fixture base 1 .

[0029] Both the first magnet 12 and the ...

Embodiment 2

[0033] During installation, the optical fiber clamp of the present invention is placed on the base of the optical fiber fusion splicer. The limit hole 13 of the fixture base 1 cooperates with the limit pin of the base of the optical fiber fusion splicer, and at the same time, the second magnet 14 of the fixture base 1 is integrally attracted to the base of the optical fiber fusion splicer to complete the installation of the optical fiber fixture; before welding, Insert the special connector fiber into the fiber groove 11, and then cover the platen cover 2. The outer contour of the special connector fiber fits perfectly with the special-shaped hole of the fiber groove 11 and the pressure plate cover 2, thereby clamping it, and finally completing the positioning of the fiber.

[0034] Such as Figure 5 One of the optical fibers with a special connector is displayed, which is an SC connector. Before fusion splicing, the optical fiber is inserted between the fiber groove 11 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com