Gear anti-rotating ferrule device and use method thereof

A ferrule and anti-rotation technology, which is applied in the direction of workpiece clamping devices, hand-held tools, manufacturing tools, etc., can solve the problems of inconvenient operation and poor versatility, and achieve the effect of strong versatility and suitable for popularization and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in combination with specific embodiments and with reference to the accompanying drawings. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

[0033] Non-limiting and non-exclusive embodiments will be described with reference to the following drawings, wherein like reference numerals refer to like parts unless specifically stated otherwise.

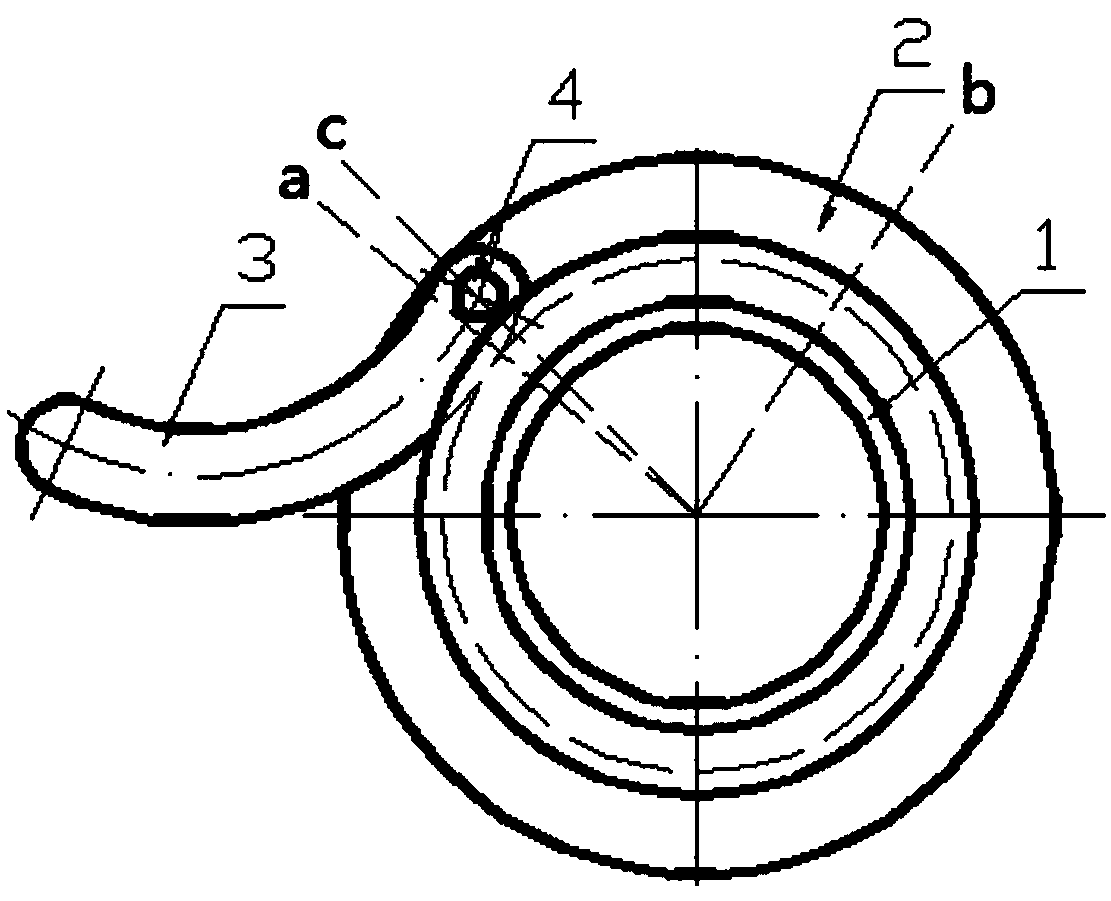

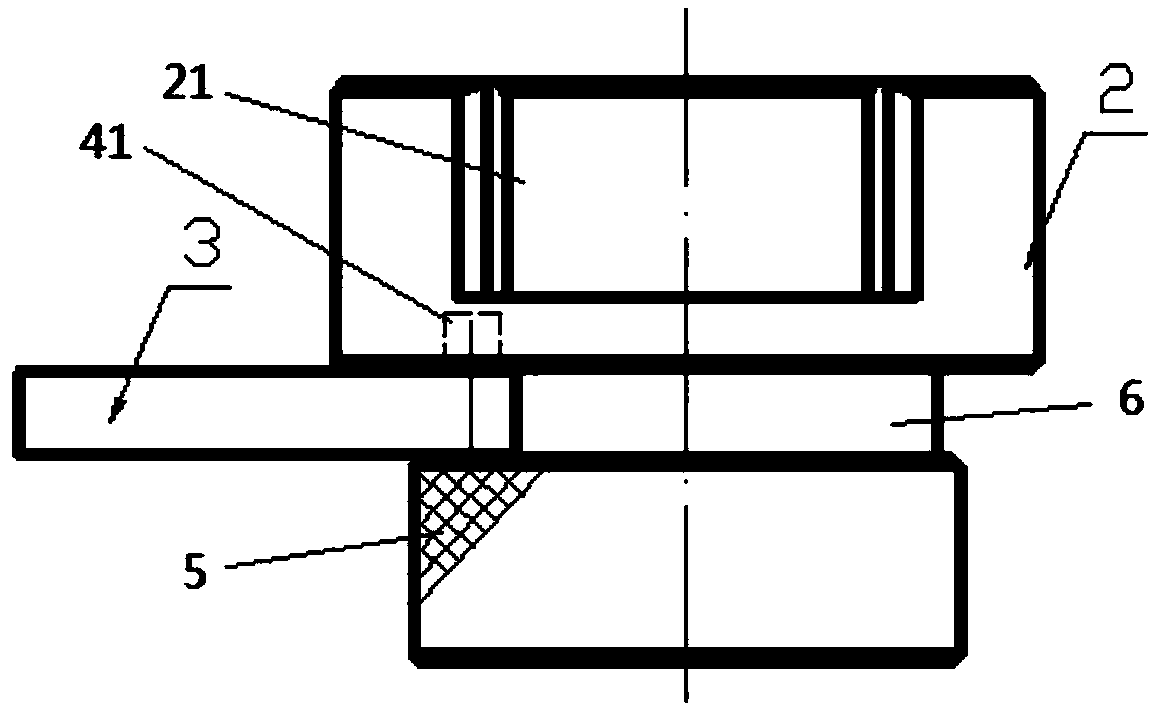

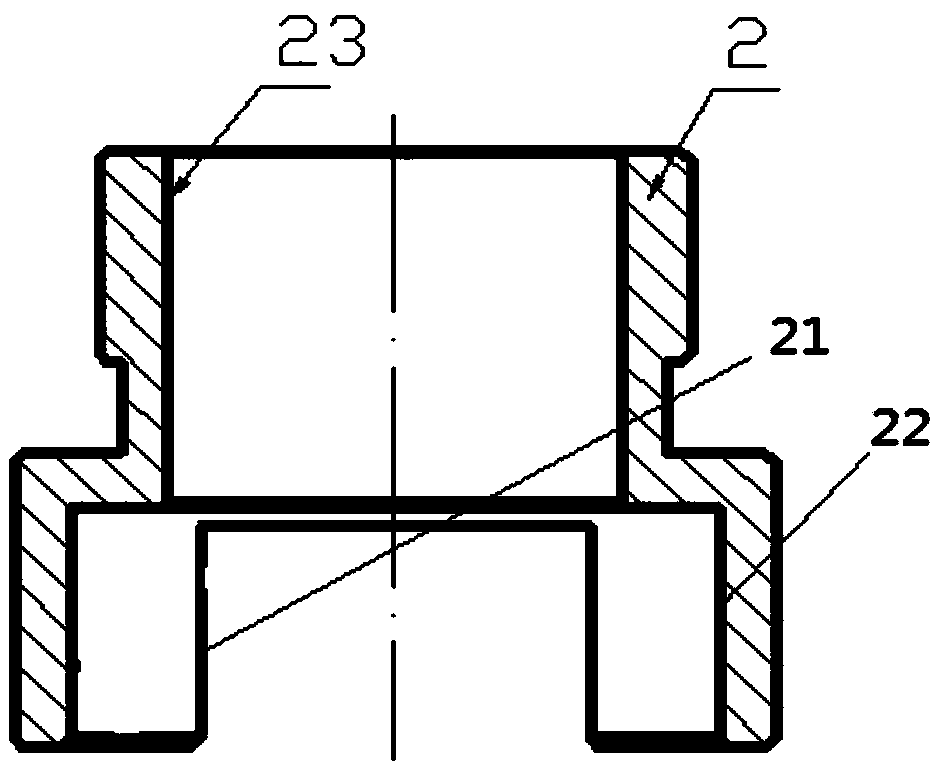

[0034] Such as Figure 1-5 A gear stopper ferrule device is shown, which is applied to the clamping of the engine gear train, including ferrule 2, which consists of two cylinders, one large and one small, to form a central coaxial boss, and there are holes running through it. The stepped hole on the end face is a large hole 22 in the large cylinder section and a small hole 23 in the small cylinder section. An annular groove 6 is provided at the junction of the two cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com