Concrete building wall crack bioremediation device

A concrete building and bioremediation technology, applied in building maintenance, building construction, construction, etc., can solve problems such as slow speed, occupation, and affecting the direction of slotting tools, and achieve the effect of increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

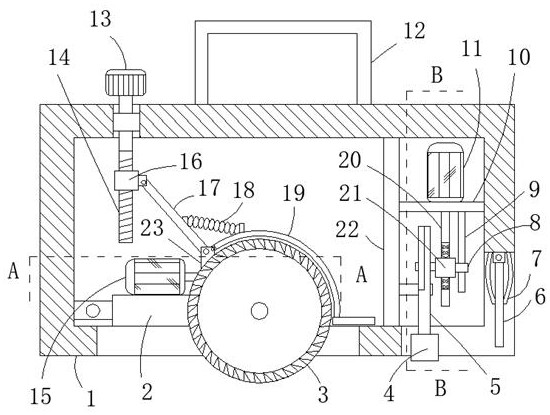

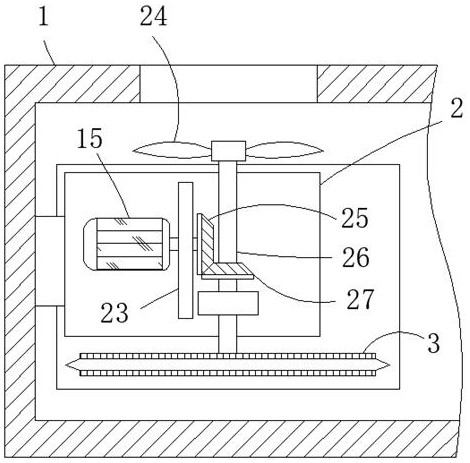

[0022] The bioremediation device for concrete building wall cracks includes a housing 1, the lower end of the housing 1 is provided with a rectangular opening, the left inner wall of the housing 1 is rotatably connected to a mounting plate 2 through a connecting shaft, and the upper end of the mounting plate 2 is fixedly connected to a mounting plate 2. One side of the mounting block is connected with a rotating shaft 26 through the first rolling bearing, one end of the rotating shaft 26 is fixedly connected with the cutting piece 3, the other end of the rotating shaft 26 passes through the first rolling bearing and is fixedly connected with the first bevel gear 27, and the mounting plate The upper end of 2 is fixedly connected with the first motor 15, the output end of the first motor 15 is fixedly connected with the second bevel gear 25, the first bevel gear 27 meshes with the second bevel gear 25, and the upper end of the mounting plate 2 is fixedly connected with a support f...

Embodiment 2

[0025] Embodiment 2: the difference based on Embodiment 1 is;

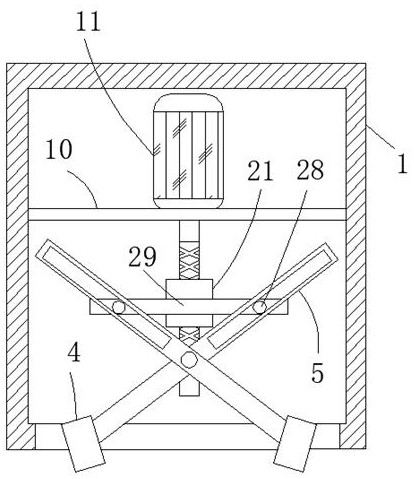

[0026] The crushing mechanism includes two swing arms 5 crossed in the gap, the intersection of the two swing arms 5 is rotationally connected with the right side of the partition plate 22 through the same pivot pin, the lower end of the swing arm 5 is fixedly connected with the breaker 4, The rod wall of the cross bar 10 is fixedly connected with the second motor 11, the output end of the second motor 11 runs through the rod wall of the cross rod 10 and is fixedly connected with the reciprocating screw rod 20, and the rod wall of the reciprocating screw rod 20 is slidingly sleeved with Reciprocating slide block 21, one side of reciprocating slide block 21 is fixedly connected with transmission rod 29, is fixedly connected with two pins 28 on the bar wall of transmission rod 29, is all provided with strip-shaped through-hole on two swing arms 5, two The pins 28 are slidingly socketed with the strip-shaped through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com