Machining condition setting method for electrical discharge machines

A technology of processing conditions and setting methods, which is applied in the direction of electric processing equipment, metal processing equipment, metal processing machinery parts, etc., and can solve the problems that the processing speed and processing accuracy cannot be achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

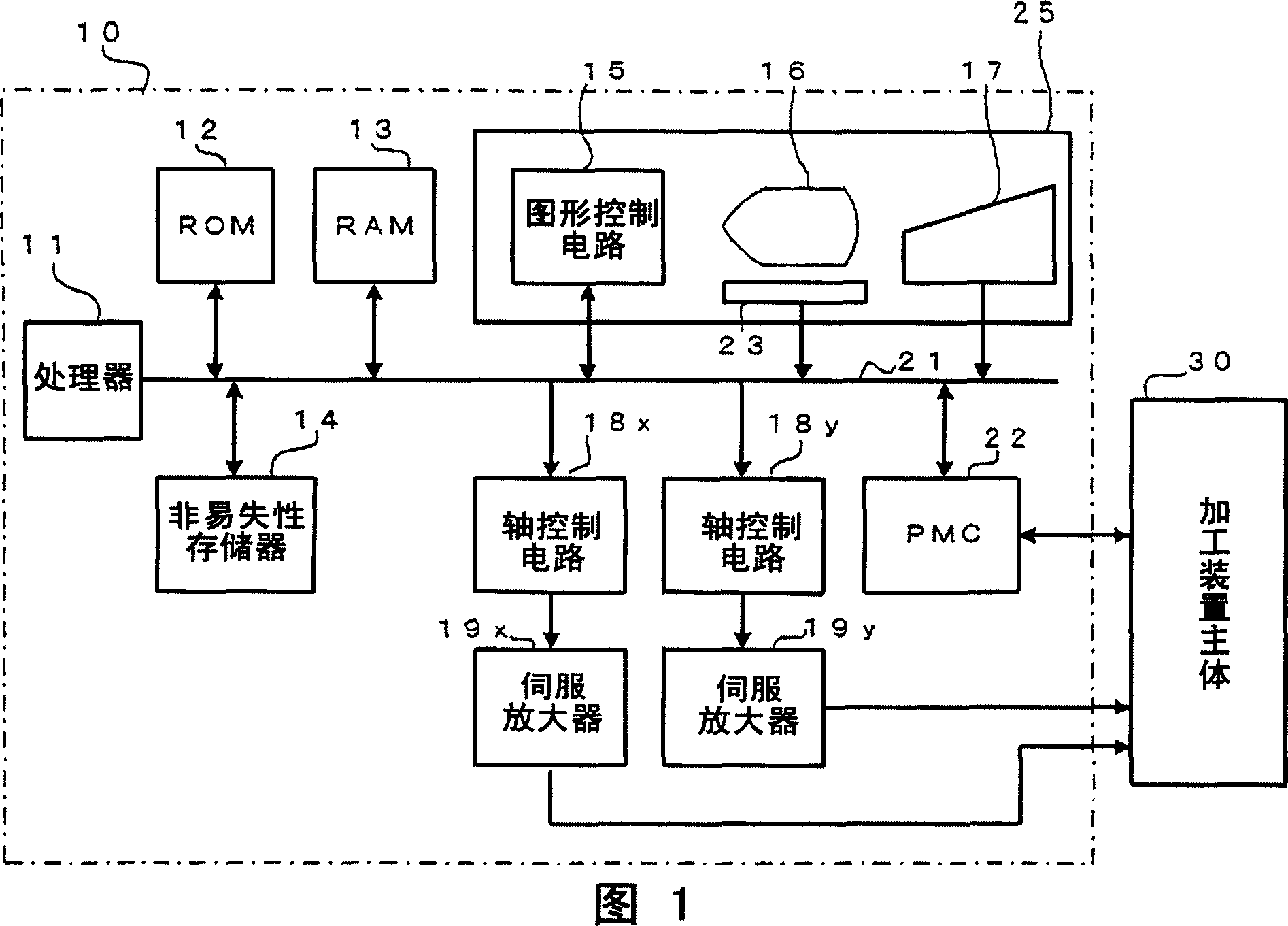

[0020] FIG. 1 is a schematic diagram of an electric discharge machining device to which the machining condition setting method of the present invention is applied, and the description focuses on a control device of the electric discharge machining device. In addition, in this embodiment, the example of the processing condition setting of a wire electric discharge cutting apparatus was shown.

[0021] Reference numeral 10 is a numerical control device constituting the control device of the electric discharge machining device, and reference numeral 30 is a main body of the electric discharge machining device (main body of the wire electric discharge machining device).

[0022] Numerical control device 10 connects ROM12, RAM13, nonvolatile memory 14, axis control circuits 18x, 18y, PMC (Programmable Mechanical Controller) 22, man-machine interface 25 and processor 11 through bus 21. The processor 11 controls the entire numerical controller 10 according to the system program store...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com