Double-headed machine tool

A machine tool and double-head technology, which is applied in manufacturing tools, metal processing, metal processing equipment, etc., can solve the problems of wasted space, increased volume and weight, and the processing efficiency of single-head is not as good as that of double-heads.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

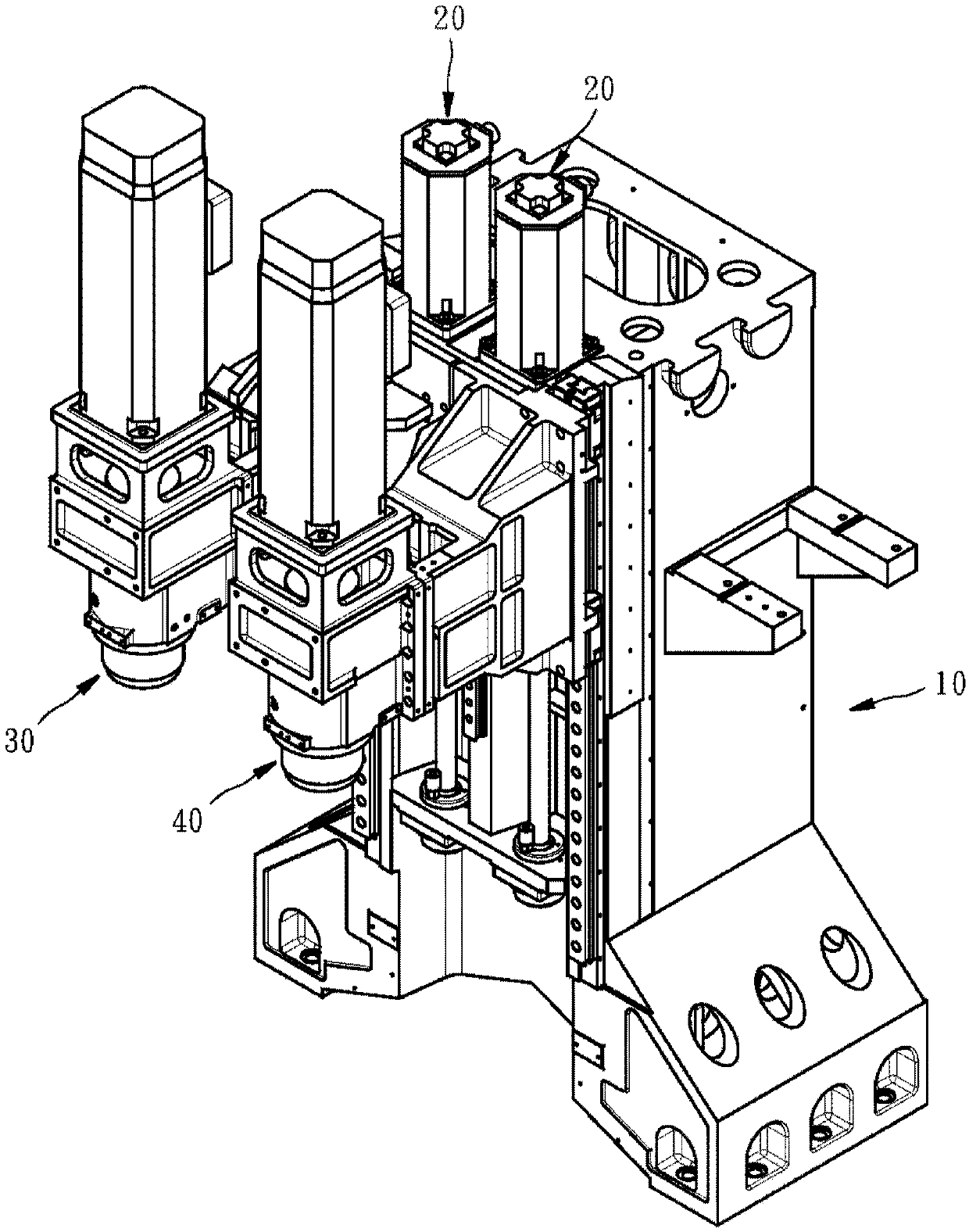

[0036] As shown in each figure, a double-head machine tool provided by the present invention includes:

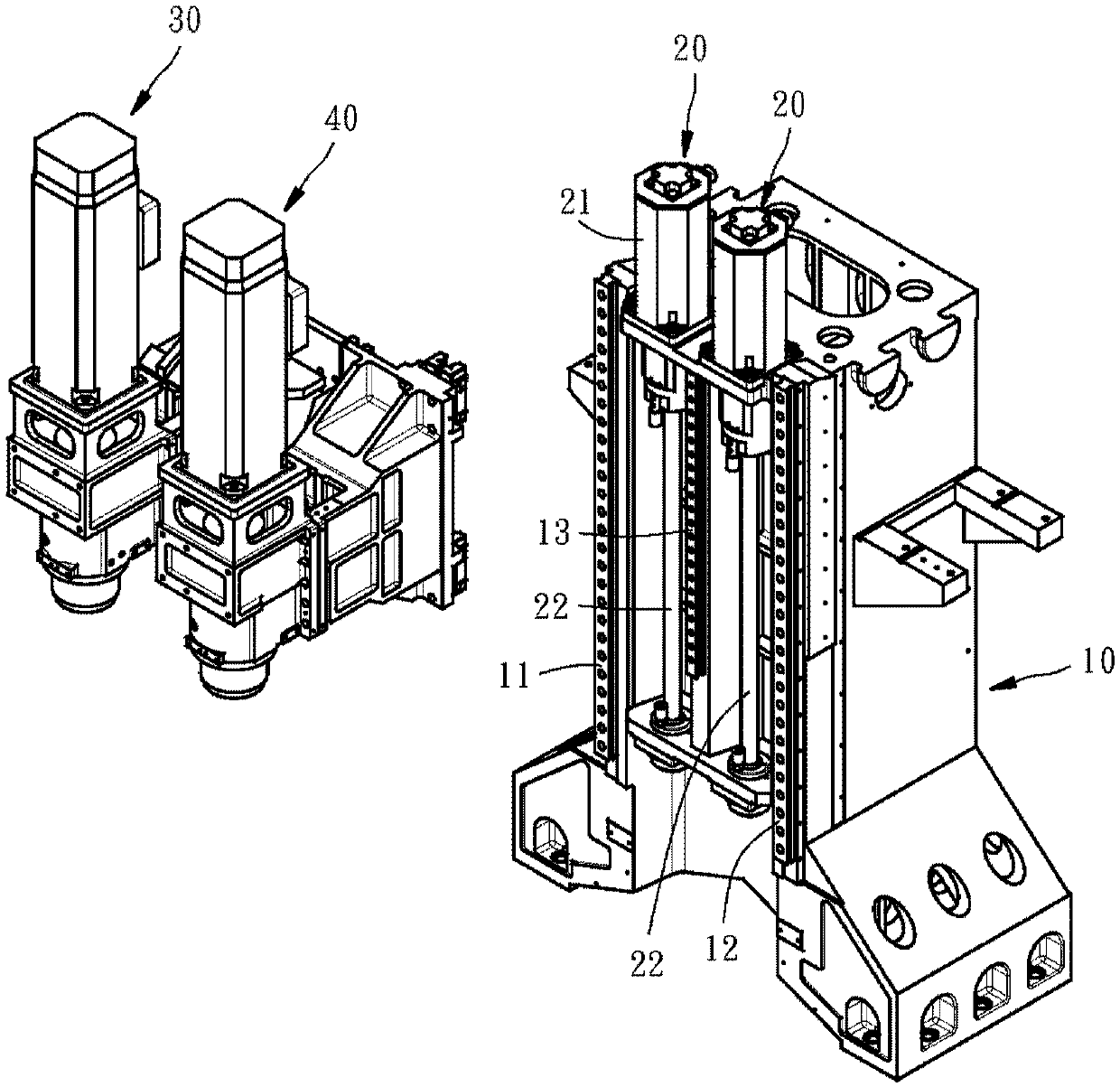

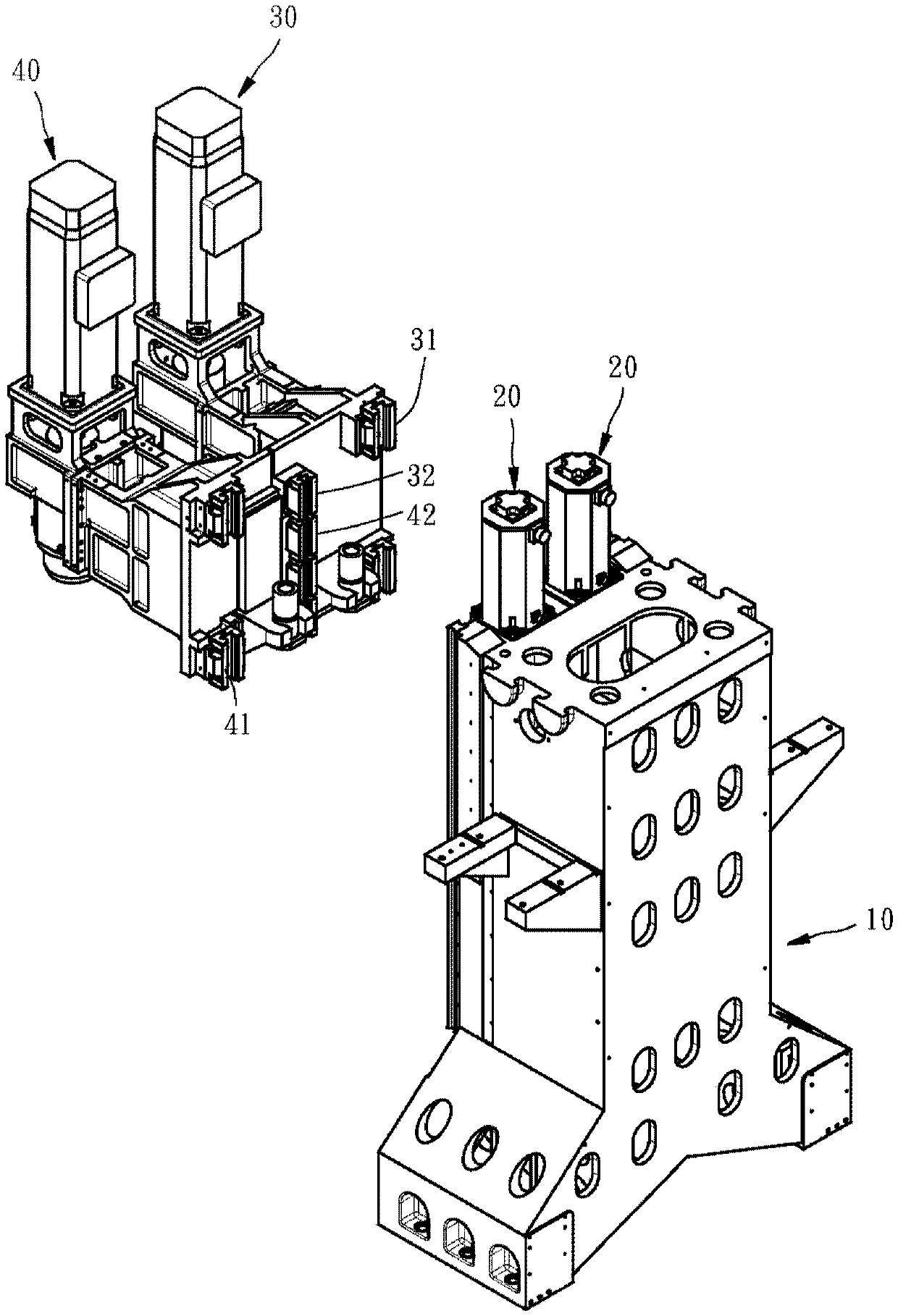

[0037] A column frame group 10 has a first line rail 11, a second line rail 12, and a third line rail 13 are located between the first line rail 11 and the second line rail 12; in addition, the column frame group 10 There is a line rail fixing part 14 for installing the third line rail 13 .

[0038] Two feed driving groups 20 are installed on the column base group 10 , and each feed driving group 20 has a driving motor 21 and a screw 22 driven by the motor 21 to rotate.

[0039] Wherein, the line rail fixing portion 14 of the column frame set 10 is located between the two screw rods 22 .

[0040] A first machine head 30 has two first sliders 31 slidingly fitted on the first line rail 11, two second sliders 32 slidingly fitted on the third line rail 13, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com