Manual rounding device

A technology of rounded corners and handles, which is applied in the direction of grinding workpiece supports, grinding machines, metal processing equipment, etc., can solve the problems of high requirements for operators, increased processing costs, and difficult precision, so as to achieve simple and easy operation and avoid processing cost, avoiding the effect of increasing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

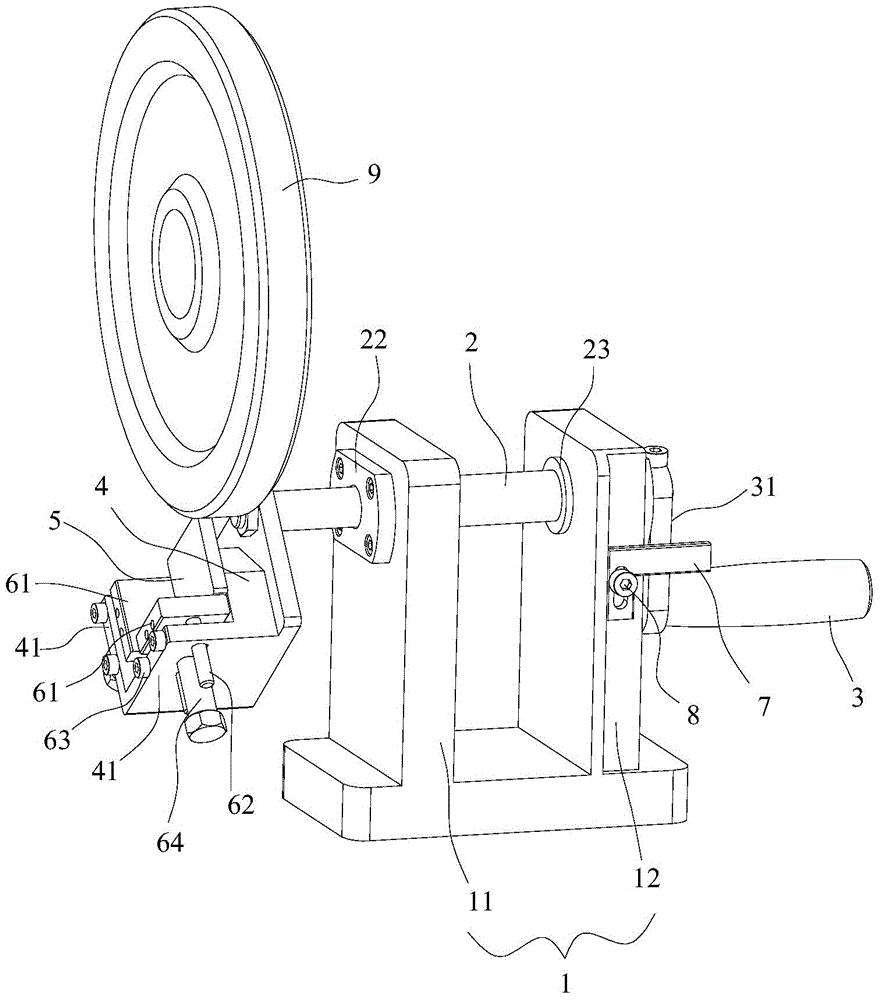

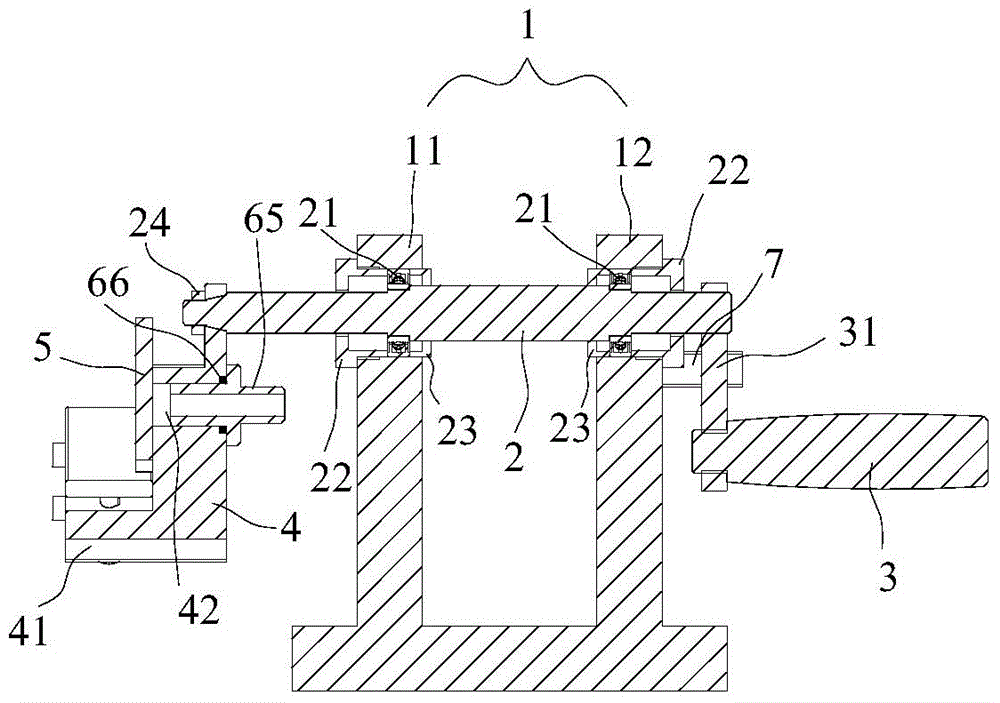

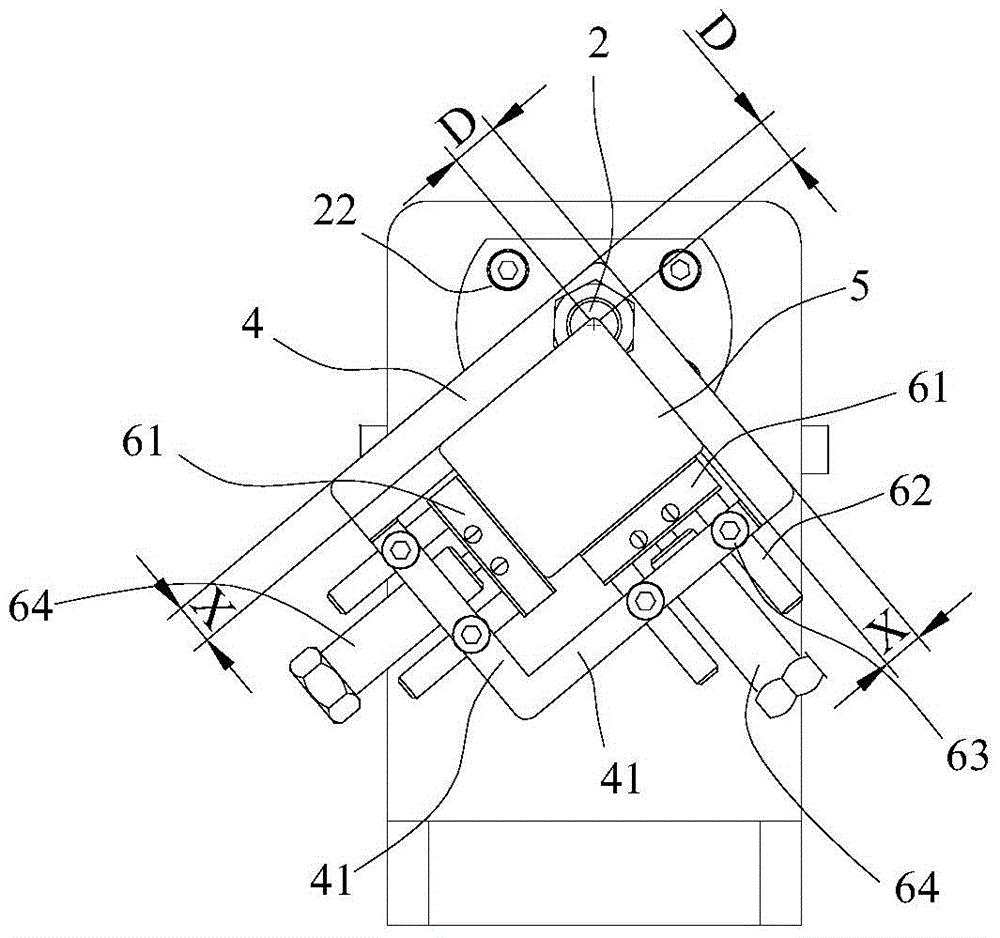

[0019] refer to Figure 1 to Figure 3 , the present invention provides a manual rounding device, comprising a support base 1, a rotary shaft 2 mounted on the support base 1, a handle 3 and a positioning block 4 respectively mounted on both ends of the rotary shaft 2, the The front side surface of the positioning block 4 is flat and forms two locating plates 41 at an angle of 90° to each other and protrudes forward perpendicular to the positioning block 4. The two positioning plates 41 form a deviation on the front side of the positioning block 4. The rotary shaft 2 is used to place the installation position of the workpiece 5 to be processed, and a positioning mechanism for fastening the workpiece 5 to be processed is provided in the installation position.

[0020] Wherein, the support seat 1 includes a first support seat 11 and a second support seat 12 arranged side by side for the rotary shaft 2 to pass through transversely, and the rotary shaft 2 and the first support seat ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com