Reverse machining method and positioner for flat-shoulder sleeve

A processing method and technology of a positioner, which are applied in positioning devices, metal processing equipment, metal processing mechanical parts, etc., can solve the problems of unsuitable batch processing, non-parallel, and the inability of the second sleeve to be assembled in place.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0055] Taking the processing of sleeve roller chains as an example, an inversion processing method for flat shoulder sleeves includes the following steps:

[0056] Step 1: Falling embryos, that is, processing cylindrical long embryos according to the actual outer diameter of the flat shoulder sleeve.

[0057] Step 2: Opening a hole at one end of the long columnar embryo.

[0058] Step 3: Clamp the above-mentioned cylindrical long blank to the tool position, specifically,

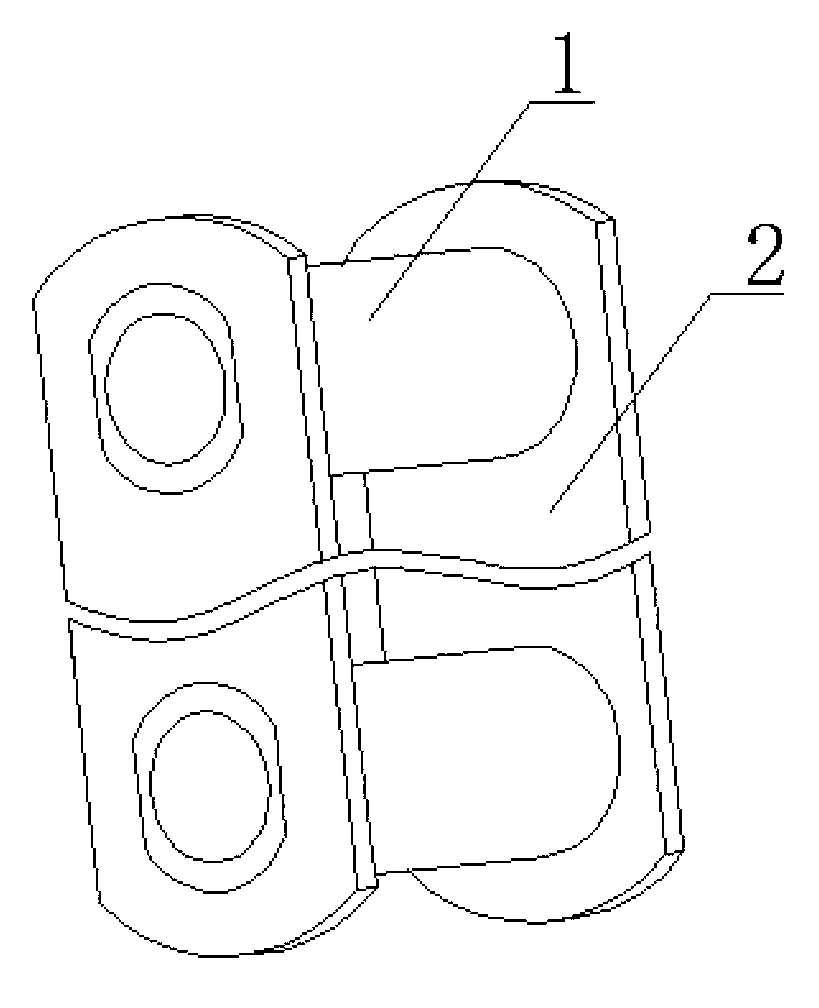

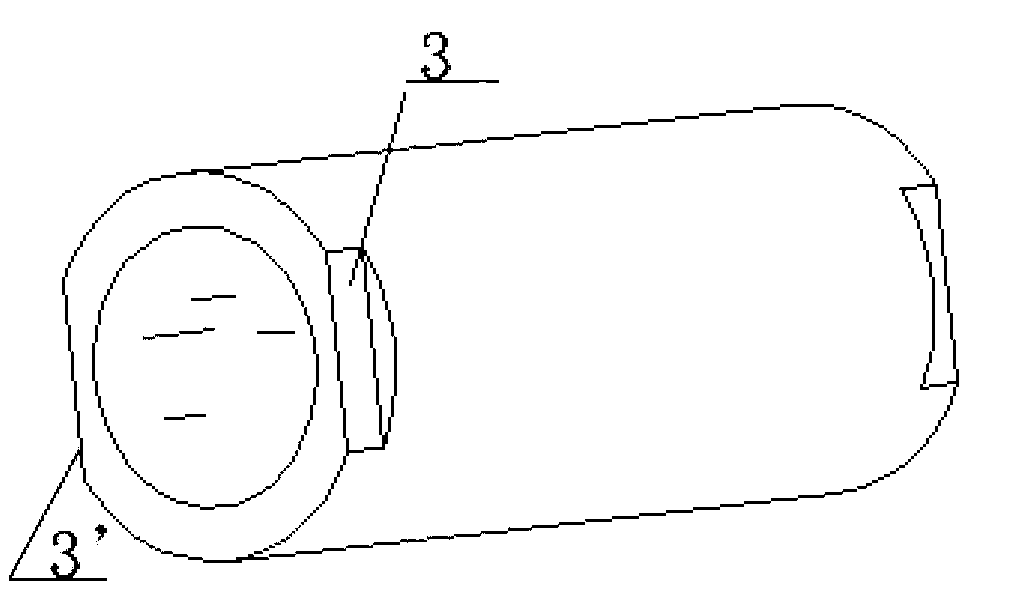

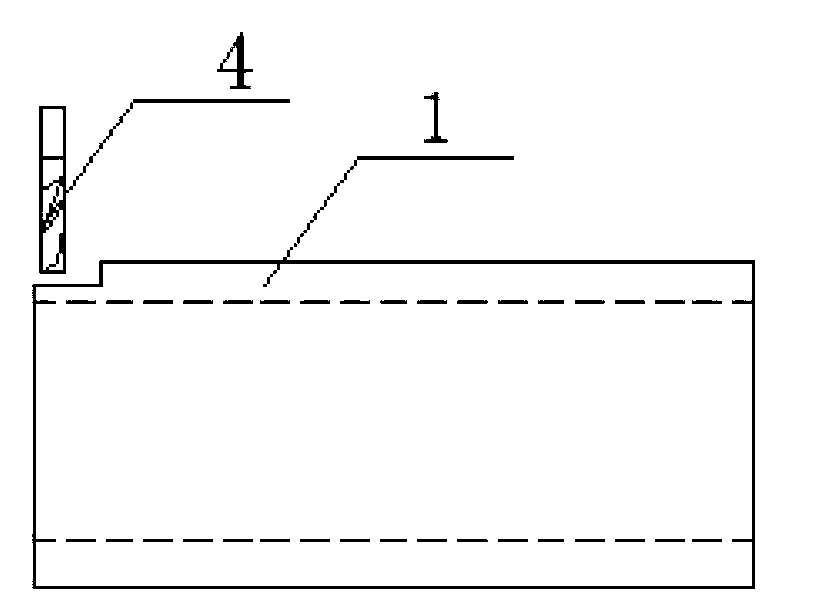

[0059] Clamp the locator with the rectangular block positioning part on the vise clamp of the planer, the above-mentioned locator also includes the cylindrical tube connected to the rectangular block positioning part and the processing port on the cylindrical tube, the center of the rectangular block positioning part There is a through hole for inserting the above-mentioned cylindrical long blank, and the positioning part of the rectangular block is located within the clamping span of the vise clamp to limi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com