High-precision thin-wall push pipe machining technology and casing tool

A processing technology and high-precision technology, which is applied in the direction of manufacturing tools, metal processing equipment, grinding workpiece supports, etc., can solve the problems that cannot meet the requirements of thin-walled push tube accuracy and shape and position accuracy, and achieve high processing efficiency and stable quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

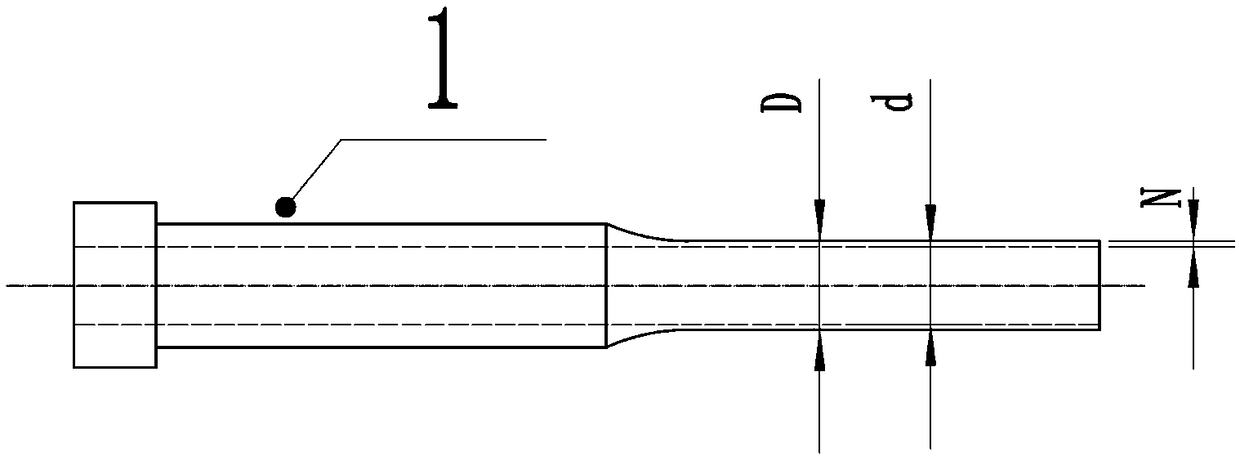

[0026] A high-precision thin-wall push tube processing technology, the thin-wall push tube to be processed in this embodiment has an aperture of less than 5mm, including the following steps:

[0027] S1. Rough machining. The inner hole of the push tube normally has a grinding amount of 0.2-0.3mm during processing, and the outer diameter is thickened. At this time, the wall thickness N of the push tube is about 1mm, which is an ordinary push tube, not a thin-walled push tube;

[0028] S2. After heat treatment, the inner hole is finished, and the reserved amount is 0.03mm. At this time, the push tube is still a common push tube;

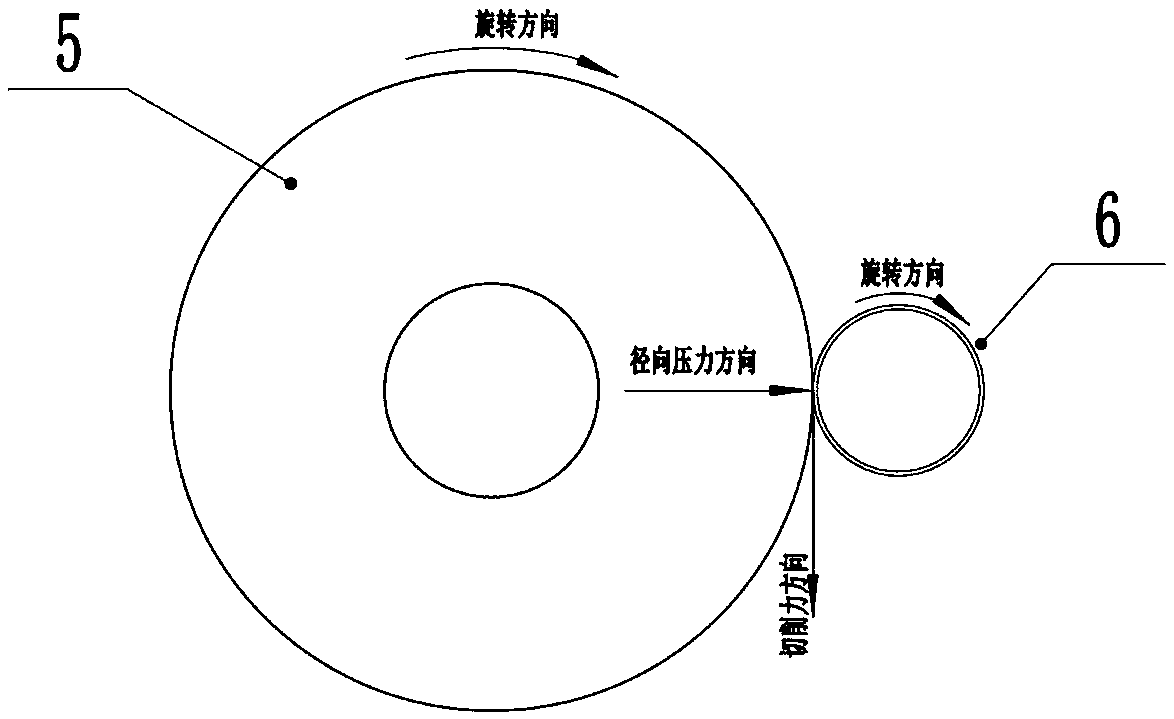

[0029] S3. Finally, the outer diameter is processed based on the inner hole, and finally the accuracy of the thin-walled push tube is guaranteed: the coaxiality is 0.005mm, and the dimensional accuracy is 0.005mm. figure 2 As shown, the ordinary corundum abrasive grinding wheel is easy to wear, and the cutting ability becomes weak after the cutting ed...

Embodiment 2

[0033] A high-precision thin-wall push tube processing technology, the aperture of the thin-wall push tube to be processed in this embodiment is greater than or equal to 5mm, including the following steps:

[0034] S1. Rough machining. The inner hole of the push tube normally has a grinding amount of 0.2-0.3mm during processing, and the outer diameter is thickened. At this time, the wall thickness N of the push tube is about 1mm, which is an ordinary push tube, not a thin-walled push tube;

[0035] S2. After heat treatment, the inner hole is finished, and the reserved amount is 0.03mm. At this time, the push tube is still a common push tube;

[0036] S3. Finally, the outer diameter is processed based on the inner hole, and finally the accuracy of the thin-walled push tube is guaranteed: the coaxiality is 0.005mm, and the dimensional accuracy is 0.005mm. figure 2 As shown, the ordinary corundum abrasive grinding wheel is easy to wear, and the cutting ability becomes weak after...

Embodiment 3

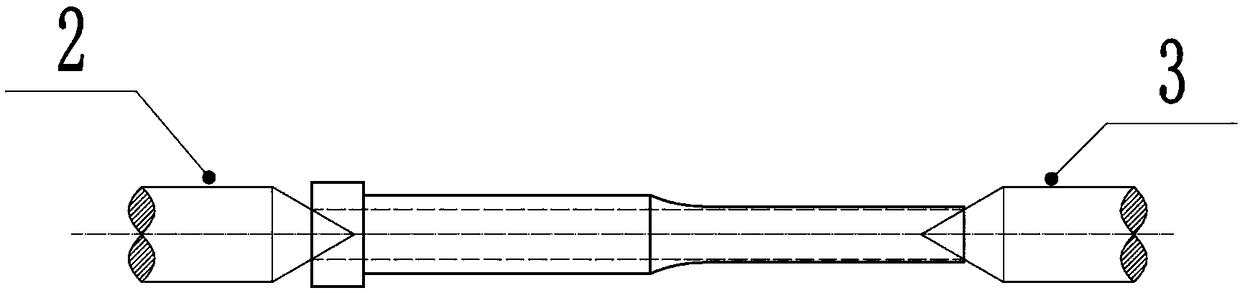

[0040] The high-precision thin-wall push tube processing set used in the processing technology described in Examples 1 and 2 includes cylindrical grinding equipment, a cone tip of a cylindrical grinder, a tapered mandrel 4, and a mandrel 7; the cylindrical grinding equipment The emery wheel that uses selects CBN abrasive emery wheel 5 for use; The cone top of described cylindrical grinder is two, as image 3 The cone tip 2 of the cylindrical grinder and the cone tip 3 of the cylindrical grinder shown in , are respectively used to be clamped at the front and back of the push tube when the aperture of the push tube to be processed is less than 5 mm; When it is greater than or equal to 5mm, it is socketed in the push tube, and the outer diameter of the tapered mandrel 4 is processed according to a taper of 1:10000; the mandrel 7 is used to insert into the inner hole of the push tube to measure the outer diameter.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com