Annular polishing surface shape accurate adjustment method for plate type optical components

A kind of optical and polishing surface technology, which is applied in the direction of optical surface grinder, grinding/polishing equipment, manufacturing tools, etc., can solve the problems of unguaranteed, single-sided surface shape accuracy difference, etc., and achieve high controllability, high adjustment accuracy, The effect of improving the qualified efficiency of surface shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

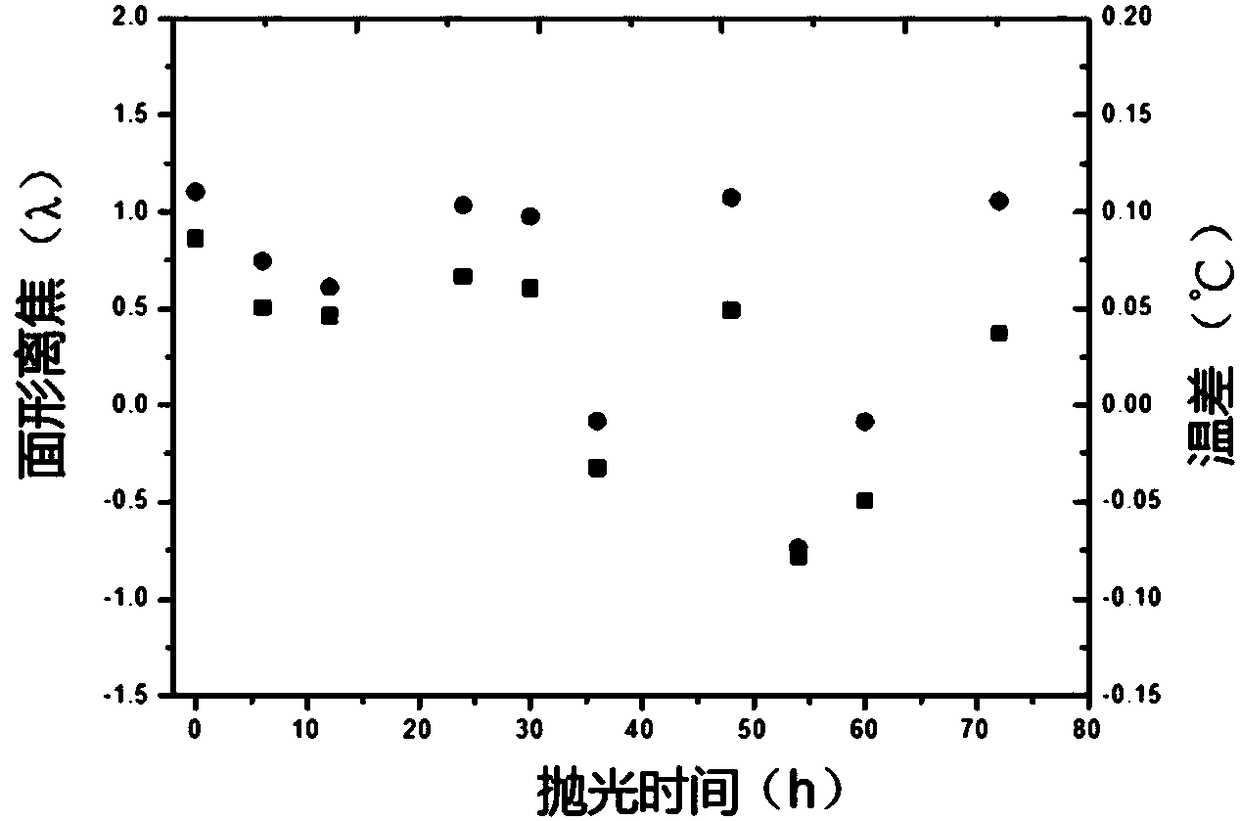

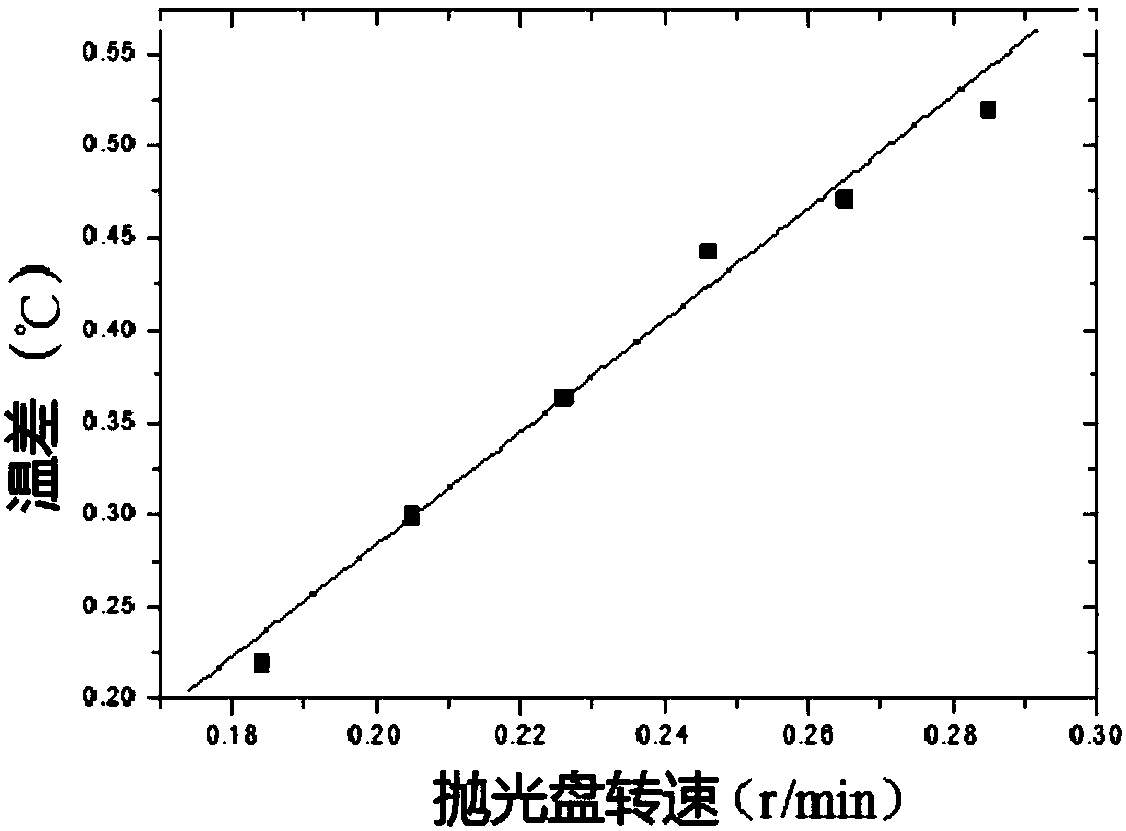

[0037] The φ4.4m ring polishing machine is used to process the neodymium glass element with a size of 810mm*460mm*40mm, and the rotating speed of the polishing disc can be adjusted in the range of 0-0.5r / min. The processing environment temperature is 22±0.1°C, the relative humidity is 65-70%RH, cerium oxide is used as the polishing liquid, the concentration is 4%, and the flow rate is 0.8L / h. The transmission wavefront index of the component requires PV to be better than 1 / 3λ, and GRMS to be better than 1 / 90λ. The processing steps are as follows:

[0038] Step 1) Polishing mold modification:

[0039] Keep the process parameters such as ambient temperature and humidity, polishing liquid concentration / flow rate unchanged, adjust the speed of the polishing disc to 0.25r / min, and modify the shape of the polishing mold by changing the eccentricity of the correction disc. During the modification process, the φ600mm plane interferometer is used to measure the surface shape of the el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com