Welding method of super thick steel plate vertical jigsaw

A welding method and technology for thick steel plates, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of inability to effectively control welding deformation, difficult to obtain satisfactory assembled products, and large structural rigidity of large-thickness steel plates. Achieve the effect of avoiding welding deformation correction, avoiding root cleaning process, and avoiding welding cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

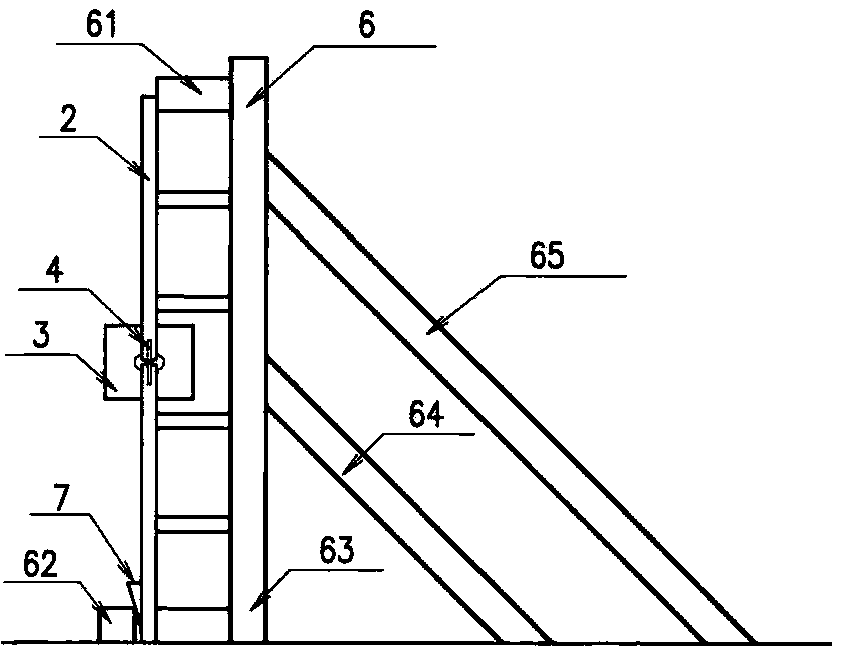

[0028] Attached below figure 1 , attached figure 2 , attached image 3 The present invention is further described with specific embodiments.

[0029] 1. Make X-shaped welding grooves on the welding parts of two ultra-thick steel plates 2 with specifications of 80 mm×2100 mm×9600 mm. Its sides are polished to a metallic sheen.

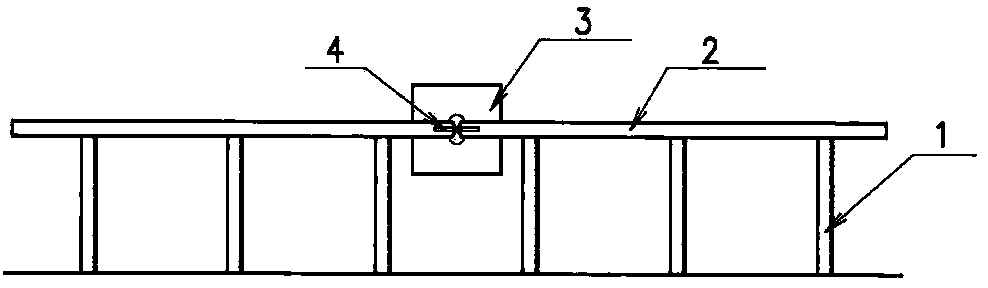

[0030] 2. Lift the ultra-thick steel plate 2 with the groove cut on the flat welding tire frame 1, adjust the welding gap between the two ultra-thick steel plates to 8mm, and weld one arc-extinguishing plate at both ends of the ultra-thick steel plate weld 4. Weld 32 fixing plates 3 near the surface on both sides of the super-thick steel plate front and back welds.

[0031] 3. Use heating equipment to preheat the range of 150mm on both sides of the welding groove to above 90°C and not more than 120°C.

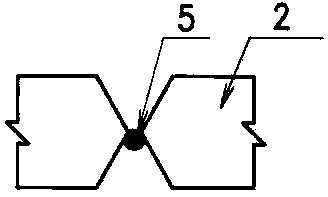

[0032] 4. The Φ10mm round rod-shaped ceramic liner 5 is pasted inside the weld seam, and carbon dioxide gas shielded welding is used to perform fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com