Slowly-rebounded mattress made from recovered grease polyether polyol

A technology of polyether polyol and slow rebound, which is applied in the field of mattresses, can solve problems such as poor air permeability, easy deformation of spring mattresses, and no health care effect, so as to achieve reasonable structure, promote ecological harmony and ecological cycle, and not hinder The effect of blood circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

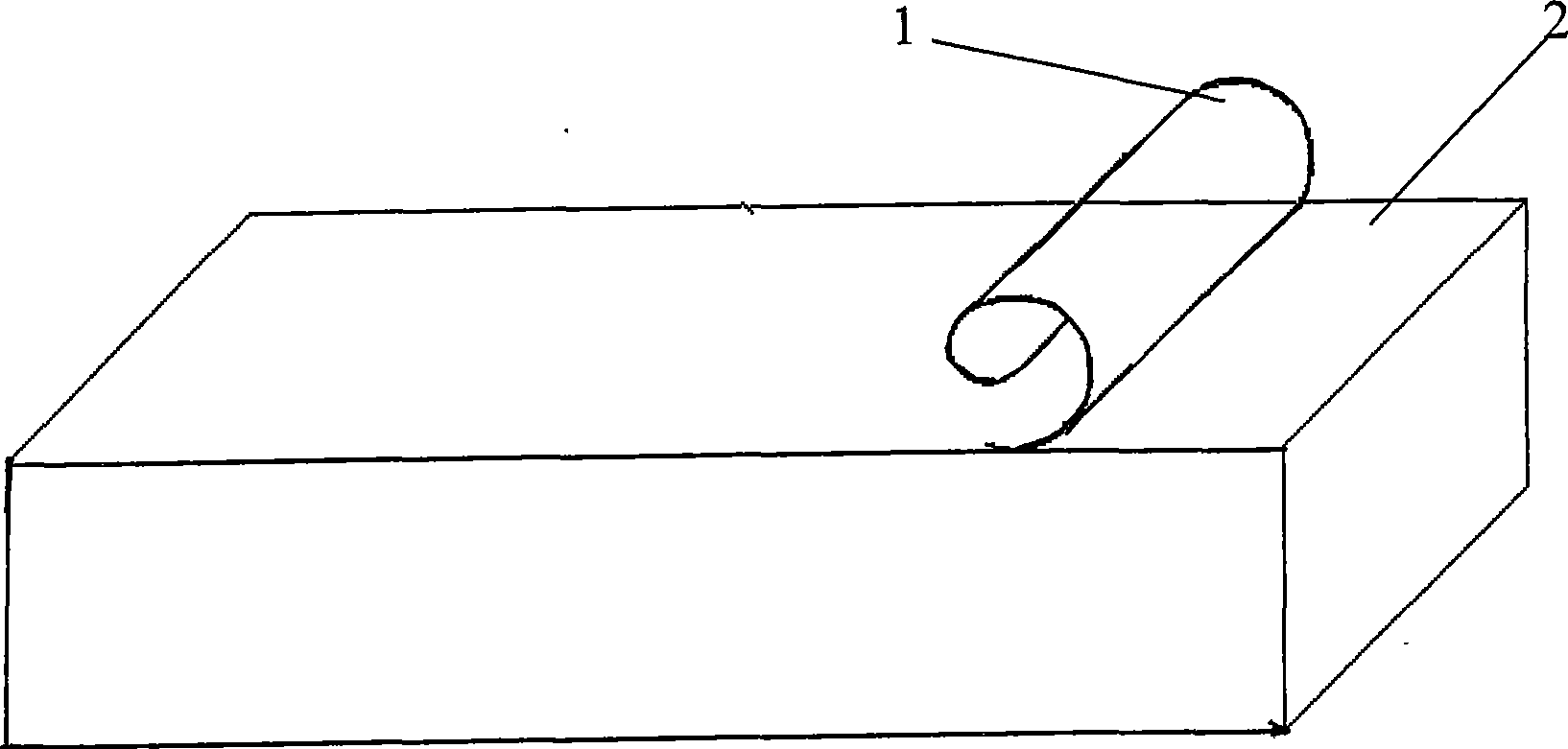

[0010] A slow-rebound mattress made from recycled grease polyether polyols, comprising a fabric layer 1 and a core layer 2, the core layer adopts resilient polyurethane soft foam made from recycled grease polyether polyols as the main raw material, Ventilation holes are arranged on the side of the fabric layer or other suitable parts. The thickness of the core layer is 4-10 cm.

[0011] The slow-rebound polyurethane soft foam is mixed with slow-rebound polyether polyols made from recycled oil and ordinary petroleum polyether polyols, and added with catalysts, blowing agents, foam stabilizers, etc. Slow resilience polyurethane soft foam made by polyisocyanate foaming reaction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com