Method of fast loading and correction of large diesel engine frame on gantry milling machine

A calibration method and technology of gantry milling machine, applied in workshop equipment, metal processing mechanical parts, manufacturing tools, etc., can solve problems such as large overhang, complex structure, and troublesome adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention cannot be limited by this.

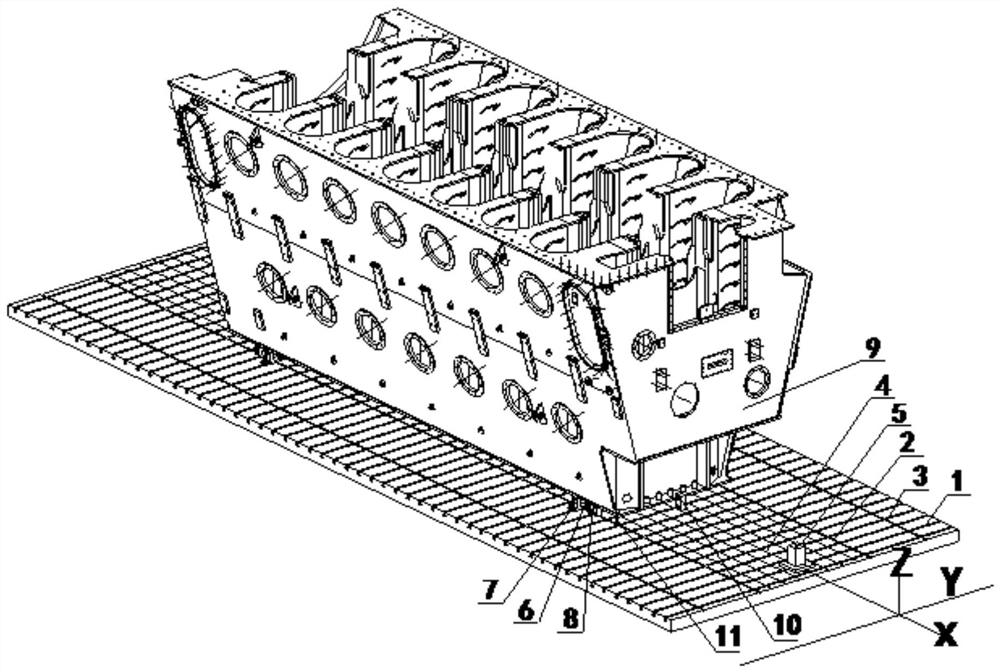

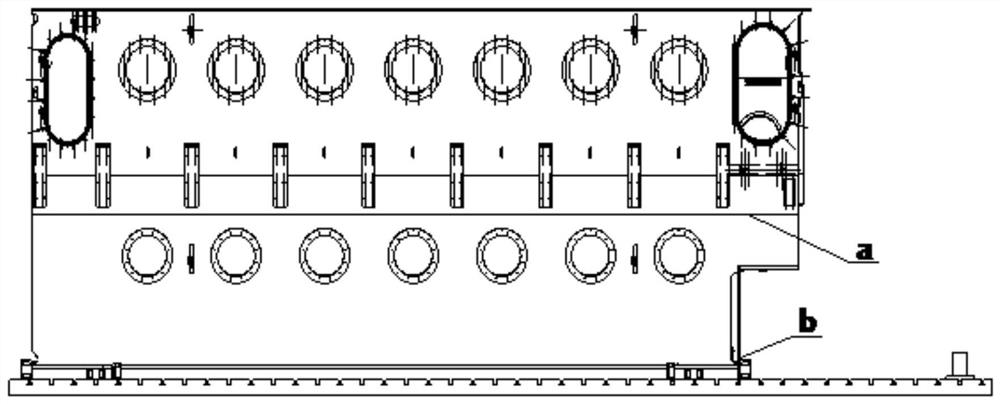

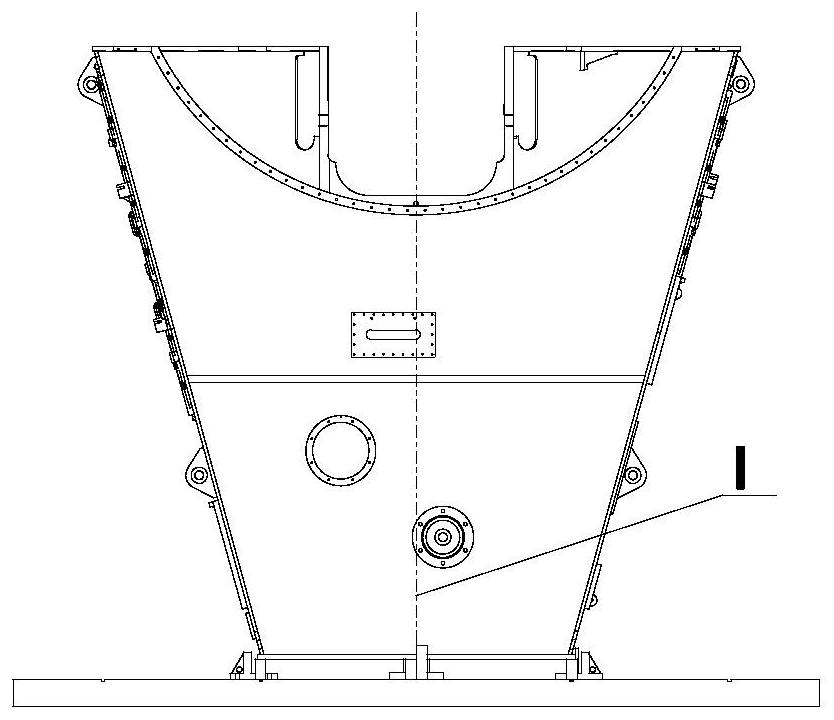

[0023] The method for quickly boarding and correcting a large diesel engine frame on a gantry milling machine according to the present invention includes: the frame uses a laser reference scribing method to draw X, Y, Z coordinate processing lines, waistlines, and workpiece centers before boarding the machine. Line and workpiece zero reference line, and further through the use of milling table surface engraving line, milling positioning groove, installation of positioning support stopper, positioning key, reference tool setting block, placement of adjustment pad, correction block, reference The technical measures of measuring block and frame laser scribing ensure the fast correction of the frame on the vehicle and complete the coordinate setting.

[0024] For the proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com