Welding method for vertically spliced super-thick steel plate

A welding method and thick steel plate technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve problems such as inability to control welding deformation very effectively, difficulty in obtaining satisfactory jigsaw products, and high rigidity of large-thickness steel plate structures. Achieve the effect of avoiding welding deformation correction, avoiding root cleaning process, and avoiding welding cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

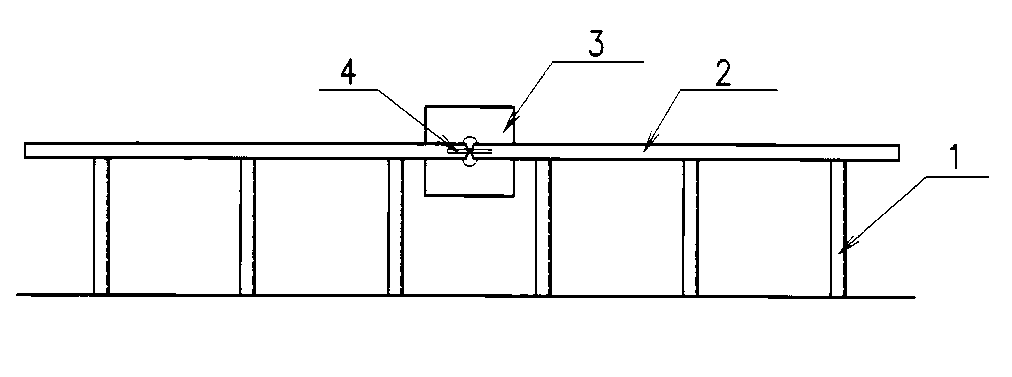

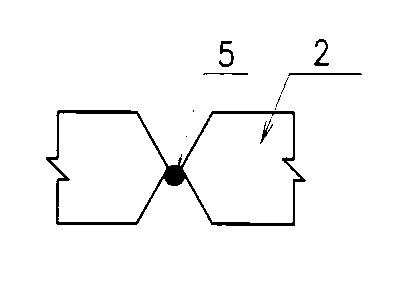

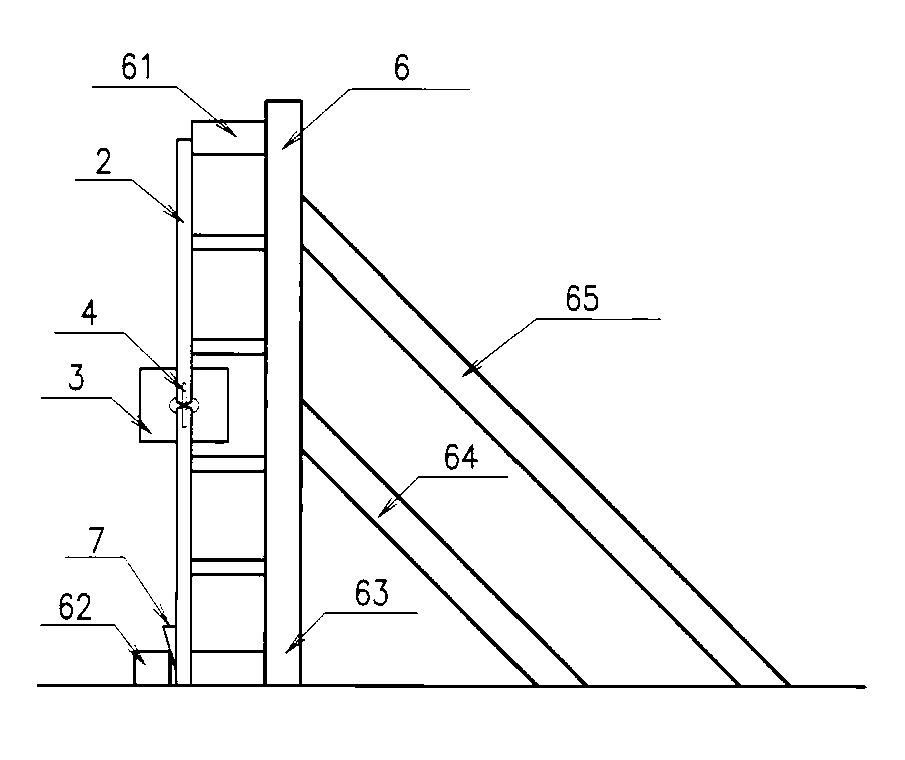

[0028] Attached below figure 1 , Attached figure 2 , Attached image 3 The present invention is further described with specific embodiments.

[0029] 1. Make X-shaped welding grooves on the welding parts of two ultra-thick steel plates 2 with specifications of 80 mm×2100 mm×9600 mm. The angles of the grooves on both sides are 20°, and there is no blunt edge in the middle, and the groove and The surfaces on both sides are polished until metallic luster appears.

[0030] 2. Hoist the ultra-thick steel plate 2 with the cut bevel to the flat welding frame 1, adjust the welding gap between the two ultra-thick steel plates to 8mm, and weld an arc ignition plate at each end of the ultra-thick steel plate weld. 4. Add 32 fixed plates 3 to the sides of the front and back welds of the ultra-thick steel plate.

[0031] 3. Use heating equipment to preheat the range of 150mm on both sides of the welding groove to above 90℃, not exceeding 120℃.

[0032] 4. Stick Φ10mm round rod type ceramic back...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com