Laser welding device with cooling system and welding method thereof

A laser welding and cooling system technology, applied in laser welding equipment, welding equipment, welding/welding/cutting items, etc., can solve the problems of welding residual stress and large deformation, improve welding quality, reduce softening phenomenon, reduce The effect of residual stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

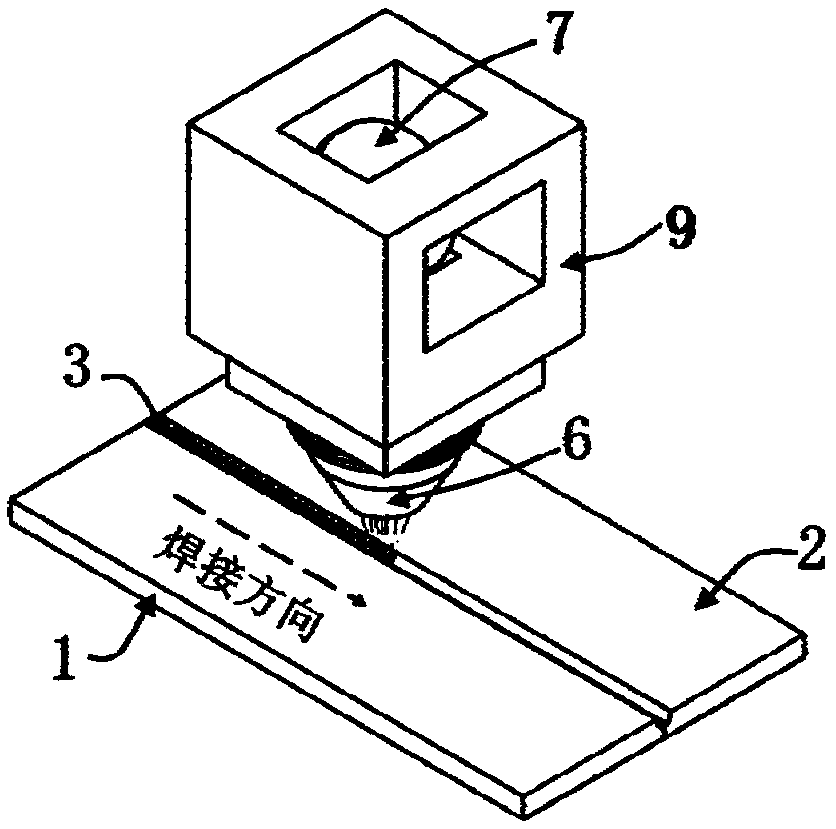

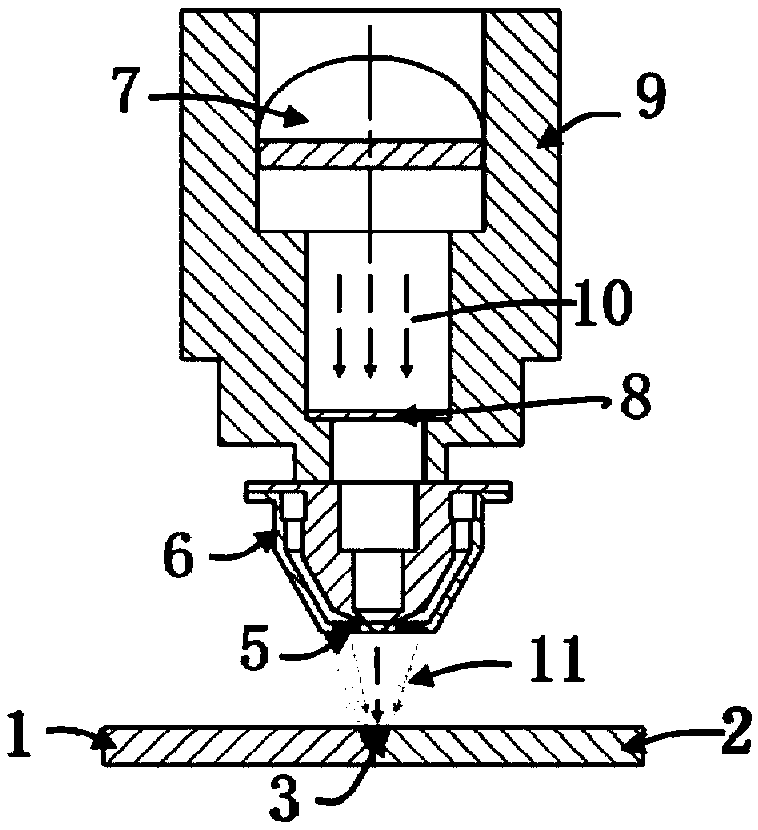

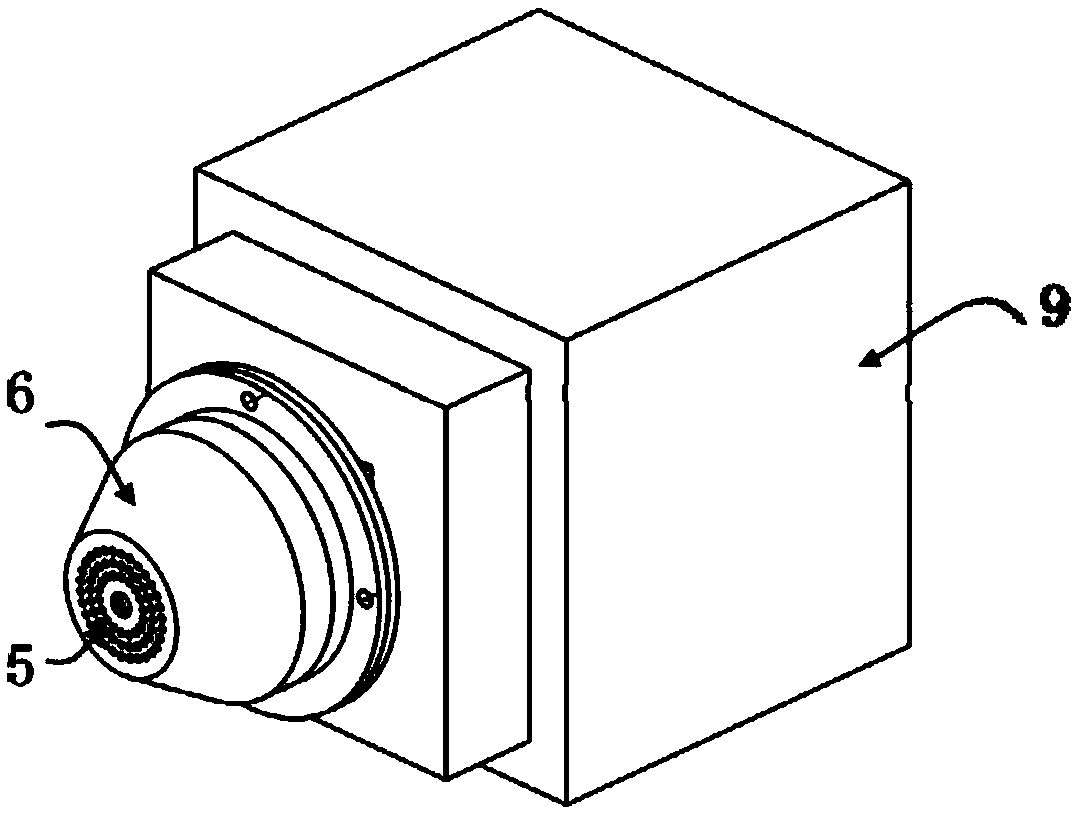

[0034] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 Shown is a schematic diagram of this embodiment.

[0035] The workpieces 1 and 2 to be welded are aluminum alloy workpieces that are prone to softening during welding. The welding point 3 is a butt linear weld formed after the workpieces 1 and 2 are welded in the form of butt joints. The welding method used is laser welding, and 5 is liquid spray cooling. System, 6 is the laser head protection nozzle, 7 is the reflective lens inside the laser head, 8 is the focusing lens, 9 is the laser head, 10 is the laser beam, 11 is the water spray, 12 is the spray system located in the laser head protection nozzle Pipeline, 13 is the place where the laser beam exits. The liquid spray cooling system 5 used is distributed inside the protective nozzle 6 of the laser head. The spray is water, the temperature is 20°C, and the flow rate is 20L / min. . Similarly, when ordinary laser welding wel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com