Metal material, process and product for welding LNG ultralow-temperature stainless steel

A welding process and metal material technology, applied in the field of welding and manufacturing of LNG stainless steel equipment and pipelines, can solve the problems of rapid heat dissipation of stainless steel, poor thermal conductivity of stainless steel, and little practical value, and achieve the elimination of welding residual stress and welding efficiency The effect of improving and improving welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] 304L pipe butt welding, pipe diameter 450mm, wall thickness 25mm.

[0066] Groove angle: unilateral 15-35°, groove type U-shaped or V-shaped, blunt edge: 1-3mm, pair gap 3.0 ±1.0 . The bevel angle and the size of the blunt edge that meet the process requirements are machined by mechanical methods.

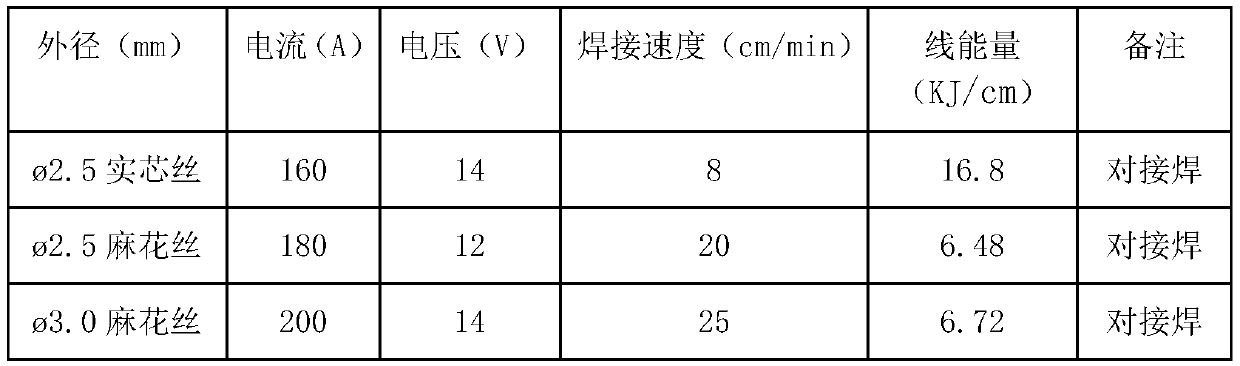

[0067] Self-shielded argon arc welding + twist welding wire argon arc welding: self-shielding solid argon arc welding wire is used as a primer, and argon arc welding twist welding wire is used for filling and covering.

[0068] Welding consumable composition is designed for pure austenitic stainless steel composition with ferrite content basically 0, and its composition formula is:

[0069] C: 0.03%, Cr: 18.1%, Si: 0.5%, Ni: 13%, Mn: 4.3%, N: 0.15%, S: 0.002%, P: 0.030%, Sr: 0.005.

[0070] After assembly, root the root for backing welding The self-shielded argon arc welding wire is used for welding to ensure that the back of the root bead is not over-oxidized. The weld...

Embodiment 2

[0074] S30403 stainless steel equipment steel plate coiled butt welding, equipment diameter 1800mm, circular seam and longitudinal seam welding, material wall thickness 16mm.

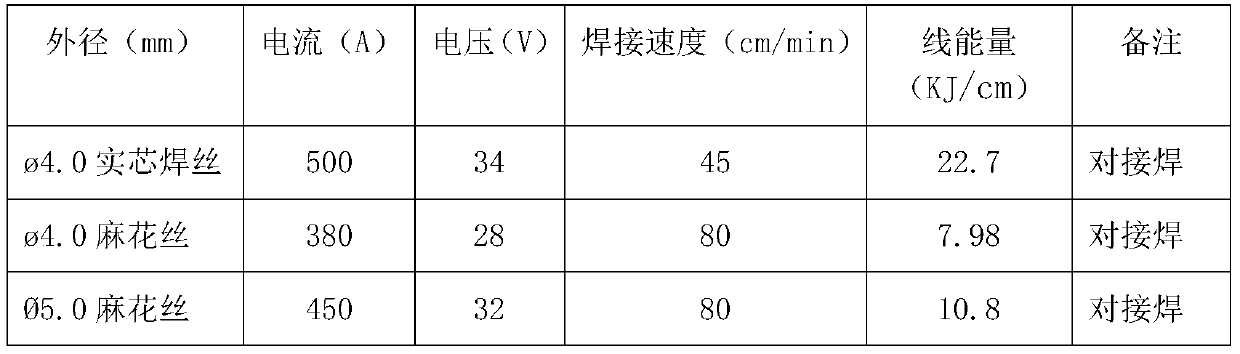

[0075] Use argon arc welding twist welding wire to make the bottom + submerged arc welding to fill and cover the surface.

[0076] The groove type is U-shaped, V-shaped or X-shaped groove, the thickness of the blunt edge is 1.0-2.0, and the gap between groups is 2.5 ±1.0 .

[0077] with diameter Twist welding wire argon arc welding as the base, and then use The submerged arc welding twist wire is filled until the cover welding is completed. After the back weld bead is cleaned with a special stainless steel grinder or a steel brush, it is filled with argon arc welding twist welding wire or submerged arc welding twist welding wire.

[0078] Welding consumables are pure austenitic stainless steel components with a designed ferrite content of basically 0, and the composition formula is:

[0079] C: 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com