Automatic wire-feeding friction stir welding method for butt joint of dissimilar metal materials

A technology of friction stir welding and dissimilar metals, applied in metal processing equipment, welding/welding/cutting items, welding equipment, etc., can solve the problem of interfacial intermetallic compound thickness reducing interface stress, not improving aluminum/steel interface strength, weld seam Effective thickness reduction and other issues, to achieve the effect of reducing hole defects, excellent mechanical properties, and reducing residual stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

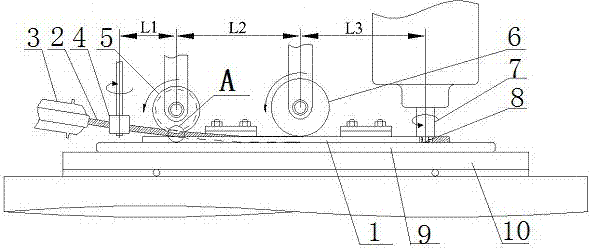

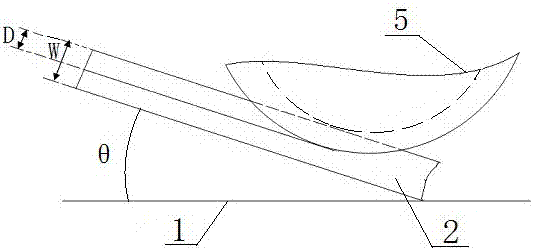

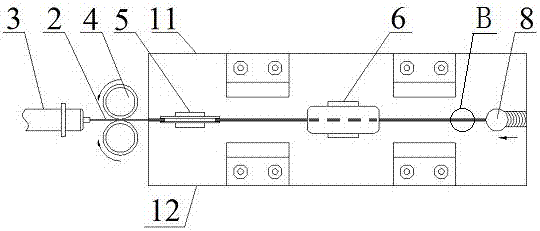

[0049] Embodiment 1, an automatic wire-feeding friction stir welding method for butt jointing of dissimilar metal materials, which includes the following steps:

[0050] Step 1, the steel material 11 to be welded and the aluminum material 12 to be welded are docked and clamped on the fixed plate 9, the fixed plate 9 is fixedly installed on the welding platform 10, and the welding platform 10 is slidably installed on the base; the steel material 11 to be welded and the aluminum material to be welded are A gap is provided between the materials 12, and the gap width a is 0.3mm. The strip welding wire 2 is drawn out from the wire feed gun 3, and the angle between the strip welding wire drawn out by the wire feed gun and the surface of the weldment is 5°, so The thickness of the strip-shaped welding wire is 0.25mm, and the material is AlSi5; the straightening wheel group 4, the embedded wheel 5 and the leveling wheel 6 are placed above the gap in sequence, and the center distance be...

Embodiment 2

[0053] Embodiment 2, a friction stir welding method for automatic wire feeding for the butt joint of dissimilar metal materials, which includes the following steps:

[0054] Step 1, the steel material 11 to be welded and the aluminum material 12 to be welded are docked and clamped on the fixed plate 9, the fixed plate 9 is fixedly installed on the welding platform 10, and the welding platform 10 is slidably installed on the base; the steel material 11 to be welded and the aluminum material to be welded are A gap is provided between the materials 12, and the gap width a is 0.08 mm. The strip welding wire 2 is drawn out from the wire feed gun 3, and the angle between the strip welding wire drawn out by the wire feed gun and the surface of the weldment is 3°, so The thickness of the strip-shaped welding wire is 0.03mm, and the material is Cu; the straightening wheel set 4, the embedded wheel 5 and the leveling wheel 6 are placed above the gap in sequence, and the center distance b...

Embodiment 3

[0057] Embodiment 3, a friction stir welding method for automatic wire feeding for the butt joint of dissimilar metal materials, which includes the following steps:

[0058] Step 1, the steel material 11 to be welded and the aluminum material 12 to be welded are docked and clamped on the fixed plate 9, the fixed plate 9 is fixedly installed on the welding platform 10, and the welding platform 10 is slidably installed on the base; the steel material 11 to be welded and the aluminum material to be welded are A gap is provided between the materials 12, and the gap width a is 1.0mm. The strip welding wire 2 is drawn out from the wire feed gun 3, and the angle between the strip welding wire drawn out by the wire feed gun and the surface of the weldment is 6°, so The thickness of the strip-shaped welding wire is 0.98mm, and the material is ZnAl5; the straightening wheel set 4, the embedded wheel 5 and the leveling wheel 6 are placed above the gap in sequence, and the center distance ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com