Plasma-arc welding method of cupronickel with thickness of 2-20 mm

A plasma arc and cupronickel technology, applied in plasma welding equipment, welding equipment, arc welding equipment, etc., can solve the problems of unseen plasma arc welding cupronickel, and achieve the effect of small welding deformation, improved welding quality and good welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

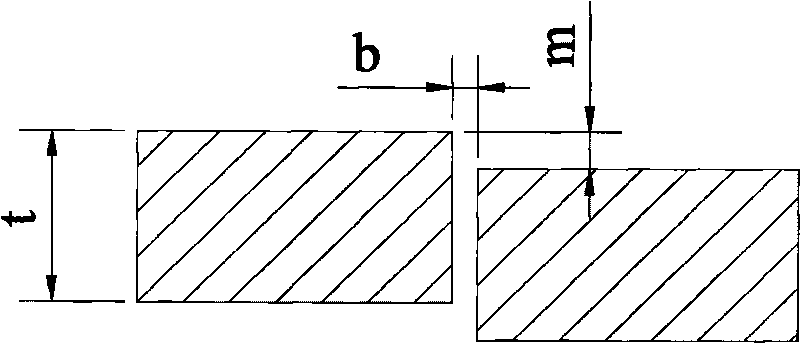

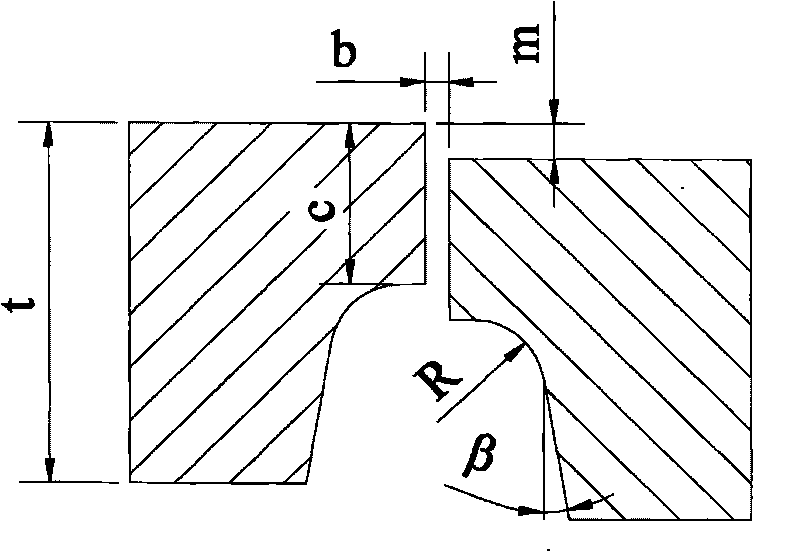

[0029] Butt welding of B10 plates with a thickness of 2mm and a length of 300mm was carried out by using the method of plasma arc welding of cupronickel. The welding process was stable and there were no welding defects. I-type groove, plasma arc welding, one-time welding, the welding process parameters used are as follows:

[0030] Welding Base Metal Welding Welding Welding Wire Feed Shielding Shielding Gas Flow

[0031] Mode Thickness Current Voltage Velocity Velocity Gas Plasma Arc Gun Protection

[0032] mm A V mm / min mm / min L / min L / min

[0033] Flat welding 2 80 18-20 300 600 Pure argon 3 20

Embodiment 2

[0035] Using the method of plasma arc welding cupronickel, carried out Butt welding of the circular seam of the B10 barrel, the welding process is stable, the appearance quality of the weld is good, and the non-destructive testing of the weld is qualified.

[0036] I-type groove is adopted, and plasma arc welding is welded at one time. The process parameters are as follows:

[0037] Welding Base metal Welding Welding Welding Wire feeding Shielding Shielding gas flow L / min

[0038] Mode Thickness Current Voltage Velocity Velocity Gas Plasma Arc Gun Protection

[0039] mm A V mm / min mm / min L / min L / min

[0040] Horizontal welding 4 120 20-22 250 800 Pure argon 4 25

Embodiment 3

[0042] Using the method of plasma arc welding cupronickel, carried out The B30 barrel longitudinal seam welding, the welding process is stable, the appearance quality of the weld seam is good, and the nondestructive inspection of the weld seam is qualified.

[0043] Using I-type groove, plasma arc welding, one-time welding, the process parameters are as follows:

[0044] Welding Base Metal Welding Welding Welding Wire Feed Shielding Shielding Gas Flow

[0045] Mode Thickness Current Voltage Velocity Velocity Gas Plasma Arc Gun Protection

[0046] mm A V mm / min mm / min L / min L / min

[0047] Flat welding 7.5 230 22-24 220 800 Pure argon 4 25

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com